Reports

Reports

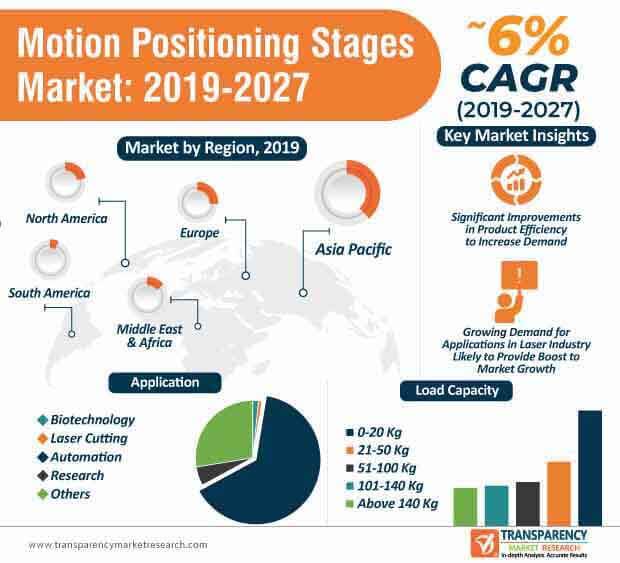

Motion positioning stages are highly critical for efficient machinery movement. As the industrial sector continues to experience waves of innovations and new developments, progress in motion positioning stages has played an important role in revolutionizing modern-day manufacturing processes. In addition, owing to significant advancements in technology, key participants in the motion positioning stages market are expected to fulfil evolving requirements of the industrial sector, which include high precision and enhanced productivity. Modern-day industrial applications require faster and finer motion control enabled by advanced motion control technologies. The growing need for highly precise motion control stages in an array of applications, including laser cutting, industrial automation, biotechnology, and research, among others, is expected to create significant demand for motion positioning stages during the forecast period (2019-2027).

With the advent of Industry 4.0, the industrial sector is shifting gears and leaning toward automated systems. Industrial automation has gained fast-paced adoption in the past few years and the trend is set to continue in the coming years. In their bid to gain a competitive edge, stakeholders in the current motion positioning stages market are increasingly focused on the development of power/energy-efficient products. The tectonic shift toward industrial automation is likely to provide an array of opportunities for key operators in the global motion positioning stages market, which is expected to reach a value of ~US$ 989 Mn by the end of 2027.

Due to technological developments, linear motors have evolved at a consistent pace in the past few decades, and offer greater accuracy and speed range. As linear motors continue to evolve, linear-motor applications are also evolving. With a growing focus on efficiency, at present, new applications of linear motors on axis have emerged, including automotive, material handlings, packaging, general automation, and off-highway, among others. Higher efficiency levels can be achieved with linear motors, owing to its direct-drive nature coupled with precise and faster strokes. Advanced linear motors with improved linear-motor designs integrated with new technologies are replacing other linear-motion alternatives.

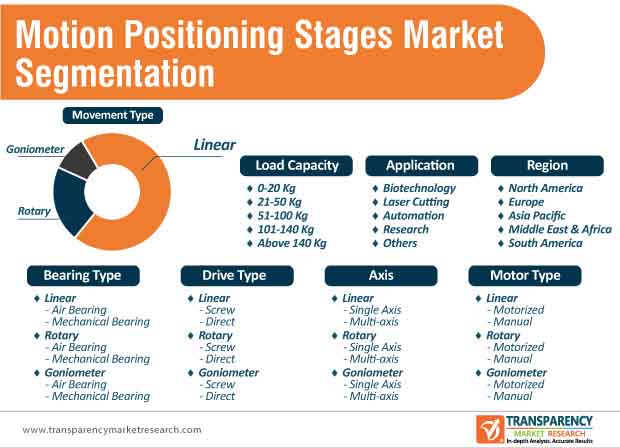

As per the findings of the research conducted by Transparency Market Research, the demand for linear stage motion positioning stages is expected to remain higher than that of rotary stages and goniometer motion positioning stages during the assessment period. The growing demand for linear stage motion positioning stages for industrial automation is anticipated to drive the growth of this segment during the forecast period. In the current scenario, a host of industrial applications is increasingly reliant on precise, accurate, and fast movement of machines. In addition, linear stage motors also fulfil the low maintenance and highly dynamic requirements of modern-day factories. The motion positioning stages market is likely to be primarily driven by new technologies that will lead to improvements in production processes. Current trends indicate a steady shift toward faster, smarter, and downsized motion control and positioning equipment.

The demand for ball screws and powerful servomotors has gained considerable pace, particularly in high-force applications. As ball screw rails can be easily lubricated by end users, the demand for the same is expected to witness significant growth during the forecast period. The adoption of motion position stages such as ball-screws is on the rise, as machine manufacturers in the laser industry are continually finding ways to improve resistance and tolerance to extremely hot particulates. In addition, for design engineers in the laser industry who regard ease of installation as a critical criterion, the adoption of new-generation linear stages is expected to witness substantial growth, particularly for seamless alignment and placement on the machine base. Stakeholders in the current motion positioning stages market are increasingly focused on the development of new linear stages that are suitable for industrial applications.

Analysts’ Viewpoint

The global motion positioning stages market is expected to grow at a healthy CAGR of ~6% during the forecast period. One of the major factors that will drive the motion positioning stages market growth includes ascending demand for accurate motion control solutions for a range of applications, including laser cutting, factory automation, and biotechnology. Industrial automation will provide stakeholders with abundant growth opportunities in the coming years, as increasingly number of factories around the world are leaning toward automated systems to enhance productivity and efficiency. Linear stage motion positioning stages will retain their popularity over other motion types, including rotational and goniometer stages. Stakeholders in the motion positioning stages market should focus on improving the functionalities of their product offerings and ensure they fulfil evolving industrial requirements.

