Reports

Reports

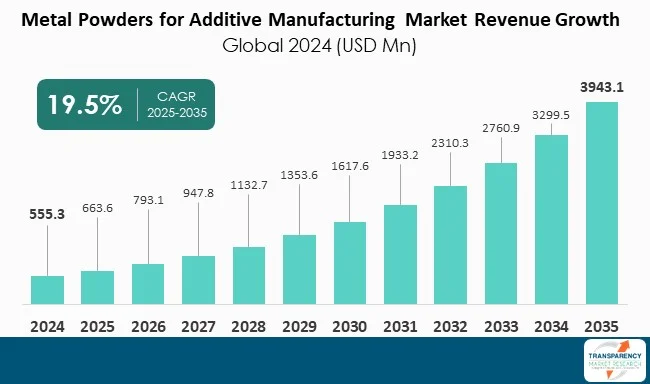

The metal powders for additive manufacturing market is expected to witness a CAGR of 19.5% during the forecast period, as 3D printing becomes more common in aerospace, defense, healthcare, and the automotive industry. Titanium is the material of choice by a large margin owing to its strength-to-weight ratio, excellent corrosion resistance, and suitability for biocompatibility with increasing applications in implants and aircraft parts.

The FDA has cleared a little more than 100 medical devices (catheters, implants, instruments, etc.), which indicates increasing acceptance by the mainstream. Initial aerospace programs by GE Aviation and Airbus have exhibited measurable cost and fuel-efficiency savings.

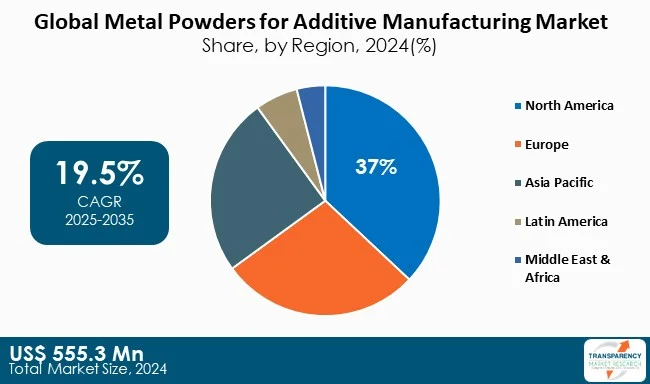

North America leads due to rapid industry integration and strong innovation feedstreams. Europe is seeing the benefits of its robust aerospace and medical ecosystems. Asia-Pacific is scaling rapidly on the backs of government-supported R&D centers and manufacturing initiatives, particularly China.

Leading players like Höganäs and Sandvik are finding market differentiation through sustainability, recyclability, and proprietary powder technologies. The market will continue to be shaped by technical advancements in powder recycling for maintaining value accurate during reprocessed or reused part or material development processes; circularity in terms of manufacturing practices; and drive toward increased range of materials that support performance as well as best practices toward environmental objectives.

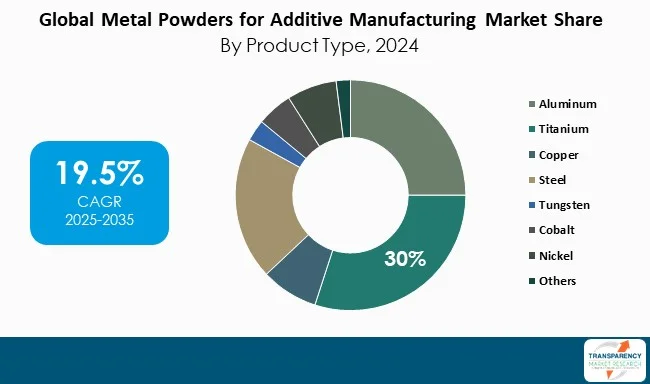

Metal powders for additive manufacturing are vital materials enabling the production of complex, lightweight, and high strength parts by using 3D printing methods including selective laser melting (SLM), and electron beam melting (EBM). The most common materials include aluminum, titanium, copper, steel, tungsten, cobalt, and nickel.

Each offering unique performance advantages - aluminum is lightweight and corrosion resistant, titanium is high-strength and biocompatible, nickel and cobalt alloys offer excellent resistance to heat and wear, steel offers ruggedness as well as cost, and tungsten and copper are used for their high conductivity and density, while also creating additional possibilities in niche sectors.

