Reports

Reports

Analysts’ Viewpoint

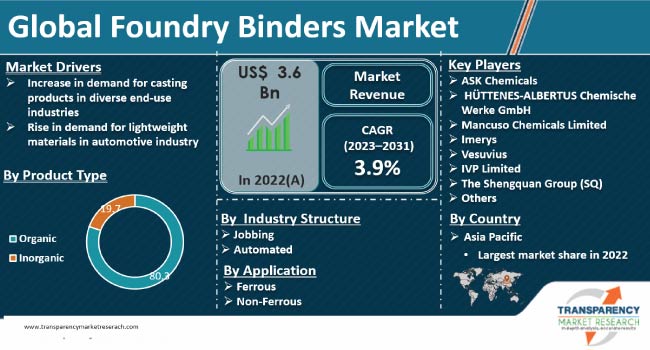

Increased demand for foundry binders in major sectors, the development of eco-friendly binders, and a focus on precise casting are anticipated to boost the global foundry binders market growth at a consistent pace in the next few years. Analysts and stakeholders are keenly interested in the market's potential for innovation and development, with an emphasis on responding to growing industrial demands and environmental issues.

Growing need for high-precision components in diverse sectors, such as automotive, aerospace, and electronics, has prompted manufacturers in these sectors to utilize foundry binders in order to create molds that can withstand the extreme conditions encountered during the metal casting process. This is estimated to create significant foundry binders market opportunities in the near future.

Foundry binders are specialty materials used in the creation of molds for metal casting. They play an important role in the fabrication of complicated metal components used in various sectors such as automotive, aerospace, and construction, among others. Foundry binders are largely responsible for binding the molding sand together, resulting in a solid and rigid structure that can survive the high temperatures and pressures associated with metal casting.

These binders can be organic or inorganic in origin, with each kind providing unique benefits depending on the application. After the metal has set, organic binders, which are frequently sourced from natural materials, such as clay or starch, offer excellent cohesiveness and collapsibility. In contrast, inorganic binders are frequently based on minerals, such as sodium silicate or phosphate, which provide high-temperature stability and lower emissions during casting.

Analysis of the foundry binders market statistics underlines the vital role of foundry binders in the manufacture of complex metal components through the casting process. The foundry binders industry is shifting toward new and sustainable binder formulations owing to the rising demand for high-precision goods and growing emphasis on environmental sensitivity.

Growing need for finely engineered metal components from various sectors, such as automotive, aircraft, construction, and electronics, has had a significant impact on the foundry binders industry growth. These parts are critical for a wide range of machinery and equipment used in today's society. For instance, in the automotive sector, demand for lightweight, robust materials is significantly high in order to improve fuel economy and comply with stringent pollution regulations. Consequently, there is a higher emphasis on precision casting, which fuels the need for modern foundry binders that offer good mold stability and precise details.

The aerospace sector, which is renowned for its stringent safety and performance standards, drives the demand for specialty casting goods. Aircraft components must have excellent strength-to-weight ratios and must be able to withstand harsh circumstances. Foundry binders are essential in the creation of molds that are capable of producing these components with accuracy and durability.

The foundry binders market demand is also increasing in the construction industry owing to a surge in demand for customized metal components in infrastructure projects. The casting industry caters to a wide range of building demands, from exquisite architectural details to sturdy steel reinforcements.

Growing focus on reduction of size and enhancement of performance in the electronics sector has considerably propelled the demand for casting components. Tiny components, such as connectors, heat sinks, and housing sections, require precision casting to fulfill certain dimensions and tolerances. Increased demand for specific components has fueled technological innovation in the foundry industry, resulting in significant breakthroughs in binders and casting techniques.

Precision metal casting is critical in key industries such as automotive, aircraft, construction, and electronics. Moreover, rising demand for precise cast components has driven advances in foundry technology, resulting in sophisticated binders and casting procedures that exceed industry requirements.

