Reports

Reports

Analysts’ Viewpoint

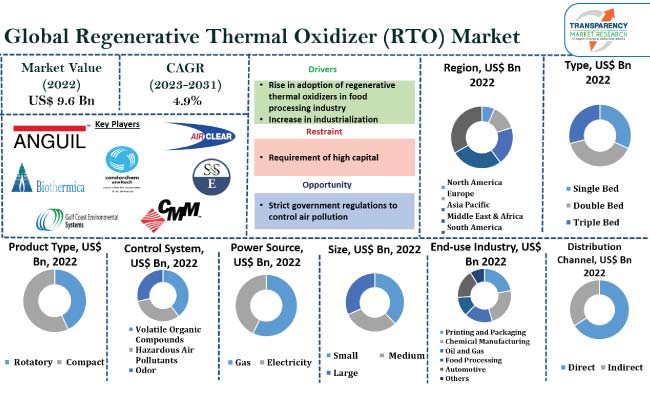

Increase in adoption of regenerative thermal oxidizers (RTOs) in the food processing industry and rise in industrialization are significant factors fueling market progress. Surge in application of RTOs in end-use industries to control air pollution and maintain environmental regulations is also augmenting regenerative thermal oxidizer (RTO) market growth.

Key players in the market are offering energy-efficient, advanced, and hybrid regenerative thermal oxidizers. Regenerative thermal oxidizer manufacturers are collaborating with different companies to expand their product portfolio and global reach. These manufacturers are also focusing on investing in research and development activities to improve the efficiency and performance of regenerative thermal oxidizers.

Regenerative thermal oxidizers are used to efficiently and effectively control air pollution. They are also known as air pollution control systems. Regenerative thermal oxidizers create high temperatures to destroy air pollutants generated by industrial processes.

Regenerative thermal oxidizers have two or three towers that contain thermal ceramic materials. These towers are connected at the top by a direct-fired burner and high-temperature combustion chamber. They reduce volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and odor by transforming emissions into CO2 and H2O before expelling them to the atmosphere with the application of heat.

Regenerative oxidizers can achieve thermal efficiencies of up to 97% and destruction efficiencies that can reach up to 99%. Therefore, they are ideal for usage in the industrial sector.

Regenerative thermal oxidizers are gaining popularity in the food processing industry. RTOs are used to treat exhaust steam from food processing operations that contain volatile organic compounds (VOCs) and other air pollutants.

RTOs are employed in a range of applications in the food processing sector, including baking, frying, roasting, and other culinary operations. These processes often release large amounts of VOCs and other air pollutants, which can negatively impact the environment and public health.

RTO oxidizers provide an effective solution for controlling these emissions, while also offering energy savings through heat recovery. RTOs are highly effective in eliminating VOCs and other pollutants. As a result, they are preferred by food producers in order to meet the stringent air quality regulations. Thus, regenerative thermal oxidizer (RTO) market demand is rising in the food processing sector.

Rapid industrialization is resulting in a significant rise in usage of regenerative thermal oxidizers in end-use industries. The need for efficient air-cleaning systems to maintain cleanliness and safety of air has become increasingly important owing to the increase in number of manufacturing plants and factories across the globe.

Regenerative thermal oxidizers effectively control emissions and ensure compliance with increasingly strict air quality regulations. This is essential in industrial environments, where air pollution and emissions have been increasing.

The U.S. Environmental Protection Agency sets regulations to reduce air pollutants under the Clean Air Act (CAA). Regenerative catalytic oxidizers provide an effective solution for controlling these emissions. Therefore, they are increasingly being used in industrial applications.

Energy efficiency is another factor contributing to the increase in adoption of RTO gas treatment. RTOs use heat recovery technology to capture and reuse the heat generated during the combustion process. This results in significant energy savings and decrease in operating costs for industrial facilities.