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

3. Executive Summary: Global Positioning Stages Market

4. Market Overview

4.1. Introduction

4.2. Market Dynamics

4.2.1. Drivers

4.2.2. Restraints

4.2.3. Opportunities

4.3. Key Trends Analysis

4.4. Key Market Indicators

4.5. Global Motion Positioning Stages Market Analysis and Forecast, 2017 - 2027

4.5.1. Market Revenue Projections (US$ Mn)

4.5.2. Market Volume Projections (Thousand Units)

4.5.3. Price Trend Analysis, By Movement Type

4.5.3.1. Linear Stage

4.5.3.2. Rotary Stage

4.5.3.3. Goniometer Stage

4.6. Porter’s Five Forces Analysis - Global Motion Positioning Stages Market

4.7. Value Chain Analysis - Global Motion Positioning Stages Market

4.8. Market Outlook

5. Global Motion Positioning Stages Market Analysis and Forecast, by Movement Type

5.1. Overview & Definitions

5.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

5.2.1. Linear Stage

5.2.2. Rotary Stage

5.2.3. Goniometer Stage

5.3. Drive Type Comparison Matrix

5.4. Market Attractiveness, by Drive Type

6. Global Motion Positioning Stages Market Analysis and Forecast, by Axis

6.1. Overview & Definitions

6.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

6.2.1. Linear Stage

6.2.1.1. Single Axis

6.2.1.2. Multi-Axis

6.2.2. Rotary Stage

6.2.2.1. Single Axis

6.2.2.2. Multi-Axis

6.2.3. Goniometer Stage

6.2.3.1. Single Axis

6.2.3.2. Multi-Axis

6.3. Axis Comparison Matrix

6.4. Market Attractiveness, by Axis

7. Global Motion Positioning Stages Market Analysis and Forecast, by Bearing Type

7.1. Overview & Definitions

7.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

7.2.1. Linear Stage

7.2.1.1. Air Bearing

7.2.1.2. Mechanical Bearing

7.2.2. Rotary Stage

7.2.2.1. Air Bearing

7.2.2.2. Mechanical Bearing

7.2.3. Goniometer Stage

7.2.3.1. Air Bearing

7.2.3.2. Mechanical Bearing

7.3. Bearing Type Comparison Matrix

7.4. Market Attractiveness, by Bearing Type

8. Global Motion Positioning Stages Market Analysis and Forecast, by Drive Type

8.1. Overview & Definitions

8.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

8.2.1. Linear Stage

8.2.1.1. Screw

8.2.1.1.1. Lead Screw

8.2.1.1.2. Ball Screw

8.2.1.2. Direct

8.2.2. Rotary Stage

8.2.2.1. Screw

8.2.2.1.1. Lead Screw

8.2.2.1.2. Ball Screw

8.2.2.2. Direct

8.2.3. Goniometer Stage

8.2.3.1. Screw

8.2.3.1.1. Lead Screw

8.2.3.1.2. Ball Screw

8.2.3.2. Direct

8.3. Drive Type Comparison Matrix

8.4. Market Attractiveness, by Drive Type

9. Global Motion Positioning Stages Market Analysis and Forecast, by Load Capacity

9.1. Overview & Definitions

9.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

9.2.1. 0-20 Kg

9.2.2. 21-50 Kg

9.2.3. 51-100 Kg

9.2.4. 101-140 Kg

9.2.5. Above 140 Kg

9.3. Load Capacity Comparison Matrix

9.4. Market Attractiveness, by Load Capacity

10. Global Motion Positioning Stages Market Analysis and Forecast, by Motor Type

10.1. Overview & Definitions

10.2. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

10.2.1. Linear Stage

10.2.1.1. Motorized

10.2.1.1.1. Step Motor Driven Linear stage

10.2.1.1.2. DC Motor Driven Linear Stage

10.2.1.1.3. Piezoelectric Linear Stage

10.2.1.2. Manual

10.2.2. Rotary Stage

10.2.2.1. Motorized

10.2.2.1.1. Step Motor Driven Linear stage

10.2.2.1.2. DC Motor Driven Linear Stage

10.2.2.1.3. Piezoelectric Linear Stage

10.2.2.2. Manual

10.2.3. Goniometer

10.2.3.1. Motorized

10.2.3.1.1. 1 Axis Goniometer Motorized Stage

10.2.3.1.2. 2 Axis Goniometer Motorized Stage

10.2.3.2. Manual

10.3. Motor Type Comparison Matrix

10.4. Market Attractiveness, by Motor Type

11. Global Motion Positioning Stages Market Analysis and Forecast, by Application

11.1. Overview & Definitions

11.2. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

11.2.1. Biotechnology

11.2.2. Laser Cutting

11.2.3. Automation

11.2.3.1. Oil & Gas

11.2.3.2. Power

11.2.3.3. Food & Beverages

11.2.3.4. Chemicals

11.2.3.5. Metals & Mining

11.2.3.6. Pulp & Paper

11.2.3.7. Pharmaceuticals

11.2.3.8. Automotive

11.2.3.9. Machine Manufacturing

11.2.3.10. Semiconductor & Electronics

11.2.3.11. Aerospace & Defense

11.2.3.12. Medical Devices

11.2.4. Research

11.2.4.1. Optical Inspection

11.2.4.2. Testing Equipment

11.2.4.3. Measurement Equipment

11.2.4.4. Others

11.2.5. Others (Construction, Machine Tool, etc.)

11.3. Load Capacity Comparison Matrix

11.4. Market Attractiveness, by Application

12. Global Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Region, 2019 – 2027

12.1. Key Findings

12.2. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Region, 2017 – 2027

12.2.1. North America

12.2.2. Europe

12.2.3. Asia Pacific

12.2.4. Middle East & Africa

12.2.5. South America

12.3. Market Attractiveness, by Region

13. North America Motion Positioning Stages Market Analysis and Forecast

13.1. Key Findings

13.2. Key Trends

13.3. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

13.3.1. Linear Stage

13.3.2. Rotary Stage

13.3.3. Goniometer Stage

13.4. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