The search of increased fuel economy and lower emissions is driving a paradigm shift in the automotive industry toward lighter materials. This move is in reaction to worldwide concerns about environmental sustainability as well as increasingly stringent car emissions rules. Lighter cars use less fuel, produce fewer greenhouse emissions, and contribute to a more sustainable future. Foundry binders are crucial in this transformation. Precision casting is becoming increasingly important as automakers strive to incorporate lighter materials, such as aluminum and new alloys, into their designs.

The ability of foundry binders to provide stability and exquisite precision in the casting process is critical for manufacturing components that fulfill the demanding quality standards of the automobile sector. This transformation aligns with the current foundry binders market trends, emphasizing the importance of sustainable practices and advanced materials.

Lightweight materials are in high demand in areas other than typical internal combustion engine vehicles. Weight reduction is becoming increasingly important with the advent of electric vehicles (EVs). Lighter EVs can go farther on a single charge, making them more desirable to customers and accelerating the transition to sustainable transportation. Foundry binder manufacturers are developing binders that are specifically tailored to the unique requirements of casting lightweight materials.

Increasing emphasis on sustainability and economy in the casting industry is driving the demand for foundry binders. Moreover, they are likely to continue to be a vital component in producing lightweight components that would shape the future of transportation.

Asia Pacific accounted for 58.8% of the global foundry binders market share in 2022. This dominant position is attributed to the increasing rate of modernization and rising demand for foundry goods, notably in the automotive and aerospace sectors in the region. Significant economic growth and technological innovation witnessed in several countries in Asia Pacific are boosting the need for precision-cast components, further propelling the foundry binders market outlook of the region.

Europe also held a significant share of the global foundry binders business in 2022. The foundry binders market size in the region is anticipated to rise significantly due to the rapid increase in adoption of industrial automation and continued technical improvements in diverse industries in the region.

The global foundry binders industry is highly competitive and prominent players adopt various techniques to consolidate their position and extend their market presence. According to the latest assessment of the foundry binders market research report, the landscape is robust, with several chances for expansion and innovation. Key players operating in the global market are ASK Chemicals, HÜTTENES-ALBERTUS Chemische Werke GmbH, Mancuso Chemicals Limited, Imerys, Vesuvius, IVP Limited, John Winter, BASF SE, United Erie, Eurotek Foundry Products Limited, The Shengquan Group (SQ), Kao Corporation, RP Minerals, and REFCOTEC.

Key players in the global foundry binders market report have been profiled based on various parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

| Attribute | Detail |

|---|---|

| Size in 2022 | US$ 3.6 Bn |

| Forecast (Value) in 2031 | US$ 5.1 Bn |

| Growth Rate (CAGR) | 3.9% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2020-2022 |

| Quantitative Tons | US$ Bn for Value and Thousand Tons for Volume |

| Market Analysis | It includes segment analysis as well as regional level analysis. Furthermore, the qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces Analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation |

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

The global market was valued at US$ 3.6 Bn in 2022

It is expected to expand at a CAGR of 3.8% from 2023 to 2031

Increase in demand for casting products in diverse end-use industries and rise in demand for lightweight materials in automotive industry

In terms of industry structure, the jobbing held the largest share in 2022

Asia Pacific was the most lucrative region in 2022

ASK Chemicals, HÜTTENES-ALBERTUS Chemische Werke GmbH, Mancuso Chemicals Limited, Imerys, Vesuvius, IVP Limited, John Winter, BASF SE, United Erie, Eurotek Foundry Products Limited, The Shengquan Group (SQ), Kao Corporation, RP Minerals, REFCOTEC

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global Foundry Binders Market Analysis and Forecast, 2023-2031

