Reports

Reports

Shifting focus of Metal Processing Companies toward High Capacity Industrial Burners to Drive Global Industrial Burner Market

Industrial furnaces, which are essential elements of heavy-duty industries, are designed to achieve high temperatures in closed systems for the processing of products. Heavy-duty businesses all around the world require high-capacity heating systems to support large-scale manufacturing, from metal melting to heat treatment. Several big metal-processing companies are focusing on high-capacity industrial burners as an alternative to massive, dangerous furnaces. Industrial burners are a preferable alternative since they fulfill the similar task as high-capacity furnaces and reactors, but at a lower cost and with less manufacturing complexities. This factor is likely to drive growth of the global industrial burner market in the years to come.

Need to Regulate Fuel-to-Air Ratio is Estimated to Boost Market Growth

Controlling the fuel-to-air ratio has been a significant problem when utilizing burners in major manufacturing applications for decades. Almost every industrial burner now has an electronic module that allows for fuel-to-air ratio adjustment. The availability of different features such as burner modulation as per the specified fuel-to-air ratio is one of the benefits of new electronic control systems that are substituting conventional relay control. Industrial burners have lambda (AFR) sensors, which allow for extremely accurate surveillance of this ratio in internal combustion activities. These factors are expected to support development of the global industrial burner market in the near future.

Altogether, control panels and stoichiometric sensors and can alter the burner's circuitry to retain the specified operating voltage for combustion as well as heat treatment activities when emission levels rise. In the future years, such factors are expected to have a beneficial influence on the global industrial burner market.

In most industrial processes, energy losses owing to inefficient equipment and mechanical limits are a significant cost component. Improved burner control systems provide plant managers with a substantial chance to increase overall efficiency.

The Industrial Technologies Program of the US Department of Energy discovered that performing routine maintenance as well as substituting underperforming industrial burners can increase combustion performance and quality of products. Regular maintenance and repair can also help to reduce emissions. While the increased demand for such industrial burners produces a balance in terms of their consumption across numerous fuels, manufacturers have challenges in meeting the additional standards for their construction.

The industrial burner market is prognosticated to witness a tremendous growth within the forecast period from 2016 to 2024 owing to the rise in the usage of BMSs or burner management system. This system efficiently deals with the protection from the boilers explosion, and this factor majorly contributes in the growth of global industrial market. The precision, superior performance and efficiency of the industrial burners are also helping in their adoption globally, resulting in an exponential market growth.

Over the next few years, the overall market for industrial burners is probably going to pick up fundamentally on the back of the momentous ascent in the interest for industrial boilers, because of the quick industrialization in developing economies and the far reaching use of these boilers in various ventures, for example, chemicals, sustenance handling, control age, and oil and gas. However, limited availability of skilled labor might have a detrimental effect on the market.

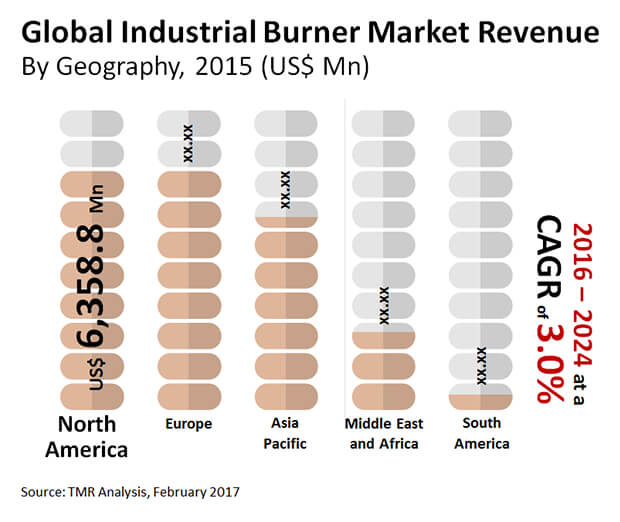

The worldwide industrial burner market was worth US$19.6 bn in year 2015. Expanding at a CAGR of 3.0% within the forecast period from 2016 to 2024, the market is expected to achieve US$25.6 bn before the finish of 2024.

