Reports

Reports

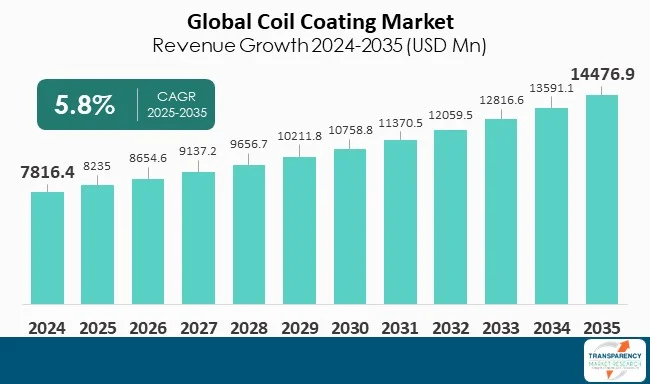

The global Coil Coating Market size was valued at US$ 7.8 billion in 2024 and is projected to reach US$ 14.5 billion by 2035, expanding at a CAGR of 5.8% from 2025 to 2035. The market growth is fueled by rising demand for high-performance coated metals, rapid expansion of construction and automotive sectors, and the shift toward durable, corrosion-resistant, and energy-efficient coating solutions.

Coil coating implies the automated and continuous process by which metals substrates like steel and aluminum are coated with specialized coatings for enhancing their product life by providing superior resistance against corrosion, chemicals, and weathering. These coatings are exclusively designed for UV resistance, preventing corrosion, and providing superior surface finish to the metals.

The coating can be primer topcoat or the surface coat. This pre-painted metal could be used in automotive, building & construction, appliances, HVAC, furniture, and so on.

The pre-coated materials find application in various end-use industries. As a part of industrialization, rapid urbanization, and smart city development, the construction sector has been witnessing a great velocity. Adoption of lightweight solutions is increasing in the automotive sectors. Pre-coated steel and aluminum that provide lightweight solutions along with aesthetic finishes have been a popular replacement.

Furthermore, shift toward greener solutions is increasing these days. The solvent-based coil coating is facing some environmental and safety concerns due to its volatile organic compound (VOC) emission and hazardous components like chromates. So the demand for low VOC and water-based coatings are the ongoing trend in this industry.

Coil coating is the automated and continuous process by which metals substrates like steel and aluminum are coated with specialized coatings to enhance their product life by providing superior resistance against corrosion, chemicals, and weathering. The coil coated products are used in diverse industries including construction sector.

| Attribute | Details |

|---|---|

| Coil Coating Market Drivers |

|

As a part of industrialization, rapid urbanization, and smart city development, the construction sector has been growing at a noticeable rate. The pre-coated materials find application in the construction sector as roofing sheets, panels, wall cladding, facades, doors, window frames, and shutters. In the construction business, coil coating is commonly used to improve the longevity, attractiveness, and performance of metal components found in both - residential and commercial buildings. Another factor fueling the market is that of the changing preference of the architects. In this modern world the builders and architects are preferring materials that can provide flexibility in design, wide spectrum of colors, superior finishes, and the other special functionalities such as anti-bacterial properties. This design freedom will provide innovative, aesthetic, and sustainable construction practices along with long-lasting and durable finishes.

Moreover, the coil coating industry is moving toward sustainable solutions as the convectional coatings would release VOC that raises safety and health concerns for humans as well as the environment.

The automotive industry, for improving fuel efficiency, reducing emissions, and enhancing performance, is actively conducting research regarding usage of lightweight material with high performance, resistance against corrosion, and being long lasting. The coil coating materials that have the conditional fulfillment of not only being lightweight and corrosion-resistant but also aesthetically appealing and cost-effective. Coil coating finds applications in automotive industry at interior panels & trims, structural body parts, heat shields, underbody parts, and so on.

Additionally, the clients are more interested in the external design of the automotive. The automotive designers are highly dependent on the coil coated products to provide high gloss customized color schemes, and textures that enhance the overall aesthetics of the vehicle. The coil coated material can produce products with superior surface finishes, uniformity in coating, scratch resistance, and long-term color retention even under extreme environmental conditions.

Moreover, the electric vehicle manufacturers want to reduce the weight of the vehicle while keeping the aesthetic appeal. The coil coated metals could be the solution for both of the problems.