2.6.1. Global Foundry Binders Market Volume (Thousand Tons)

2.6.2. Global Foundry Binders Market Value (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Component Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealer/Distributors

2.9.4. List of Potential Customers

2.10. Product Specification Analysis

2.11. Production Overview

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on the Supply Chain of the Foundry Binders

3.2. Impact on the Demand of Foundry Binders Market – Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Thousand Tons)

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East and Africa

6. Price Trend Analysis and Forecast (US$/Ton), 2023-2031

6.1. Price Comparison Analysis by Product Type

6.2. Price Comparison Analysis by Region

7. Global Foundry Binders Market Analysis and Forecast, by Product Type , 2023-2031

7.1. Introduction and Definitions

7.2. Global Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type, 2023-2031

7.2.1. Organic

7.2.1.1. Heat Curing

7.2.1.2. No-Bake

7.2.1.2.1. Furan

7.2.1.2.2. Polyurethane No-Bake

7.2.1.2.3. Alkyd

7.2.1.2.4. Phenolic

7.2.1.2.5. Easter Cured

7.2.1.2.6. Others

7.2.1.3. ColdBox

7.2.1.3.1. Polyurethane Coldbox

7.2.1.3.2. Phonelic Resole

7.2.1.3.3. Epoxy

7.2.1.3.4. Others

7.2.2. Inorganic

7.2.2.1. Self- Set

7.2.2.2. Gassing

7.2.2.3. Heat Cured Sodium Silicate

7.3. Global Foundry Binders Market Attractiveness, by Product Type

8. Global Foundry Binders Market Analysis and Forecast, by Industry Structure, 2023-2031

8.1. Introduction and Definitions

8.2. Global Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

8.2.1. Jobbing

8.2.2. Automated

8.3. Global Foundry Binders Market Attractiveness, by Industry Structure

9. Global Foundry Binders Market Analysis and Forecast, by Application, 2023-2031

9.1. Introduction and Definitions

9.2. Global Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

9.2.1. Ferrous Metals

9.2.2. Non-Ferrous Metals

9.3. Global Foundry Binders Market Attractiveness, by Application

10. Foundry Binders Market Analysis and Forecast, by Region, 2023-2031

10.1. Key Findings

10.2. Global Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Region, 2023-2031

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Global Foundry Binders Market Attractiveness, by Region

11. North America Foundry Binders Market Analysis and Forecast, 2023-2031

11.1. Key Findings

11.2. North America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

11.3. North America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

11.4. North America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

11.5. North America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Country, 2023-2031

11.5.1. U.S. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

11.5.2. U.S. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

11.5.3. U.S. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

11.5.4. Canada Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

11.5.5. Canada Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

11.5.6. Canada Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

11.6. North America Foundry Binders Market Attractiveness Analysis

12. Europe Foundry Binders Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.3. Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.4. Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5. Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

12.5.1. Germany Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Material, 2023-2031

12.5.2. Germany Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.3. Germany Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5.4. France Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.5.5. France Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.6. France Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5.7. U.K. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.5.8. U.K. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.9. U.K. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5.10. Italy Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.5.11. Italy. Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.12. Italy Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5.13. Russia & CIS Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.5.14. Russia & CIS Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.15. Russia & CIS Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.5.16. Rest of Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

12.5.17. Rest of Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

12.5.18. Rest of Europe Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

12.6. Europe Foundry Binders Market Attractiveness Analysis

13. Asia Pacific Foundry Binders Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type

13.3. Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.4. Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.5. Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

13.5.1. China Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

13.5.2. China Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

13.5.3. China Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.5.4. Japan Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

13.5.5. Japan Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

13.5.6. Japan Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.5.7. India Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

13.5.8. India Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

13.5.9. India Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.5.10. ASEAN Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

13.5.11. ASEAN Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

13.5.12. ASEAN Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.5.13. Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

