Reports

Reports

Analysts’ Viewpoint

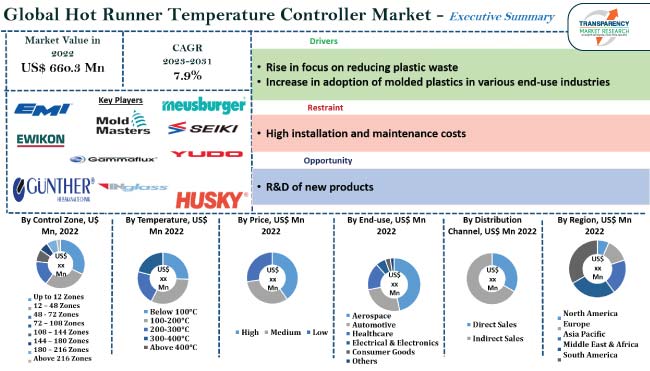

Increase in demand for plastic injection molding in various end-use industries is expected to propel the hot runner temperature controller market size during the forecast period. Rise in focus on reducing plastic waste is also fueling the demand for Hot Runner Temperature Controllers.

R&D in hot temperature control systems, such as improved control algorithms and user-friendly interfaces, is likely to offer lucrative opportunities to vendors in the global Hot Runner Temperature Controller industry. Technologically advanced products with high monitoring capabilities are gaining traction among end-users. Moreover, end-users are preferring machine components that are flexible and easy to maintain. Expansion in end-use industries is anticipated to contribute to the hot runner temperature controller market progress in the next few years.

Hot runner temperature controller is a device that maintains the design temperature of specialized injection mold components to keep the mold material flowing. This customized temperature controller is interconnected with the hot system. Hot temperature control systems are used in many sectors such as medical, packaging, electronics, appliances, automotive, building, and logistics. Hot system controllers, such as HMI-based hot controllers, standard plug-in hot controllers, one card control two zones, and 48*48 PID control units, are gaining popularity in the sector.

Impact of manufacturing regulations on controller standards varies from country to country. European countries have regulations that prioritize controller standards for automotive applications. Countries in North America often align their controller standards with global norms to facilitate exports and imports. Temperature control helps improve industrial processes and product quality. It also contributes to huge cost reductions. Controlling temperatures is also crucial for both safety and the environment. Car manufacturers must achieve extremely stringent criteria for material quality and impact resistance in the automotive sector. Temperature controllers ensure the quality of laboratory-tested automotive materials.

Hot controllers aid in the reduction of plastic waste by producing plastic that can be properly disposed of. Scrap is limited or absent when plastic is molded at an ideal temperature. The equal distribution of temperature avoids material waste during the entire production process. These advantages are boosting the demand for hot controllers, thereby propelling the Hot Runner Temperature Controller market value.

The packaging sector heavily relies on hot systems for the production of plastic packaging items. These systems are employed to manufacture bottle caps, closures, containers, and lids with consistent quality and low waste. Moreover, hot runner temperature controllers are designed to be energy-efficient. These controllers heat the plastic only when necessary, reducing overall energy consumption compared to traditional systems. Any scrap produced during the process is reused.

Rise in adoption of hot controllers for plastic molding is creating global hot runner temperature controller market growth opportunities for vendors. Molded plastics are widely utilized in manufacturing vehicles, home appliances, and electrical & electronic products. Molded plastic components are often more cost-effective to produce than equivalent parts made from other materials such as metal or glass. This cost advantage is further driving the demand for hot runner temperature controllers in various end-use industries.

Surge in adoption of plastic components in the production of flexible packaging, piping, insulation & coatings, and medical devices is propelling the demand for hot controller devices. The packaging sector relies on plastic molding to deliver bulk packs. Reusable packaging is gaining traction among consumers. Plastic components are generally lighter than their metal counterparts. Automotive and aerospace industries require lightweight materials to enhance fuel efficiency and reduce transportation costs. Injection-molded plastic is also used in the construction sector to manufacture floorings, walls, roofing materials, and pipes. Thus, expansion in the construction sector is driving the hot runner temperature controller market expansion.