RTOs are relatively low-maintenance and have a long service life, thus making them a cost-effective solution over the long term. They are designed to handle a wide range of flow rates and pollutant concentrations. Hence, RTOs are a flexible option for a variety of industrial applications.

According to the regenerative thermal oxidizer (RTO) market research analysis, the double bed type segment is anticipated to account for major share during the forecast period.

Double bed regenerative thermal oxidizers are gaining traction, as they are highly efficient and possess energy-saving capabilities. Double bed regenerative thermal oxidizers are designed for greater thermal efficiency, as they enable the heat exchanger to recover more heat from the combustion process, thus leading to less fuel consumption. This helps maintain high temperatures needed for effective destruction of pollutants.

Double bed regenerative thermal oxidizers are incorporated with advanced control systems and monitoring equipment to optimize performance and reduce operating costs.

According to the regenerative thermal oxidizer market analysis, North America is projected to account for major share in the near future. Well-established automotive and pharmaceutical sectors are fueling regenerative thermal oxidizer (RTO) industry growth in the region.

Enactment of stringent regulations by the U.S. Environmental Protection Agency to control the emission of air pollutants is augmenting regenerative thermal oxidizer (RTO) market development in the country.

The regenerative thermal oxidizer (RTO) market size in Asia Pacific is also anticipated to increase at a steady pace during the forecast period, owing to rapid industrialization in the region.

The global landscape is highly competitive, with the presence of a few key players controlling majority of the regenerative thermal oxidizer (RTO) market share. As per the regenerative thermal oxidizer (RTO) industry research report, majority of companies are investing significantly in comprehensive R&D activities, primarily to develop innovative products.

Mergers, acquisitions, and expansion of product portfolios are the key strategies adopted by manufacturers operating in the global regenerative thermal oxidizer (RTO) market.

Prominent companies in the global regenerative thermal oxidizer (RTO) market are Air Clear LLC, Anguil Environmental Systems, Inc., Biothermica Technologies Inc., Catalytic Products International Inc, Condorchem Envitech, Gulf Coast Environmental Systems, LLC, Nitro Environmental LLC., Ship & Shore Environmental, Inc., The CMM Group, and TKS Industrial Company. These players are following the latest regenerative thermal oxidizer (RTO) market trends to avail the lucrative revenue opportunities.

Leading players have been profiled in the global regenerative thermal oxidizer (RTO) market forecast report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and latest developments.

|

Attribute |

Detail |

|

Market Value in 2022 (Base Year) |

US$ 9.6 Bn |

|

Market Forecast Value in 2031 |

US$ 12.6 Bn |

|

Growth Rate (CAGR) |

4.9% |

|

Forecast Period |

2023-2031 |

|

Quantitative Units |

US$ Bn for Value and Thousand Units for Volume |

|

Market Analysis |

Global qualitative analysis includes drivers, restraints, opportunities, key trends, key market indicators, Porter’s Five Forces analysis, value chain analysis, SWOT analysis, etc. Furthermore, at the regional level, qualitative analysis includes key trends, price trends, and key supplier analysis. |

|

Competition Landscape |

|

|

Region Covered |

|

|

Market Segmentation |

|

|

Companies Profile |

|

|

Customization Scope |

Available upon Request |

|

Pricing |

Available upon Request |

It was valued at US$ 9.6 Bn in 2022

It is anticipated to grow at a CAGR of 4.9% during the forecast period

It is likely to reach US$ 12.6 Bn in 2031

Rise in adoption of regenerative thermal oxidizers in the food processing industry and increase in industrialization

The double bed type segment is projected to account for major share in the near future

North America is a more lucrative region for vendors

Air Clear LLC, Anguil Environmental Systems, Inc., Biothermica Technologies Inc., Catalytic Products International Inc, Condorchem Envitech, Gulf Coast Environmental Systems, LLC, Nitro Environmental LLC., Ship & Shore Environmental, Inc., The CMM Group, and TKS Industrial Company

