Reports

Reports

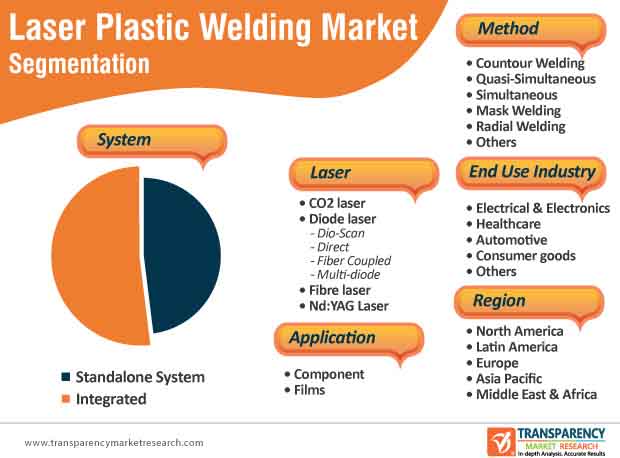

Laser plastic welding is extensively used across a host of industrial sectors, including medical, automotive, and electronic packaging. Advancements in textile joining, along with joining of different types of materials such as metal to plastics and more will continue to propel the demand for laser plastic welding across the world. Laser plastic welding is increasingly being deployed, particularly while developing products that are made of thermally sensitive materials. Laser plastic welding is also gaining considerable traction in wide-area lamination, as it offers precise patterns and increased complexity in joints that are made. Moreover, the demand for laser plastic welding is witnessing consistent growth, as it provides optimum strength and minimizes the cycle time in chemical bonding and mechanical joining applications.

Some of the popular laser plastic welding techniques include ultrasonic vibration, hot plate, spin, radiofrequency, implant, and laser/infrared, among others. At present, product developers and companies operating in the current laser plastic welding market are increasingly focusing on opportunities in the healthcare sector. In addition, companies are also expected to focus on introducing new product designs in the current market landscape, and enhancing the overall efficacy and performance of their assembly/joining processes. Laser plastic welding has emerged as an ideal solution to create permanent bonds and applications that require a permanent seal or joint between different components. The global laser plastic welding market is on course to reach a market value of ~US$ 1.5 Bn by 2025.

Although the cost of equipment for laser plastic welding is comparatively higher than other alternatives, its exceptional versatility makes it an ideal choice for applications in the medical sector. Laser plastic welding is used to assemble and join components made from a broad range of materials in different sizes and shapes. Moreover, as laser plastic welding requires negligible vibration and relative movement between two parts, it is capable of joining delicate components without inflicting damage. The adoption of laser plastic welding for the assembly of in vitro diagnostic (IVD) and micro-fluidic devices has witnessed consistent growth over the past decade and the trend is likely to continue over the stipulated time of the study. Companies operating in the laser plastic welding market are focusing on fulfilling the design requirements of their customers. The demand for laser plastic welding is on the rise as it offers exceptional welding quality, and improved aesthetics efficiently address the challenges put forward while joining complex geometries, versatility, etc.

While the healthcare sector will remain a prominent end-use industry in the laser plastic welding market, the automotive sector is expected to account for the highest market share. Advancements in laser plastic welding technologies have played a key role in improving the accuracy and weld quality of laser plastic welding due to which, conventional techniques in the laser plastic welding market are likely to be replaced during the forecast period.

Apart from focusing on improving the performance and quality of their welds, companies operating in the laser plastic welding market are also inclined toward expanding their market share by relying on inorganic growth strategies such as mergers & acquisitions. In addition, companies are also focusing on expanding their product portfolio to improve their position in the laser plastic welding market landscape. For instance, in June 2019, Dukane enhanced its laser plastic welding portfolio by acquiring the Blackhawk Technology Group. Dukane further announced that the acquisition of Blackhawk Technology would play an important role in improving its position in the market. The move will further strengthen the company’s product portfolio, which finds application in a host of industrial sectors.

While inorganic growth strategies are likely to gain considerable momentum, multiple companies are also expected to focus on introducing cutting-edge technologies to improve the quality of their laser plastic welds. For instance, in July 2017, Trumpf GmbH announced that the company is integrating EHLA– a new technology that is faster and offers greater efficiency than conventional laser deposition welding.

Analysts’ Viewpoint

The global laser plastic welding market is expected to grow at an impressive CAGR of 8.4% during the forecast period. The market growth is driven by a host of factors, including soaring demand from end-use industries, progress in laser technology, dwindling prices of laser technology, exceptional versatility, and progress in technology. Companies operating in the current landscape should focus on expanding their product portfolio, integrate new technologies, and enhance the quality of their products. The automotive and healthcare sectors will present players in the laser plastic welding market with plenty of opportunities as the demand for improved joining and assembly technologies is anticipated to move in the upward trajectory, particularly from these two sectors.