Increased Implementation of Government Policies to Fuel Market Growth

Increased Implementation of Government Policies to Fuel Market GrowthThe minimal effort of work and raw materials in growing regions, for example, Asia Pacific could enable the world industrial burner to market to grandstand a speedier development within the coming years. Moreover, the rising execution of a few government strategies for lessening carbon emission and significant growth in mining and petrochemicals sector have been anticipated to promote industrial burner in Asia Pacific. Regardless of the stunning advancement of the worldwide industrial burner market, there could be some difficulties that are anticipated to hamper the growth. This is because of the cumbersome modification of industrial burners.

Among all the regions, Asia Pacific is expected to emerge as the most important market for industrial burners in the coming years. With a substantial pool of worldwide players setting up their assembling units in India and China, lured by low cost of land and labor and also the affordability of raw materials is anticipated to boost the Asia Pacific industrial burner market in the following couple of years. Developed regions, for example, North America have been estimated to add to the global development of the world industrial burner market in terms of the accessibility of a plentitude of common assets, more prominent profitability, and complex framework. Within a reasonable time-frame, North America could be overwhelmed by Canada and the U.S. where the last is a critical maker of oil and gas over the globe. Contrasted with different nations in North America, the U.S. has been anticipated to display a bigger interest for industrial burner.

ANDRITZ, Alzeta Corp., Baltur S.p.A, Forbes Marshall, Bloom Engineering, Foster Wheeler AG, Limpsfield Combustion Engineering Ltd, Honeywell International Inc., Mitsubishi Hitachi Power Systems Ltd, Osaka Gas Co. Ltd, Oilon, QED Combustion, Wesman Group, and Selas Heat Technology Co. are some of the leading firms dominating the global industrial burner market.

The escalating use of burner management systems around the world and the superior performance of industrial burners may bring extensive growth prospects for the industrial burner market through the assessment period of 2016-2024.

The global Industrial Burner Market was worth US$25.6 bn and is projected to reach a value of US$25.6 bn Mn by the end of 2024

Key players in the global Industrial Burner Market include ANDRITZ, Alzeta Corp., Baltur S.p.A, Forbes Marshall, Bloom Engineering, Foster Wheeler AG, Limpsfield Combustion Engineering Ltd, Honeywell International Inc., Mitsubishi Hitachi Power Systems Ltd, Osaka Gas Co. Ltd, Oilon, QED Combustion, Wesman Group, and Selas Heat Technology Co.

The growing industrial applications of boilers, increasing industrialization in emerging nations, and rise in the demand for industrial boilers have been envisaged to up market growth in the coming years.

The forecast period considered for the Industrial Burner Market is 2016 – 2024

Asia Pacific is more attractive region for vendors in the Industrial Burner Market