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions

3. Research Methodology

4. Executive Summary

5. Market Overview

5.1. Introduction

5.2. Market Dynamics

5.2.1. Drivers

5.2.2. Restraints

5.2.3. Opportunities

5.3. Key Trends Analysis

5.3.1. Demand Side Analysis

5.3.2. Supply Side Analysis

5.4. Key Market Indicators

5.4.1. Overall Oxidizer Industry Overview

5.5. Porter’s Five Forces Analysis

5.6. Industry SWOT Analysis

5.7. Value Chain Analysis

5.8. Raw Material Analysis

5.9. Trade Analysis

5.10. Technological Overview Analysis

5.11. Regulatory Framework

5.12. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, 2023 - 2031

5.12.1. Market Value Projections (US$ Bn)

5.12.2. Market Volume Projections (Thousand Units)

6. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Type

6.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type, 2023 - 2031

6.1.1. Single Bed

6.1.2. Double Bed

6.1.3. Triple Bed

6.2. Incremental Opportunity, By Type

7. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Product Type

7.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

7.1.1. Rotatory

7.1.2. Compact

7.2. Incremental Opportunity, By Product Type

8. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Control System

8.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

8.1.1. Volatile Organic Compounds

8.1.2. Hazardous Air Pollutants

8.1.3. Odor

8.2. Incremental Opportunity, By Control System

9. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Power Source

9.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

9.1.1. Gas

9.1.2. Electricity

9.2. Incremental Opportunity, By Power Source

10. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Size

10.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

10.1.1. Small

10.1.2. Medium

10.1.3. Large

10.2. Incremental Opportunity, By Size

11. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By End-use Industry

11.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

11.1.1. Printing and Packaging

11.1.2. Chemical Manufacturing

11.1.3. Oil and Gas

11.1.4. Food Processing

11.1.5. Automotive

11.1.6. Others

11.2. Incremental Opportunity, By End-use Industry

12. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Distribution Channel

12.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

12.1.1. Direct

12.1.2. Indirect

12.2. Incremental Opportunity, By Distribution Channel

13. Global Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast, By Region

13.1. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Region, 2023 - 2031

13.1.1. North America

13.1.2. Europe

13.1.3. Asia Pacific

13.1.4. Middle East & Africa

13.1.5. South America

13.2. Incremental Opportunity, By Region

14. North America Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast

14.1. Regional Snapshot

14.2. Key Trends Analysis

14.2.1. Demand Side

14.2.2. Supplier Side

14.3. Price Trend Analysis

14.3.1. Weighted Average Selling Price (USD)

14.4. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type,2023 - 2031

14.4.1. Single Bed

14.4.2. Double Bed

14.4.3. Triple Bed

14.5. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

14.5.1. Rotatory

14.5.2. Compact

14.6. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

14.6.1. Volatile Organic Compounds

14.6.2. Hazardous Air Pollutants

14.6.3. Odor

14.7. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

14.7.1. Gas

14.7.2. Electricity

14.8. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

14.8.1. Small

14.8.2. Medium

14.8.3. Large

14.9. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

14.9.1. Printing and Packaging

14.9.2. Chemical Manufacturing

14.9.3. Oil and Gas

14.9.4. Food Processing

14.9.5. Automotive

14.9.6. Others

14.10. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

14.10.1. Direct

14.10.2. Indirect

14.11. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Country, 2023 - 2031

14.11.1. U.S

14.11.2. Canada

14.11.3. Rest of North America

14.12. Incremental Opportunity Analysis

15. Europe Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast

15.1. Regional Snapshot

15.2. Key Trends Analysis

15.2.1. Demand Side

15.2.2. Supplier Side

15.3. Price Trend Analysis

15.3.1. Weighted Average Selling Price (USD)

15.4. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type,2023 - 2031

