Reports

Reports

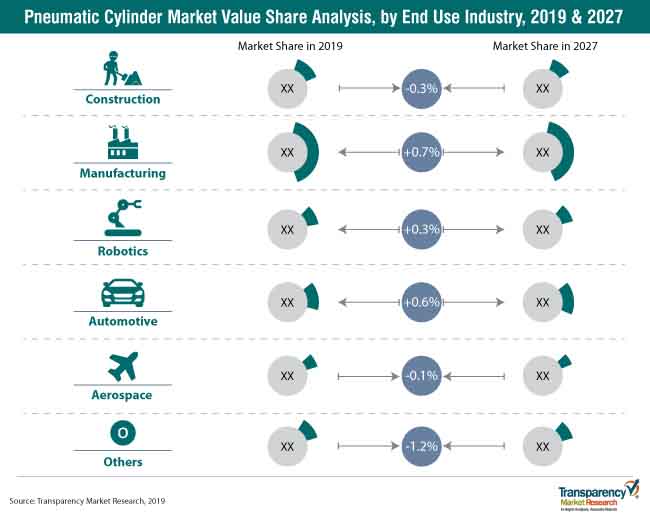

If there’s one word that aptly describes the story of the pneumatic cylinder market, it is diversification. Traditionally, demand for pneumatic cylinders has remained limited to construction, automotive, manufacturing, and aerospace. However, in the recent past, new opportunities have emerged. Pneumatic cylinder manufacturers are now eyeing opportunities across a wide range of sectors. The foray into the uncharted has been enabled by consistent advances in technology, notably, automation and robotics. Transparency Market Research (TMR), in its new offering, lays bare the overt and the covert, the subtle and the obvious, and the niche and the holistic, to present a comprehensive, 360 degree analysis of the global market.

Single-action cylinders are quickly being replaced by double-action pneumatic cylinders, as the requirements of end-users have witnessed a sea change over the years. Single-action cylinders, known for their easy operational method, fail-safe mechanism, and low operational costs are proving to be incongruous with the shifting demand. Double-action cylinders have catered to these limitations, and today, they remain the pneumatic cylinder of choice in a range of industries.

According to TMR’s research, over 11,000 units of pneumatic cylinders were sold in 2017. Buoyed by growing applications in novel avenues, global sales are likely to reach nearly 12,700 units in 2019. Transparency Market Research (TMR) maintains a bullish outlook on the pneumatic cylinder market, and opines that global sales will grow at over 5% consistently throughout the course of the forecast period (2019-2027).

The broader advances in robotics and automation has rubbed off on the demand for pneumatic cylinders. To power the robotics of tomorrow, pneumatic cylinder manufacturers are investing in R&D and collaborative development activities. The ubiquity of pneumatic cylinders is likely to create new growth opportunities for pneumatic cylinder manufacturers. Although advances in robotics will augment market growth, it will be the traditional stalwarts—manufacturing and automotive—that will hold sway in terms of total sales and revenues.

Considering the buyer focus on competitive pricing, many pneumatic cylinder players have a manufacturing plant in regions where labor costs are relatively lower. Also, it is a strategic move by market players to set up plants in countries where compliance costs do not add up to the final product cost.

Although China and India may have lost some of their sheen as global manufacturing hubs, as labor costs have shot up in recent years, these countries continue to serve as manufacturing hubs for pneumatic cylinder companies. Among the players that have manufacturing centers in India and China, the prominent ones include Parker Hannifin Corporation, Camozzi Group, AirTAC International Group, The Emerson Electric Co., SMC Corp, and Festo Corp.

Mergers and acquisitions have been the norm rather than the exception in pneumatic cylinder market. The spate of M&As has been especially heightened since 2016, with many top-line players making strategic moves to acquire other companies. Of notable prominence has been the acquisition spree of IMI plc, and it has got Bimba Manufacturing and Analytical Flow Products (AFP).

In addition to mergers and acquisitions, expansion and new product development remain the other key focus areas. SMC Corp, Festo, and Parker Hannifin Corporation are among the key names that have invested significantly in new product development.

The pneumatic cylinder market is also witnessing a phase where unmet end-user needs are quickly passed on to the R&D and innovation labs, and a new product is in the market to gain first-mover advantage. For instance, to meet the space-related limitations, Festo rolled out inch series pancake cylinders. Further, to offer end-users greater flexibility and application-specific customization, IMI Norgen launched the MC Series magnetically coupled Rodless cylinders earlier this year.