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

3. Executive Summary: Global Industrial Burner Market

4. Market Overview

4.1. Industry Developments

4.2. Key Market Indicators

4.2.1. Industrial Boiler Market

4.2.2. Combustion Systems Market

4.3. Market Dynamics

4.3.1. Drivers

4.3.2. Restraints

4.3.3. Opportunity

4.4. Global Industrial Burner Market Analysis and Forecasts, 2014 – 2024

4.4.1. Market Revenue and Volume Projections (US$ Mn and Thousand Units)

4.4.2. Key Findings

4.5. Porter’s Five Forces Analysis

5. Global Industrial Burner Market Analysis and Forecasts, By Fuel Type

5.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

5.1.1. Oil-based

5.1.1.1. Pressure Jet

5.1.1.2. Swirl

5.1.1.3. Rotary Cup

5.1.1.4. Gun burner

5.1.2. Gas-based

5.1.3. Dual fuel

6. Global Industrial Burner Market Analysis and Forecasts, By Automation

6.1. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

6.1.1. Monoblock

6.1.2. Duoblock

7. Global Industrial Burner Market Analysis and Forecasts, By Burner Type

7.1. Definition

7.2. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

7.2.1. Regenerative Burners (Heat Recovery)

7.2.2. High Velocity Burner

7.2.3. Thermal Radiation

7.2.4. Radiant Burner

7.2.4.1. Wall

7.2.4.2. Tube

7.2.5. Natural Draft

7.2.6. Flat Flame Burner

7.2.7. Line Burner

7.2.8. Customized (Burner Boiler)

7.2.9. Others

8. Global Industrial Burner Market Analysis and Forecasts, By Operating Temperature

8.1. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 – 2024

8.1.1. High Temperature (> 1400F)

8.1.2. Low Temp (< 1400F)

9. Global Industrial Burner Market Analysis and Forecasts, By Application

9.1. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

9.1.1. Boilers

9.1.2. Furnace/Oven/Kiln

9.1.3. Air Heating/Drying

9.1.4. Others

10. Global Industrial Burner Market Analysis and Forecasts, By End-Use

10.1. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

10.1.1. Petrochemicals (Oil & Gas, Exploration & Refining)

10.1.2. Power Generation

10.1.3. Chemicals & Specialty Chemicals

10.1.4. Mining & Mineral

10.1.5. Metal

10.1.6. Pharmaceutical

10.1.7. Glass

10.1.8. Ceramics

10.1.9. Food Processing

10.1.10. Automotive

10.1.11. Printing & Publishing

10.1.12. Others

10.2. Market Attractiveness by End-Use

11. Global Industrial Burner Market Analysis and Forecasts, By Region

11.1. Key Findings

11.2. Key Trends

11.3. Market Size (US$ Mn and Thousand Units) Forecast By Region, 2014 – 2024

11.3.1. North America

11.3.2. Europe

11.3.3. Asia Pacific

11.3.4. Middle East and Africa

11.3.5. South America

12. Global Industrial Burner Market Attractiveness Analysis

12.1. By Fuel Type

12.2. By Automation

12.3. By Operating Temperature

12.4. By Burner Type

12.5. By Application

12.6. By Industry Vertical

12.7. By Region

13. North America Industrial Burner Market Analysis and Forecast

13.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

13.1.1. Oil-based

13.1.1.1. Pressure Jet

13.1.1.2. Swirl

13.1.1.3. Rotary Cup

13.1.1.4. Gun burner

13.1.2. Gas-based

13.1.3. Dual fuel

13.2. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

13.2.1. Monoblock

13.2.2. Duoblock

13.3. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

13.3.1. Regenerative Burners (Heat Recovery)

13.3.2. High Velocity Burner

13.3.3. Thermal Radiation

13.3.4. Radiant Burner

13.3.4.1. Wall

13.3.4.2. Tube

13.3.5. Natural Draft

13.3.6. Flat Flame Burner

13.3.7. Line Burner

13.3.8. Customized (Burner Boiler)

13.3.9. Others

13.4. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 – 2024

13.4.1. High Temperature (> 1400F)

13.4.2. Low Temp (< 1400F)

13.5. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

13.5.1. Boilers

13.5.2. Furnace/Oven/Kiln

13.5.3. Air Heating/Drying

13.5.4. Others

13.6. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

13.6.1. Petrochemicals (Oil & Gas, Exploration & Refining)

13.6.2. Power Generation

13.6.3. Chemicals & Specialty Chemicals

13.6.4. Mining & Mineral

13.6.5. Metal

13.6.6. Pharmaceutical

13.6.7. Glass

13.6.8. Ceramics

13.6.9. Food Processing

13.6.10. Automotive

13.6.11. Printing & Publishing

13.6.12. Others

13.7. Market Size (US$ Mn and Thousand Units) Forecast By Country*, 2014 – 2024

13.7.1. United States

13.7.2. Canada

13.7.3. Mexico

13.7.4. Rest of North America

*Cross segment analysis have been covered for all the above mentioned countries

13.8. Market Attractiveness Analysis

13.8.1. By Fuel Type

13.8.2. By Automation

13.8.3. By Operating Temperature

13.8.4. By Burner Type

13.8.5. By Application

13.8.6. By Industry Vertical

13.8.7. By Country

14. Europe Industrial Burner Market Analysis and Forecast

14.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

14.1.1. Oil-based

14.1.1.1. Pressure Jet

14.1.1.2. Swirl

14.1.1.3. Rotary Cup

14.1.1.4. Gun burner

14.1.2. Gas-based

14.1.3. Dual fuel

14.2. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

14.2.1. Monoblock

14.2.2. Duoblock

14.3. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

14.3.1. Regenerative Burners (Heat Recovery)

14.3.2. High Velocity Burner

14.3.3. Thermal Radiation

14.3.4. Radiant Burner

14.3.4.1. Wall

14.3.4.2. Tube

14.3.5. Natural Draft

14.3.6. Flat Flame Burner

14.3.7. Line Burner

14.3.8. Customized (Burner Boiler)

14.3.9. Others

14.4. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 – 2024

14.4.1. High Temperature (> 1400F)

14.4.2. Low Temp (< 1400F)

14.5. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

14.5.1. Boilers

14.5.2. Furnace/Oven/Kiln

14.5.3. Air Heating/Drying

14.5.4. Others

14.6. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

14.6.1.1. Petrochemicals (Oil & Gas, Exploration & Refining)

14.6.1.2. Power Generation

14.6.1.3. Chemicals & Specialty Chemicals

14.6.1.4. Mining & Mineral

14.6.1.5. Metal

14.6.1.6. Pharmaceutical

14.6.1.7. Glass

14.6.1.8. Ceramics

14.6.1.9. Food Processing

14.6.1.10. Automotive

14.6.1.11. Printing & Publishing

14.6.1.12. Others

14.7. Market Size (US$ Mn and Thousand Units) Forecast By Country*, 2014 – 2024

14.7.1. Germany

14.7.2. France

14.7.3. Russia

14.7.4. Turkey

