Reports

Reports

Growing atrocities of unpredictable weather conditions have triggered the demand for efficacious wind power coatings. Manufacturing companies are aiming to expand their product portfolio of polymer coatings for wind towers and blades that are witnessing an increase in demand. As such, the polymer coatings type segment dominates the wind power coatings market, in terms of value and volume, and is estimated to reach a volume of ~178,200 kilo liters by the end of 2022. Hence, manufacturers are innovating in new polymer coatings. For instance, German supplier of high-tech polymer materials Convestro, has gained expertise in PUR (Polyurethanes)-based topcoats that offer lasting corrosion protection for wind towers.

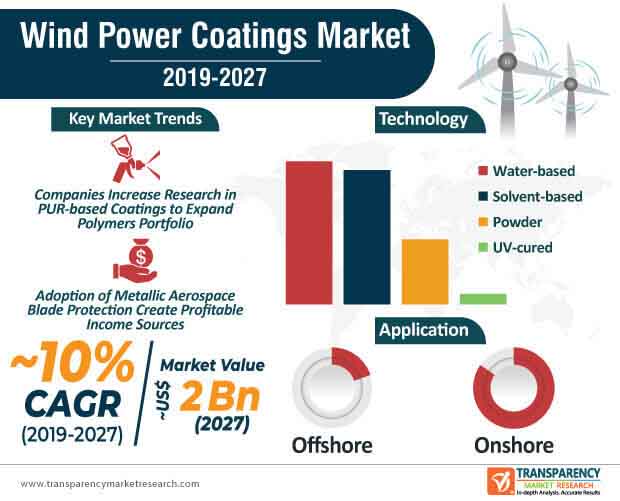

Companies in the market for wind power coatings are increasing their research activities to develop high-performance wind energy coatings. They are adding value to polymer coatings by offering exceptional gloss and color retention attributes in coatings. Furthermore, companies in the wind power coatings market are increasing production capacities to manufacture PUR-based coatings to provide lasting mechanical performance and protection from abrasion for smooth functionality of turbine blades. Companies are helping stakeholders in onshore and offshore segments to achieve high productivity by increasing the availability of low-VOC content coatings.

Companies in the wind power coatings market are boosting their credibility credentials by developing greener corrosion protection coatings. Apart from gaining stability in polymer-based coatings, manufacturers are increasing efforts to gain trust and reliability in the global market landscape by developing eco-friendly coatings. This goal is being achieved with the help of graphene additives.

Exceptional mechanical strength and thermal conductive properties of graphene are gaining increased popularity in the market for wind power coatings. Hence, manufacturers are combining the properties of graphene with solvent- and water-based coatings to develop eco-friendly coatings. As such, the water-based technology segment accounts for the highest revenue in the wind power coatings market. This segment is expected to reach a value of ~US$ 800 Mn by 2027.

Moreover, manufacturers are increasing production capabilities to develop water-based coatings to address the growing concerns of corrosion in onshore and offshore applications. Companies are experimenting by combining graphene with other corrosion-protection pigments to offer anti-corrosion function in coatings.

High industry standards in the European wind power coatings market are giving rise to efficient coating systems. There is a growing demand for advanced coatings that improve operational life of wind turbines. Hence, manufacturers in the wind power coatings market are increasing the availability of protective coatings and gel coatings for blades of wind power plants. As such, the onshore blade application segment of the wind power coatings market is estimated to reach an output of ~66,000 kilo liters by 2027. Hence, manufacturers are increasing efforts to meet productivity and long-lasting performance without the need for maintenance requirements of end users.

Companies in the wind power coatings market are gaining efficacy in waterborne topcoats that provide low solvent emissions. They are tapping into opportunities in coatings for rotor blades to offer leading-edge protection.

Innovations in offshore application are contributing to the exponential growth of the market, even though onshore application dominates the wind power coatings market in terms of volume and value. Companies are adopting new approaches such as using the aerospace technology to develop leading-edge protection systems. These novel coatings are being increasingly used for offshore wind turbines. Continuous product developments in the wind power coatings market are helping stakeholders in the offshore segment to achieve cost-efficiency. Cost-efficiency is being achieved through advanced coating systems that eliminate the need for intervention due to rain erosion. Thus, improved coatings are paving the way for lighter wind turbine blades.

