Reports

Reports

Lead-free and heavy metal-free PVC (Poly Vinyl Chloride) foam sheets are in high demand for wall claddings and model making. This is evident since building & construction applications are estimated to account for the third-highest revenue in the PVC foam sheet market for structural composites. As such, the PVC foam sheet market for structural composites is projected to reach a value of ~US$ 1.4 Bn by the end of 2030.

Companies in the PVC foam sheet market for structural composites are increasing their efficacy in customizable services to meet specific requirements of clients. For instance, TOPOLO— an investor CFRT (Continuous Fiber Reinforced Thermoplastic) composite production lines, offers customizable services to manufacture PVC foam sandwich panels that are integrated with PET (Polyethylene terephthalate) and PU (Polyurethane) materials.

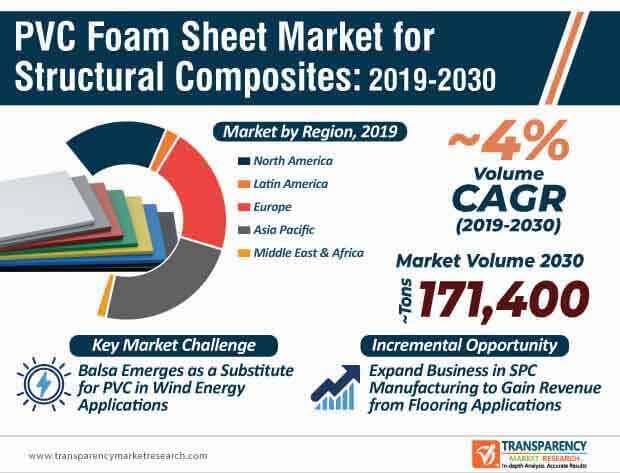

Manufacturers in the PVC foam sheet market for structural composites are tapping into incremental opportunities in wind energy applications. This explains why the revenue of wind energy applications is predicted for aggressive growth during the forecast period in the PVC foam sheet market for structural composites. As such, PCV foam sheet manufacturers are leveraging value-grab opportunities in the development of wind blades. However, the availability of substitute materials to PCV foam sheets are likely to hamper market growth. This explains why the PVC foam sheet market for structural composites is expected to expand at a modest CAGR of ~4% during the forecast period.

Balsa is being highly publicized for its high density attributes. However, balsa is more expensive than PVC. Hence, manufacturers are using PCV foam sheets in areas of wind energy that require weight savings since PVC is more lightweight than balsa.

Breakthrough technological innovations in PVC sheet extruder lines are bolstering growth for the PVC foam sheet market for structural composites. For instance, leading professional manufacturer of PVC foam board machines QINGAO SANYI has introduced the parallel twin screw lines for manufacturing of stone polymer composites (SPC) that involve PVC foam sheets. Such technological innovations are bolstering the growth of the PVC foam sheet market for structural composites.

Leading machinery manufacturers are expanding their business potentials by delivering quality machinery to PVC foam sheet manufacturers. As such, the PVC foam sheet market for structural composites is consolidated with top four market players dictating a market stake of ~76% during the forecast period. Machinery manufacturers are increasing their focus to provide equipment to companies that cater to SPC manufacturing. Thus, SPC is emerging as a key driver responsible for market growth.

Companies in the PVC foam sheet market for structural composites are taking cues from emerging innovators to manufacture face shields for the COVID-19 (coronavirus) health workers. For instance, technocrat turned IAS (Indian Administrative Service) officer Aditya Ranjan designed a face shield made from transparent PVC sheets in order to keep the frontline health workers protected from the virus. Thus, companies in the PVC foam sheet market for structural composites are capitalizing on such opportunities and innovating in other products made from PVC foam sheets that may be required by users now that the novel virus is subsiding in many countries. However, Brazil and the U.S. are still under scrutiny for increasing number of active COVID-19 cases.

Analysts’ Viewpoint

Healthcare systems in Brazil and the U.S. have generated a demand for PVC face shields. Apart from PVC face shields, manufacturers are tapping into opportunities in SPC products that are being extensively used in flooring applications.

The PVC foam sheet market for structural composites is estimated to reach a significant milestone by 2030, in terms of volume. However, high density materials such as balsa are emerging as a threat to replace PVC from wind energy applications. Hence, companies in the PVC foam sheet market for structural composites are increasingly focusing on areas of wind energy applications that require lightweight materials such as PVC foam sheets, since balsa is heavier than PVC.