According to the latest hot runner temperature controller market forecast, Asia Pacific is expected to hold largest share from 2023 to 2031. Growth in packaging and manufacturing sectors is fueling the market dynamics of the region. Diversity in modern packaging technology makes plastics indispensable in various sectors. Rise in adoption of technologically advanced packaging techniques is also propelling the hot runner temperature controller market statistics in Asia Pacific.

Rapid economic development through industrialization is boosting market revenue in Europe. Expansion in automotive and industrial sectors is also augmenting demand for hot runner temperature controllers in the region. Hot Runner Temperature Controllers are employed in aerospace, mining, food processing, agriculture, manufacturing, automotive, healthcare, and other industries.

Detailed profiles of companies are provided in the hot runner temperature controller market report to evaluate their financials, key product offerings, recent developments, and strategies.

Most hot runner temperature controller companies are investing significantly in comprehensive R&D activities, primarily to develop innovative products. They are also adopting partnership, collaboration, and M&A strategies to increase their hot runner temperature controller market share.

EMI Corporation, EWIKON Heißkanalsysteme GmbH, Gammaflux L.P., GÜNTHER Heisskanaltechnik GmbH, Hillenbrand, Inc. (Mold-Masters), Husky Injection Molding Systems Ltd., INglass S.p.A., Meusburger Georg GmbH & Co KG, Seiki Corporation, and YUDO Holdings Co., Ltd. are prominent hot runner temperature controller manufacturers.

Each of these players has been profiled in the global hot runner temperature controller market research report based on parameters such as company overview, financial overview, business strategies, product portfolio, and business segments.

| Attribute | Detail |

|---|---|

| Market Value in 2022 (Base Year) | US$ 660.3 Mn |

| Market Forecast Value in 2031 | US$ 1.3 Bn |

| Growth Rate (CAGR) | 7.9% |

| Forecast Period | 2023-2031 |

| Quantitative Units | US$ Mn/Bn for Value and Thousand Units for Volume |

| Market Analysis | The global qualitative analysis includes drivers, restraints, opportunities, key trends, key market indicators, Porter’s Five Forces analysis, value chain analysis, SWOT analysis, etc. Furthermore, at the regional level, the qualitative analysis includes key trends, price trends, and key supplier analysis. |

| Competition Landscape |

|

| Regions Covered |

|

| Countries Covered |

|

| Market Segmentation |

|

| Companies Profiled |

|

| Customization Scope | Available upon Request |

| Pricing | Available upon Request |

It was valued at US$ 660.3 Mn in 2022

It is expected to reach US$ 1.3 Bn by the end of 2031

Rise in focus on reducing plastic waste and increase in adoption of molded plastics in various end-use industries

12 - 48 zones was the largest control zone segment in 2022

Asia Pacific accounted for 34.0% share in 2022

EMI Corporation, EWIKON Heißkanalsysteme GmbH, Gammaflux L.P., GÜNTHER Heisskanaltechnik GmbH, Hillenbrand, Inc. (Mold-Masters), Husky Injection Molding Systems Ltd., INglass S.p.A., Meusburger Georg GmbH & Co KG, Seiki Corporation, and YUDO Holdings Co., Ltd.