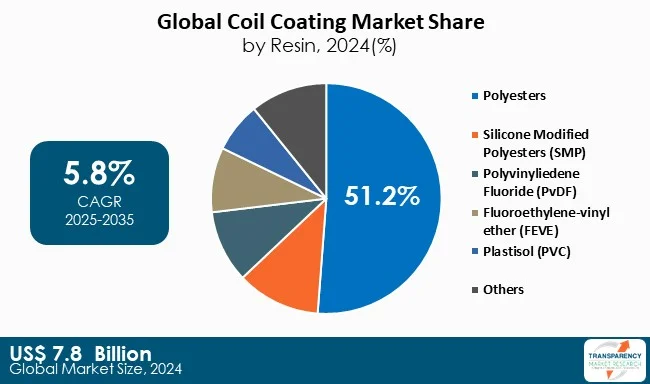

The polyester-based coatings are dominating the coil coating market due to its cost-effectiveness and versatile applications. The polyester coatings are not only cost-effective but also feasible for outdoor use. They have UV resistance along with scratch resistance, and flexibility for general outdoor use. Polyesters are easy to cure, work well with high-speed coil coating lines, and are available from a wide range of global suppliers.

Polyester is followed by the silicon-modified polyester segment. Although silicon-modified polyester is more expensive than regular polyester, it offers better resistance to chalking, fading, and corrosion, particularly in abrasive settings. In order to comply with green building certifications (such as LEED), new generation polyester systems are being developed using waterborne carriers or low-VOC solvents. To achieve sustainability goals several systems, include bio-based or recyclable components.

The construction industry has been witnessing geometric progression as a result of industrialization, rapid urbanization, and the development of smart cities. Pre-coated materials are utilized in the construction industry as wall cladding, doors, window frames, shutters, panels, and roofing sheets. Coil coating is broadly employed in the construction industry to boost the performance, longevity, and aesthetics of metal components used in residential as well as commercial structures. This makes it possible to produce pre-painted aluminum and steel, which can be later manufactured into construction components without the need for post-painting.

In the end-use segmentation the automotive segment is trailing the building & construction segment. The automotive industry is continuously developing lightweight materials that are high-performing, corrosion-resistant, and long-lasting in order to improve performance, optimize fuel efficiency, and lower emissions.

| Attribute | Details |

|---|---|

| Leading Region |

|

Research states that the Asia-Pacific dominates the global coil coating market and is expected to witness the fastest growth over the years to come. The results are due to rapid urbanization & infrastructure growth and cost advantages. The construction industry in the developing Asian countries is growing rapidly due to the fast urbanization. Another important factor is that the low production cost in these countries.

Although global giants lead in production capability, technological innovation, and global reach, the market has lots of regional and niche players serving localized demands and particular categories of materials.

The major players such as Akzo Nobel N.V, PPG Industries, Inc., BASF SE, and Axalta Coating Systems dominate the market with a diverse portfolio of different products for specific application in this market. The other key companies that manufacture coil coating are Nippon Paint Holdings Co., Ltd, Beckers Group, Sherwin-William, Jotun Group, and Kansai Nerolac Paints Limited.

| Attribute | Details |

|---|---|

| Market Size Value in 2024 | US$ 7.8 Bn |

| Market Forecast Value in 2035 | US$ 14.5 Bn |

| Growth Rate (CAGR) | 5.8 % |

| Forecast Period | 2025-2035 |

| Historical Data Available for | 2020-2023 |

| Quantitative Units | Tons For Volume and US$ Bn For Value |

| Market Analysis | It includes cross segment analysis at Global as well as country level. Furthermore, qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Example: Electronic (PDF) + Excel |

| Market Segmentation | By Resin

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled (Potential Manufacturers) |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

The market stood at US$ 7.8 Bn in 2024

The market is expected to grow at a CAGR of 5.8 % from 2025 to 2035

Growing demand for pre-painted metal in the construction sector & rising preference for lightweight and aesthetic materials in automotive manufacturing

Building & Construction held the largest share under end-use segment in 2024

Asia Pacific was the most lucrative region of the coil coating market in 2024

Akzo Nobel N.V, PPG Industries, Inc., BASF SE, Axalta Coating Systems, Nippon Paint Holdings Group, Beckers Group, Sherwin-Williams, Jotun Group, Kansai Nerolac Paints Limited, and Yung Chi Paints

Table 1 Global Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 2 Global Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 3 Global Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 4 Global Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 5 Global Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 6 Global Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 7 Global Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 8 Global Coil Coating Market Value (US$ Bn) Forecast, by Finish, 2020 to 2035

Table 9 Global Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 10 Global Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 11 Global Coil Coating Market Volume (Tons) Forecast, by Region, 2020 to 2035

Table 12 Global Coil Coating Market Value (US$ Bn) Forecast, by Region, 2020 to 2035

Table 13 North America Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 14 North America Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 15 North America Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 16 North America Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 17 North America Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 18 North America Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 19 North America Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 20 North America Coil Coating Market Value (US$ Bn) Forecast, by Finish, 2020 to 2035

Table 21 North America Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 22 North America Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 23 North America Coil Coating Market Volume (Tons) Forecast, by Country, 2020 to 2035

Table 24 North America Coil Coating Market Value (US$ Bn) Forecast, by Country, 2020 to 2035