The Analyst Viewpoint

Innovation and extinction – these two words may adequately sum up the future for many players in the pneumatic cylinders market. Companies who are able to fully understand the opportunities created by Industrial Internet of Things (IIoT) and scale up by developing cost-effective, yet innovative products, will have a better shot at success. The massive investments in factory automation, combined with a renewed focus on operational efficiency are there for all to be exploited. Players who are able to meet the evolving needs emerging from non-traditional sectors, especially in aerospace and defense, can have a wider canvas to play with.

The global market has been segmented based on type, movement, end use industry, and region.

Some of the prominent players operating in the global pneumatic cylinder industry are Bosch Rexroth AG, SMC Corporation, Emerson Electric Co., Parker Hannifin Corporation, AirTAC International Group, Sheffer Corporation, IMI Precision Engineering, Eaton Corporation, Metal Work Pneumatic, Univer Group, Hafner-Pneumatik Krämer KG, FESTO, Ingersoll-Rand Plc, CMB Srl, Pneumax S.p.a., Vesta Automation Srl, Aignep S.p.A., Waircom MBS SpA, Megliani Luigi Srl, Bonesi Pneumatik Srl, AirWork Pneumatic Equipment, CY.PAG. Srl, KPM Srl, Nexoil, and Aircomp Stampotecnica.

The global market worth is projected to reach USD 1.5 billion by the end of 2027.

The market is expected to grow at a CAGR of 4.4% during 2019 – 2027

Rising adoption of industrial automation to drive the global market.

Major companies across the market are Bosch Rexroth AG, SMC Corporation, Emerson Electric Co., Parker Hannifin Corporation, AirTAC International Group, Sheffer Corporation, IMI Precision Engineering, Eaton Corporation, Metal Work Pneumatic, Univer Group, Hafner-Pneumatik Krämer KG, FESTO, Ingersoll-Rand Plc, CMB Srl, Pneumax S.p.a., Vesta Automation Srl, Aignep S.p.A., Waircom MBS SpA, Megliani Luigi Srl, Bonesi Pneumatik Srl, AirWork Pneumatic Equipment, CY.PAG. Srl, KPM Srl, Nexoil, and Aircom

North America and Europe are mature regions of the global market, due to presence of major end-use industries in these regions.