Laser Plastic Welding Market to expand at a CAGR of 8.0% during the forecast period 2025

Some of the leading players in the laser plastic welding market are TRUMPF GmbH + Co. KG, Han's Laser Technology Industry Group Co., Nippon Avionics Co., Ltd., Jenoptik AG, Rofin Sinar Technologies Inc., Amada Miyachi Co. Ltd., Bielomatik Leuze GmbH + Co. KG, LPKF Laser & Electronics AG, DILAS Diodelaser GmbH, Leister Technologies AG and Dukane IAS LLC

Laser Plastic Welding Market is expected to rise to US$ 1.5 Bn by 2025

The Laser Plastic Welding Market is studied from 2020-2025

The demand for advanced laser plastic welding systems in these industries is consistently rising due to its ability to weld 3D and complex shapes. Prominent end-use industries such as healthcare and electrical & electronics have witnessed a healthy growth over the past 10 years, and this is anticipated to continue during the forecast period

1. Executive Summary

2. Market Introduction

2.1. Market Definition

2.2. Market Taxonomy

3. Laser Plastic Welding Market Overview

3.1. Introduction

3.2. Industry Trends and Recent Developments

3.2.1. Design Level Trends and Market Developments

3.2.2. Technology Level Trends and Market Developments

3.2.3. Business Level Trends and Market Developments

3.3. Laser Plastic Welding Market and Y-o-Y Growth

3.4. Laser Plastic Welding Market (US$ Mn) and Forecast

4. Laser Plastic Welding Market Pricing Analysis

4.1. Price Projections by Region

4.2. Laser Plastic Welding Market value Chain Analysis

4.2.1. Value Chain

4.2.2. Profitability Margin

4.2.3. List of Active Participants

4.2.3.1. Raw Material Suppliers

4.2.3.2. Manufacturer

4.2.3.3. Distributors

5. Market Dynamics

5.1. Drivers

5.1.1. Supply Side

5.1.2. Demand Side

5.2. Restraints

5.3. Opportunity

5.4. On-Going Research

6. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by Laser Plastic Welding Systems

6.1. Introduction

6.1.1. Market share and Basis Points (BPS) Analysis by Laser Plastic Welding Systems

6.1.2. Y-o-Y Growth Projections by Laser Plastic Welding Systems

6.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Plastic Welding Systems

6.2.1. Standalone

6.2.2. Integrated

6.3. Market Attractiveness Analysis by Laser Plastic Welding Systems

7. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by Laser Plastic Welding Method

7.1. Introduction

7.1.1. Market share and Basis Points (BPS) Analysis by Laser Plastic Welding Method

7.1.2. Y-o-Y Growth Projections by Laser Plastic Welding Method

7.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Plastic Welding Method

7.2.1. Contour Welding

7.2.2. Quasi-Simultaneous Welding

7.2.3. Simultaneous Welding

7.2.4. Mask Welding

7.2.5. Radial Welding

7.2.6. Others

7.3. Market Attractiveness Analysis by Laser Plastic Welding Method

8. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by Laser Type

8.1. Introduction

8.1.1. Market share and Basis Points (BPS) Analysis by Laser Type

8.1.2. Y-o-Y Growth Projections by Laser Type

8.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

8.2.1. CO2 Laser

8.2.2. Diode Laser

8.2.2.1. Dio-Scan

8.2.2.2. Direct

8.2.2.3. Fiber-Coupled

8.2.2.4. Multi-diode

8.2.3. Fiber Laser

8.2.4. Nd:YAG Laser

8.3. Market Attractiveness Analysis by Laser Type

9. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by Plastic welding Application

9.1. Introduction

9.1.1. Market share and Basis Points (BPS) Analysis by Plastic welding Application

9.1.2. Y-o-Y Growth Projections by Plastic welding Application

9.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Plastic welding Application