13.4.1. Linear Stage

13.4.1.1. Single Axis

13.4.1.2. Multi-Axis

13.4.2. Rotary Stage

13.4.2.1. Single Axis

13.4.2.2. Multi-Axis

13.4.3. Goniometer Stage

13.4.3.1. Single Axis

13.4.3.2. Multi-Axis

13.5. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

13.5.1. Linear Stage

13.5.1.1. Air Bearing

13.5.1.2. Mechanical Bearing

13.5.2. Rotary Stage

13.5.2.1. Air Bearing

13.5.2.2. Mechanical Bearing

13.5.3. Goniometer Stage

13.5.3.1. Air Bearing

13.5.3.2. Mechanical Bearing

13.6. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

13.6.1. Linear Stage

13.6.1.1. Screw

13.6.1.1.1. Lead Screw

13.6.1.1.2. Ball Screw

13.6.1.2. Direct

13.6.2. Rotary Stage

13.6.2.1. Screw

13.6.2.1.1. Lead Screw

13.6.2.1.2. Ball Screw

13.6.2.2. Direct

13.6.3. Goniometer Stage

13.6.3.1. Screw

13.6.3.1.1. Lead Screw

13.6.3.1.2. Ball Screw

13.6.3.2. Direct

13.7. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

13.7.1. 0-20 Kg

13.7.2. 21-50 Kg

13.7.3. 51-100 Kg

13.7.4. 101-140 Kg

13.7.5. Above 140 Kg

13.8. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

13.8.1. Linear Stage

13.8.1.1. Motorized

13.8.1.1.1. Step Motor Driven Linear stage

13.8.1.1.2. DC Motor Driven Linear Stage

13.8.1.1.3. Piezoelectric Linear Stage

13.8.1.2. Manual

13.8.2. Rotary Stage

13.8.2.1. Motorized

13.8.2.1.1. Step Motor Driven Linear stage

13.8.2.1.2. DC Motor Driven Linear Stage

13.8.2.1.3. Piezoelectric Linear Stage

13.8.2.2. Manual

13.8.3. Goniometer

13.8.3.1. Motorized

13.8.3.1.1. 1 Axis Goniometer Motorized Stage

13.8.3.1.2. 2 Axis Goniometer Motorized Stage

13.8.3.2. Manual

13.9. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

13.9.1. Biotechnology

13.9.2. Laser Cutting

13.9.3. Automation

13.9.3.1. Oil & Gas

13.9.3.2. Power

13.9.3.3. Food & Beverages

13.9.3.4. Chemicals

13.9.3.5. Metals & Mining

13.9.3.6. Pulp & Paper

13.9.3.7. Pharmaceuticals

13.9.3.8. Automotive

13.9.3.9. Machine Manufacturing

13.9.3.10. Semiconductor & Electronics

13.9.3.11. Aerospace & Defense

13.9.3.12. Medical Devices

13.9.4. Research

13.9.4.1. Optical Inspection

13.9.4.2. Testing Equipment

13.9.4.3. Measurement Equipment

13.9.4.4. Others

13.9.5. Others (Construction, Machine Tool, etc.)

13.10. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Country and Sub-region, 2019 – 2027

13.10.1. United Sates

13.10.2. Canada

13.10.3. Rest of North America

14. Europe Motion Positioning Stages Market Analysis and Forecast

14.1. Key Findings

14.2. Key Trends

14.3. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

14.3.1. Linear Stage

14.3.2. Rotary Stage

14.3.3. Goniometer Stage

14.4. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

14.4.1. Linear Stage

14.4.1.1. Single Axis

14.4.1.2. Multi-Axis

14.4.2. Rotary Stage

14.4.2.1. Single Axis

14.4.2.2. Multi-Axis

14.4.3. Goniometer Stage

14.4.3.1. Single Axis

14.4.3.2. Multi-Axis

14.5. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

14.5.1. Linear Stage

14.5.1.1. Air Bearing

14.5.1.2. Mechanical Bearing

14.5.2. Rotary Stage

14.5.2.1. Air Bearing

14.5.2.2. Mechanical Bearing

14.5.3. Goniometer Stage

14.5.3.1. Air Bearing

14.5.3.2. Mechanical Bearing

14.6. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

14.6.1. Linear Stage

14.6.1.1. Screw

14.6.1.1.1. Lead Screw

14.6.1.1.2. Ball Screw

14.6.1.2. Direct

14.6.2. Rotary Stage

14.6.2.1. Screw

14.6.2.1.1. Lead Screw

14.6.2.1.2. Ball Screw

14.6.2.2. Direct

14.6.3. Goniometer Stage

14.6.3.1. Screw

14.6.3.1.1. Lead Screw

14.6.3.1.2. Ball Screw

14.6.3.2. Direct

14.7. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

14.7.1. 0-20 Kg

14.7.2. 21-50 Kg

14.7.3. 51-100 Kg

14.7.4. 101-140 Kg

14.7.5. Above 140 Kg

14.8. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

14.8.1. Linear Stage

14.8.1.1. Motorized

14.8.1.1.1. Step Motor Driven Linear stage

14.8.1.1.2. DC Motor Driven Linear Stage

14.8.1.1.3. Piezoelectric Linear Stage

14.8.1.2. Manual

14.8.2. Rotary Stage

14.8.2.1. Motorized

14.8.2.1.1. Step Motor Driven Linear stage

14.8.2.1.2. DC Motor Driven Linear Stage

14.8.2.1.3. Piezoelectric Linear Stage

14.8.2.2. Manual

14.8.3. Goniometer

14.8.3.1. Motorized

14.8.3.1.1. 1 Axis Goniometer Motorized Stage

14.8.3.1.2. 2 Axis Goniometer Motorized Stage

14.8.3.2. Manual

14.9. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

14.9.1. Biotechnology

14.9.2. Laser Cutting

14.9.3. Automation

14.9.3.1. Oil & Gas

14.9.3.2. Power

14.9.3.3. Food & Beverages

14.9.3.4. Chemicals

14.9.3.5. Metals & Mining

14.9.3.6. Pulp & Paper

14.9.3.7. Pharmaceuticals

14.9.3.8. Automotive

14.9.3.9. Machine Manufacturing

14.9.3.10. Semiconductor & Electronics

14.9.3.11. Aerospace & Defense

14.9.3.12. Medical Devices

14.9.4. Research

14.9.4.1. Optical Inspection

14.9.4.2. Testing Equipment

14.9.4.3. Measurement Equipment

14.9.4.4. Others

14.9.5. Others (Construction, Machine Tool, etc.)

14.10. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Country and Sub-region, 2019 – 2027