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions

3. Research Methodology

4. Executive Summary

5. Market Overview

5.1. Market Dynamics

5.1.1. Drivers

5.1.2. Restraints

5.1.3. Opportunities

5.2. Key Trends Analysis

5.2.1. Demand Side Analysis

5.2.2. Supply Side Analysis

5.3. Key Market Indicators

5.4. Porter’s Five Forces Analysis

5.5. Value Chain Analysis

5.6. Industry SWOT Analysis

5.7. Regulatory Framework

5.8. Technology Overview

5.9. Global Hot Runner Temperature Controller Market Analysis and Forecast, 2017 - 2031

5.9.1. Market Value Projection (US$ Mn)

5.9.2. Market Volume Projection (Thousand Units)

6. Global Hot Runner Temperature Controller Market Analysis and Forecast, By Control Zone

6.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

6.1.1. Up to 12 Zones

6.1.2. 12 - 48 Zones

6.1.3. 48 - 72 Zones

6.1.4. 72 - 108 Zones

6.1.5. 108 - 144 Zones

6.1.6. 144 - 180 Zones

6.1.7. 180 - 216 Zones

6.1.8. Above 216 Zones

6.2. Incremental Opportunity, By Control Zone

7. Global Hot Runner Temperature Controller Market Analysis and Forecast, By Temperature

7.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

7.1.1. Below 100°C

7.1.2. 100-200°C

7.1.3. 200-300°C

7.1.4. 300-400°C

7.1.5. Above 400°C

7.2. Incremental Opportunity, By Temperature

8. Global Hot Runner Temperature Controller Market Analysis and Forecast, By Price

8.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

8.1.1. High

8.1.2. Medium

8.1.3. Low

8.2. Incremental Opportunity, By Price

9. Global Hot Runner Temperature Controller Market Analysis and Forecast, By End-use

9.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

9.1.1. Aerospace

9.1.2. Automotive

9.1.3. Healthcare

9.1.4. Electrical & Electronics

9.1.5. Consumer Goods

9.1.6. Others (Consumer Goods, Packaging, etc.)

9.2. Incremental Opportunity, By End-use

10. Global Hot Runner Temperature Controller Market Analysis and Forecast, By Distribution Channel

10.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

10.1.1. Direct Sales

10.1.2. Indirect Sales

10.2. Incremental Opportunity, By Distribution Channel

11. Global Hot Runner Temperature Controller Market Analysis and Forecast, Region

11.1. Global Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Region, 2017 - 2031

11.1.1. North America

11.1.2. Europe

11.1.3. Asia Pacific

11.1.4. Middle East & Africa

11.1.5. South America

11.2. Incremental Opportunity, By Region

12. North America Hot Runner Temperature Controller Market Analysis and Forecast

12.1. Regional Snapshot

12.2. Key Trends Analysis

12.2.1. Demand Side Analysis

12.2.2. Supply Side Analysis

12.3. Key Supplier Analysis

12.4. Price Trend Analysis

12.4.1. Weighted Average Selling Price (US$)

12.5. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

12.5.1. Up to 12 Zones

12.5.2. 12 - 48 Zones

12.5.3. 48 - 72 Zones

12.5.4. 72 - 108 Zones

12.5.5. 108 - 144 Zones

12.5.6. 144 - 180 Zones

12.5.7. 180 - 216 Zones

12.5.8. Above 216 Zones

12.6. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

12.6.1. Below 100°C

12.6.2. 100-200°C

12.6.3. 200-300°C

12.6.4. 300-400°C

12.6.5. Above 400°C

12.7. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

12.7.1. High

12.7.2. Medium

12.7.3. Low

12.8. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

12.8.1. Aerospace

12.8.2. Automotive

12.8.3. Healthcare

12.8.4. Electrical & Electronics

12.8.5. Consumer Goods

12.8.6. Others (Consumer Goods, Packaging, etc.)

12.9. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

12.9.1. Direct Sales

12.9.2. Indirect Sales

12.10. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Country, 2017 - 2031

12.10.1. U.S.

12.10.2. Canada

12.10.3. Rest of North America

12.11. Incremental Opportunity Analysis

13. Europe Hot Runner Temperature Controller Market Analysis and Forecast

13.1. Regional Snapshot

13.2. Key Trends Analysis

13.2.1. Demand Side Analysis

13.2.2. Supply Side Analysis

13.3. Key Supplier Analysis

13.4. Price Trend Analysis

13.4.1. Weighted Average Selling Price (US$)