9.2.1. Components

9.2.2. Films

9.3. Market Attractiveness Analysis by Plastic welding Application

10. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by End Use Industry

10.1. Introduction

10.1.1. Market share and Basis Points (BPS) Analysis by End Use Industry

10.1.2. Y-o-Y Growth Projections by End Use Industry

10.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

10.2.1. Electrical & Electronics

10.2.2. Healthcare

10.2.3. Automotive

10.2.4. Consumer Goods

10.2.5. Others

10.3. Market Attractiveness Analysis by End Use Industry

11. Global Laser Plastic Welding Market Analysis and Forecast (2020-2025), by Region

11.1. Introduction

11.1.1. Market share and Basis Points (BPS) Analysis by Region

11.1.2. Y-o-Y Growth Projections by Region

11.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Region

11.2.1. North America

11.2.2. Europe

11.2.3. Asia Pacific

11.2.4. Latin America

11.2.5. Middle East and Africa (MEA)

11.3. Market Attractiveness Analysis by Region

12. North America Laser Plastic Welding Market Analysis and Forecast (2020-2025)

12.1. Introduction

12.1.1. Market share and Basis Points (BPS) Analysis by Country

12.1.2. Y-o-Y Growth Projections by Country

12.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Country

12.2.1. U.S.

12.2.2. Canada

12.3. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Systems

12.3.1. Stand-alone systems

12.3.2. Integrated Systems

12.4. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Method

12.4.1. Contour Welding

12.4.2. Quasi-Simultaneous Welding

12.4.3. Simultaneous Welding

12.4.4. Mask Welding

12.4.5. Radial Welding

12.4.6. Others

12.5. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

12.5.1. CO2 Laser

12.5.2. Diode Laser

12.5.2.1. Dio-Scan

12.5.2.2. Direct

12.5.2.3. Fiber-Coupled

12.5.2.4. Multi-diode

12.5.3. Fiber Laser

12.5.4. Nd:YAG Laser

12.6. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by welding Application

12.6.1. Components

12.6.2. Films

12.7. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

12.7.1. Electrical & Electronics

12.7.2. Healthcare

12.7.3. Automotive

12.7.4. Consumer Goods

12.7.5. Others

12.8. Market Attractiveness Analysis

12.8.1. by Laser Plastic Welding Systems

12.8.2. by Laser Welding Method

12.8.3. by Laser Type

12.8.4. by Plastic welding Application

12.8.5. by End Use Industry

12.9. Drivers and Restraints: Impact Analysis

13. Latin America Laser Plastic Welding Market Analysis and Forecast (2020-2025)

13.1. Introduction

13.1.1. Market share and Basis Points (BPS) Analysis by Country

13.1.2. Y-o-Y Growth Projections by Country

13.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Country

13.2.1. Brazil

13.2.2. Mexico

13.2.3. Argentina

13.2.4. Rest of Latin America

13.3. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Systems

13.3.1. Stand-alone systems

13.3.2. Integrated Systems

13.4. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Method

13.4.1. Contour Welding

13.4.2. Quasi-Simultaneous Welding

13.4.3. Simultaneous Welding

13.4.4. Mask Welding

13.4.5. Radial Welding

13.4.6. Others

13.5. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

13.5.1. CO2 Laser

13.5.2. Diode Laser

13.5.2.1. Dio-Scan

13.5.2.2. Direct

13.5.2.3. Fiber-Coupled

13.5.2.4. Multi-diode

13.5.3. Fiber Laser

13.5.4. Nd:YAG Laser

13.6. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by welding Application

13.6.1. Components

13.6.2. Films

13.7. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

13.7.1. Electrical & Electronics

13.7.2. Healthcare

13.7.3. Automotive

13.7.4. Consumer Goods

13.7.5. Others

13.8. Market Attractiveness Analysis

13.8.1. by Laser Plastic Welding Systems

13.8.2. by Laser Welding Method

13.8.3. by Laser Type

13.8.4. by Plastic welding Application

13.8.5. by End Use Industry

13.9. Drivers and Restraints: Impact Analysis

14. Europe Laser Plastic Welding Market Analysis and Forecast (2020-2025)

14.1. Introduction

14.1.1. Market share and Basis Points (BPS) Analysis by Country

14.1.2. Y-o-Y Growth Projections by Country

14.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Country

14.2.1. Germany

14.2.2. Spain

14.2.3. Italy

14.2.4. France

14.2.5. U.K.

14.2.6. BENELUX

14.2.7. Russia

14.2.8. Rest of Europe

14.3. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Systems

14.3.1. Stand-alone systems

14.3.2. Integrated Systems

14.4. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Method

14.4.1. Contour Welding

14.4.2. Quasi-Simultaneous Welding

14.4.3. Simultaneous Welding

14.4.4. Mask Welding

14.4.5. Radial Welding

14.4.6. Others

14.5. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

14.5.1. CO2 Laser

14.5.2. Diode Laser

14.5.2.1. Dio-Scan

14.5.2.2. Direct

14.5.2.3. Fiber-Coupled

14.5.2.4. Multi-diode

14.5.3. Fiber Laser

14.5.4. Nd:YAG Laser

14.6. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by welding Application

14.6.1. Components

14.6.2. Films

14.7. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

14.7.1. Electrical & Electronics

14.7.2. Healthcare

14.7.3. Automotive

14.7.4. Consumer Goods

14.7.5. Others

14.8. Market Attractiveness Analysis

14.8.1. by Laser Plastic Welding Systems

14.8.2. by Laser Welding Method

14.8.3. by Laser Type

14.8.4. by Plastic welding Application

14.8.5. by End Use Industry

14.9. Drivers and Restraints: Impact Analysis

15. Asia Pacific Laser Plastic Welding Market Analysis and Forecast (2020-2025)

15.1. Introduction

15.1.1. Market share and Basis Points (BPS) Analysis by Country

15.1.2. Y-o-Y Growth Projections by Country

15.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Country

15.2.1. China

15.2.2. India

15.2.3. Japan

15.2.4. ASEAN

15.2.5. Australia and New Zealand

15.2.6. Rest of APAC

15.3. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Systems

15.3.1. Stand-alone systems

15.3.2. Integrated Systems

15.4. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Method

15.4.1. Contour Welding

15.4.2. Quasi-Simultaneous Welding

15.4.3. Simultaneous Welding

15.4.4. Mask Welding

15.4.5. Radial Welding

15.4.6. Others

15.5. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

15.5.1. CO2 Laser

15.5.2. Diode Laser

15.5.2.1. Dio-Scan

15.5.2.2. Direct

15.5.2.3. Fiber-Coupled

15.5.2.4. Multi-diode

15.5.3. Fiber Laser

15.5.4. Nd:YAG Laser

15.6. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by welding Application

15.6.1. Components

15.6.2. Films

15.7. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

15.7.1. Electrical & Electronics

15.7.2. Healthcare

15.7.3. Automotive

15.7.4. Consumer Goods

15.7.5. Others

15.8. Market Attractiveness Analysis

15.8.1. by Laser Plastic Welding Systems

15.8.2. by Laser Welding Method

15.8.3. by Laser Type

15.8.4. by Plastic welding Application

15.8.5. by End Use Industry

15.9. Drivers and Restraints: Impact Analysis

16. Middle East and Africa (MEA) Laser Plastic Welding Market Analysis and Forecast (2020-2025)

16.1. Introduction

16.1.1. Market share and Basis Points (BPS) Analysis by Country

16.1.2. Y-o-Y Growth Projections by Country

16.2. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Country

16.2.1. North Africa

16.2.2. South Africa

16.2.3. GCC countries

16.2.4. Rest of MEA

16.3. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Systems

16.3.1. Stand-alone systems

16.3.2. Integrated Systems

16.4. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025) by Laser Plastic Welding Method