13.5.14. Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

13.5.15. Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

13.6. Asia Pacific Foundry Binders Market Attractiveness Analysis

14. Latin America Foundry Binders Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type Coat Type, 2023-2031

14.3. Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

14.4. Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

14.5. Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

14.5.1. Brazil Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

14.5.2. Brazil Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

14.5.3. Brazil Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

14.5.4. Mexico Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

14.5.5. Mexico Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

14.5.6. Mexico Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

14.5.7. Rest of Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

14.5.8. Rest of Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

14.5.9. Rest of Latin America Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

14.6. Latin America Foundry Binders Market Attractiveness Analysis

15. Middle East & Africa Foundry Binders Market Analysis and Forecast, 2023-2031

15.1. Key Findings

15.2. Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

15.3. Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

15.4. Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

15.5. Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

15.5.1. GCC Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

15.5.2. GCC Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

15.5.3. GCC Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

15.5.4. South Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

15.5.5. South Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

15.5.6. South Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application,2023-2031

15.5.7. Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Product Type , 2023-2031

15.5.8. Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Industry Structure, 2023-2031

15.5.9. Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) and Value (US$ Mn) Forecast, by Application, 2023-2031

15.6. Middle East & Africa Foundry Binders Market Attractiveness Analysis

16. Competition Landscape

16.1. Market Players - Competition Matrix (by Tier and Size of Companies)

16.2. Market Share Analysis, 2021

16.3. Market Footprint Analysis

16.3.1. By Product Type

16.3.2. By Application

16.4. Company Profiles

16.4.1. ASK Chemicals

16.4.1.1. Company Revenue

16.4.1.2. Business Overview

16.4.1.3. Product Segments

16.4.1.4. Geographic Footprint

16.4.1.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.1.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.2. HÜTTENES-ALBERTUS Chemische Werke GmbH

16.4.2.1. Company Revenue

16.4.2.2. Business Overview

16.4.2.3. Product Segments

16.4.2.4. Geographic Footprint

16.4.2.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.2.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.3. Mancuso Chemicals Limited

16.4.3.1. Company Revenue

16.4.3.2. Business Overview

16.4.3.3. Product Segments

16.4.3.4. Geographic Footprint

16.4.3.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.3.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.4. Imerys

16.4.4.1. Company Revenue

16.4.4.2. Business Overview

16.4.4.3. Product Segments

16.4.4.4. Geographic Footprint

16.4.4.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.4.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.5. Vesuvius

16.4.5.1. Company Revenue

16.4.5.2. Business Overview

16.4.5.3. Product Segments

16.4.5.4. Geographic Footprint

16.4.5.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.5.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.6. IVP Limited

16.4.6.1. Company Revenue

16.4.6.2. Business Overview

16.4.6.3. Product Segments

16.4.6.4. Geographic Footprint

16.4.6.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.6.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.7. John Winter

16.4.7.1. Company Revenue

16.4.7.2. Business Overview

16.4.7.3. Product Segments

16.4.7.4. Geographic Footprint

16.4.7.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.7.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.8. BASF SE

16.4.8.1. Company Revenue

16.4.8.2. Business Overview

16.4.8.3. Product Segments

16.4.8.4. Geographic Footprint

16.4.8.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.8.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.9. United Erie

16.4.9.1. Company Revenue

16.4.9.2. Business Overview

16.4.9.3. Product Segments

16.4.9.4. Geographic Footprint

16.4.9.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.9.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.10. Eurotek Foundry Products Ltd

16.4.10.1. Company Revenue

16.4.10.2. Business Overview

16.4.10.3. Product Segments

16.4.10.4. Geographic Footprint

16.4.10.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.10.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.11. The Shengquan Group (SQ)

16.4.11.1. Company Revenue

16.4.11.2. Business Overview

16.4.11.3. Product Segments

16.4.11.4. Geographic Footprint

16.4.11.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.11.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.12. Kao Corporation