14.10.1. Germany

14.10.2. U.K.

14.10.3. France

14.10.4. Rest of Europe

15. Asia Pacific Motion Positioning Stages Market Analysis and Forecast

15.1. Key Findings

15.2. Key Trends

15.3. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

15.3.1. Linear Stage

15.3.2. Rotary Stage

15.3.3. Goniometer Stage

15.4. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

15.4.1. Linear Stage

15.4.1.1. Single Axis

15.4.1.2. Multi-Axis

15.4.2. Rotary Stage

15.4.2.1. Single Axis

15.4.2.2. Multi-Axis

15.4.3. Goniometer Stage

15.4.3.1. Single Axis

15.4.3.2. Multi-Axis

15.5. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

15.5.1. Linear Stage

15.5.1.1. Air Bearing

15.5.1.2. Mechanical Bearing

15.5.2. Rotary Stage

15.5.2.1. Air Bearing

15.5.2.2. Mechanical Bearing

15.5.3. Goniometer Stage

15.5.3.1. Air Bearing

15.5.3.2. Mechanical Bearing

15.6. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

15.6.1. Linear Stage

15.6.1.1. Screw

15.6.1.1.1. Lead Screw

15.6.1.1.2. Ball Screw

15.6.1.2. Direct

15.6.2. Rotary Stage

15.6.2.1. Screw

15.6.2.1.1. Lead Screw

15.6.2.1.2. Ball Screw

15.6.2.2. Direct

15.6.3. Goniometer Stage

15.6.3.1. Screw

15.6.3.1.1. Lead Screw

15.6.3.1.2. Ball Screw

15.6.3.2. Direct

15.7. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

15.7.1. 0-20 Kg

15.7.2. 21-50 Kg

15.7.3. 51-100 Kg

15.7.4. 101-140 Kg

15.7.5. Above 140 Kg

15.8. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

15.8.1. Linear Stage

15.8.1.1. Motorized

15.8.1.1.1. Step Motor Driven Linear stage

15.8.1.1.2. DC Motor Driven Linear Stage

15.8.1.1.3. Piezoelectric Linear Stage

15.8.1.2. Manual

15.8.2. Rotary Stage

15.8.2.1. Motorized

15.8.2.1.1. Step Motor Driven Linear stage

15.8.2.1.2. DC Motor Driven Linear Stage

15.8.2.1.3. Piezoelectric Linear Stage

15.8.2.2. Manual

15.8.3. Goniometer

15.8.3.1. Motorized

15.8.3.1.1. 1 Axis Goniometer Motorized Stage

15.8.3.1.2. 2 Axis Goniometer Motorized Stage

15.8.3.2. Manual

15.9. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

15.9.1. Biotechnology

15.9.2. Laser Cutting

15.9.3. Automation

15.9.3.1. Oil & Gas

15.9.3.2. Power

15.9.3.3. Food & Beverages

15.9.3.4. Chemicals

15.9.3.5. Metals & Mining

15.9.3.6. Pulp & Paper

15.9.3.7. Pharmaceuticals

15.9.3.8. Automotive

15.9.3.9. Machine Manufacturing

15.9.3.10. Semiconductor & Electronics

15.9.3.11. Aerospace & Defense

15.9.3.12. Medical Devices

15.9.4. Research

15.9.4.1. Optical Inspection

15.9.4.2. Testing Equipment

15.9.4.3. Measurement Equipment

15.9.4.4. Others

15.9.5. Others (Construction, Machine Tool, etc.)

15.10. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Country and Sub-region, 2019 – 2027