On the other hand, new product offerings for onshore applications are helping manufacturers in the wind power coatings market to accomplish business stability. As such, the onshore application segment accounts for ~97% of the wind power coatings market share. However, there is a need for better products to address erosion due to rain. Hence, companies in the wind power coatings market are adopting the aerospace technology to enhance the blades operational life.

Analysts’ Viewpoint

The wind power coatings market is largely consolidated with three major players accounting to ~75% of the market share. Companies are focusing on niche requirements for fewer coats and faster curing in painting operations. They are increasing awareness about the inspection technology to improve the operational life of wind turbine blades in onshore and offshore applications.

However, conventional coating methods, such as using zinc powder lead to growing concerns about the degradation of the environment. Hence, manufacturers are developing coatings with graphene additives to help develop greener coatings. Companies should invest in powder and water-based coatings, since they are projected for exponential growth.

Wind Power Coatings Market: Overview

Wind Power Coatings Market: Key Growth Drivers

Wind Power Coatings Market: Major Challenges

Wind Power Coatings Market: Opportunities

Asia Pacific Dominates Wind Power Coatings Market

Extensive Usage of Wind Power Coatings in Onshore Application

Key Developments in Wind Power Coatings Market

Wind Power Coatings Market To Reach A Valuation Of US$ 2 Bn By 2027

Wind Power Coatings Market is growing at a CAGR of 10% during forecast period

Akzo Nobel N.V., 3M Co., The Sherwin-Williams Company are the top key players in the Wind Power Coatings Market

Asia Pacific holds the leading share of the global Wind Power Coatings Market

Polymer coatings type segment is the rising prominent segment in the Wind Power Coatings Market