13.5. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

13.5.1. Up to 12 Zones

13.5.2. 12 - 48 Zones

13.5.3. 48 - 72 Zones

13.5.4. 72 - 108 Zones

13.5.5. 108 - 144 Zones

13.5.6. 144 - 180 Zones

13.5.7. 180 - 216 Zones

13.5.8. Above 216 Zones

13.6. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

13.6.1. Below 100°C

13.6.2. 100-200°C

13.6.3. 200-300°C

13.6.4. 300-400°C

13.6.5. Above 400°C

13.7. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

13.7.1. High

13.7.2. Medium

13.7.3. Low

13.8. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

13.8.1. Aerospace

13.8.2. Automotive

13.8.3. Healthcare

13.8.4. Electrical & Electronics

13.8.5. Consumer Goods

13.8.6. Others (Consumer Goods, Packaging, etc.)

13.9. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

13.9.1. Direct Sales

13.9.2. Indirect Sales

13.10. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Country, 2017 - 2031

13.10.1. U.K.

13.10.2. Germany

13.10.3. France

13.10.4. Rest of Europe

13.11. Incremental Opportunity Analysis

14. Asia Pacific Hot Runner Temperature Controller Market Analysis and Forecast

14.1. Regional Snapshot

14.2. Key Trends Analysis

14.2.1. Demand Side Analysis

14.2.2. Supply Side Analysis

14.3. Key Supplier Analysis

14.4. Price Trend Analysis

14.4.1. Weighted Average Selling Price (US$)

14.5. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

14.5.1. Up to 12 Zones

14.5.2. 12 - 48 Zones

14.5.3. 48 - 72 Zones

14.5.4. 72 - 108 Zones

14.5.5. 108 - 144 Zones

14.5.6. 144 - 180 Zones

14.5.7. 180 - 216 Zones

14.5.8. Above 216 Zones

14.6. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

14.6.1. Below 100°C

14.6.2. 100-200°C

14.6.3. 200-300°C

14.6.4. 300-400°C

14.6.5. Above 400°C

14.7. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

14.7.1. High

14.7.2. Medium

14.7.3. Low

14.8. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

14.8.1. Aerospace

14.8.2. Automotive

14.8.3. Healthcare

14.8.4. Electrical & Electronics

14.8.5. Consumer Goods

14.8.6. Others (Consumer Goods, Packaging, etc.)

14.9. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

14.9.1. Direct Sales

14.9.2. Indirect Sales

14.10. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Country, 2017 - 2031

14.10.1. China

14.10.2. India

14.10.3. Japan

14.10.4. Rest of Asia Pacific

14.11. Incremental Opportunity Analysis

15. Middle East & Africa Hot Runner Temperature Controller Market Analysis and Forecast

15.1. Regional Snapshot

15.2. Key Trends Analysis

15.2.1. Demand Side Analysis

15.2.2. Supply Side Analysis

15.3. Key Supplier Analysis

15.4. Price Trend Analysis

15.4.1. Weighted Average Selling Price (US$)

15.5. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

15.5.1. Up to 12 Zones

15.5.2. 12 - 48 Zones

15.5.3. 48 - 72 Zones

15.5.4. 72 - 108 Zones

15.5.5. 108 - 144 Zones

15.5.6. 144 - 180 Zones

15.5.7. 180 - 216 Zones

15.5.8. Above 216 Zones

15.6. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

15.6.1. Below 100°C

15.6.2. 100-200°C

15.6.3. 200-300°C

15.6.4. 300-400°C

15.6.5. Above 400°C

15.7. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

15.7.1. High

15.7.2. Medium

15.7.3. Low

15.8. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

15.8.1. Aerospace

15.8.2. Automotive

15.8.3. Healthcare

15.8.4. Electrical & Electronics

15.8.5. Consumer Goods

15.8.6. Others (Consumer Goods, Packaging, etc.)

15.9. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

15.9.1. Direct Sales

15.9.2. Indirect Sales

15.10. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Country, 2017 - 2031

15.10.1. GCC

15.10.2. South Africa

15.10.3. Rest of Middle East & Africa

15.11. Incremental Opportunity Analysis

16. South America Hot Runner Temperature Controller Market Analysis and Forecast

16.1. Regional Snapshot

16.2. Key Trends Analysis

16.2.1. Demand Side Analysis

16.2.2. Supply Side Analysis

16.3. Key Supplier Analysis

16.4. Price Trend Analysis

16.4.1. Weighted Average Selling Price (US$)

16.5. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Control Zone, 2017 - 2031