15.4.1. Single Bed

15.4.2. Double Bed

15.4.3. Triple Bed

15.5. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

15.5.1. Rotatory

15.5.2. Compact

15.6. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

15.6.1. Volatile Organic Compounds

15.6.2. Hazardous Air Pollutants

15.6.3. Odor

15.7. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

15.7.1. Gas

15.7.2. Electricity

15.8. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

15.8.1. Small

15.8.2. Medium

15.8.3. Large

15.9. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

15.9.1. Printing and Packaging

15.9.2. Chemical Manufacturing

15.9.3. Oil and Gas

15.9.4. Food Processing

15.9.5. Automotive

15.9.6. Others

15.10. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

15.10.1. Direct

15.10.2. Indirect

15.11. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Country, 2023 - 2031

15.11.1. U.K

15.11.2. Germany

15.11.3. France

15.11.4. Rest of Europe

15.12. Incremental Opportunity Analysis

16. Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast

16.1. Regional Snapshot

16.2. Key Trends Analysis

16.2.1. Demand Side

16.2.2. Supplier Side

16.3. Price Trend Analysis

16.3.1. Weighted Average Selling Price (USD)

16.4. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type,2023 - 2031

16.4.1. Single Bed

16.4.2. Double Bed

16.4.3. Triple Bed

16.5. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

16.5.1. Rotatory

16.5.2. Compact

16.6. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

16.6.1. Volatile Organic Compounds

16.6.2. Hazardous Air Pollutants

16.6.3. Odor

16.7. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

16.7.1. Gas

16.7.2. Electricity

16.8. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

16.8.1. Small

16.8.2. Medium

16.8.3. Large

16.9. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

16.9.1. Printing and Packaging

16.9.2. Chemical Manufacturing

16.9.3. Oil and Gas

16.9.4. Food Processing

16.9.5. Automotive

16.9.6. Others

16.10. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

16.10.1. Direct

16.10.2. Indirect

16.11. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Country, 2023 - 2031

16.11.1. India

16.11.2. China

16.11.3. Japan

16.11.4. Rest of Asia Pacific

16.12. Incremental Opportunity Analysis

17. Middle East & South Africa Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast

17.1. Regional Snapshot

17.2. Key Trends Analysis

17.2.1. Demand Side

17.2.2. Supplier Side

17.3. Price Trend Analysis

17.3.1. Weighted Average Selling Price (USD)

17.4. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type,2023 - 2031

17.4.1. Single Bed

17.4.2. Double Bed

17.4.3. Triple Bed

17.5. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

17.5.1. Rotatory

17.5.2. Compact

17.6. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

17.6.1. Volatile Organic Compounds

17.6.2. Hazardous Air Pollutants

17.6.3. Odor

17.7. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

17.7.1. Gas

17.7.2. Electricity

17.8. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

17.8.1. Small

17.8.2. Medium

17.8.3. Large

17.9. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

17.9.1. Printing and Packaging

17.9.2. Chemical Manufacturing

17.9.3. Oil and Gas

17.9.4. Food Processing

17.9.5. Automotive

17.9.6. Others

17.10. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

17.10.1. Direct

17.10.2. Indirect

17.11. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Country, 2023 - 2031

17.11.1. GCC

17.11.2. Rest of MEA

17.12. Incremental Opportunity Analysis

18. South America Regenerative Thermal Oxidizer (RTO) Market Analysis and Forecast

18.1. Regional Snapshot

18.2. Key Trends Analysis

18.2.1. Demand Side

18.2.2. Supplier Side

18.3. Price Trend Analysis

18.3.1. Weighted Average Selling Price (USD)

18.4. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Type,2023 - 2031

18.4.1. Single Bed

18.4.2. Double Bed

18.4.3. Triple Bed

18.5. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Product Type, 2023 - 2031

18.5.1. Rotatory

18.5.2. Compact

18.6. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Control System,2023 - 2031

18.6.1. Volatile Organic Compounds

18.6.2. Hazardous Air Pollutants

18.6.3. Odor

18.7. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Power Source,2023 - 2031