14.7.5. United Kingdom

14.7.6. Rest of Europe

*Cross segment analysis have been covered for all the above mentioned countries

14.8. Market Attractiveness Analysis

14.8.1. By Fuel Type

14.8.2. By Automation

14.8.3. By Operating Temperature

14.8.4. By Burner Type

14.8.5. By Application

14.8.6. By Industry Vertical

14.8.7. By Country

15. Asia Pacific Industrial Burner Market Analysis and Forecast

15.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

15.1.1. Oil-based

15.1.1.1. Pressure Jet

15.1.1.2. Swirl

15.1.1.3. Rotary Cup

15.1.1.4. Gun burner

15.1.2. Gas-based

15.1.3. Dual fuel

15.2. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

15.2.1. Monoblock

15.2.2. Duoblock

15.3. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

15.3.1. Regenerative Burners (Heat Recovery)

15.3.2. High Velocity Burner

15.3.3. Thermal Radiation

15.3.4. Radiant Burner

15.3.4.1. Wall

15.3.4.2. Tube

15.3.5. Natural Draft

15.3.6. Flat Flame Burner

15.3.7. Line Burner

15.3.8. Customized (Burner Boiler)

15.3.9. Others

15.4. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 – 2024

15.4.1. High Temperature (> 1400F)

15.4.2. Low Temp (< 1400F)

15.5. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

15.5.1. Boilers

15.5.2. Furnace/Oven/Kiln

15.5.3. Air Heating/Drying

15.5.4. Others

15.6. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

15.6.1. Petrochemicals (Oil & Gas, Exploration & Refining)

15.6.2. Power Generation

15.6.3. Chemicals & Specialty Chemicals

15.6.4. Mining & Mineral

15.6.5. Metal

15.6.6. Pharmaceutical

15.6.7. Glass

15.6.8. Ceramics

15.6.9. Food Processing

15.6.10. Automotive

15.6.11. Printing & Publishing

15.6.12. Others

15.7. Market Size (US$ Mn and Thousand Units) Forecast By Country*, 2014 – 2024

15.7.1. China

15.7.2. India

15.7.3. Japan

15.7.4. Rest of Asia Pacific

*Cross segment analysis have been covered for all the above mentioned countries

15.8. Market Attractiveness Analysis

15.8.1. By Fuel Type

15.8.2. By Automation

15.8.3. By Operating Temperature

15.8.4. By Burner Type

15.8.5. By Application

15.8.6. By Industry Vertical

15.8.7. By Country

16. Middle East and Africa Industrial Burner Market Analysis and Forecast

16.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

16.1.1. Oil-based

16.1.1.1. Pressure Jet

16.1.1.2. Swirl

16.1.1.3. Rotary Cup

16.1.1.4. Gun burner

16.1.2. Gas-based

16.1.3. Dual fuel

16.2. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

16.2.1. Monoblock

16.2.2. Duoblock

16.3. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

16.3.1. Regenerative Burners (Heat Recovery)

16.3.2. High Velocity Burner

16.3.3. Thermal Radiation

16.3.4. Radiant Burner

16.3.4.1. Wall

16.3.4.2. Tube

16.3.5. Natural Draft

16.3.6. Flat Flame Burner

16.3.7. Line Burner

16.3.8. Customized (Burner Boiler)

16.3.9. Others

16.4. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 – 2024

16.4.1. High Temperature (> 1400F)

16.4.2. Low Temp (< 1400F)

16.5. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

16.5.1. Boilers

16.5.2. Furnace/Oven/Kiln

16.5.3. Air Heating/Drying

16.5.4. Others

16.6. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

16.6.1. Petrochemicals (Oil & Gas, Exploration & Refining)

16.6.2. Power Generation

16.6.3. Chemicals & Specialty Chemicals

16.6.4. Mining & Mineral

16.6.5. Metal

16.6.6. Pharmaceutical

16.6.7. Glass

16.6.8. Ceramics

16.6.9. Food Processing

16.6.10. Automotive

16.6.11. Printing & Publishing

16.6.12. Others

16.7. Market Size (US$ Mn and Thousand Units) Forecast By Country*, 2014 – 2024

16.7.1. UAE

16.7.2. South Africa

16.7.3. Rest of Middle East and Africa

*Cross segment analysis have been covered for all the above mentioned countries

16.8. Market Attractiveness Analysis

16.8.1. By Fuel Type

16.8.2. By Automation

16.8.3. By Operating Temperature

16.8.4. By Burner Type

16.8.5. By Application

16.8.6. By Industry Vertical

16.8.7. By Country

17. South America Industrial Burner Market Analysis and Forecast

17.1. Market Size (US$ Mn and Thousand Units) Forecast By Fuel Type, 2014 – 2024

17.1.1. Oil-based

17.1.1.1. Pressure Jet

17.1.1.2. Swirl

17.1.1.3. Rotary Cup

17.1.1.4. Gun burner

17.1.2. Gas-based

17.1.3. Dual fuel

17.2. Market Size (US$ Mn and Thousand Units) Forecast By Automation, 2014 – 2024

17.2.1. Monoblock

17.2.2. Duoblock

17.3. Market Size (US$ Mn and Thousand Units) Forecast By Burner Type, 2014 – 2024

17.3.1. Regenerative Burners (Heat Recovery)

17.3.2. High Velocity Burner

17.3.3. Thermal Radiation

17.3.4. Radiant Burner

17.3.4.1. Wall

17.3.4.2. Tube

17.3.5. Natural Draft

17.3.6. Flat Flame Burner

17.3.7. Line Burner

17.3.8. Customized (Burner Boiler)

17.3.9. Others

17.4. Market Size (US$ Mn and Thousand Units) Forecast By Operating Temperature, 2014 -2024

17.4.1. High Temperature (> 1400F)

17.4.2. Low Temp (< 1400F)

17.5. Market Size (US$ Mn and Thousand Units) Forecast By Application, 2014 – 2024

17.5.1. Boilers

17.5.2. Furnace/Oven/Kiln

17.5.3. Air Heating/Drying

17.5.4. Others

17.6. Market Size (US$ Mn and Thousand Units) Forecast By End-Use 2014 – 2024

17.6.1. Petrochemicals (Oil & Gas, Exploration & Refining)

17.6.2. Power Generation

17.6.3. Chemicals & Specialty Chemicals

17.6.4. Mining & Mineral

17.6.5. Metal

17.6.6. Pharmaceutical

17.6.7. Glass

17.6.8. Ceramics

17.6.9. Food Processing

17.6.10. Automotive

17.6.11. Printing & Publishing

17.6.12. Others

17.7. Market Size (US$ Mn and Thousand Units) Forecast By Country*, 2014 – 2024

17.7.1. Brazil

17.7.2. Argentina

17.7.3. Rest of South America

*Cross segment analysis have been covered for all the above mentioned countries

17.8. Market Attractiveness Analysis

17.8.1. By Fuel Type

17.8.2. By Automation

17.8.3. By Operating Temperature

17.8.4. By Burner Type

17.8.5. By Application

17.8.6. By Industry Vertical

17.8.7. By Country

18. Competition Landscape

18.1. Market Player – Competition Matrix (By Tier and Type of companies)

18.2. Market Share Analysis by Company (2015)

18.3. Company Profiles

18.3.1. Alzeta Corporation

18.3.1.1. Company Details (HQ, Foundation Year, Employee Strength)