16.5.1. Up to 12 Zones

16.5.2. 12 - 48 Zones

16.5.3. 48 - 72 Zones

16.5.4. 72 - 108 Zones

16.5.5. 108 - 144 Zones

16.5.6. 144 - 180 Zones

16.5.7. 180 - 216 Zones

16.5.8. Above 216 Zones

16.6. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Temperature, 2017 - 2031

16.6.1. Below 100°C

16.6.2. 100-200°C

16.6.3. 200-300°C

16.6.4. 300-400°C

16.6.5. Above 400°C

16.7. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Price, 2017 - 2031

16.7.1. High

16.7.2. Medium

16.7.3. Low

16.8. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By End-use, 2017 - 2031

16.8.1. Aerospace

16.8.2. Automotive

16.8.3. Healthcare

16.8.4. Electrical & Electronics

16.8.5. Consumer Goods

16.8.6. Others (Consumer Goods, Packaging, etc.)

16.9. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Distribution Channel, 2017 - 2031

16.9.1. Direct Sales

16.9.2. Indirect Sales

16.10. Hot Runner Temperature Controller Market Size (US$ Mn and Thousand Units), By Country, 2017 - 2031

16.10.1. Brazil

16.10.2. Rest of South America

16.11. Incremental Opportunity Analysis

17. Competition Landscape

17.1. Market Player - Competition Dashboard

17.2. Market Share Analysis (%), 2022

17.3. Company Profiles (Details - Company Overview, Sales Area/Geographical Presence, Financial/Revenue, Strategy & Business Overview, Sales Channel Analysis, Size Portfolio)