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

3. Executive Summary: Global Wind Power Coatings Market

4. Production Outlook, 2018

4.1. Production Outlook, by Region

5. Global Wind Power Coatings Market, Import-Export Analysis

6. Pricing Analysis, 2018 (Benchmarking)

6.1. Price Comparison Analysis, by Region

6.2. Price Comparison Analysis, by Type

6.3. Price Comparison Analysis, by Application

6.4. Price Comparison Analysis, by Technology

6.5. Price Comparison Analysis, by Wind Turbine Blades

7. Market Overview

7.1. Introduction

7.2. Key Market Indicators/Definitions

7.3. Market Dynamics

7.3.1. Drivers

7.3.2. Restraints

7.3.3. Opportunities

7.4. Porters Five Forces Analysis

7.5. Value Chain Analysis

7.6. Market Dynamics, by Wind Blade Market

7.6.1. Drivers

7.6.2. Restraints

7.6.3. Opportunities

7.7. Regulatory Landscape

8. Global Wind Power Coatings Market Analysis and Forecast, by Type

8.1. Introduction & Key Findings

8.2. Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

8.2.1. Polymer Coatings

8.2.2. Ceramic Coatings

8.2.3. Metal Coatings

8.3. Global Wind Power Coatings Market Attractiveness, by Type

9. Global Wind Power Coatings Market Analysis and Forecast, by Application

9.1. Introduction

9.2. Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2028

9.2.1. Offshore

9.2.1.1. Offshore Blade

9.2.1.2. Offshore Tower

9.2.1.3. Offshore Interior

9.2.2. Onshore

9.2.2.1. Onshore Blade

9.2.2.2. Onshore Tower

9.2.2.3. Onshore Interior

9.3. Global Wind Power Coatings Market Attractiveness, by Application

10. Global Wind Power Coatings Market Analysis and Forecast, by Technology

10.1. Introduction & Key Findings

10.2. Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2028

10.2.1. Water based

10.2.2. Solvent based

10.2.3. Powder

10.2.4. UV Cured

11. Global Wind Power Coatings Market Attractiveness, by Technology

12. Global Wind Power Coatings Market Analysis and Forecast, by Region

12.1. Key Findings

12.2. Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Region, 20110–2027

12.3. Global Wind Power Coatings Market Attractiveness, by Region

13. North America Wind Power Coatings Market Analysis and Forecast

13.1. Key Findings

13.2. North America Wind Power Coatings Market Forecast, by Type, 2018–2027

13.3. North America Wind Power Coatings Forecast, by Application, 2018–2027

13.4. North America Wind Power Coatings Market Forecast, by Technology, 2018–2027

13.5. North America Wind Power Coatings Market Forecast, by Country, 2018–2027

13.5.1. U.S. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

13.5.2. U.S. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

13.5.3. U.S. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

13.5.4. Canada Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

13.5.5. Canada Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

13.5.6. Canada Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

13.6. North America Wind Power Coatings Market Attractiveness Analysis

14. Europe Wind Power Coatings Market Analysis and Forecast

14.1. Key Findings

14.2. Europe Wind Power Coatings Market Forecast, by Type, 2018–2027

14.3. Europe Wind Power Coatings Forecast, by Application, 2018–2027

14.4. Europe Wind Power Coatings Market Forecast, by Technology, 2018–2027

14.5. Europe Wind Power Coatings Market Forecast, by Country and Sub-region, 2018–2027

14.5.1. Germany Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.2. Germany Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.3. Germany Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.4. Spain Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.5. Spain Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.6. Spain Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.7. U.K. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.8. U.K. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.9. U.K. Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.10. France Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.11. France Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.12. France Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.13. Italy Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.14. Italy Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.15. Italy Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.16. Russia & CIS Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.17. Russia & CIS Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.18. Russia & CIS Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.5.19. Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

14.5.20. Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.5.21. Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

14.6. Europe Wind Power Coatings Market Attractiveness Analysis

15. Asia Pacific Wind Power Coatings Market Analysis and Forecast

15.1. Key Findings

15.2. Asia Pacific Wind Power Coatings Market Forecast, by Type, 2018–2027

15.3. Asia Pacific Wind Power Coatings Forecast, by Application, 2018–2027

15.4. Asia Pacific Wind Power Coatings Market Forecast, by Technology, 2018–2027

15.5. Asia Pacific Wind Power Coatings Market Forecast, by Country and Sub-region, 2018–2027

15.5.1. China Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

15.5.2. China Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

15.5.3. China Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

15.5.4. India Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

15.5.5. India Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

15.5.6. India Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

15.5.7. Japan Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

15.5.8. Australia Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

15.5.9. Australia Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

15.5.10. Australia Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

15.5.11. Japan Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

15.5.12. Japan Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

15.5.13. Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

15.5.14. Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

15.5.15. Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

15.6. Asia Pacific Wind Power Coatings Market Attractiveness Analysis

16. Latin America Wind Power Coatings Market Analysis and Forecast

16.1. Key Findings

16.2. Latin America Wind Power Coatings Market Forecast, by Type, 2018–2027

16.3. Latin America Wind Power Coatings Forecast, by Application, 2018–2027

16.4. Latin America Wind Power Coatings Market Forecast, by Technology, 2018–2027

16.5. Latin America Wind Power Coatings Market Forecast, by Country and Sub-region, 2018–2027

16.5.1. Brazil Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

16.5.2. Brazil Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

16.5.3. Brazil Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

16.5.4. Mexico Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

16.5.5. Mexico Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

16.5.6. Mexico Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

16.5.7. Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

16.5.8. Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

16.5.9. Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

16.6. 13.6. Latin America Wind Power Coatings Market Attractiveness Analysis

17. Middle East & Africa Wind Power Coatings Market Analysis and Forecast

17.1. Key Findings

17.2. Middle East & Africa Wind Power Coatings Market Forecast, by Type, 2018–2027

17.3. Middle East & Africa Wind Power Coatings Forecast, by Application, 2018–2027

17.4. Middle East & Africa Wind Power Coatings Market Forecast, by Technology, 2018–2027

17.5. Middle East & Africa Wind Power Coatings Market Forecast, by Country and Sub-region, 2018–2027

17.5.1. South Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

17.5.2. South Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

17.5.3. South Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

17.5.4. Egypt Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

17.5.5. Egypt Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

17.5.6. Egypt Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

17.5.7. Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Type, 2018–2027

17.5.8. Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Application, 2018–2027