16.4.1. Contour Welding

16.4.2. Quasi-Simultaneous Welding

16.4.3. Simultaneous Welding

16.4.4. Mask Welding

16.4.5. Radial Welding

16.4.6. Others

16.5. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by Laser Type

16.5.1. CO2 Laser

16.5.2. Diode Laser

16.5.2.1. Dio-Scan

16.5.2.2. Direct

16.5.2.3. Fiber-Coupled

16.5.2.4. Multi-diode

16.5.3. Fiber Laser

16.5.4. Nd:YAG Laser

16.6. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by welding Application

16.6.1. Components

16.6.2. Films

16.7. Market Size (US$ Mn) and Volume (Units) Forecast (2020-2025), by End Use Industry

16.7.1. Electrical & Electronics

16.7.2. Healthcare

16.7.3. Automotive

16.7.4. Consumer Goods

16.7.5. Others

16.8. Market Attractiveness Analysis

16.8.1. by Laser Plastic Welding Systems

16.8.2. by Laser Welding Method

16.8.3. by Laser Type

16.8.4. by Plastic welding Application

16.8.5. by End Use Industry

16.9. Drivers and Restraints: Impact Analysis

17. Competitive Landscape

17.1. Competition Dashboard

17.2. Company Market Share Analysis

17.3. Company Profiles (Details – Overview, Financials, Strategy, Recent Developments, SWOT analysis)

17.3.1. TRUMPF GmbH + Co. KG

17.3.1.1. Overview

17.3.1.2. Financials

17.3.1.3. Strategy

17.3.1.4. Recent Developments

17.3.1.5. SWOT analysis

17.3.2. Han's Laser Technology Industry Group Co., Ltd

17.3.2.1. Overview

17.3.2.2. Financials

17.3.2.3. Strategy

17.3.2.4. Recent Developments

17.3.2.5. SWOT analysis

17.3.3. LPKF Laser & Electronics AG

17.3.3.1. Overview

17.3.3.2. Financials

17.3.3.3. Strategy

17.3.3.4. Recent Developments

17.3.3.5. SWOT analysis

17.3.4. Jenoptik AG

17.3.4.1. Overview

17.3.4.2. Financials

17.3.4.3. Strategy

17.3.4.4. Recent Developments

17.3.4.5. SWOT analysis

17.3.5. Emerson Electric Co.

17.3.5.1. Overview

17.3.5.2. Financials

17.3.5.3. Strategy

17.3.5.4. Recent Developments

17.3.5.5. SWOT analysis

17.3.6. Nippon Avionics Co., Ltd.

17.3.6.1. Overview

17.3.6.2. Financials

17.3.6.3. Strategy

17.3.6.4. Recent Developments

17.3.6.5. SWOT analysis

17.3.7. Rofin Sinar Technologies Inc.

17.3.7.1. Overview

17.3.7.2. Financials

17.3.7.3. Strategy

17.3.7.4. Recent Developments

17.3.7.5. SWOT analysis

17.3.8. Leister Technologies AG

17.3.8.1. Overview

17.3.8.2. Financials

17.3.8.3. Strategy

17.3.8.4. Recent Developments

17.3.8.5. SWOT analysis

17.3.9. Amada Miyachi Co. Ltd.

17.3.9.1. Overview

17.3.9.2. Financials

17.3.9.3. Strategy

17.3.9.4. Recent Developments

17.3.9.5. SWOT analysis

17.3.10. DILAS Diodelaser GmbH

17.3.10.1. Overview

17.3.10.2. Financials

17.3.10.3. Strategy

17.3.10.4. Recent Developments

17.3.10.5. SWOT analysis

17.3.11. CEMAS Elettra S.R.L.

17.3.11.1. Overview

17.3.11.2. Financials

17.3.11.3. Strategy

17.3.11.4. Recent Developments

17.3.11.5. SWOT analysis

17.3.12. Dukane IAS LLC

17.3.12.1. Overview

17.3.12.2. Financials

17.3.12.3. Strategy

17.3.12.4. Recent Developments

17.3.12.5. SWOT analysis

17.3.13. Control Micro Systems, Inc.

17.3.13.1. Overview

17.3.13.2. Financials

17.3.13.3. Strategy

17.3.13.4. Recent Developments

17.3.13.5. SWOT analysis

17.3.14. Bielomatik Leuze GmbH + Co. KG

17.3.14.1. Overview

17.3.14.2. Financials

17.3.14.3. Strategy

17.3.14.4. Recent Developments

17.3.14.5. SWOT analysis

17.3.15. O.R. Lasertechnology GmbH

17.3.15.1. Overview

17.3.15.2. Financials

17.3.15.3. Strategy

17.3.15.4. Recent Developments

17.3.15.5. SWOT analysis

17.3.16. Seidensha Electronics Co., Ltd

17.3.16.1. Overview

17.3.16.2. Financials

17.3.16.3. Strategy

17.3.16.4. Recent Developments

17.3.16.5. SWOT analysis

17.3.17. Sahajanand Laser Technology Ltd.

17.3.17.1. Overview

17.3.17.2. Financials

17.3.17.3. Strategy

17.3.17.4. Recent Developments

17.3.17.5. SWOT analysis

17.3.18. Scantech Laser Pvt. Ltd.

17.3.18.1. Overview

17.3.18.2. Financials

17.3.18.3. Strategy

17.3.18.4. Recent Developments

17.3.18.5. SWOT analysis

17.3.19. Wuhan Chuyu Optoelectronic Technology Co., Ltd.

17.3.19.1. Overview

17.3.19.2. Financials

17.3.19.3. Strategy

17.3.19.4. Recent Developments

17.3.20. SWOT analysis

18. Assumptions and Acronyms Used

19. Research Methodology

List of Tables

Table 01: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 02: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By method Type, 2016–2025

Table 03: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Machine Type, 2016–2025

Table 04: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 05: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry Industry, 2016–2025

Table 06: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Region, 2016–2025

Table 07: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (units) Forecast, By Country, 2016–2025

Table 08: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 09: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Method, 2016–2025

Table 10: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Laser, 2016–2025

Table 11: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 12: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry, 2016–2025