17.3.1. EMI Corporation

17.3.1.1. Company Overview

17.3.1.2. Sales Area/Geographical Presence

17.3.1.3. Financial/Revenue

17.3.1.4. Strategy & Business Overview

17.3.1.5. Sales Channel Analysis

17.3.1.6. Size Portfolio

17.3.2. EWIKON Heißkanalsysteme GmbH

17.3.2.1. Company Overview

17.3.2.2. Sales Area/Geographical Presence

17.3.2.3. Financial/Revenue

17.3.2.4. Strategy & Business Overview

17.3.2.5. Sales Channel Analysis

17.3.2.6. Size Portfolio

17.3.3. Gammaflux L.P.

17.3.3.1. Company Overview

17.3.3.2. Sales Area/Geographical Presence

17.3.3.3. Financial/Revenue

17.3.3.4. Strategy & Business Overview

17.3.3.5. Sales Channel Analysis

17.3.3.6. Size Portfolio

17.3.4. GÜNTHER Heisskanaltechnik GmbH

17.3.4.1. Company Overview

17.3.4.2. Sales Area/Geographical Presence

17.3.4.3. Financial/Revenue

17.3.4.4. Strategy & Business Overview

17.3.4.5. Sales Channel Analysis

17.3.4.6. Size Portfolio

17.3.5. Hillenbrand, Inc. (Mold-Masters)

17.3.5.1. Company Overview

17.3.5.2. Sales Area/Geographical Presence

17.3.5.3. Financial/Revenue

17.3.5.4. Strategy & Business Overview

17.3.5.5. Sales Channel Analysis

17.3.5.6. Size Portfolio

17.3.6. Husky Injection Molding Systems Ltd

17.3.6.1. Company Overview

17.3.6.2. Sales Area/Geographical Presence

17.3.6.3. Financial/Revenue

17.3.6.4. Strategy & Business Overview

17.3.6.5. Sales Channel Analysis

17.3.6.6. Size Portfolio

17.3.7. INglass S.p.A

17.3.7.1. Company Overview

17.3.7.2. Sales Area/Geographical Presence

17.3.7.3. Financial/Revenue

17.3.7.4. Strategy & Business Overview

17.3.7.5. Sales Channel Analysis

17.3.7.6. Size Portfolio

17.3.8. Meusburger Georg GmbH & Co KG

17.3.8.1. Company Overview

17.3.8.2. Sales Area/Geographical Presence

17.3.8.3. Financial/Revenue

17.3.8.4. Strategy & Business Overview

17.3.8.5. Sales Channel Analysis

17.3.8.6. Size Portfolio

17.3.9. Seiki Corporation

17.3.9.1. Company Overview

17.3.9.2. Sales Area/Geographical Presence

17.3.9.3. Financial/Revenue

17.3.9.4. Strategy & Business Overview

17.3.9.5. Sales Channel Analysis

17.3.9.6. Size Portfolio

17.3.10. YUDO Holdings Co., Ltd.

17.3.10.1. Company Overview

17.3.10.2. Sales Area/Geographical Presence

17.3.10.3. Financial/Revenue

17.3.10.4. Strategy & Business Overview

17.3.10.5. Sales Channel Analysis

17.3.10.6. Size Portfolio

17.3.11. Other Key Players

17.3.11.1. Company Overview

17.3.11.2. Sales Area/Geographical Presence

17.3.11.3. Financial/Revenue

17.3.11.4. Strategy & Business Overview

17.3.11.5. Sales Channel Analysis

17.3.11.6. Size Portfolio

18. Go To Market Strategy

18.1. Identification of Potential Market Spaces

18.2. Understanding Buying Process of Customers

18.3. Preferred Sales & Marketing Strategy

List of Tables

Table 1: Global Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 2: Global Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 3: Global Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 4: Global Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 5: Global Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 6: Global Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 7: Global Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 8: Global Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 9: Global Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 10: Global Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 11: Global Hot Runner Temperature Controller Market Value, by Region, US$ Mn, 2017-2031

Table 12: Global Hot Runner Temperature Controller Market Volume, by Region, Thousand Units, 2017-2031

Table 13: North America Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 14: North America Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 15: North America Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 16: North America Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 17: North America Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 18: North America Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 19: North America Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 20: North America Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 21: North America Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 22: North America Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 23: North America Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Table 24: North America Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Table 25: Europe Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 26: Europe Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 27: Europe Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 28: Europe Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 29: Europe Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 30: Europe Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 31: Europe Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 32: Europe Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 33: Europe Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 34: Europe Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 35: Europe Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Table 36: Europe Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Table 37: Asia Pacific Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 38: Asia Pacific Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 39: Asia Pacific Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 40: Asia Pacific Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 41: Asia Pacific Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 42: Asia Pacific Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 43: Asia Pacific Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 44: Asia Pacific Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 45: Asia Pacific Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 46: Asia Pacific Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 47: Asia Pacific Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Table 48: Asia Pacific Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Table 49: Middle East & Africa Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 50: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 51: Middle East & Africa Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 52: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 53: Middle East & Africa Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 54: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 55: Middle East & Africa Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 56: Middle East & Africa Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 57: Middle East & Africa Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 58: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 59: Middle East & Africa Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Table 60: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Table 61: South America Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Table 62: South America Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Table 63: South America Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Table 64: South America Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Table 65: South America Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Table 66: South America Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Table 67: South America Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Table 68: South America Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Table 69: South America Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Table 70: South America Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Table 71: South America Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Table 72: South America Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

List of Figures

Figure 1: Global Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 2: Global Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 3: Global Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 4: Global Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 5: Global Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 6: Global Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 7: Global Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 8: Global Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 9: Global Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 10: Global Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 11: Global Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 12: Global Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 13: Global Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 14: Global Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 15: Global Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 16: Global Hot Runner Temperature Controller Market Value, by Region, US$ Mn, 2017-2031

Figure 17: Global Hot Runner Temperature Controller Market Volume, by Region, Thousand Units, 2017-2031

Figure 18: Global Hot Runner Temperature Controller Market Incremental Opportunity, by Region,2023-2031