17.5.9. Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, by Technology, 2018–2027

17.6. Middle East & Africa Wind Power Coatings Market Attractiveness Analysis

18. Competition Landscape

18.1. Global Wind Power Coatings Market Share Analysis, by Company, 2018

18.2. Competition Matrix

18.2.1. Teknos Group Oy

18.2.2. Hempel A/S

18.2.3. Jotun Group

18.2.4. PPG Industries, Inc.

18.3. Company Profiles

18.3.1. Hempel A/S

18.3.1.1. Company Description

18.3.1.2. Business Overview

18.3.1.3. Financial Details

18.3.1.4. Key Developments

18.3.2. PPG Industries, Inc.

18.3.2.1. Company Description

18.3.2.2. Business Overview

18.3.2.3. Financial Details

18.3.2.4. Key Developments

18.3.3. Akzo Nobel N.V.

18.3.3.1. Company Description

18.3.3.2. Business Overview

18.3.3.3. Financial Details

18.3.3.4. Key Developments

18.3.4. Jotun Group

18.3.4.1. Company Description

18.3.4.2. Business Overview

18.3.4.3. Financial Details

18.3.4.4. Key Developments

18.3.5. Teknos Group Oy

18.3.5.1. Company Description

18.3.5.2. Business Overview

18.3.5.3. Financial Details

18.3.5.4. Key Developments

18.3.6. 3M

18.3.6.1. Company Description

18.3.6.2. Business Overview

18.3.6.3. Financial Details

18.3.6.4. Key Developments

18.3.7. The Sherwin-Williams Company

18.3.7.1. Company Description

18.3.7.2. Business Overview

18.3.7.3. Financial Details

18.3.7.4. Key Developments

18.3.8. Mankiewicz Gebr. & Co. (GmbH & Co. KG)

18.3.8.1. Company Description

18.3.8.2. Business Overview

18.3.9. Bergolin GmbH & Co. KG

18.3.9.1. Company Description

18.3.9.2. Business Overview

18.3.10. Duromar, Inc.

18.3.10.1. Company Description

18.3.10.2. Business Overview

18.3.10.3. Financial Details

18.3.10.4. Key Developments

18.3.11. Aeolus Coatings B.V.

18.3.11.1. Company Description

18.3.11.2. Business Overview

List of Tables

Table 1: Global Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 2: Global Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 3: Global Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Application, 2018–2027

Table 4: Global Wind Power Coatings Market Value (US$ Mn) and Forecast, by Application, 2018–2027

Table 5: Global Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Onshore, 2018–2027

Table 6: Global Wind Power Coatings Market Value (US$ Mn) and Forecast, by Onshore, 2018–2027

Table 7: Global Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Offshore, 2018–2027

Table 8: Global Wind Power Coatings Market Value (US$ Mn) and Forecast, by Offshore, 2018–2027

Table 9: Global Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 10: Global Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 11: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 12: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 13: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 14: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 15: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 16: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 17: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 18: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 19: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 20: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 21: North America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Country, 2018–2027

Table 22: North America Wind Power Coatings Market Value (US$ Mn) Forecast, by Country, 2018–2027

Table 23: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 24: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 25: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 26: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 27: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 28: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 29: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 30: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 31: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 32: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 33: Canada Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 34: Canada Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 35: Canada Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 36: Canada Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 37: Canada Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 38: Canada Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 39: Canada Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 40: Canada Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 41: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 42: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 43: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 44: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 45: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 46: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 47: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 48: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 49: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 50: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 51: Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Country and Sub-region, 2018–2027