18.7.1. Gas

18.7.2. Electricity

18.8. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Size,2023 - 2031

18.8.1. Small

18.8.2. Medium

18.8.3. Large

18.9. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By End-use Industry,2023 - 2031

18.9.1. Printing and Packaging

18.9.2. Chemical Manufacturing

18.9.3. Oil and Gas

18.9.4. Food Processing

18.9.5. Automotive

18.9.6. Others

18.10. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Distribution Channel, 2023 - 2031

18.10.1. Direct

18.10.2. Indirect

18.11. Regenerative Thermal Oxidizer (RTO) Market Size (US$ Bn and Thousand Units) Forecast, By Country, 2023 - 2031

18.11.1. Brazil

18.11.2. Rest of South America

18.12. Incremental Opportunity Analysis

19. Competition Landscape

19.1. Market Player - Competition Dashboard

19.2. Market Share Analysis (%), by Company, (2022)

19.3. Company Profiles (Details - Company Overview, Sales Area/Geographical Presence, Revenue, Strategy & Business Overview)

19.3.1. Air Clear LLC

19.3.1.1. Company Overview

19.3.1.2. Sales Area/Geographical Presence

19.3.1.3. Revenue

19.3.1.4. Strategy & Business Overview

19.3.2. Anguil Environmental Systems, Inc.

19.3.2.1. Company Overview

19.3.2.2. Sales Area/Geographical Presence

19.3.2.3. Revenue

19.3.2.4. Strategy & Business Overview

19.3.3. Biothermica Technologies Inc.

19.3.3.1. Company Overview

19.3.3.2. Sales Area/Geographical Presence

19.3.3.3. Revenue

19.3.3.4. Strategy & Business Overview

19.3.4. Catalytic Products International Inc

19.3.4.1. Company Overview

19.3.4.2. Sales Area/Geographical Presence

19.3.4.3. Revenue

19.3.4.4. Strategy & Business Overview

19.3.5. Condorchem Envitech

19.3.5.1. Company Overview

19.3.5.2. Sales Area/Geographical Presence

19.3.5.3. Revenue

19.3.5.4. Strategy & Business Overview

19.3.6. Gulf Coast Environmental Systems, LLC

19.3.6.1. Company Overview

19.3.6.2. Sales Area/Geographical Presence

19.3.6.3. Revenue

19.3.6.4. Strategy & Business Overview

19.3.7. Nitro Environmental LLC.

19.3.7.1. Company Overview

19.3.7.2. Sales Area/Geographical Presence

19.3.7.3. Revenue

19.3.7.4. Strategy & Business Overview

19.3.8. Ship & Shore Environmental, Inc.

19.3.8.1. Company Overview

19.3.8.2. Sales Area/Geographical Presence

19.3.8.3. Revenue

19.3.8.4. Strategy & Business Overview

19.3.9. The CMM Group

19.3.9.1. Company Overview

19.3.9.2. Sales Area/Geographical Presence

19.3.9.3. Revenue

19.3.9.4. Strategy & Business Overview

19.3.10. TKS Industrial Company

19.3.10.1. Company Overview

19.3.10.2. Sales Area/Geographical Presence

19.3.10.3. Revenue

19.3.10.4. Strategy & Business Overview

20. Go To Market Strategy

20.1. Identification of Potential Market Spaces

20.2. Prevailing Market Risks

20.3. Understanding the Buying Process of the Customers

20.4. Preferred Sales & Marketing Strategy

List of Tables

Table 1: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 2: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 3: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 4: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 5: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 6: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 7: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 8: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 9: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 10: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 11: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 12: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 13: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 14: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 15: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Region, 2023-2031