PVC Foam Sheet Market for Structural Composites: Overview

Key Growth Drivers of PVC Foam Sheet Market for Structural Composites

Restraining Factors of PVC Foam Sheet Market for Structural Composites

Asia Pacific to Dominate PVC Foam Sheet Market for Structural Composites

Leading Players in PVC Foam Sheet Market for Structural Composites

1. Executive Summary

1.1. Market Snapshot: Global PVC Foam Sheet Market for Structural Composites

1.2. Key Trends

1.3. Global PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019

2. Market Overview

2.1. Product Overview

2.2. Market Indicators

2.3. Drivers and Restraints Snapshot Analysis

2.3.1. Drivers

2.3.2. Restraints

2.3.3. Opportunities

2.4. Porter’s Five Forces Analysis

2.4.1. Threat of Substitutes

2.4.2. Bargaining Power of Buyers

2.4.3. Bargaining Power of Suppliers

2.4.4. Threat of New Entrants

2.4.5. Degree of Competition

2.5. Regulatory Scenario

2.6. Value Chain Analysis

2.7. List of Potential Customers

3. COVID-19 Impact Analysis

4. Production Output Analysis

5. Pricing Analysis

5.1. Global PVC Foam Sheet Market for Structural Composites Pricing Analysis (US$/Ton), by Application, 2019-2030

5.2. Global PVC Foam Sheet Market for Structural Composites Pricing Analysis (US$/Ton), by Region, 2019-2030

6. Global PVC Foam Sheet Market for Structural Composites Analysis and Forecast, by Application

6.1. Introduction

6.2. Global PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2020 and 2030

6.3. Global PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

6.3.1. Transportation

6.3.1.1. Automotive

6.3.1.2. Buses

6.3.1.3. Railways

6.3.1.4. Aircraft

6.3.1.5. Commercial Vehicles

6.3.2. Wind Energy

6.3.2.1. Rotor Blades

6.3.2.2. Nacelle Covers

6.3.2.3. Others (including Generator Casing)

6.3.3. Marine

6.3.4. Building & Construction

6.3.5. Others (LNG Tankers and Ice Hockey Sticks)

6.4. Global PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

7. Global PVC Foam Sheet Market for Structural Composites Analysis and Forecast, by Region

7.1. Global PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Region, 2020 and 2030

7.2. Global PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Region, 2019–2030

7.2.1. North America

7.2.2. Latin America

7.2.3. Europe

7.2.4. Asia Pacific

7.2.5. Middle East & Africa

7.3. Global PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Region

8. North America PVC Foam Sheet Market for Structural Composites Analysis and Forecast

8.1. Key Findings

8.2. North America PVC Foam Sheet Market for Structural Composites Overview

8.3. North America PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Application, 2020 and 2030

8.4. North America PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

8.4.1. Transportation

8.4.1.1. Automotive

8.4.1.2. Buses

8.4.1.3. Railways

8.4.1.4. Aircraft

8.4.1.5. Commercial Vehicles

8.4.2. Wind Energy

8.4.2.1. Rotor Blades

8.4.2.2. Nacelle Covers

8.4.2.3. Others (including Generator Casing)

8.4.3. Marine

8.4.4. Building & Construction

8.4.5. Others (LNG Tankers and Ice Hockey Sticks)

8.5. North America PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Country, 2020 and 2030

8.6. North America PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Country, 2019–2030

8.6.1. U.S. PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

8.6.2. Canada PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9. Europe PVC Foam Sheet Market for Structural Composites Analysis and Forecast

9.1. Key Findings

9.2. Europe PVC Foam Sheet Market for Structural Composites Overview

9.3. Europe PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Application, 2020 and 2030

9.4. Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.4.1. Transportation

9.4.1.1. Automotive

9.4.1.2. Buses

9.4.1.3. Railways

9.4.1.4. Aircraft

9.4.1.5. Commercial Vehicles

9.4.2. Wind Energy

9.4.2.1. Rotor Blades

9.4.2.2. Nacelle Covers

9.4.2.3. Others (including Generator Casing)

9.4.3. Marine

9.4.4. Building & Construction

9.4.5. Others (LNG Tankers and Ice Hockey Sticks)

9.5. Europe PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Country and Sub-region, 2020 and 2030

9.6. Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

9.6.1. Germany PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.2. Italy PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.3. U.K. PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.4. France PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.5. Spain PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.6. Russia & CIS PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.6.7. Rest of Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10. Asia Pacific PVC Foam Sheet Market for Structural Composites Analysis and Forecast

10.1. Key Findings

10.2. Asia Pacific PVC Foam Sheet Market for Structural Composites Overview

10.3. Asia Pacific PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Application, 2020 and 2030

10.4. Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.4.1. Transportation

10.4.1.1. Automotive

10.4.1.2. Buses

10.4.1.3. Railways

10.4.1.4. Aircraft

10.4.1.5. Commercial Vehicles

10.4.2. Wind Energy

10.4.2.1. Rotor Blades

10.4.2.2. Nacelle Covers

10.4.2.3. Others (including Generator Casing)

10.4.3. Marine

10.4.4. Building & Construction

10.4.5. Others (LNG Tankers and Ice Hockey Sticks)

10.5. Asia Pacific PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Country and Sub-region, 2020 and 2030

10.6. Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

10.6.1. China PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.6.2. India PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.6.3. Japan PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.6.4. ASEAN PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.6.5. Rest of Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11. Latin America PVC Foam Sheet Market for Structural Composites Analysis and Forecast