16.4.12.1. Company Revenue

16.4.12.2. Business Overview

16.4.12.3. Product Segments

16.4.12.4. Geographic Footprint

16.4.12.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.12.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.13. RP Minerals

16.4.13.1. Company Revenue

16.4.13.2. Business Overview

16.4.13.3. Product Segments

16.4.13.4. Geographic Footprint

16.4.13.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.13.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

16.4.14. REFCOTEC

16.4.14.1. Company Revenue

16.4.14.2. Business Overview

16.4.14.3. Product Segments

16.4.14.4. Geographic Footprint

16.4.14.5. Production Coat Type/Plant Details, etc. (*As Applicable)

16.4.14.6. Strategic Partnership, Coat Type Expansion, New Product Innovation, etc.

17. Primary Research: Key Insights

18. Appendix

List of Tables

Table 1: Global Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 2: Global Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 3: Global Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 4: Global Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 5: Global Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 6: Global Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 7: Global Foundry Binders Market Volume (Thousand Tons) Forecast, by Region, 2023–2031

Table 8: Global Foundry Binders Market Value (US$ Mn) Forecast, by Region, 2023–2031

Table 9: North America Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 10: North America Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 11: North America Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 12: North America Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 13: North America Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 14: North America Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 15: North America Foundry Binders Market Volume (Thousand Tons) Forecast, by Country, 2023–2031

Table 16: North America Foundry Binders Market Value (US$ Mn) Forecast, by Country, 2023–2031

Table 17: U.S. Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 18: U.S. Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 19: U.S. Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 20: U.S. Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 21: U.S. Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 22: U.S. Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 23: Canada Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 24: Canada Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 25: Canada Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 26: Canada Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 27: Canada Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 28: Canada Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 29: Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 30: Europe Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 31: Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 32: Europe Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 33: Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 34: Europe Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 35: Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Country and Sub-region, 2023–2031

Table 36: Europe Foundry Binders Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 37: Germany Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 38: Germany Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 39: Germany Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 40: Germany Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 41: Germany Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 42: Germany Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 43: France Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 44: France Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 45: France Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 46: France Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 47: France Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 48: France Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 49: U.K. Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 50: U.K. Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 51: U.K. Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 52: U.K. Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 53: U.K. Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 54: U.K. Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 55: Italy Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 56: Italy Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 57: Italy Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 58: Italy Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 59: Italy Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 60: Italy Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 61: Spain Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 62: Spain Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 63: Spain Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 64: Spain Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 65: Spain Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 66: Spain Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 67: Russia & CIS Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 68: Russia & CIS Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 69: Russia & CIS Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 70: Russia & CIS Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 71: Russia & CIS Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 72: Russia & CIS Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 73: Rest of Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 74: Rest of Europe Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 75: Rest of Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 76: Rest of Europe Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 77: Rest of Europe Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 78: Rest of Europe Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 79: Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 80: Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 81: Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 82: Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 83: Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 84: Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 85: Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Country and Sub-region, 2023–2031

Table 86: Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 87: China Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 88: China Foundry Binders Market Value (US$ Mn) Forecast, by Product Type 2023–2031

Table 89: China Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 90: China Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 91: China Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 92: China Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 93: Japan Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 94: Japan Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 95: Japan Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 96: Japan Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 97: Japan Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 98: Japan Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 99: India Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 100: India Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 101: India Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 102: India Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 103: India Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 104: India Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 105: ASEAN Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 106: ASEAN Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 107: ASEAN Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 108: ASEAN Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 109: ASEAN Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 110: ASEAN Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 111: Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 112: Rest of Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 113: Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 114: Rest of Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 115: Rest of Asia Pacific Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 116: Rest of Asia Pacific Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 117: Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 118: Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 119: Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 120: Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 121: Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 122: Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 123: Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Country and Sub-region, 2023–2031