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

3. Executive Summary: Global Pneumatic Cylinder Market

4. Market Overview

4.1. Introduction

4.2. Market Dynamics

4.2.1. Drivers

4.2.2. Restraints

4.2.3. Opportunities

4.3. Key Trends Analysis

4.4. Key Market Indicators

4.5. Global Pneumatic Cylinder Market Analysis and Forecast, 2017–2027

4.5.1. Market Revenue Projection (US$ Mn)

4.5.2. Market Volume Projection (Thousand Units)

4.5.3. Price Trend Analysis

4.6. Porter’s Five Forces Analysis - Global Pneumatic Cylinder Market

4.7. Value Chain Analysis - Global Pneumatic Cylinder Market

4.8. Market Outlook

5. Global Pneumatic Cylinder Market Analysis and Forecast, by Type

5.1. Overview & Definitions

5.2. Global Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

5.2.1. Single-acting Cylinder

5.2.2. Double-acting Cylinder

5.3. Type Comparison Matrix

5.4. Global Pneumatic Cylinder Market Attractiveness, by Type

6. Global Pneumatic Cylinder Market Analysis and Forecast, by Movement

6.1. Overview & Definitions

6.2. Global Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

6.2.1. Linear

6.2.2. Rotary

6.3. Movement Comparison Matrix

6.4. Global Pneumatic Cylinder Market Attractiveness, by Movement

7. Global Pneumatic Cylinder Market Analysis and Forecast, by End-use Industry

7.1. Overview & Definitions

7.2. Global Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

7.2.1. Construction

7.2.2. Manufacturing

7.2.3. Robotics

7.2.4. Automotive

7.2.5. Aerospace

7.2.6. Others

7.3. End-use Industry Comparison Matrix

7.4. Global Pneumatic Cylinder Market Attractiveness, by End-use Industry

8. Global Pneumatic Cylinder Market Analysis and Forecast, by Geography

8.1. Key Findings

8.2. Global Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Geography, 2017–2027

8.2.1. North America

8.2.2. Europe

8.2.3. Asia Pacific

8.2.4. Middle East & Africa

8.2.5. South America

8.3. Global Pneumatic Cylinder Market Attractiveness, by Geography

9. North America Pneumatic Cylinder Market Analysis and Forecast

9.1. Key Findings

9.2. Key Trend Analysis

9.3. North America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

9.3.1. Single-acting Cylinder

9.3.2. Double-acting Cylinder

9.4. North America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

9.4.1. Linear

9.4.2. Rotary

9.5. North America Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

9.5.1. Construction

9.5.2. Manufacturing

9.5.3. Robotics

9.5.4. Automotive

9.5.5. Aerospace

9.5.6. Others

9.6. North America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

9.6.1. U.S.

9.6.2. Canada

9.6.3. Rest of North America

9.7. North America Pneumatic Cylinder Market Attractiveness Analysis

9.7.1. by Type

9.7.2. by Movement

9.7.3. by End-use Industry

9.7.4. by Country/Sub-region

10. Europe Pneumatic Cylinder Market Analysis and Forecast

10.1. Key Findings

10.2. Key Trend Analysis

10.3. Europe Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

10.3.1. Single-acting Cylinder

10.3.2. Double-acting Cylinder

10.4. Europe Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

10.4.1. Linear

10.4.2. Rotary

10.5. Europe Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

10.5.1. Construction

10.5.2. Manufacturing

10.5.3. Robotics

10.5.4. Automotive

10.5.5. Aerospace

10.5.6. Others

10.6. Europe Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

10.6.1. Germany

10.6.2. U.K.

10.6.3. France

10.6.4. Rest of Europe

10.7. Europe Pneumatic Cylinder Market Attractiveness Analysis

10.7.1. by Type

10.7.2. by Movement

10.7.3. by End-use Industry

10.7.4. by Country/Sub-region

11. Asia Pacific (APAC) Pneumatic Cylinder Market Analysis and Forecast

11.1. Key Findings

11.2. Key Trend Analysis

11.3. APAC Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

11.3.1. Single-acting Cylinder

11.3.2. Double-acting Cylinder

11.4. APAC Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

11.4.1. Linear

11.4.2. Rotary

11.5. APAC Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

11.5.1. Construction

11.5.2. Manufacturing

11.5.3. Robotics

11.5.4. Automotive

11.5.5. Aerospace

11.5.6. Others

11.6. APAC Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

11.6.1. China

11.6.2. Japan

11.6.3. India

11.6.4. Australia

11.6.5. Rest of Asia Pacific

11.7. APAC Pneumatic Cylinder Market Attractiveness Analysis

11.7.1. by Type

11.7.2. by Movement

11.7.3. by End-use Industry

11.7.4. by Country/Sub-region

12. Middle East & Africa (MEA) Pneumatic Cylinder Market Analysis and Forecast

12.1. Key Findings

12.2. Key Trend Analysis

12.3. MEA Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

12.3.1. Single-acting Cylinder

12.3.2. Double-acting Cylinder

12.4. MEA Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

12.4.1. Linear

12.4.2. Rotary

12.5. MEA Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

12.5.1. Construction

12.5.2. Manufacturing

12.5.3. Robotics

12.5.4. Automotive

12.5.5. Aerospace

12.5.6. Others

12.6. MEA Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

12.6.1. GCC

12.6.2. South Africa

12.6.3. Rest of MEA

12.7. MEA Pneumatic Cylinder Market Attractiveness Analysis

12.7.1. by Type

12.7.2. by Movement

12.7.3. by End-use Industry

12.7.4. by Country/Sub-region

13. South America Pneumatic Cylinder Market Analysis and Forecast

13.1. Key Findings

13.2. Key Trend Analysis

13.3. South America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Type, 2017–2027

13.3.1. Single-acting Cylinder

13.3.2. Double-acting Cylinder

13.4. South America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Movement, 2017–2027

13.4.1. Linear

13.4.2. Rotary