Table 52: Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 53: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 54: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 55: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 56: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 57: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 58: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 59: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 60: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 61: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 62: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 63: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 64: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 65: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 66: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 67: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 68: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 69: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 70: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 71: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 72: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 73: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 74: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 75: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 76: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 77: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 78: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 79: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 80: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 81: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 82: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 83: France Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 84: France Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 85: France Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 86: France Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 87: France Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 88: France Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 89: France Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 90: France Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 91: Italy Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 92: Italy Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 93: Italy Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 94: Italy Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 95: Italy Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 96: Italy Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 97: Italy Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 98: Italy Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 99: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 100: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 101: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 102: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 103: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 104: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 105: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 106: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 107: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 108: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 109: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 110: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 111: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 112: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 113: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 114: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 115: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 116: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 117: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 118: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 119: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Country and Sub-region, 2018–2027

Table 120: Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 121: China Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 122: China Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 123: China Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 124: China Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 125: China Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 126: China Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 127: China Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 128: China Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 129: China Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 130: China Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 131: India Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 132: India Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 133: India Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 134: India Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 135: India Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 136: India Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 137: India Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 138: India Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 139: Australia Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 140: Australia Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 141: Australia Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 142: Australia Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 143: Australia Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 144: Australia Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 145: Australia Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 146: Australia Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 147: Japan Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 148: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 149: Japan Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 150: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 151: Japan Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 152: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 153: Japan Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 154: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 155: Japan Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 156: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 157: Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 158: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 159: Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 160: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 161: Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 162: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 163: Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Offshore, 2018–2027

Table 164: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Offshore, 2018–2027

Table 165: Rest of Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 166: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 167: Latin America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 168: Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 169: Latin America Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Application, 2018–2027

Table 170: Latin America Wind Power Coatings Market Value (US$ Mn) and Forecast, by Application, 2018–2027

Table 171: Global Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Onshore, 2018–2027

Table 172: Global Wind Power Coatings Market Value (US$ Mn) and Forecast, by Onshore, 2018–2027

Table 173: Latin America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 174: Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 175: Latin America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Country/Sub-region, 2018–2027

Table 176: Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, by Country/Sub-region, 2018–2027

Table 177: Brazil Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 178: Brazil Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 179: Brazil Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Application, 2018–2027

Table 180: Brazil Wind Power Coatings Market Value (US$ Mn) and Forecast, by Application, 2018–2027

Table 181: Brazil Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Onshore, 2018–2027

Table 182: Brazil Wind Power Coatings Market Value (US$ Mn) and Forecast, by Onshore, 2018–2027

Table 183: Brazil Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 184: Brazil Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 185: Mexico Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 186: Mexico Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 187: Mexico Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Application, 2018–2027

Table 188: Mexico Wind Power Coatings Market Value (US$ Mn) and Forecast, by Application, 2018–2027

Table 189: Mexico Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Onshore, 2018–2027

Table 190: Mexico Wind Power Coatings Market Value (US$ Mn) and Forecast, by Onshore, 2018–2027

Table 191: Mexico Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 192: Mexico Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 193: Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 194: Rest of Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 195: Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Application, 2018–2027

Table 196: Rest of Latin America Wind Power Coatings Market Value (US$ Mn) and Forecast, by Application, 2018–2027

Table 197: Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) and Forecast, by Onshore, 2018–2027

Table 198: Rest of Latin America Wind Power Coatings Market Value (US$ Mn) and Forecast, by Onshore, 2018–2027

Table 199: Rest of Latin America Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 200: Rest of Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 201: Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 202: Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 203: Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 204: Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 205: Global Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 206: Global Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 207: Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 208: Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 209: Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Country and Sub-region, 2018–2027

Table 210: Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 211: South Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 212: South Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 213: South Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 214: South Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 215: South Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 216: South Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 217: South Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 218: South Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 219: Egypt Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 220: Egypt Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 221: Egypt Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 222: Egypt Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 223: Egypt Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 224: Egypt Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 225: Egypt Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 226: Egypt Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

Table 227: Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Type, 2018–2027

Table 228: Rest of Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Type, 2018–2027

Table 229: Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Application, 2018–2027

Table 230: Rest of Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 231: Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Onshore, 2018–2027

Table 232: Rest of Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Onshore, 2018–2027

Table 233: Rest of Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) Forecast, by Technology, 2018–2027

Table 234: Rest of Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, by Technology, 2018–2027

List of Figures

Figure 1: Market Snapshot, Global Wind Power Coatings Market, Indicative Volume (Kilo Liters) and Value (US$ Mn), 2018–2027