18.3.1.2. Market Presence, By Segment.

18.3.1.3. Strategy

18.3.1.4. Revenue and Operating Profits

18.3.1.5. SWOT Analysis

*Similar details are provided for all the below mentioned companies

18.3.2. Andritz

18.3.3. Baltur S.p.A

18.3.4. Bloom Engineering

18.3.5. Forbes Marshall

18.3.6. Foster Wheeler AG

18.3.7. Honeywell International Inc. (Maxon)

18.3.8. Limpsfield Combustion Engineering Ltd

18.3.9. Mitsubishi Hitachi Power Systems, Ltd

18.3.10. Oilon

18.3.11. Osaka Gas Co., Ltd

18.3.12. QED Combustion

18.3.13. Selas Heat Technology Company

18.3.14. Wesman Group

18. Key Takeaways

List of Tables

Table 1: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 2: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 3: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 4: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 5: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 6: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 7: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 8: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 9: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 10: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 11: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 12: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 13: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 14: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 15: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 16: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 17: Global Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Region, 2014–2024

Table 18: Global Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Region, 2014–2024

Table 19: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 20: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 21: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 22: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 23: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 24: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 25: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 26: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 27: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 28: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 29: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 30: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 31: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 32: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 33: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 34: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 35: North America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Country, 2014–2024

Table 36: North America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Country, 2014–2024

Table 37: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 38: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 39: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 40: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 41: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 42: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 43: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 44: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 45: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 46: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 47: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 48: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 49: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 50: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 51: The U.S. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 52: The U.S. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 53: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 54: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 55: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 56: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 57: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 58: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 59: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 60: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 61: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 62: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 63: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 64: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 65: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 66: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 67: Canada Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 68: Canada Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 69: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 70: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 71: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 72: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 73: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 74: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 75: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 76: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 77: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 78: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 79: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 80: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 81: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 82: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 83: Mexico Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 84: Mexico Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 85: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 86: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 87: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 88: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 89: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 90: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 91: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 92: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 93: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 94: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 95: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 96: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 97: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 98: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 99: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 100: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 101: Europe Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Country, 2014–2024

Table 102: Europe Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Country, 2014–2024

Table 103: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 104: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 105: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 106: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 107: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 108: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 109: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 110: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 111: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 112: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 113: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 114: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 115: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 116: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 117: Germany Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 118: Germany Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 119: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 120: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 121: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 122: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 123: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 124: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 125: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 126: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 127: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 128: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 129: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 130: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 131: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 132: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 133: France Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 134: France Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 135: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 136: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 137: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 138: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 139: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 140: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 141: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 142: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 143: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 144: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 145: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 146: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 147: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 148: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 149: Russia Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 150: Russia Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 151: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 152: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 153: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 154: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 155: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 156: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 157: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 158: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 159: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 160: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 161: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 162: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 163: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 164: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 165: Turkey Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 166: Turkey Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 167: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 168: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 169: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 170: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 171: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 172: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 173: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 174: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 175: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 176: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 177: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 178: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 179: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 180: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 181: The U.K. Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 182: The U.K. Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 183: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 184: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 185: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 186: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 187: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 188: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 189: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 190: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 191: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 192: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 193: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 194: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 195: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 196: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 197: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 198: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 199: Asia Pacific Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Country, 2014–2024