Table 16: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Region, 2023-2031

Table 17: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 18: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 19: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 20: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 21: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 22: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 23: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 24: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 25: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 26: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 27: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 28: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 29: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 30: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 31: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Table 32: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Table 33: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 34: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 35: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 36: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 37: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 38: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 39: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 40: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 41: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 42: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 43: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 44: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 45: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 46: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 47: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Table 48: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Table 49: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 50: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 51: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 52: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 53: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 54: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 55: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 56: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 57: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 58: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 59: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 60: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 61: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 62: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 63: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Table 64: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Table 65: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 66: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 67: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 68: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 69: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 70: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 71: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 72: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 73: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 74: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 75: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 76: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 77: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 78: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 79: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Table 80: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Table 81: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Table 82: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Table 83: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Table 84: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Table 85: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Table 86: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Table 87: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Table 88: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Table 89: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Table 90: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Table 91: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Table 92: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Table 93: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Table 94: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Table 95: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Table 96: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

List of Figures

Figure 1: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 2: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 3: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 4: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 5: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 6: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 7: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 8: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 9: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 10: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 11: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 12: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 13: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 14: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 15: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 16: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 17: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 18: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 19: Global Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Region, 2023-2031

Figure 20: Global Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Region, 2023-2031

Figure 21: Global Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Region, 2023-2031

Figure 22: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Figure 23: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Figure 24: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Type, 2023-2031

Figure 25: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 26: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 27: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 28: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 29: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 30: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 31: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 32: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 33: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 34: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 35: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 36: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 37: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 38: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 39: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 40: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 41: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 42: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 43: North America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Figure 44: North America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Figure 45: North America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Country, 2023-2031

Figure 46: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Figure 47: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Figure 48: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Type, 2023-2031

Figure 49: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 50: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 51: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 52: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 53: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 54: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 55: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 56: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 57: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 58: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 59: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 60: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 61: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 62: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 63: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 64: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 65: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 66: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 67: Europe Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Figure 68: Europe Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Figure 69: Europe Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Country, 2023-2031

Figure 70: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Figure 71: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Figure 72: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Type, 2023-2031

Figure 73: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 74: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 75: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 76: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 77: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 78: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 79: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 80: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 81: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 82: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 83: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 84: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 85: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 86: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 87: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 88: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 89: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 90: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 91: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Figure 92: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Figure 93: Asia Pacific Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Country, 2023-2031

Figure 94: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Figure 95: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Figure 96: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Type, 2023-2031

Figure 97: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 98: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 99: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 100: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 101: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 102: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 103: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 104: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 105: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 106: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 107: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 108: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 109: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 110: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 111: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 112: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 113: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 114: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 115: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Figure 116: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Figure 117: Middle East & Africa Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Country, 2023-2031

Figure 118: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Type, 2023-2031

Figure 119: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Type, 2023-2031

Figure 120: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Type, 2023-2031

Figure 121: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Product Type, 2023-2031

Figure 122: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Product Type, 2023-2031

Figure 123: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Product Type, 2023-2031

Figure 124: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Control System, 2023-2031

Figure 125: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Control System, 2023-2031

Figure 126: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Control System, 2023-2031

Figure 127: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Power Source, 2023-2031

Figure 128: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Power Source, 2023-2031

Figure 129: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Power Source, 2023-2031

Figure 130: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Size, 2023-2031

Figure 131: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Size, 2023-2031

Figure 132: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Size, 2023-2031

Figure 133: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by End-user Industry, 2023-2031

Figure 134: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by End-user Industry, 2023-2031

Figure 135: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by End-user Industry, 2023-2031

Figure 136: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Distribution Channel, 2023-2031

Figure 137: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Distribution Channel, 2023-2031

Figure 138: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Distribution Channel, 2023-2031

Figure 139: South America Regenerative Thermal Oxidizer (RTO) Market Volume (Thousand Units) Share, by Country, 2023-2031

Figure 140: South America Regenerative Thermal Oxidizer (RTO) Market Value (US$ Bn) Share, by Country, 2023-2031

Figure 141: South America Regenerative Thermal Oxidizer (RTO) Market Incremental Opportunity (US$ Bn), by Country, 2023-2031