Table 13: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (units) Forecast, By Country, 2016–2025

Table 14: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 15: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Method, 2016–2025

Table 16: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Laser, 2016–2025

Table 17: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 18: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry, 2016–2025

Table 19: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (units) Forecast, By Country, 2016–2025

Table 20: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 21: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Method, 2016–2025

Table 22: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Laser, 2016–2025

Table 23: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 24: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry, 2016–2025

Table 25: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (units) Forecast, By Country, 2016–2025

Table 26: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 27: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Method, 2016–2025

Table 28: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Laser, 2016–2025

Table 29: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 30: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry, 2016–2025

Table 31: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (units) Forecast, By Country, 2016–2025

Table 32: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By System, 2016–2025

Table 33: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Method, 2016–2025

Table 34: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Laser, 2016–2025

Table 35: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Application, 2016–2025

Table 36: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By End-Use Industry, 2016–2025

List of Figures

Figure 01: Global Laser Plastic Welding Market, BPS Analysis by System, 2017 & 2025

Figure 02: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by System, 2016–2025

Figure 03: Global Laser Plastic Welding Market Attractiveness Index by System, 2017–2025

Figure 04: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Standalone Segment, 2016–2025

Figure 05: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Standalone Segment, 2017?2025

Figure 6: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Integrated Segment, 2016–2025

Figure 7: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Integrated Segment, 2017?2025

Figure 8: Global Laser Plastic Welding Market, BPS Analysis by Method Type, 2017 & 2025

Figure 9: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by Method Type, 2016–2025

Figure 10: Global Laser Plastic Welding Market Attractiveness Index by Method Type, 2017–2025

Figure 11: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Contour Welding segment, 2016–2025

Figure 12: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Contour Welding Segment, 2017?2025

Figure 13: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Quasi-Simultaneous segment, 2016–2025

Figure 14: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Quasi-Simultaneous Segment, 2017?2025

Figure 15: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Simultaneous method, 2016–2025

Figure 16: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Simultaneous method Segment, 2017?2025

Figure 17: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Mask Welding method, 2016–2025

Figure 18: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Mask Welding method Segment, 2017?2025

Figure 19: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Radial Welding method, 2016–2025

Figure 20: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Radial Welding method Segment, 2017?2025

Figure 21: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Others Welding method, 2016–2025

Figure 22: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Others Welding method Segment, 2017?2025

Figure 23: Global Laser Plastic Welding Market, BPS Analysis by Laser Type, 2017 & 2025

Figure 24: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by Laser Type, 2016–2025

Figure 25: Global Laser Plastic Welding Market Attractiveness Index by Laser Type, 2017–2025

Figure 26: Global Lasers Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By CO2 Laser Segment, 2016–2025

Figure 27: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By CO2 Laser Segment, 2017?2025

Figure 28: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Diode Laser Segment, 2016–2025

Figure 29: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Diode Laser Segment, 2017?2025

Figure 30: Global Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 31: Global Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 32: Global Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 33: Global Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 34: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Fiber Laser Segment, 2016–2025

Figure 35: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Fiber Laser Segment, 2017?2025