15.10.1. China

15.10.2. Japan

15.10.3. India

15.10.4. Rest of Asia Pacific

16. Middle East & Africa Motion Positioning Stages Market Analysis and Forecast

16.1. Key Findings

16.2. Key Trends

16.3. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

16.3.1. Linear Stage

16.3.2. Rotary Stage

16.3.3. Goniometer Stage

16.4. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

16.4.1. Linear Stage

16.4.1.1. Single Axis

16.4.1.2. Multi-Axis

16.4.2. Rotary Stage

16.4.2.1. Single Axis

16.4.2.2. Multi-Axis

16.4.3. Goniometer Stage

16.4.3.1. Single Axis

16.4.3.2. Multi-Axis

16.5. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

16.5.1. Linear Stage

16.5.1.1. Air Bearing

16.5.1.2. Mechanical Bearing

16.5.2. Rotary Stage

16.5.2.1. Air Bearing

16.5.2.2. Mechanical Bearing

16.5.3. Goniometer Stage

16.5.3.1. Air Bearing

16.5.3.2. Mechanical Bearing

16.6. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

16.6.1. Linear Stage

16.6.1.1. Screw

16.6.1.1.1. Lead Screw

16.6.1.1.2. Ball Screw

16.6.1.2. Direct

16.6.2. Rotary Stage

16.6.2.1. Screw

16.6.2.1.1. Lead Screw

16.6.2.1.2. Ball Screw

16.6.2.2. Direct

16.6.3. Goniometer Stage

16.6.3.1. Screw

16.6.3.1.1. Lead Screw

16.6.3.1.2. Ball Screw

16.6.3.2. Direct

16.7. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

16.7.1. 0-20 Kg

16.7.2. 21-50 Kg

16.7.3. 51-100 Kg

16.7.4. 101-140 Kg

16.7.5. Above 140 Kg

16.8. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

16.8.1. Linear Stage

16.8.1.1. Motorized

16.8.1.1.1. Step Motor Driven Linear stage

16.8.1.1.2. DC Motor Driven Linear Stage

16.8.1.1.3. Piezoelectric Linear Stage

16.8.1.2. Manual

16.8.2. Rotary Stage

16.8.2.1. Motorized

16.8.2.1.1. Step Motor Driven Linear stage

16.8.2.1.2. DC Motor Driven Linear Stage

16.8.2.1.3. Piezoelectric Linear Stage

16.8.2.2. Manual

16.8.3. Goniometer

16.8.3.1. Motorized

16.8.3.1.1. 1 Axis Goniometer Motorized Stage

16.8.3.1.2. 2 Axis Goniometer Motorized Stage

16.8.3.2. Manual

16.9. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

16.9.1. Biotechnology

16.9.2. Laser Cutting

16.9.3. Automation

16.9.3.1. Oil & Gas

16.9.3.2. Power

16.9.3.3. Food & Beverages

16.9.3.4. Chemicals

16.9.3.5. Metals & Mining

16.9.3.6. Pulp & Paper

16.9.3.7. Pharmaceuticals

16.9.3.8. Automotive

16.9.3.9. Machine Manufacturing

16.9.3.10. Semiconductor & Electronics

16.9.3.11. Aerospace & Defense

16.9.3.12. Medical Devices

16.9.4. Research

16.9.4.1. Optical Inspection

16.9.4.2. Testing Equipment

16.9.4.3. Measurement Equipment

16.9.4.4. Others

16.9.5. Others (Construction, Machine Tool, etc.)

16.10. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Country and Sub-region, 2019 – 2027

16.10.1. GCC

16.10.2. South Africa

16.10.3. Rest of Middle East & Africa

17. South America Motion Positioning Stages Market Analysis and Forecast

17.1. Key Findings

17.2. Key Trends

17.3. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Movement Type, 2017 - 2027

17.3.1. Linear Stage

17.3.2. Rotary Stage

17.3.3. Goniometer Stage

17.4. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Axis, 2017 - 2027

17.4.1. Linear Stage

17.4.1.1. Single Axis

17.4.1.2. Multi-Axis

17.4.2. Rotary Stage

17.4.2.1. Single Axis

17.4.2.2. Multi-Axis

17.4.3. Goniometer Stage

17.4.3.1. Single Axis

17.4.3.2. Multi-Axis

17.5. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Bearing Type, 2017 - 2027

17.5.1. Linear Stage

17.5.1.1. Air Bearing

17.5.1.2. Mechanical Bearing

17.5.2. Rotary Stage

17.5.2.1. Air Bearing

17.5.2.2. Mechanical Bearing

17.5.3. Goniometer Stage

17.5.3.1. Air Bearing

17.5.3.2. Mechanical Bearing

17.6. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Drive Type, 2017 - 2027

17.6.1. Linear Stage

17.6.1.1. Screw

17.6.1.1.1. Lead Screw

17.6.1.1.2. Ball Screw

17.6.1.2. Direct

17.6.2. Rotary Stage

17.6.2.1. Screw

17.6.2.1.1. Lead Screw

17.6.2.1.2. Ball Screw

17.6.2.2. Direct

17.6.3. Goniometer Stage

17.6.3.1. Screw

17.6.3.1.1. Lead Screw

17.6.3.1.2. Ball Screw

17.6.3.2. Direct

17.7. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Load Capacity, 2017 - 2027

17.7.1. 0-20 Kg

17.7.2. 21-50 Kg

17.7.3. 51-100 Kg

17.7.4. 101-140 Kg

17.7.5. Above 140 Kg

17.8. Motion Positioning Stages Market Size (US$ Mn and Thousand Units) Forecast, by Motor Type, 2017 - 2027

17.8.1. Linear Stage

17.8.1.1. Motorized

17.8.1.1.1. Step Motor Driven Linear stage

17.8.1.1.2. DC Motor Driven Linear Stage

17.8.1.1.3. Piezoelectric Linear Stage

17.8.1.2. Manual

17.8.2. Rotary Stage

17.8.2.1. Motorized

17.8.2.1.1. Step Motor Driven Linear stage

17.8.2.1.2. DC Motor Driven Linear Stage

17.8.2.1.3. Piezoelectric Linear Stage

17.8.2.2. Manual

17.8.3. Goniometer

17.8.3.1. Motorized

17.8.3.1.1. 1 Axis Goniometer Motorized Stage

17.8.3.1.2. 2 Axis Goniometer Motorized Stage

17.8.3.2. Manual

17.9. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Application, 2017 - 2027