Table 200: Asia Pacific Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Country, 2014–2024

Table 201: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 202: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 203: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 204: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 205: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 206: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 207: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 208: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 209: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 210: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 211: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 212: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 213: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 214: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 215: China Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 216: China Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 217: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 218: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 219: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 220: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 221: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 222: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 223: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 223: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 224: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 225: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 226: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 227: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 228: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 229: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 230: India Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 231: India Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 232: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 233: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 234: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 235: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 236: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 237: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 238: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 239: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 240: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 241: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 242: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 243: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 244: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 245: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 246: Japan Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 247: Japan Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 248: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 249: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 250: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 251: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 252: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 253: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 254: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 255: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 256: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 257: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 258: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 259: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 260: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 261: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 262: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 263: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 264: Middle East and Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Country, 2014–2024

Table 265: Middle East and Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Country, 2014–2024

Table 266: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 267: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 268: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 269: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 270: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 271: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 272: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 273: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 274: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 275: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 276: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 277: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 278: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 279: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 280: UAE Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 281: UAE Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 282: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 283: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 284: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 285: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 286: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 287: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 288: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 289: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 290: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 291: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 292: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 293: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 294: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 295: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 296: South Africa Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 297: South Africa Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 298: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 299: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 300: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 301: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 302: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 303: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 304: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 305: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 306: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 307: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 308: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 309: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 310: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 311: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 312: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 313: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 314: South America Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Country, 2014–2024

Table 315: South America Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Country, 2014–2024

Table 316: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 317: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 318: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 319: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 320: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 321: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 322: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 323: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 324: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 325: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 326: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 327: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 328: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 329: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 330: Brazil Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 331: Brazil Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

Table 332: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Fuel Type, 2014–2024

Table 333: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Fuel Type, 2014–2024

Table 334: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Oil-based, 2014–2024

Table 335: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Oil-based, 2014–2024

Table 336: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Automation, 2014–2024

Table 337: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Automation, 2014–2024

Table 338: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Burner Type, 2014–2024

Table 339: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Burner Type, 2014–2024

Table 340: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 341: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Radiant Burner, 2014–2024

Table 342: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 343: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Operating Temperature, 2014–2024

Table 344: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by Application, 2014–2024

Table 345: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by Application, 2014–2024

Table 346: Argentina Industrial Burner Market Revenue (US$ Mn) Forecast and CAGR, by End-use, 2014–2024

Table 347: Argentina Industrial Burner Market Volume (Thousand Units) Forecast and CAGR, by End-use, 2014–2024

List of Figures

Figure 1: Global Industrial Burner Market Revenue Projection (US$ Mn), 2014 – 2024

Figure 2: Global Industrial Burner Market Volume Projection (Thousand Units), 2014 – 2024

Figure 3: Global Industrial Burner Market Y-o-Y Growth (Value and Volume %) Forecast, 2015 - 2024

Figure 4: Global Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 5: Global Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 6: Global Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 7: Global Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 8: Global Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)

Figure 9: Global Industrial Burner Market Attractiveness Analysis, By Region (2016)

Figure 10: Global Industrial Burner Market Attractiveness Analysis, By End-Use (2016)

Figure 11: Global Industrial Burner Market Size and Y-o-Y Growth, by Region – North America, 2014 – 2024, (US$ Mn & Value %)

Figure 12: Global Industrial Burner Market Size and Y-o-Y Growth, by Region – Europe, 2014 – 2024, (US$ Mn & Value %)

Figure 13: Global Industrial Burner Market Size and Y-o-Y Growth, by Region – Asia Pacific, 2014 – 2024, (US$ Mn & Value %)

Figure 14: Global Industrial Burner Market Size and Y-o-Y Growth, by Region – MEA, 2014 – 2024, (US$ Mn & Value %)

Figure 15: Global Industrial Burner Market Size and Y-o-Y Growth, by Region – SA, 2014 – 2024, (US$ Mn & Value %)