Figure 36: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Nd:YAG Laser Segment, 2016–2025

Figure 37: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Nd:YAG Laser Segment, 2017?2025

Figure 38: Global Laser Plastic Welding Market, BPS Analysis by Application, 2017 & 2025

Figure 39: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by Application, 2016–2025

Figure 40: Global Laser Plastic Welding Market Attractiveness Index by Application, 2017–2025

Figure 41: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Component segment, 2016–2025

Figure 42: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Component Segment, 2017?2025

Figure 43: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Film segment, 2016–2025

Figure 44: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Film Segment, 2017?2025

Figure 45: Global Laser Plastic Welding Market, BPS Analysis by End-Use Industry Industry, 2017 & 2025

Figure 46: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by End-Use Industry Industry, 2016–2025

Figure 47: Global Laser Plastic Welding Market Attractiveness Index by End-Use Industry Industry, 2017–2025

Figure 48: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Electrical & Electronics segment, 2016–2025

Figure 49: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Electrical & Electronics Segment, 2017?2025

Figure 50: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Healthcare segment, 2016–2025

Figure 51: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Healthcare Segment, 2017?2025

Figure 52: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Automotive segment, 2016–2025

Figure 53: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Automotive Segment, 2017?2025

Figure 55: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Consumer Goods Segment, 2017?2025

Figure 55: Global Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, By Others segment, 2016–2025

Figure 56: Global Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), By Others Segment, 2017?2025

Figure 57: Global Laser Plastic Welding Market, BPS Analysis by Region, 2017 & 2025

Figure 58: Global Laser Plastic Welding Market Revenue Y-o-Y Growth by Region, 2016–2025

Figure 59: Global Laser Plastic Welding Market Attractiveness Index by Region, 2017–2025

Figure 60: North America Laser Plastic Welding Market Value Share by Country, 2016

Figure 61: North America Laser Plastic Welding Market Value Share by Laser, 2016

Figure 62: North America Laser Plastic Welding Market Value Share by system Type, 2016

Figure 63: North America Laser Plastic Welding Market Value Share by Application, 2016

Figure 64: North America Laser Plastic Welding Market Value Share by method, 2016

Figure 65: North America Laser Plastic Welding Market Value Share by End-Use Industry, 2016

Figure 66: North America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, 2016–2025

Figure 67: North America Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), 2017?2025

Figure 68: North America Laser Plastic Welding Market, BPS Analysis by Country, 2017 & 2025

Figure 69: North America Laser Plastic Welding Market Revenue Y-o-Y Growth by Country, 2016–2025

Figure 70: North America Laser Plastic Welding Market Attractiveness Index by Country, 2017–2025

Figure 71: US Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 72: Canada Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 73: North America Laser Plastic Welding Market Value (US$ Mn) by System, 2016–2025

Figure 74: North America Laser Plastic Welding Market Volume (units) by System, 2016–2025

Figure 75: North America Laser Plastic Welding Market Attractiveness by system, 2016–2025

Figure 76: North America Laser Plastic Welding Market Value (US$ Mn) by Method, 2016–2025

Figure 77: North America Laser Plastic Welding Market Volume (units) by Method, 2016–2025

Figure 78: North America Laser Plastic Welding Market Attractiveness by Method, 2016–2025

Figure 79: North America Laser Plastic Welding Market Value (US$ Mn) by Laser, 2016–2025

Figure 80: North America Laser Plastic Welding Market Volume (units) by Laser, 2016–2025

Figure 81: North America Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 82: North America Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 83: North America Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 84: North America Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 85: North America Laser Plastic Welding Market Attractiveness by Laser, 2016–2025

Figure 86: North America Laser Plastic Welding Market Value (US$ Mn) by Application, 2016–2025

Figure 87: North America Laser Plastic Welding Market Volume (units) by Application, 2016–2025

Figure 88: North America Laser Plastic Welding Market Attractiveness by Application, 2016–2025

Figure 89: North America Laser Plastic Welding Market Value (US$ Mn) by End-Use Industry, 2016–2025

Figure 90: North America Laser Plastic Welding Market Volume (units) by End-Use Industry, 2016–2025

Figure 91: North America Laser Plastic Welding Market Attractiveness by End-Use Industry, 2016–2025

Figure 92: Latin America Laser Plastic Welding Market Value Share by Country, 2016

Figure 93: Latin America Laser Plastic Welding Market Value Share by Laser, 2016

Figure 94: Latin America Laser Plastic Welding Market Value Share by system Type, 2016

Figure 95: Latin America Laser Plastic Welding Market Value Share by Application, 2016

Figure 96: Latin America Laser Plastic Welding Market Value Share by method, 2016

Figure 97: Latin America Laser Plastic Welding Market Value Share by End-Use Industry, 2016

Figure 98: Latin America Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, 2016–2025

Figure 99: Latin America Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), 2017?2025

Figure 100: Latin America Laser Plastic Welding Market, BPS Analysis by Country, 2017 & 2025

Figure 101: Latin America Laser Plastic Welding Market Revenue Y-o-Y Growth by Country, 2016–2025

Figure 102: Latin America Laser Plastic Welding Market Attractiveness Index by Country, 2017–2025