17.9.1. Biotechnology

17.9.2. Laser Cutting

17.9.3. Automation

17.9.3.1. Oil & Gas

17.9.3.2. Power

17.9.3.3. Food & Beverages

17.9.3.4. Chemicals

17.9.3.5. Metals & Mining

17.9.3.6. Pulp & Paper

17.9.3.7. Pharmaceuticals

17.9.3.8. Automotive

17.9.3.9. Machine Manufacturing

17.9.3.10. Semiconductor & Electronics

17.9.3.11. Aerospace & Defense

17.9.3.12. Medical Devices

17.9.4. Research

17.9.4.1. Optical Inspection

17.9.4.2. Testing Equipment

17.9.4.3. Measurement Equipment

17.9.4.4. Others

17.9.5. Others (Construction, Machine Tool, etc.)

17.10. Motion Positioning Stages Market Size (US$ Mn) Forecast, by Country and Sub-region, 2019 – 2027

17.10.1. Brazil

17.10.2. Rest of South America

18. Competition Landscape

18.1. Market Player – Competition Matrix

18.2. Market Revenue Share Analysis (%), by Company (2018)

19. Company Profiles (Details – Overview, Financials, Product Portfolio, SWOT Analysis, Strategy)

19.1. Aerotech Inc.

19.1.1. Overview

19.1.2. Financials

19.1.3. Product Portfolio

19.1.4. SWOT Analysis

19.1.5. Strategy

19.2. Dover Motion

19.2.1. Overview

19.2.2. Financials

19.2.3. Product Portfolio

19.2.4. SWOT Analysis

19.2.5. Strategy

19.3. Edmund Optics, Ltd

19.3.1. Overview

19.3.2. Financials

19.3.3. Product Portfolio

19.3.4. SWOT Analysis

19.3.5. Strategy

19.4. Misumi USA, Inc.

19.4.1. Overview

19.4.2. Financials

19.4.3. Product Portfolio

19.4.4. SWOT Analysis

19.4.5. Strategy

19.5. Newport Corporation

19.5.1. Overview

19.5.2. Financials

19.5.3. Product Portfolio

19.5.4. SWOT Analysis

19.5.5. Strategy

19.6. Optimal Engineering Systems Inc.

19.6.1. Overview

19.6.2. Financials

19.6.3. Product Portfolio

19.6.4. SWOT Analysis

19.6.5. Strategy

19.7. OWIS GmbH

19.7.1. Overview

19.7.2. Financials

19.7.3. Product Portfolio

19.7.4. SWOT Analysis

19.7.5. Strategy

19.8. Parker Hannifin Corp

19.8.1. Overview

19.8.2. Financials

19.8.3. Product Portfolio

19.8.4. SWOT Analysis

19.8.5. Strategy

19.9. Physik Instrumente (PI) GmbH & Co. KG.

19.9.1. Overview

19.9.2. Financials

19.9.3. Product Portfolio

19.9.4. SWOT Analysis

19.9.5. Strategy

19.10. STANDA Ltd.

19.10.1. Overview

19.10.2. Financials

19.10.3. Product Portfolio

19.10.4. SWOT Analysis

19.10.5. Strategy

19.11. Thorlabs, Inc.

19.11.1. Overview

19.11.2. Financials

19.11.3. Product Portfolio

19.11.4. SWOT Analysis

19.11.5. Strategy

19.12. OptoSigma Corporation

19.12.1. Overview

19.12.2. Financials

19.12.3. Product Portfolio

19.12.4. SWOT Analysis

19.12.5. Strategy

19.13. Zaber Technologies

19.13.1. Overview

19.13.2. Financials

19.13.3. Product Portfolio

19.13.4. SWOT Analysis

19.13.5. Strategy

19.14. Newmark Systems Inc.

19.14.1. Overview

19.14.2. Financials

19.14.3. Product Portfolio

19.14.4. SWOT Analysis

19.14.5. Strategy

19.15. Lintech

19.15.1. Overview

19.15.2. Financials

19.15.3. Product Portfolio

19.15.4. SWOT Analysis

19.15.5. Strategy

19.16. Etel S.A.

19.16.1. Overview

19.16.2. Financials

19.16.3. Product Portfolio

19.16.4. SWOT Analysis

19.16.5. Strategy

19.17. Yaskawa Electric Corporation

19.17.1. Overview

19.17.2. Financials

19.17.3. Product Portfolio

19.17.4. SWOT Analysis

19.17.5. Strategy

19.18. KML Linear Motion Technology GmbH

19.18.1. Overview

19.18.2. Financials

19.18.3. Product Portfolio

19.18.4. SWOT Analysis

19.18.5. Strategy

19.19. Rockwell Automation, Inc

19.19.1. Overview

19.19.2. Financials

19.19.3. Product Portfolio

19.19.4. SWOT Analysis

19.19.5. Strategy

20. Key Takeaways

List of Tables

Table 01: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 02: Global Motion Positioning Stages Market Volume (Thousands Units) Forecast, by Movement Type, 2017 - 2027

Table 03: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 04: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 05: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 06: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 07: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 08: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 09: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 10: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 11: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 12: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 13: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 14: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 15: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 16: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 17: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 18: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 19: Global Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 20: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 21: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 22: Global Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

Table 23: Global Motion Positioning Stages Market Revenue Forecast, by Country, 2017–2027 (US$ Mn)

Table 24: Global Motion Positioning Stages Market Volume (Thousand Units)Forecast, by Country, 2017–2027 (US$ Mn)

Table 25: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 26: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Movement Type, 2017 - 2027

Table 27: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 28: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 29: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 30: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 31: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 32: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 33: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 34: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 35: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 36: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 37: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 38: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 39: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 40: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 41: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 42: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 43: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 44: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 45: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 46: North America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

Table 47: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Country, 2017 - 2027

Table 48: North America Motion Positioning Stages Market Volume (Thousand units) Forecast, by Country, 2017 - 2027

Table 49: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 50: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Movement Type, 2017 - 2027

Table 51: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 52: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 53: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 54: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 55: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 56: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 57: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 58: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 59: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 60: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 61: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 62: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 63: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 64: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 65: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 66: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 67: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 68: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 69: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 70: Europe Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

Table 71: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Country, 2017 - 2027

Table 72: Europe Motion Positioning Stages Market Volume (Thousand units) Forecast, by Country, 2017 - 2027

Table 73: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 74: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Movement Type, 2017 - 2027

Table 75: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 76: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 77: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 78: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 79: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 80: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 81: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 82: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 83: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 84: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 85: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 86: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 87: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 88: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 89: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 90: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 91: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 92: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 93: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 94: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

Table 95: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Country, 2017 - 2027

Table 96: Asia Pacific Motion Positioning Stages Market Volume (Thousand units) Forecast, by Country, 2017 - 2027

Table 97: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 98: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Movement Type, 2017 - 20277

Table 99: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 100: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 101: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 102: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 103: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 104: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 105: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 106: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 107: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 108: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 109: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 110: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 111: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 112: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 113: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 114: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 115: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 116: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 117: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 118: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

Table 119: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Country, 2017 - 2027

Table 120: Middle East & Africa Motion Positioning Stages Market Volume (Thousand units) Forecast, by Country, 2017 - 2027

Table 121: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Movement Type, 2017 - 2027

Table 122: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Movement Type, 2017 - 2027

Table 123: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Axis, 2017 - 2027

Table 124: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Axis, 2017 - 2027

Table 125: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Bearing Type, 2017 - 2027

Table 126: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Bearing Type, 2017 - 2027

Table 127: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Drive Type, 2017 - 2027

Table 128: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Drive Type, 2017 - 2027

Table 129: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Load Capacity, 2017 - 2027

Table 130: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Load Capacity, 2017 - 2027

Table 131: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 132: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 133: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 134: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Linear Stage, 2017 - 2027