Figure 2: Market Snapshot, Indicative % Value Share and Top Trends

Figure 3: Global Wind Power Coatings Market Value Share, by Type, 2018

Figure 4: Global Wind Power Coatings Market Value Share, by Application, 2018

Figure 5: Global Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 6: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, Polymer Coatings, 2018–2027

Figure 7: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, Metal Coatings, 2018–2027

Figure 8: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Ceramic Coatings, 2018–2027

Figure 9: Global Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 10: Global Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 11: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Onshore, 2018–2027

Figure 12: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Offshore, 2018–2027

Figure 13: Global Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 14: Global Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 15: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Water-based, 2018–2027

Figure 16: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Solvent-based, 2018–2027

Figure 17: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by Powder, 2018–2027

Figure 18: Global Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Analysis, by UV Cured, 2018–2027

Figure 19: Global Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 20: North America Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, 2018–2027

Figure 21: North America Wind Power Coatings Market Attractiveness Analysis, by Country

Figure 22: North America Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 23: North America Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 24: North America Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 25: North America Wind Power Coatings Market Value Share Analysis, by Country, 2018 and 2027

Figure 26: U.S. Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 27: U.S. Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 28: Canada Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 29: Canada Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 30: North America Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 31: North America Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 32: North America Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 33: Europe Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, 2018–2027

Figure 34: Europe Wind Power Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 35: Europe Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 36: Europe Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 37: Europe Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 38: Europe Wind Power Coatings Market Value Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 39: Germany Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 40: Germany Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 41: Spain Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 42: Spain Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 43: U.K. Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 44: U.K. Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 45: France Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 46: France Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 47: Italy Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 48: Italy Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 49: Rest of Europe Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 50: Rest of Europe Wind Power Coatings Market Volume (Kilo Liters) Forecast, 2018–2027

Figure 51: Europe Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 52: Europe Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 53: Europe Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 54: Asia Pacific Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, 2018–2027

Figure 55: Asia Pacific Wind Power Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 56: Asia Pacific Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 57: Asia Pacific Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 58: Asia Pacific Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 59: Asia Pacific Wind Power Coatings Market Value Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 60: China Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 61: China Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 62: India Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 63: India Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 64: Australia Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 65: Australia Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 66: Japan Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 67: Japan Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 68: Rest of Asia Pacific Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 69: Rest of Asia Pacific Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 70: Asia Pacific Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 71: Asia Pacific Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 72: Asia Pacific Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 73: Latin America Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, 2018–2027

Figure 74: Latin America Wind Power Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 75: Latin America Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 76: Latin America Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 77: Latin America Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 78: Latin America Wind Power Coatings Market Value Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 79: Brazil Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 80: Brazil Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 81: Mexico Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 82: Mexico Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 83: Rest of Latin America Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 84: Rest of Latin America Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 85: Latin America Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 86: Latin America Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 87: Latin America Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 88: Middle East & Africa Wind Power Coatings Market Volume (Kilo Liters) and Value (US$ Mn) Forecast, 2018–2027

Figure 89: Middle East & Africa Wind Power Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 90: Middle East & Africa Wind Power Coatings Market Value Share Analysis, by Type, 2018 and 2027

Figure 91: Middle East & Africa Wind Power Coatings Market Value Share Analysis, by Application, 2018 and 2027

Figure 92: Middle East & Africa Wind Power Coatings Market Value Share Analysis, by Technology, 2018 and 2027

Figure 93: Middle East & Africa Wind Power Coatings Market Value Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 94: South Africa Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 95: South Africa Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 96: Egypt Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 97: Egypt Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 98: Rest of Middle East & Africa Wind Power Coatings Market Value (US$ Mn) Forecast, 2018–2027

Figure 99: Rest of Middle East & Africa Wind Power Coatings Volume (Kilo Liters) Forecast, 2018–2027

Figure 100: Middle East & Africa Wind Power Coatings Market Attractiveness Analysis, by Type

Figure 101: Middle East & Africa Wind Power Coatings Market Attractiveness Analysis, by Application

Figure 102: Middle East & Africa Wind Power Coatings Market Attractiveness Analysis, by Technology

Figure 103: Global Wind Power Coatings Market Share Analysis, by Company (2018)