Figure 103: Brazil Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 104: Mexico Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 105: Argentina Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 106: Rest of L.A. Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 107: Latin America Laser Plastic Welding Market Value (US$ Mn) by System, 2016–2025

Figure 108: Latin America Laser Plastic Welding Market Volume (units) by System, 2016–2025

Figure 109: Latin America Laser Plastic Welding Market Attractiveness by system, 2016–2025

Figure 110: Latin America Laser Plastic Welding Market Value (US$ Mn) by Method, 2016–2025

Figure 111: Latin America Laser Plastic Welding Market Volume (units) by Method, 2016–2025

Figure 112: Latin America Laser Plastic Welding Market Attractiveness by Method, 2016–2025

Figure 113: Latin America Laser Plastic Welding Market Value (US$ Mn) by Laser, 2016–2025

Figure 114: Latin America Laser Plastic Welding Market Volume (units) by Laser, 2016–2025

Figure 115: Latin America Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 116: Latin America Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 117: Latin America Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 118: Latin America Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 119: Latin America Laser Plastic Welding Market Attractiveness by Laser, 2016–2025

Figure 120: Latin America Laser Plastic Welding Market Value (US$ Mn) by Application, 2016–2025

Figure 121: Latin America Laser Plastic Welding Market Volume (units) by Application, 2016–2025

Figure 122: Latin America Laser Plastic Welding Market Attractiveness by Application, 2016–2025

Figure 123: Latin America Laser Plastic Welding Market Value (US$ Mn) by End-Use Industry, 2016–2025

Figure 124: Latin America Laser Plastic Welding Market Volume (units) by End-Use Industry, 2016–2025

Figure 125: Latin America Laser Plastic Welding Market Attractiveness by End-Use Industry, 2016–2025

Figure 126: Europe Laser Plastic Welding Market Value Share by Country, 2016

Figure 127: Europe Laser Plastic Welding Market Value Share by Laser, 2016

Figure 128: Europe Laser Plastic Welding Market Value Share by system Type, 2016

Figure 129: Europe Laser Plastic Welding Market Value Share by Application, 2016

Figure 130: Europe Laser Plastic Welding Market Value Share by method, 2016

Figure 131: Europe Laser Plastic Welding Market Value Share by End-Use Industry, 2016

Figure 132: Europe Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, 2016–2025

Figure 133: Europe Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), 2017?2025

Figure 134: Europe Laser Plastic Welding Market, BPS Analysis by Country, 2017 & 2025

Figure 135: Europe Laser Plastic Welding Market Revenue Y-o-Y Growth by Country, 2016–2025

Figure 136: Europe Laser Plastic Welding Market Attractiveness Index by Country, 2017–2025

Figure 137: Germany Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 138: Spain Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 139: Italy Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 140: France Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 141: UK Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 142: Benelux Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 143: Russia Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 144: Rest of Europe Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 145: Europe Laser Plastic Welding Market Value (US$ Mn) by System, 2016–2025

Figure 146: Europe Laser Plastic Welding Market Volume (units) by System, 2016–2025

Figure 147: Europe Laser Plastic Welding Market Attractiveness by system, 2016–2025

Figure 148: Europe Laser Plastic Welding Market Value (US$ Mn) by Method, 2016–2025

Figure 149: Europe Laser Plastic Welding Market Volume (units) by Method, 2016–2025

Figure 150: Europe Laser Plastic Welding Market Attractiveness by Method, 2016–2025

Figure 151: Europe Laser Plastic Welding Market Value (US$ Mn) by Laser, 2016–2025

Figure 152: Europe Laser Plastic Welding Market Volume (units) by Laser, 2016–2025

Figure 153: Europe Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 154: Europe Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 155: Europe Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 156: Europe Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 157: Europe Laser Plastic Welding Market Attractiveness by Laser, 2016–2025

Figure 158: Europe Laser Plastic Welding Market Value (US$ Mn) by Application, 2016–2025

Figure 159: Europe Laser Plastic Welding Market Volume (units) by Application, 2016–2025

Figure 160: Europe Laser Plastic Welding Market Attractiveness by Application, 2016–2025

Figure 161: Europe Laser Plastic Welding Market Value (US$ Mn) by End-Use Industry, 2016–2025

Figure 162: Europe Laser Plastic Welding Market Volume (units) by End-Use Industry, 2016–2025

Figure 163: Europe Laser Plastic Welding Market Attractiveness by End-Use Industry, 2016–2025

Figure 164: Asia Pacific Laser Plastic Welding Market Value Share by Country, 2016

Figure 165: Asia Pacific Laser Plastic Welding Market Value Share by Laser, 2016

Figure 166: Asia Pacific Laser Plastic Welding Market Value Share by system Type, 2016

Figure 167: Asia Pacific Laser Plastic Welding Market Value Share by Application, 2016

Figure 168: Asia Pacific Laser Plastic Welding Market Value Share by method, 2016

Figure 169: Asia Pacific Laser Plastic Welding Market Value Share by End-Use Industry, 2016

Figure 170: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, 2016–2025

Figure 171: Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), 2017?2025

Figure 172: Asia Pacific Laser Plastic Welding Market, BPS Analysis by Country, 2017 & 2025