Table 135: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Rotary Stage, 2017 - 2027

Table 136: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Motor Type, by Goniometer Stage, 2017 - 2027

Table 137: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, 2017 - 2027

Table 138: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Automation, 2017 - 2027

Table 139: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, by Application, by Research, 2017 - 2027

Table 140: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, 2017 - 2027

Table 141: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Automation, 2017 - 2027

Table 142: South America Motion Positioning Stages Market Volume (Thousand Units) Forecast, by Application, Research, 2017 - 2027

List of Figures

Figure 01: Global Motion Positioning Stages Market Revenue, Historical and Forecast, 2017 - 2027

Figure 02: Global Motion Positioning Stages Market CAGR

Figure 03: Europe Motion Positioning Stages Market CAGR

Figure 04: Asia Pacific Motion Positioning Stages Market CAGR

Figure 05: Middle East & Africa Motion Positioning Stages Market CAGR

Figure 06: South America Motion Positioning Stages Market CAGR

Figure 07: Global Motion Positioning Stages Market Share by Country, 2018

Figure 08: Global Motion Positioning Stages Market Revenue Projection and Y – O– Y Growth, 2017-2027 (US$ Mn and %)

Figure 09: Global Motion Positioning Stages Market Volume Projection and Y – O– Y Growth, 2017-2027 (Thousand Units and %)

Figure 10: Price Trend Analysis, by Movement Type, 2018 (US$)

Figure 11: Value Chain Analysis

Figure 12: Global Motion Positioning Stages Market Overview (US$ Mn)

Figure 13: Global Motion Positioning Stages Market Overview (Thousand Units)

Figure 14: Global Motion Positioning Stages Market, by Movement Type (2018)

Figure 15: Global Motion Positioning Stages Market, by Axis (2018)

Figure 16: Global Motion Positioning Stages Market, by Bearing Type (2018)

Figure 17: Global Motion Positioning Stages Market, by Drive Type (2018)

Figure 18: Global Motion Positioning Stages Market, by Load Capacity Type (2018)

Figure 19: Global Motion Positioning Stages Market, by Motor Type (2018)

Figure 20: Global Motion Positioning Stages Market, Application (2018)

Figure 21: Global Motion Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 22: Global Motion Positioning Stages Market, by Movement Type, Linear Stage

Figure 23: Global Motion Positioning Stages Market, by Movement Type, Rotary Stage

Figure 24: Global Motion Positioning Stages Market, by Movement Type, Goniometer Stage

Figure 25: Segment Growth Matrix, 2019 - 27 (%)

Figure 26: Segment Revenue Contribution, 2019 - 27 (%)

Figure 27: Segment Compounded Growth Matrix (CAGR %)

Figure 28: Global Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 29: Global Motion Positioning Stages Market Share Analysis, by Axis, 2019 and 2027

Figure 30: Global Motion Positioning Stages Market, by Axis, Single Axis

Figure 31: Global Motion Positioning Stages Market, by Axis, Multi-Axis

Figure 32: Segment Growth Matrix, 2019 - 27 (%)

Figure 33: Segment Revenue Contribution, 2019 - 27 (%)

Figure 34: Segment Compounded Growth Matrix (CAGR %)

Figure 35: Global Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 36: Global Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 37: Global Motion Positioning Stages Market, by Bearing Type, Air Bearing

Figure 38: Global Motion Positioning Stages Market, by Bearing Type, Mechanical Bearing

Figure 39: Segment Growth Matrix, 2019 - 27 (%)

Figure 40: Segment Revenue Contribution, 2019 - 27 (%)

Figure 41: Segment Compounded Growth Matrix (CAGR %)

Figure 42: Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 43: Global Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 44: Global Motion Positioning Stages Market, by Drive Type, Screw

Figure 45: Global Motion Positioning Stages Market, by Drive Type, Direct

Figure 46: Segment Growth Matrix, 2019 - 27 (%)

Figure 47: Segment Revenue Contribution, 2019 - 27 (%)

Figure 48: Segment Compounded Growth Matrix (CAGR %)

Figure 49: Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 50: Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 51: Global Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 52: Global Motion Positioning Stages Market, Load Capacity, 0-20 Kg

Figure 53: Global Motion Positioning Stages Market, by Load Capacity, 21-50 Kg

Figure 54: Global Motion Positioning Stages Market, Load Capacity, 51-100 Kg

Figure 55: Global Motion Positioning Stages Market, by Load Capacity, 101-140 Kg

Figure 56: Global Motion Positioning Stages Market, by Load Capacity, Above 140 Kg

Figure 57: Segment Growth Matrix, 2019 - 27 (%)

Figure 58: Segment Revenue Contribution, 2019 - 27 (%)

Figure 59: Segment Compounded Growth Matrix (CAGR %)

Figure 60: Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 61: Global Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 62: Global Motion Positioning Stages Market, by Motor Type, Motorized

Figure 63: Global Motion Positioning Stages Market, by Motor Type, Manual

Figure 64: Segment Growth Matrix, 2019 - 27 (%)

Figure 65: Segment Revenue Contribution, 2019 - 27 (%)

Figure 66: Segment Compounded Growth Matrix (CAGR %)

Figure 67: Global Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 68: Global Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 69: Global Motion Positioning Stages Market Application, Biotechnology

Figure 70: Global Motion Positioning Stages Market, by Application, Laser Cutting

Figure 71: Global Motion Positioning Stages Market, by Application, Automation

Figure 72: Global Motion Positioning Stages Market, by Application, Research

Figure 73: Global Motion Positioning Stages Market, Application, Others

Figure 74: Segment Growth Matrix, 2019 - 27 (%)

Figure 75: Segment Revenue Contribution, 2019 - 27 (%)

Figure 76: Segment Compounded Growth Matrix (CAGR %)

Figure 77: Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 78: Global Motion Positioning Stages Market, by Country , North America

Figure 79: Global Motion Positioning Stages Market, by Country , Europe

Figure 80: Global Motion Positioning Stages Market, by Region, Asia Pacific

Figure 81: Global Motion Positioning Stages Market, by Region, Middle East & Africa