11.1. Key Findings

11.2. Latin America PVC Foam Sheet Market for Structural Composites Overview

11.3. Latin America PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Application, 2020 and 2030

11.4. Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.4.1. Transportation

11.4.1.1. Automotive

11.4.1.2. Buses

11.4.1.3. Railways

11.4.1.4. Aircraft

11.4.1.5. Commercial Vehicles

11.4.2. Wind Energy

11.4.2.1. Rotor Blades

11.4.2.2. Nacelle Covers

11.4.2.3. Others (including Generator Casing)

11.4.3. Marine

11.4.4. Building & Construction

11.4.5. Others (LNG Tankers and Ice Hockey Sticks)

11.5. Latin America PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Country and Sub-region, 2020 and 2030

11.6. Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

11.6.1. Brazil PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.6.2. Mexico PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.6.3. Rest of Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12. Middle East & Africa PVC Foam Sheet Market for Structural Composites Analysis and Forecast

12.1. Key Findings

12.2. Middle East & Africa PVC Foam Sheet Market for Structural Composites Overview

12.3. Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Application, 2020 and 2030

12.4. Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.4.1. Transportation

12.4.1.1. Automotive

12.4.1.2. Buses

12.4.1.3. Railways

12.4.1.4. Aircraft

12.4.1.5. Commercial Vehicles

12.4.2. Wind Energy

12.4.2.1. Rotor Blades

12.4.2.2. Nacelle Covers

12.4.2.3. Others (including Generator Casing)

12.4.3. Marine

12.4.4. Building & Construction

12.4.5. Others (LNG Tankers and Ice Hockey Sticks)

12.5. Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume Share Analysis and Forecast, by Country and Sub-region, 2020 and 2030

12.6. Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

12.6.1. GCC PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.6.2. South Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.6.3. Rest of Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

13. Competition Landscape

13.1. Global PVC Foam Sheet Market for Structural Composites Share Analysis, by Company (2019)

13.2. Company Profiles

13.2.1. 3A Composites

13.2.1.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.1.2. Company Description

13.2.1.3. Business Segments

13.2.1.4. Product Line

13.2.1.5. Grades of AIREX C70

13.2.1.6. Breakdown of Revenue, by Business Segment, 2019

13.2.1.7. Breakdown of Revenue, by Region, 2019

13.2.1.8. Revenue (US$ Mn) and Y-o-Y Growth (%), 2016–2019

13.2.1.9. Key Business Strategies

13.2.2. Gurit

13.2.2.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.2.2. Company Description

13.2.2.3. Business Segments

13.2.2.4. Sub-segments

13.2.2.5. Grades of PVC

13.2.2.6. Breakdown of Revenue, by Business Segment, 2019

13.2.2.7. Breakdown of Revenue, by Region, 2019

13.2.2.8. Revenue (US$ Mn) and Y-o-Y Growth (%), 2016–2019

13.2.2.9. Key Business Strategies

13.2.2.10. Grades of Gurit PVC and Gurit PVC HT

13.2.3. Diab

13.2.3.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.3.2. Company Description

13.2.3.3. Business Segments

13.2.3.4. Sub-segments

13.2.3.5. Grades of DIVINYCELL HP

13.2.3.6. Breakdown of Revenue, by Business Segment, 2019

13.2.3.7. Breakdown of Revenue, by Region, 2019

13.2.3.8. Revenue (US$ Mn) and Y-o-Y Growth (%), 2016–2019

13.2.3.9. Key Business Strategies

13.2.3.10. Mechanical Properties of Various Grades of DIVINYCELL HP

13.2.4. Armacell International S.A.

13.2.4.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.4.2. Company Description

13.2.4.3. Business Segments

13.2.4.4. Product Line

13.2.4.5. Brand

13.2.4.6. Breakdown of Revenue, by Business Segment, 2019

13.2.4.7. Breakdown of Revenue, by Region, 2019

13.2.4.8. Revenue (US$ Mn) and Y-o-Y Growth (%), 2016–2019

13.2.4.9. Key Business Strategies

13.2.5. CoreLite, Inc.

13.2.5.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.5.2. Company Description

13.2.5.3. Product Segments

13.2.5.4. Application

13.2.5.5. Grades of PVC Foam

13.2.6. Changzhou Tiansheng New Materials CO., LTD.

13.2.6.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.6.2. Company Description