Figure 17: North America Industrial Burner Market Size and Y-o-Y Growth, by Country – The U.S., 2014 – 2024, (US$ Mn & Value %)

Figure 18: North America Industrial Burner Market Size and Y-o-Y Growth, by Country –Canada, 2014 – 2024, (US$ Mn & Value %)

Figure 19: North America Industrial Burner Market Size and Y-o-Y Growth, by Country – Mexico, 2014 – 2024, (US$ Mn & Value %)

Figure 20: North America Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 21: North America Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 22: North America Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 23: North America Industrial Burner Market Attractiveness Analysis, By Country (2016)

Figure 24: North America Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 25: North America Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)

Figure 26: North America Industrial Burner Market Attractiveness Analysis, By End-Use (2016)

Figure 27: Europe Industrial Burner Market Size and Y-o-Y Growth, by Country – The U.K., 2014 – 2024, (US$ Mn & Value %)

Figure 28: Europe Industrial Burner Market Size and Y-o-Y Growth, by Country – Germany, 2014 – 2024, (US$ Mn & Value %)

Figure 29: Europe Industrial Burner Market Size and Y-o-Y Growth, by Country – France, 2014 – 2024, (US$ Mn & Value %)

Figure 30: Europe Industrial Burner Market Size and Y-o-Y Growth, by Country –Russia, 2014 – 2024, (US$ Mn, & Value %)

Figure 31: Europe Industrial Burner Market Size and Y-o-Y Growth, by Country – Turkey, 2014 – 2024, (US$ Mn & Value %)

Figure 32: Europe Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 33: Europe Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 34: Europe Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 35: Europe Industrial Burner Market Attractiveness Analysis, By Country (2016)

Figure 36: Europe Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 37: Europe Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)

Figure 38: Europe Industrial Burner Market Attractiveness Analysis, By End-Use (2016)

Figure 39: Asia Pacific Industrial Burner Market Size and Y-o-Y Growth, by Country – China, 2014 – 2024, (US$ Mn & Value %)

Figure 40: Asia Pacific Industrial Burner Market Size and Y-o-Y Growth, by Country –India, 2014 – 2024, (US$ Mn & Value %)

Figure 41: Asia Pacific Industrial Burner Market Size and Y-o-Y Growth, by Country – Japan, 2014 – 2024, (US$ Mn & Value %)

Figure 42: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 43: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 44: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 45: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Country (2016)

Figure 46: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 47: Asia Pacific Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)

Figure 48: Asia Pacific Industrial Burner Market Attractiveness Analysis, By End-Use (2016)

Figure 49: Middle East and Africa Industrial Burner Market Size and Y-o-Y Growth, by Country – UAE, 2014 – 2024, (US$ Mn & Value %)

Figure 50: Middle East and Africa Industrial Burner Market Size and Y-o-Y Growth, by Country –South Africa, 2014 – 2024, (US$ Mn & Value %)

Figure 51: MEA Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 52: MEA Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 53: MEA Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 54: MEA Industrial Burner Market Attractiveness Analysis, By Country (2016)

Figure 55: MEA Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 56: MEA Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)

Figure 57: MEA Industrial Burner Market Attractiveness Analysis, By End-Use (2016)

Figure 58: South America Industrial Burner Market Size and Y-o-Y Growth, by Country – Brazil, 2014 – 2024, (US$ Mn & Value %)

Figure 59: South America Industrial Burner Market Size and Y-o-Y Growth, by Country –Argentina, 2014 – 2024, (US$ Mn & Value %)

Figure 60: South America Industrial Burner Market Attractiveness Analysis, By Burner Type (2016)

Figure 61: South America Industrial Burner Market Attractiveness Analysis, By Application (2016)

Figure 62: South America Industrial Burner Market Attractiveness Analysis, By Automation (2016)

Figure 63: South America Industrial Burner Market Attractiveness Analysis, By Country (2016)

Figure 64: South America Industrial Burner Market Attractiveness Analysis, By Fuel Type (2016)

Figure 65: South America Industrial Burner Market Attractiveness Analysis, By Operating Temperature (2016)