Figure 82: Global Motion Positioning Stages Market, by Country, South America

Figure 83: Global Motion Positioning Stages Market Attractiveness Analysis, by Region

Figure 84: North America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, 2017 - 2027

Figure 85: North America Motion Positioning Stages Market Y-o-Y Growth Analysis, 2017 - 2027

Figure 86: North America Motion Positioning Stages Market Volume (Thousand Units ) Forecast, 2017 - 2027

Figure 87: North America Motion Positioning Stages Market Volume Y-o-Y Growth Analysis, 2017 - 2027

Figure 88: North America Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 89: North America Motion Positioning Stages Market Share Analysis, by Axis , 2019 and 2027

Figure 90: North America Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 91: North America Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 92: North America Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 93: North America Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 94: North America Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 95: North America Motion Positioning Stages Market Share Analysis, by Country, 2019 and 2027

Figure 96: North America Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 97: North America Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 98: North America Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 99: North America Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 100: North America Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 101: North America Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 102: North America Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 103: North America Motion Positioning Stages Market Attractiveness Analysis, by Country

Figure 104: Europe Motion Positioning Stages Market Revenue (US$ Mn) Forecast, 2017 - 2027

Figure 105: Europe Motion Positioning Stages Market Y-o-Y Growth Analysis, 2017 - 2027

Figure 106: Europe Motion Positioning Stages Market Volume (Thousand Units ) Forecast, 2017 - 2027

Figure 107: Europe Motion Positioning Stages Market Volume Y-o-Y Growth Analysis, 2017 - 2027

Figure 108: Europe Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 109: Europe Motion Positioning Stages Market Share Analysis, by Axis , 2019 and 2027

Figure 110: Europe Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 111: Europe Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 112: Europe Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 113: Europe Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 114: Europe Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 115: Europe Motion Positioning Stages Market Share Analysis, by Country, 2019 and 2027

Figure 116: Europe Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 117: Europe Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 118: Europe Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 119: Europe Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 120: Europe Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 121: Europe Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 122: Europe Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 123: Europe Motion Positioning Stages Market Attractiveness Analysis, by Country

Figure 124: Asia Pacific Motion Positioning Stages Market Revenue (US$ Mn) Forecast, 2017 - 2027

Figure 125: Asia Pacific Motion Positioning Stages Market Y-o-Y Growth Analysis, 2017 - 2027

Figure 126: Asia Pacific Motion Positioning Stages Market Volume (Thousand Units ) Forecast, 2017 - 2027

Figure 127: Asia Pacific Motion Positioning Stages Market Volume Y-o-Y Growth Analysis, 2017 - 2027

Figure 128: Asia Pacific Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 129: Asia Pacific Motion Positioning Stages Market Share Analysis, by Axis , 2019 and 2027

Figure 130: Asia Pacific Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 131: Asia Pacific Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 132: Asia Pacific Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 133: Asia Pacific Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 134: Asia Pacific Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 135: Asia Pacific Motion Positioning Stages Market Share Analysis, by Country, 2019 and 2027

Figure 136: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 137: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 138: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 139: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 140: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 141: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 142: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 143: Asia Pacific Motion Positioning Stages Market Attractiveness Analysis, by Country

Figure 144: Middle East & Africa Motion Positioning Stages Market Revenue (US$ Mn) Forecast, 2017 - 2027

Figure 145: Middle East & Africa Motion Positioning Stages Market Y-o-Y Growth Analysis, 2017 - 2027

Figure 146: Middle East & Africa Motion Positioning Stages Market Volume (Thousand Units ) Forecast, 2017 - 2027

Figure 147: Middle East & Africa Motion Positioning Stages Market Volume Y-o-Y Growth Analysis, 2017 - 2027

Figure 148: Middle East & Africa Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 149: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Axis , 2019 and 2027

Figure 150: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 151: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 152: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 153: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 154: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 155: Middle East & Africa Motion Positioning Stages Market Share Analysis, by Country, 2019 and 2027

Figure 156: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 157: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 158: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 159: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 160: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 161: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 162: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 163: Middle East & Africa Motion Positioning Stages Market Attractiveness Analysis, by Country

Figure 164: South America Motion Positioning Stages Market Revenue (US$ Mn) Forecast, 2017 - 2027

Figure 165: South America Motion Positioning Stages Market Y-o-Y Growth Analysis, 2017 - 2027

Figure 166: South America Motion Positioning Stages Market Volume (Thousand Units ) Forecast, 2017 - 2027

Figure 167: South America Motion Positioning Stages Market Volume Y-o-Y Growth Analysis, 2017 - 2027

Figure 168: South America Positioning Stages Market Share Analysis, by Movement Type, 2019 and 2027

Figure 169: South America Motion Positioning Stages Market Share Analysis, by Axis, 2019 and 2027

Figure 170: South America Motion Positioning Stages Market Share Analysis, by Bearing Type, 2019 and 2027

Figure 171: South America Motion Positioning Stages Market Share Analysis, by Drive Type, 2019 and 2027

Figure 172: South America Motion Positioning Stages Market Share Analysis, by Load Capacity, 2019 and 2027

Figure 173: South America Motion Positioning Stages Market Share Analysis, by Motor Type, 2019 and 2027

Figure 174: South America Motion Positioning Stages Market Share Analysis, by Application, 2019 and 2027

Figure 175: South America Motion Positioning Stages Market Attractiveness Analysis, by Movement Type

Figure 176: South America Motion Positioning Stages Market Attractiveness Analysis, by Axis

Figure 177: South America Motion Positioning Stages Market Attractiveness Analysis, by Bearing Type

Figure 178: South America Motion Positioning Stages Market Attractiveness Analysis, by Drive Type

Figure 179: South America Motion Positioning Stages Market Attractiveness Analysis, by Load Capacity

Figure 180: South America Motion Positioning Stages Market Attractiveness Analysis, by Motor Type

Figure 181: South America Motion Positioning Stages Market Attractiveness Analysis, by Application

Figure 182: South America Motion Positioning Stages Market Attractiveness Analysis, by Country

Figure 183: Global Motion Positioning Stages Market Revenue Share Analysis, by Company (2018)