13.2.6.3. Business Segments

13.2.6.4. Product

13.2.6.5. Application

13.2.6.6. Properties of Various Grades of STRUCELL P

13.2.7. POTENTECH (GUANGDONG) LIMITED

13.2.7.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.7.2. Company Description

13.2.7.3. Product Segments

13.2.8. Maricell S.r.l.

13.2.8.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.8.2. Company Description

13.2.8.3. Product Segments

13.2.9. Novagard Solutions, Inc.

13.2.9.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.9.2. Company Description

13.2.9.3. Brands

13.2.10. CHANGZHOU UTEK COMPOSITE CO., LTD

13.2.10.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.10.2. Company Description

13.2.10.3. Product Segments

13.2.10.4. Product Line

13.2.11. FOAMTECH Ltd

13.2.11.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.11.2. Company Description

13.2.11.3. Product Segments

13.2.11.4. Application

13.2.12. Deqing Sanhe Rubber & Plastic Co., Ltd

13.2.12.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.12.2. Company Description

13.2.12.3. Product Segments

13.2.13. Ludlow Composites, Corp.

13.2.13.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.13.2. Company Description

13.2.13.3. Product Segments

13.2.13.4. Application

13.2.14. Brett Martin Plastic Sheets

13.2.14.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

13.2.14.2. Company Description

13.2.14.3. Product Segments

13.2.14.4. Brand

13.2.14.5. Product Line

14. Primary Research – Key Insights

15. Assumptions and Research Methodology

15.1. Report Assumptions

15.2. Secondary Sources and Acronyms Used

15.3. Research Methodology

List of Tables

Table 01: Global PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 02: Global PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 03: Global PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Region, 2019–2030

Table 04: Global PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Region, 2019–2030

Table 05: North America PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 06: North America PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 07: North America PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Country, 2019–2030

Table 08: North America PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Country, 2019–2030

Table 09: U.S. PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 10: U.S. PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 11: Canada PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 12: Canada PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 13: Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 14: Europe PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 15: Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 16: Europe PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 17: Germany PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 18: Germany PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 19: U.K. PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 20: U.K. PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 21: France PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 22: France PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 23: Italy PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 24: Italy PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 25: Spain PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 26: Spain PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 27: Russia & CIS PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 28: Russia & CIS PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 29: Rest of Europe PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 30: Rest of Europe PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 31: Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 32: Asia Pacific PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 33: Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 34: Asia Pacific PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 35: China PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 36: China PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 37: India PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 38: India PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 39: Japan PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 40: Japan PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 41: ASEAN PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 42: ASEAN PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 43: Rest of Asia Pacific PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 44: Rest of Asia Pacific PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 45: Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 46: Latin America PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 47: Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 48: Latin America PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Country and sub-region, 2019–2030

Table 49: Brazil PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 50: Brazil PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 51: Mexico PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 52: Mexico PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 53: Rest of Latin America PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 54: Rest of Latin America PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 55: Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 56: Middle East & Africa PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 57: Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 58: Middle East & Africa PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 59: GCC PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 60: GCC PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 61: South Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 62: South Africa PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 63: Rest of Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume (Tons) Forecast, by Application, 2019–2030

Table 64: Rest of Middle East & Africa PVC Foam Sheet Market for Structural Composites Value (US$ Thousand) Forecast, by Application, 2019–2030

List of Figures

Figure 01: Global PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 02: Global PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 03: Global PVC Foam Sheet Market for Structural Composites Share Analysis, by Region, 2019, 2024, and 2030

Figure 04: Global PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Region

Figure 05: North America PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 06: North America PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 07: North America PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Country, 2019, 2024, and 2030

Figure 08: North America PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Country

Figure 09: Europe PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 10: Europe PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 11: Europe PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Country and Sub-region, 2019, 2024, and 2030

Figure 12: Europe PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Country and Sub-region

Figure 13: Asia Pacific PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 14: Asia Pacific PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 15: Asia Pacific PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Country and Sub-region, 2019 and 2030

Figure 16: Asia Pacific PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Country and Sub-region

Figure 17: Latin America PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 18: Latin America PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 19: Latin America PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Country and Sub-region, 2019, and 2030

Figure 20: Latin America PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Country and Sub-region

Figure 21: Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Application, 2019, 2024, and 2030

Figure 22: Middle East & Africa PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Application

Figure 23: Middle East & Africa PVC Foam Sheet Market for Structural Composites Volume Share Analysis, by Country and sub-region, 2019, and 2030

Figure 24: Middle East & Africa PVC Foam Sheet Market for Structural Composites Attractiveness Analysis, by Country and Sub-region

Figure 25: Global PVC Foam Sheet Market for Structural Composites Share Analysis, by Company, 2019