The applications span aerospace and defense where lightweight precision parts are needed, automotives for performance related parts, healthcare for implants and surgical tools, and energy industries with turbines and heat exchangers. Industrial machinery and tooling also represents a significant field of use, with metal powders allowing for bespoke design of components that are lightweight and efficient with meeting demanding performance criteria for many applications.

| Attribute | Detail |

|---|---|

| Metal Powders for Additive Manufacturing Market Drivers |

|

The aerospace and defense sectors are the strongest growth segments for the metal powders for additive manufacturing market due to their need for being lightweight, high-strength, and geometrically complex components. Metal powders such as titanium and nickel-based superalloys are increasingly used to make turbine blades, fuel nozzles, and structural components that need to survive extreme operating conditions.

GE Aviation has, in fact, made over 100,000 fuel nozzles using additive manufacturing, while reducing the part count by 25% and the weight by 30% leading to direct fuel savings. Not to be outdone, Airbus has ramped up use of titanium powders to create lightweight brackets and components, a chain reaction that can lead to a reduction of aircraft weight by 15%.

Defense programs in the U.S. and Europe are accelerating the use of additive manufacturing in earnest; the U.S. Air Force has committed funds to develop 3D-printed spare parts for its aging fleets. This expanding development and integration of additive manufacturing for mission-critical programs and parts are keeping demand for metal powders at elevated levels.

Healthcare is becoming a prominent growth driver for the metal powders for additive manufacturing market, resulting from the increasing use of additive manufacturing in implants, surgical tools, and dental prosthetics. Titanium powder comprises the bulk of this segment owing to its great biocompatibility, corrosion resistance, and strength-to-weight ratio, thereby making it the preferred solution for orthopedic, craniofacial and spinal implants.

Regulatory acceptance is also strengthening as the U.S. FDA has approved more than 100 additive-manufactured medical devices, signaling great acceptance of these implants. Some of the leading firms such as Stryker are already taking advantage of this trend with its AMagine system producing 3D-printed titanium implants as the potential for porous lattice structures inspires osseointegration that could not be accomplished using conventional techniques.

Dentistry is another rapidly growing segment with over 500,000 metal crowns and bridges being manufactured annually from cobalt-chrome and titanium powders. The addition of rising healthcare spending and the demand for minimally invasive surgery are also contributing to the growth of these advanced medical devices.

Titanium has become the dominant type segment in the metal powders for additive manufacturing industry, thanks to its superior mechanical and biological properties. Its exceptional strength-to-weight ratio, along with biocompatibility and exceptional corrosion resistance and biocompatibility, make it a critical metal throughout key sectors such as automotive, aerospace, and healthcare. In aerospace, titanium alloys represent almost 15% of the structural weight of modern aircraft and manufacturers such as Airbus and Boeing are using 3D-printed titanium components for reducing weight and fuel costs, which ultimately saves US$2-$3 Mn per aircraft year on operational costs.

In healthcare, titanium powder is mostly used for advanced production of orthopedic and craniofacial implants, and for additive-manufactured medical devices, there are more than 100 FDA-approved devices sold commercially. Another major factor contributing to the growth of titanium in the metal powders for additive manufacturing is the ability to print complex lattice and porous structures, which usually improves mechanical performance while providing greater material use efficiency in terms of cost. Titanium is recyclable, which is also of significance to industries now focusing on circular manufacturing and sustainability.

| Attribute | Detail |

|---|---|

| Leading Region |

|

North America dominates the metal powders for additive manufacturing, driven by robust take-up in defense, aerospace, and healthcare. The industry majors such as GE Additive and Carpenter Technology tends to benefit, as the FAA has cleared the use of nickel and titanium alloy parts in aircraft engines and structures.

Europe comes next, led by Germany, France, and the UK, where titans - Airbus and Rolls-Royce are using titanium and stainless-steel powders in tomorrow's aircraft. Europe also enjoys strong regulation for medical 3D printing, with more than 600 German dental labs employing metal powders for implants and prosthetics.

Asia-Pacific is the region that is emerging as the fastest-growing one, driven by China, Japan, and South Korea, which are the major investors in automotive lightweighting and electronics applications. China alone has set up over 300 additive manufacturing research institutes, demonstrating the scale-up aggression and long-term potential of the region.

RIO Tinto Metal Powders, Kennametal Inc, GE Additive, Carpenter Technology Corporation, Aubert & Duval, Elementum 3D, Metalysis, GKN Powder Metallurgy, ATI, Markforged, Renishaw, Linde PLC, Astro Alloys Inc, EOS GmbH, Oerlikon AM, Tekna Advanced Materials Inc, VDM Metals GmbH, TRUMPF, and SSAB are some other major companies in the metal powders for additive manufacturing market.