Figure 173: Asia Pacific Laser Plastic Welding Market Revenue Y-o-Y Growth by Country, 2016–2025

Figure 174: Asia Pacific Laser Plastic Welding Market Attractiveness Index by Country, 2017–2025

Figure 175: China Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 176: India Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 177: Japan Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 178: ASEAN Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 179: Australia & NZ Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 180: Rest of Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 181: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) by System, 2016–2025

Figure 182: Asia Pacific Laser Plastic Welding Market Volume (units) by System, 2016–2025

Figure 183: Asia Pacific Laser Plastic Welding Market Attractiveness by system, 2016–2025

Figure 184: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) by Method, 2016–2025

Figure 185: Asia Pacific Laser Plastic Welding Market Volume (units) by Method, 2016–2025

Figure 186: Asia Pacific Laser Plastic Welding Market Attractiveness by Method, 2016–2025

Figure 187: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) by Laser, 2016–2025

Figure 188: Asia Pacific Laser Plastic Welding Market Volume (units) by Laser, 2016–2025

Figure 189: Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 190: Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 191: Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 192: Asia Pacific Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 193: Asia Pacific Laser Plastic Welding Market Attractiveness by Laser, 2016–2025

Figure 194: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) by Application, 2016–2025

Figure 195: Asia Pacific Laser Plastic Welding Market Volume (units) by Application, 2016–2025

Figure 196: Asia Pacific Laser Plastic Welding Market Attractiveness by Application, 2016–2025

Figure 197: Asia Pacific Laser Plastic Welding Market Value (US$ Mn) by End-Use Industry, 2016–2025

Figure 198: Asia Pacific Laser Plastic Welding Market Volume (units) by End-Use Industry, 2016–2025

Figure 199: Asia Pacific Laser Plastic Welding Market Attractiveness by End-Use Industry, 2016–2025

Figure 200: MEA Laser Plastic Welding Market Value Share by Country, 2016

Figure 201: MEA Laser Plastic Welding Market Value Share by Laser, 2016

Figure 202: MEA Laser Plastic Welding Market Value Share by system Type, 2016

Figure 203: MEA Laser Plastic Welding Market Value Share by Application, 2016

Figure 204: MEA Laser Plastic Welding Market Value Share by method, 2016

Figure 205: MEA Laser Plastic Welding Market Value Share by End-Use Industry, 2016

Figure 206: MEA Laser Plastic Welding Market Value (US$ Mn) and Volume (Units) Forecast, 2016–2025

Figure 207: MEA Laser Plastic Welding Market Absolute $ Opportunity (US$ Mn), 2017?2025

Figure 208: MEA Laser Plastic Welding Market, BPS Analysis by Country, 2017 & 2025

Figure 209: MEA Laser Plastic Welding Market Revenue Y-o-Y Growth by Country, 2016–2025

Figure 210: MEA Laser Plastic Welding Market Attractiveness Index by Country, 2017–2025

Figure 211: North Africa Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 212: South Africa Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 213: GCC Countries Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 214: Rest of MEA Laser Plastic Welding Market Absolute $ Opportunity, 2017-2025

Figure 215: MEA Laser Plastic Welding Market Value (US$ Mn) by System, 2016–2025

Figure 216: MEA Laser Plastic Welding Market Volume (units) by System, 2016–2025

Figure 217: MEA Laser Plastic Welding Market Attractiveness by system, 2016–2025

Figure 218: MEA Laser Plastic Welding Market Value (US$ Mn) by Method, 2016–2025

Figure 219: MEA Laser Plastic Welding Market Volume (units) by Method, 2016–2025

Figure 220: MEA Laser Plastic Welding Market Attractiveness by Method, 2016–2025

Figure 221: MEA Laser Plastic Welding Market Value (US$ Mn) by Laser, 2016–2025

Figure 222: MEA Laser Plastic Welding Market Volume (units) by Laser, 2016–2025

Figure 223: MEA Laser Plastic Welding Market Absolute $ Opportunity, by Dio-Scan Sub-Segment, 2017-2025

Figure 224: MEA Laser Plastic Welding Market Absolute $ Opportunity, by Direct Sub-Segment, 2017-2025

Figure 225: MEA Laser Plastic Welding Market Absolute $ Opportunity, by Fiber Coupled Sub-Segment, 2017-2025

Figure 226: MEA Laser Plastic Welding Market Absolute $ Opportunity, by Multi-Diode Sub-Segment, 2017-2025

Figure 227: MEA Laser Plastic Welding Market Attractiveness by Laser, 2016–2025

Figure 228: MEA Laser Plastic Welding Market Value (US$ Mn) by Application, 2016–2025

Figure 229: MEA Laser Plastic Welding Market Volume (units) by Application, 2016–2025

Figure 230: MEA Laser Plastic Welding Market Attractiveness by Application, 2016–2025

Figure 231: MEA Laser Plastic Welding Market Value (US$ Mn) by End-Use Industry, 2016–2025

Figure 232: MEA Laser Plastic Welding Market Volume (units) by End-Use Industry, 2016–2025

Figure 233: MEA Laser Plastic Welding Market Attractiveness by End-Use Industry, 2016–2025