Table 124: Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 125: Brazil Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 126: Brazil Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 127: Brazil Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 128: Brazil Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 129: Brazil Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 130: Brazil Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 131: Mexico Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 132: Mexico Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 133: Mexico Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 134: Mexico Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 135: Mexico Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 136: Mexico Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 137: Rest of Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 138: Rest of Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 139: Rest of Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 140: Rest of Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 141: Rest of Latin America Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 142: Rest of Latin America Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 143: Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 144: Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 145: Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 146: Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 147: Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 148: Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 149: Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Country and Sub-region, 2023–2031

Table 150: Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 151: GCC Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 152: GCC Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 153: GCC Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 154: GCC Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 155: GCC Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 156: GCC Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 157: South Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 158: South Africa Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 159: South Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 160: South Africa Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 161: South Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 162: South Africa Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

Table 163: Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Product Type , 2023–2031

Table 164: Rest of Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Product Type , 2023–2031

Table 165: Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Industry Structure, 2023–2031

Table 166: Rest of Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Industry Structure, 2023–2031

Table 167: Rest of Middle East & Africa Foundry Binders Market Volume (Thousand Tons) Forecast, by Application, 2023–2031

Table 168: Rest of Middle East & Africa Foundry Binders Market Value (US$ Mn) Forecast, by Application, 2023–2031

List of Figures

Figure 1: Global Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 2: Global Foundry Binders Market Attractiveness, by Product Type

Figure 3: Global Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 4: Global Foundry Binders Market Attractiveness, by Industry Structure

Figure 5: Global Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 6: Global Foundry Binders Market Attractiveness, by Application

Figure 7: Global Foundry Binders Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 8: Global Foundry Binders Market Attractiveness, by Region

Figure 9: North America Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 10: North America Foundry Binders Market Attractiveness, by Product Type

Figure 11: North America Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 12: North America Foundry Binders Market Attractiveness, by Industry Structure

Figure 13: North America Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 14: North America Foundry Binders Market Attractiveness, by Application

Figure 15: North America Foundry Binders Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 16: North America Foundry Binders Market Attractiveness, by Country and Sub-region

Figure 17: Europe Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 18: Europe Foundry Binders Market Attractiveness, by Product Type

Figure 19: Europe Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 20: Europe Foundry Binders Market Attractiveness, by Industry Structure

Figure 21: Europe Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 22: Europe Foundry Binders Market Attractiveness, by Application

Figure 23: Europe Foundry Binders Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Europe Foundry Binders Market Attractiveness, by Country and Sub-region

Figure 25: Asia Pacific Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 26: Asia Pacific Foundry Binders Market Attractiveness, by Product Type

Figure 27: Asia Pacific Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 28: Asia Pacific Foundry Binders Market Attractiveness, by Industry Structure

Figure 29: Asia Pacific Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 30: Asia Pacific Foundry Binders Market Attractiveness, by Application

Figure 31: Asia Pacific Foundry Binders Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 32: Asia Pacific Foundry Binders Market Attractiveness, by Country and Sub-region

Figure 33: Latin America Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 34: Latin America Foundry Binders Market Attractiveness, by Product Type

Figure 35: Latin America Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 36: Latin America Foundry Binders Market Attractiveness, by Industry Structure

Figure 37: Latin America Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 38: Latin America Foundry Binders Market Attractiveness, by Application

Figure 39: Latin America Foundry Binders Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Latin America Foundry Binders Market Attractiveness, by Country and Sub-region

Figure 41: Middle East & Africa Foundry Binders Market Volume Share Analysis, by Product Type , 2022, 2027, and 2031

Figure 42: Middle East & Africa Foundry Binders Market Attractiveness, by Product Type

Figure 43: Middle East & Africa Foundry Binders Market Volume Share Analysis, by Industry Structure, 2022, 2027, and 2031

Figure 44: Middle East & Africa Foundry Binders Market Attractiveness, by Industry Structure

Figure 45: Middle East & Africa Foundry Binders Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 46: Middle East & Africa Foundry Binders Market Attractiveness, by Application

Figure 47: Middle East & Africa Foundry Binders Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 48: Middle East & Africa Foundry Binders Market Attractiveness, by Country and Sub-region