Each of these players has been profiled in the metal powders for additive manufacturing market research report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

| Attribute | Detail |

|---|---|

| Market Size Value in 2024 | US$ 555.3 Mn |

| Market Forecast Value in 2035 | US$ 3.9 Bn |

| Growth Rate (CAGR) | 19.5% |

| Forecast Period | 2025-2035 |

| Historical Data Available for | 2020-2023 |

| Quantitative Units | US$ Mn/Bn for Value & Tons for Volume |

| Market Analysis | It includes cross-segment analysis at the global as well as regional level. Furthermore, the qualitative analysis includes drivers, restraints, Metal Powders for Additive Manufacturing market opportunities, key trends, Porter’s Five Forces analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation | Type

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

The metal powders for additive manufacturing market was valued at US$ 555.3 Mn in 2024

The metal powders for additive manufacturing market is expected to grow at a CAGR of 19.5% from 2025 to 2035

Rising adoption in aerospace and defense, and expanding medical and healthcare applications

Titanium was the largest type segment in the metal powders for additive manufacturing industry.

North America was the most lucrative region in 2024

Höganäs AB, Sandvik, RIO Tinto Metal Powders, Kennametal Inc, GE Additive, Carpenter Technology Corporation, Aubert & Duval, Elementum 3D, Metalysis, GKN Powder Metallurgy, ATI, Markforged, Renishaw, Linde PLC, Astro Alloys Inc, EOS GmbH, Oerlikon AM, Tekna Advanced Materials Inc, VDM Metals GmbH, TRUMPF, and SSAB are some of the major companies in the global metal powders for additive manufacturing market.

Table 1 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 2 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 3 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 4 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 5 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology 2025 to 2035

Table 6 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology 2025 to 2035

Table 7 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution 2025 to 2035

Table 8 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution 2025 to 2035

Table 9 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 10 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 11 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 12 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use, 2025 to 2035

Table 13 Global Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Region, 2025 to 2035

Table 14 Global Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Region, 2025 to 2035

Table 15 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 16 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 17 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 18 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 19 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology 2025 to 2035

Table 20 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology 2025 to 2035

Table 21 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution 2025 to 2035

Table 22 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution 2025 to 2035

Table 23 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 24 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 25 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 26 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use, 2025 to 2035

Table 27 North America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Country, 2025 to 2035

Table 28 North America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Country, 2025 to 2035

Table 29 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 30 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 31 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 32 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 33 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology 2025 to 2035

Table 34 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 35 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution 2025 to 2035

Table 36 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 37 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 38 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 39 U.S. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 40 U.S. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use, 2025 to 2035

Table 41 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 42 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 43 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 44 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 45 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 46 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 47 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 48 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 49 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 50 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 51 Canada Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 52 Canada Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 53 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 54 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 55 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 56 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 57 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology 2025 to 2035

Table 58 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 59 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution 2025 to 2035

Table 60 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 61 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 62 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 63 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 64 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 65 Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Country and Sub-region, 2025 to 2035

Table 66 Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Country and Sub-region, 2025 to 2035

Table 67 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 68 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 69 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 70 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 71 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 72 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 73 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 74 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 75 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 76 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 77 Germany Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 78 Germany Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 79 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 80 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 81 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 82 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 83 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 84 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 85 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 86 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 87 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 88 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 89 France Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 90 France Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 91 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 92 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 93 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 94 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 95 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 96 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 97 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 98 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 99 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 100 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 101 U.K. Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 102 U.K. Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 103 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 104 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 105 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 106 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 107 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 108 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 109 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 110 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 111 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 112 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 113 Italy Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 114 Italy Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 115 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 116 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 117 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 118 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 119 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 120 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 121 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 122 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 123 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 124 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 125 Spain Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 126 Spain Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 127 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 128 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 129 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 130 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 131 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 132 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 133 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 134 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 135 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 136 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 137 Russia & CIS Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 138 Russia & CIS Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 139 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 140 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 141 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 142 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 143 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 144 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 145 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 146 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 147 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 148 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 149 Rest of Europe Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 150 Rest of Europe Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 151 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 152 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 153 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 154 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 155 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 156 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 157 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 158 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 159 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 160 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 161 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 162 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 163 Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Country and Sub-region, 2025 to 2035

Table 164 Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Country and Sub-region, 2025 to 2035

Table 165 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 166 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type 2025 to 2035