13.5. South America Pneumatic Cylinder Market Value (US$ Mn) Forecast, by End-use Industry, 2017–2027

13.5.1. Construction

13.5.2. Manufacturing

13.5.3. Robotics

13.5.4. Automotive

13.5.5. Aerospace

13.5.6. Others

13.6. South America Pneumatic Cylinder Market Value (US$ Mn) and Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

13.6.1. Brazil

13.6.2. Rest of South America

13.7. South America Pneumatic Cylinder Market Attractiveness Analysis

13.7.1. by Type

13.7.2. by Movement

13.7.3. by End-use Industry

13.7.4. by Country/Sub-region

14. Competition Landscape

14.1. Market Players – Competition Matrix

14.2. Manufacturing Plant Mapping, by Company

14.3. Major Long-term Strategies Adopted by Leading Players

14.4. Global Pneumatic Cylinder Market Share Analysis (%), by Company (2018)

14.5. Company Profiles (Details – Overview, Financials, SWOT Analysis, Strategy)

14.5.1. Aignep S.p.A.

14.5.2. Aircomp Stampotecnica srl

14.5.3. AirTAC International Group

14.5.4. Airwork Pneumatic Equipment

14.5.5. Bonesi Pneumatik

14.5.6. Bosch Rexroth AG

14.5.7. Camozzi Group

14.5.8. CMB Srl

14.5.9. Cy.Pag. S.r.l.

14.5.10. Eaton Corporation (Vickers)

14.5.11. Emerson Electric (ASCO) & Aventics

14.5.12. Festo

14.5.13. Hafner-Pneumatik Krämer KG

14.5.14. IMI Precision Engineering

14.5.15. Ingersoll-Rand plc

14.5.16. Megliani Luigi srl

14.5.17. Metal Work S.p.A.

14.5.18. Nexoil s.r.l.

14.5.19. Parker Hannifin Corporation

14.5.20. Pneumax S.p.A.

14.5.21. Roben Industrial (KPM)

14.5.22. SMC Corporation

14.5.23. Univer Group

14.5.24. Vesta Automation Srl

14.5.25. Waircom MBS

15. Key Takeaways

List of Tables:

Table 01: Global Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 02: Global Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 03: Short-term and Long-term CAGR Analysis

Table 04: Global Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 05: Global Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 06: Short-term and Long-term CAGR Analysis

Table 07: Global Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 08: Short-term and Long-term CAGR Analysis

Table 09: Global Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Geography, 2017–2027

Table 10: Global Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Geography, 2017–2027

Table 11: North America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 12: North America Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 13: Short-term and Long-term CAGR Analysis

Table 14: North America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 15: North America Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 16: Short-term and Long-term CAGR Analysis

Table 17: North America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 18: Short-term and Long-term CAGR Analysis

Table 19: North America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2017–2027

Table 20: North America Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

Table 21: Short-term and Long-term CAGR Analysis

Table 22: Europe Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 23: Europe Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 24: Short-term and Long-term CAGR Analysis

Table 25: Europe Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 26: Europe Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 27: Short-term and Long-term CAGR Analysis

Table 28: Europe Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 29: Short-term and Long-term CAGR Analysis

Table 30: Europe Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2017–2027

Table 31: Europe Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Country/Sub-region, 2017–2027

Table 32: Short-term and Long-term CAGR Analysis

Table 33: Asia Pacific Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 34: Asia Pacific Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 35: Short-term and Long-term CAGR Analysis

Table 36: Asia Pacific Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 37: Asia Pacific Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 38: Short-term and Long-term CAGR Analysis

Table 39: Asia Pacific Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 40: Short-term and Long-term CAGR Analysis

Table 41: Asia Pacific Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2017–2027

Table 42: Asia Pacific Pneumatic Cylinder Market Volume (Units) Forecast, by Country/Sub-region, 2017–2027

Table 43: Short-term and Long-term CAGR Analysis

Table 44: MEA Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 45: MEA Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 46: Short-term and Long-term CAGR Analysis

Table 47: MEA Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 48: MEA Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 49: Short-term and Long-term CAGR Analysis

Table 50: MEA Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 51: Short-term and Long-term CAGR Analysis

Table 52: MEA Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2017–2027

Table 53: MEA Pneumatic Cylinder Market Volume (Units) Forecast, by Country/Sub-region, 2017–2027

Table 54: Short-term and Long-term CAGR Analysis

Table 55: South America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Type, 2017–2027

Table 56: South America Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Type, 2017–2027

Table 57: Short-term and Long-term CAGR Analysis

Table 58: South America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Movement, 2017–2027

Table 59: South America Pneumatic Cylinder Market Volume (Thousand Units) Forecast, by Movement, 2017–2027

Table 60: Short-term and Long-term CAGR Analysis

Table 61: South America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by End-use Industry, 2017–2027