Figure 19: North America Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 20: North America Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 21: North America Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 22: North America Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 23: North America Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 24: North America Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 25: North America Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 26: North America Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 27: North America Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 28: North America Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 29: North America Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 30: North America Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 31: North America Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 32: North America Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 33: North America Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 34: North America Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Figure 35: North America Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Figure 36: North America Hot Runner Temperature Controller Market Incremental Opportunity, by Country/Sub-region, 2023-2031

Figure 37: Europe Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 38: Europe Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 39: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 40: Europe Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 41: Europe Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 42: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 43: Europe Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 44: Europe Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 45: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 46: Europe Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 47: Europe Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 48: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 49: Europe Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 50: Europe Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 51: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 52: Europe Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Figure 53: Europe Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Figure 54: Europe Hot Runner Temperature Controller Market Incremental Opportunity, by Country/Sub-region, 2023-2031

Figure 55: Asia Pacific Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 56: Asia Pacific Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 57: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 58: Asia Pacific Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 59: Asia Pacific Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 60: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 61: Asia Pacific Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 62: Asia Pacific Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 63: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 64: Asia Pacific Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 65: Asia Pacific Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 66: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 67: Asia Pacific Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 68: Asia Pacific Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 69: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 70: Asia Pacific Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Figure 71: Asia Pacific Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Figure 72: Asia Pacific Hot Runner Temperature Controller Market Incremental Opportunity, by Country/Sub-region, 2023-2031

Figure 73: Middle East & Africa Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 74: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 75: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 76: Middle East & Africa Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 77: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 78: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 79: Middle East & Africa Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 80: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 81: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 82: Middle East & Africa Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 83: Middle East & Africa Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 84: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 85: Middle East & Africa Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 86: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 87: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 88: Middle East & Africa Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Figure 89: Middle East & Africa Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Figure 90: Middle East & Africa Hot Runner Temperature Controller Market Incremental Opportunity, by Country/Sub-region, 2023-2031

Figure 91: South America Hot Runner Temperature Controller Market Value, by Control Zone, US$ Mn, 2017-2031

Figure 92: South America Hot Runner Temperature Controller Market Volume, by Control Zone, Thousand Units, 2017-2031

Figure 93: South America Hot Runner Temperature Controller Market Incremental Opportunity, by Control Zone 2023-2031

Figure 94: South America Hot Runner Temperature Controller Market Value, by Temperature, US$ Mn, 2017-2031

Figure 95: South America Hot Runner Temperature Controller Market Volume, by Temperature, Thousand Units, 2017-2031

Figure 96: South America Hot Runner Temperature Controller Market Incremental Opportunity, by Temperature 2023-2031

Figure 97: South America Hot Runner Temperature Controller Market Value, by Price, US$ Mn, 2017-2031

Figure 98: South America Hot Runner Temperature Controller Market Volume, by Price, Thousand Units, 2017-2031

Figure 99: South America Hot Runner Temperature Controller Market Incremental Opportunity, by Price, 2023-2031

Figure 100: South America Hot Runner Temperature Controller Market Value, by End-use, US$ Mn, 2017-2031

Figure 101: South America Hot Runner Temperature Controller Market Volume, by End-use, Thousand Units, 2017-2031

Figure 102: South America Hot Runner Temperature Controller Market Incremental Opportunity, by End-use, 2023-2031

Figure 103: South America Hot Runner Temperature Controller Market Value, by Distribution Channel, US$ Mn, 2017-2031

Figure 104: South America Hot Runner Temperature Controller Market Volume, by Distribution Channel, Thousand Units, 2017-2031

Figure 105: South America Hot Runner Temperature Controller Market Incremental Opportunity, by Distribution Channel, 2023-2031

Figure 106: South America Hot Runner Temperature Controller Market Value, by Country/Sub-region, US$ Mn, 2017-2031

Figure 107: South America Hot Runner Temperature Controller Market Volume, by Country/Sub-region, Thousand Units, 2017-2031

Figure 108: South America Hot Runner Temperature Controller Market Incremental Opportunity, by Country/Sub-region, 2023-2031