Table 167 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 168 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 169 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 170 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 171 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 172 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 173 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 174 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 175 China Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 176 China Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 177 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 178 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 179 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 180 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 181 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 182 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 183 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 184 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 185 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 186 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 187 Japan Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 188 Japan Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 189 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 190 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 191 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 192 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 193 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 194 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 195 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 196 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 197 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 198 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 199 India Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 200 India Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 201 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 202 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 203 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 204 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 205 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 206 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 207 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 208 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 209 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 210 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 211 ASEAN Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 212 ASEAN Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 213 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 214 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 215 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 216 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 217 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 218 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 219 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 220 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 221 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 222 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 223 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 224 Rest of Asia Pacific Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 225 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 226 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 227 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 228 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 229 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 230 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 231 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 232 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 233 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 234 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 235 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 236 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 237 Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Country and Sub-region, 2025 to 2035

Table 238 Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Country and Sub-region, 2025 to 2035

Table 239 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 240 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 241 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 242 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 243 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 244 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 245 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 246 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 247 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 248 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 249 Brazil Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 250 Brazil Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 251 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 252 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 253 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 254 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 255 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 256 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 257 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 258 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 259 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 260 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 261 Mexico Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 262 Mexico Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 263 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 264 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 265 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 266 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 267 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 268 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 269 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 270 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 271 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 272 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 273 Rest of Latin America Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 274 Rest of Latin America Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 275 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 276 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 277 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 278 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 279 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 280 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 281 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 282 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 283 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 284 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 285 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 286 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 287 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Country and Sub-region, 2025 to 2035

Table 288 Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Country and Sub-region, 2025 to 2035

Table 289 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 290 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 291 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 292 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 293 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 294 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 295 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 296 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 297 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 298 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 299 GCC Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 300 GCC Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 301 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 302 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 303 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 304 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 305 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 306 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 307 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 308 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 309 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 310 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 311 South Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 312 South Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Table 313 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Type, 2025 to 2035

Table 314 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Type, 2025 to 2035

Table 315 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Process, 2025 to 2035

Table 316 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Process, 2025 to 2035

Table 317 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Technology, 2025 to 2035

Table 318 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Technology, 2025 to 2035

Table 319 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Size Distribution, 2025 to 2035

Table 320 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Size Distribution, 2025 to 2035

Table 321 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by Application, 2025 to 2035

Table 322 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by Application, 2025 to 2035

Table 323 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Volume (Tons) Forecast, by End-use, 2025 to 2035

Table 324 Rest of Middle East & Africa Metal Powders for Additive Manufacturing Market Value (US$ Mn) Forecast, by End-use 2025 to 2035

Figure 1 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 2 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 3 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 4 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 5 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 6 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 7 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 8 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 9 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 10 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 11 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 12 Global Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 13 Global Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Region, 2024, 2028, and 2034

Figure 14 Global Metal Powders for Additive Manufacturing Market Attractiveness, by Region

Figure 15 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 16 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 17 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 18 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 19 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 20 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 21 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 22 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 23 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 24 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 25 North America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 26 North America Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 27 North America Metal Powders for Additive Manufacturing Market Attractiveness, by Country and Sub-region

Figure 28 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 29 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 30 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 31 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 32 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 33 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 34 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 35 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 36 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 37 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 38 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 39 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 40 Europe Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Country and Sub-region, 2024, 2028, and 2034

Figure 41 Europe Metal Powders for Additive Manufacturing Market Attractiveness, by Country and Sub-region

Figure 42 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 43 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 44 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 45 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 46 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 47 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 48 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 49 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 50 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 51 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 52 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 53 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 54 Asia Pacific Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Country and Sub-region, 2024, 2028, and 2034

Figure 55 Asia Pacific Metal Powders for Additive Manufacturing Market Attractiveness, by Country and Sub-region

Figure 56 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 57 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 58 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 59 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 60 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 61 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 62 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 63 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 64 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 65 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 66 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 67 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 68 Latin America Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Country and Sub-region, 2024, 2028, and 2034

Figure 69 Latin America Metal Powders for Additive Manufacturing Market Attractiveness, by Country and Sub-region

Figure 70 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Type, 2024, 2028, and 2034

Figure 71 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Type

Figure 72 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Process, 2024, 2028, and 2034

Figure 73 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Process

Figure 74 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Technology, 2024, 2028, and 2034

Figure 75 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Technology

Figure 76 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Size Distribution, 2024, 2028, and 2034

Figure 77 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Size Distribution

Figure 78 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Application, 2024, 2028, and 2034

Figure 79 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Application

Figure 80 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by End-use, 2024, 2028, and 2034

Figure 81 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by End-use

Figure 82 Middle East & Africa Metal Powders for Additive Manufacturing Market Volume Share Analysis, by Country and Sub-region, 2024, 2028, and 2034

Figure 83 Middle East & Africa Metal Powders for Additive Manufacturing Market Attractiveness, by Country and Sub-region