Table 62: Short-term and Long-term CAGR Analysis

Table 63: South America Pneumatic Cylinder Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2017–2027

Table 64: South America Pneumatic Cylinder Market Volume (Units) Forecast, by Country/Sub-region, 2017–2027

Table 65: Short-term and Long-term CAGR Analysis

List of Figures:

Figure 01: Global Pneumatic Cylinder Market Revenue (US$ Mn) and Volume (Thousand Units) Projection and Y–o–Y Growth, 2017–2027Units)

Figure 02: Global Pneumatic Cylinder Price Trend Analysis, by Type, 2018–2027

Figure 03: Porter’s Five Force Analysis

Figure 04: Value Chain Analysis

Figure 05: Market Outlook

Figure 06: Global Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 07: Global Pneumatic Cylinder Market Comparison Matrix, by Type

Figure 08: Global Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 09: Global Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 10: Global Pneumatic Cylinder Market Comparison Matrix, by Movement

Figure 11: Global Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 12: Global Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 13: Global Pneumatic Cylinder Market Comparison Matrix, by End-use Industry

Figure 14: Global Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 15: Global Pneumatic Cylinder Market, by Geography: Snapshot (2018E)

Figure 16: Global Pneumatic Cylinder Market Attractiveness Analysis, by Geography

Figure 17: North America Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 18: North America Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 19: North America Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 20: North America Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2019 and 2027

Figure 21: North America Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 22: North America Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 23: North America Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 24: North America Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 25: Europe Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 26: Europe Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 27: Europe Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 28: Europe Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2019 and 2027

Figure 29: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 30: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 31: Europe Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 32: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 33: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 34: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 35: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 36: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 37: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 38: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 39: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 40: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 41: MEA Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 42: MEA Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 43: MEA Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 44: MEA Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 45: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 46: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 47: MEA Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 48: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 49: South America Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 50: South America Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 51: South America Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 52: South America Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 53: South America Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 54: South America Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 55: South America Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 56: South America Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 57: Global Pneumatic Cylinder Market Share Analysis, by Company (2018)

Figure 01: Global Pneumatic Cylinder Market Revenue (US$ Mn) and Volume (Thousand Units) Projection and Y–o–Y Growth, 2017–2027Units)

Figure 02: Global Pneumatic Cylinder Price Trend Analysis, by Type, 2018–2027

Figure 03: Porter’s Five Force Analysis

Figure 04: Value Chain Analysis

Figure 05: Market Outlook

Figure 06: Global Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 07: Global Pneumatic Cylinder Market Comparison Matrix, by Type

Figure 08: Global Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 09: Global Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 10: Global Pneumatic Cylinder Market Comparison Matrix, by Movement

Figure 11: Global Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 12: Global Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 13: Global Pneumatic Cylinder Market Comparison Matrix, by End-use Industry

Figure 14: Global Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 15: Global Pneumatic Cylinder Market, by Geography: Snapshot (2018E)

Figure 16: Global Pneumatic Cylinder Market Attractiveness Analysis, by Geography

Figure 17: North America Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 18: North America Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 19: North America Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 20: North America Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2019 and 2027

Figure 21: North America Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 22: North America Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 23: North America Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 24: North America Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 25: Europe Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 26: Europe Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 27: Europe Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 28: Europe Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2019 and 2027

Figure 29: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 30: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 31: Europe Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 32: Europe Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 33: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 34: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 35: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 36: Asia Pacific Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 37: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 38: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 39: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 40: Asia Pacific Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 41: MEA Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 42: MEA Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 43: MEA Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 44: MEA Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 45: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 46: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 47: MEA Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 48: MEA Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 49: South America Pneumatic Cylinder Market Value Share Analysis, by Type, 2019 and 2027

Figure 50: South America Pneumatic Cylinder Market Value Share Analysis, by Movement, 2019 and 2027

Figure 51: South America Pneumatic Cylinder Market Value Share Analysis, by End-use Industry, 2019 and 2027

Figure 52: South America Pneumatic Cylinder Market Value Share Analysis, by Country/Sub-region, 2018 and 2026

Figure 53: South America Pneumatic Cylinder Market Attractiveness Analysis, by Type

Figure 54: South America Pneumatic Cylinder Market Attractiveness Analysis, by Movement

Figure 55: South America Pneumatic Cylinder Market Attractiveness Analysis, by End-use Industry

Figure 56: South America Pneumatic Cylinder Market Attractiveness Analysis, by Country/Sub-region

Figure 57: Global Pneumatic Cylinder Market Share Analysis, by Company (2018)