Table 25 U.S. Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 26 U.S. Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 27 U.S. Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 28 U.S. Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 29 U.S. Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 30 U.S. Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 31 U.S. Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 32 U.S. Coil Coating Market Value (US$ Bn) Forecast, by Finish, 2020 to 2035

Table 33 U.S. Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 34 U.S. Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 35 Canada Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 36 Canada Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 37 Canada Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 38 Canada Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 39 Canada Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 40 Canada Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 41 Canada Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 42 Canada Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 43 Canada Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 44 Canada Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 45 Europe Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 46 Europe Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 47 Europe Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 48 Europe Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 49 Europe Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 50 Europe Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 51 Europe Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 52 Europe Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 53 Europe Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 54 Europe Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 55 Europe Coil Coating Market Volume (Tons) Forecast, by Country and Sub-region, 2020 to 2035

Table 56 Europe Coil Coating Market Value (US$ Bn) Forecast, by Country and Sub-region, 2020 to 2035

Table 57 Germany Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 58 Germany Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 59 Germany Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 60 Germany Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 61 Germany Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 62 Germany Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 63 Germany Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 64 Germany Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 65 Germany Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 66 Germany Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 67 France Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 68 France Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 69 France Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 70 France Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 71 France Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 72 France Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 73 France Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 74 France Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 75 France Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 76 France Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 77 U.K. Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 78 U.K. Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 79 U.K. Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 80 U.K. Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 81 U.K. Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 82 U.K. Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 83 U.K. Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 84 U.K. Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 85 U.K. Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 86 U.K. Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 87 Italy Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 88 Italy Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 89 Italy Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 90 Italy Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 91 Italy Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 92 Italy Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 93 Italy Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 94 Italy Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 95 Italy Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 96 Italy Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 97 Spain Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 98 Spain Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 99 Spain Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 100 Spain Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 101 Spain Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 102 Spain Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 103 Spain Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 104 Spain Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 105 Spain Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 106 Spain Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 107 Russia & CIS Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 108 Russia & CIS Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 109 Russia & CIS Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 110 Russia & CIS Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 111 Russia & CIS Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 112 Russia & CIS Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 113 Russia & CIS Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 114 Russia & CIS Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 115 Russia & CIS Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 116 Russia & CIS Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 117 Rest of Europe Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 118 Rest of Europe Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 119 Rest of Europe Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 120 Rest of Europe Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 121 Rest of Europe Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 122 Rest of Europe Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 123 Rest of Europe Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 124 Rest of Europe Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 125 Rest of Europe Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 126 Rest of Europe Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 127 Asia Pacific Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 128 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 129 Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 130 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 131 Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 132 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 133 Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 134 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 135 Asia Pacific Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 136 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 137 Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Country and Sub-region, 2020 to 2035

Table 138 Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Country and Sub-region, 2020 to 2035

Table 139 China Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 140 China Coil Coating Market Value (US$ Bn) Forecast, By Resin2020 to 2035

Table 141 China Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 142 China Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 143 China Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 144 China Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 145 China Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 146 China Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 147 China Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 148 China Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 149 Japan Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 150 Japan Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 151 Japan Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 152 Japan Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 153 Japan Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 154 Japan Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 155 Japan Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 156 Japan Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 157 Japan Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 158 Japan Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 159 India Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 160 India Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 161 India Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 162 India Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 163 India Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 164 India Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 165 India Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 166 India Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 167 India Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 168 India Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 169 ASEAN Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 170 ASEAN Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 171 ASEAN Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 172 ASEAN Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 173 ASEAN Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 174 ASEAN Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 175 ASEAN Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 176 ASEAN Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 177 ASEAN Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 178 ASEAN Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 179 Rest of Asia Pacific Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 180 Rest of Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 181 Rest of Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 182 Rest of Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 183 Rest of Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 184 Rest of Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 185 Rest of Asia Pacific Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 186 Rest of Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 187 Rest of Asia Pacific Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 188 Rest of Asia Pacific Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 189 Latin America Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 190 Latin America Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 191 Latin America Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 192 Latin America Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 193 Latin America Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 194 Latin America Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 195 Latin America Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 196 Latin America Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 197 Latin America Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 198 Latin America Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 199 Latin America Coil Coating Market Volume (Tons) Forecast, by Country and Sub-region, 2020 to 2035

Table 200 Latin America Coil Coating Market Value (US$ Bn) Forecast, by Country and Sub-region, 2020 to 2035

Table 201 Brazil Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 202 Brazil Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 203 Brazil Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 204 Brazil Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 205 Brazil Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 206 Brazil Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 207 Brazil Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 208 Brazil Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 209 Brazil Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 210 Brazil Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 211 Mexico Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 212 Mexico Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 213 Mexico Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 214 Mexico Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 215 Mexico Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 216 Mexico Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 217 Mexico Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 218 Mexico Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 219 Mexico Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 220 Mexico Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 221 Rest of Latin America Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 222 Rest of Latin America Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 223 Rest of Latin America Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 224 Rest of Latin America Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 225 Rest of Latin America Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 226 Rest of Latin America Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 227 Rest of Latin America Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 228 Rest of Latin America Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 229 Rest of Latin America Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 230 Rest of Latin America Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 231 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 232 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 233 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 234 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 235 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 236 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 237 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 238 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 239 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 240 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 241 Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Country and Sub-region, 2020 to 2035

Table 242 Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Country and Sub-region, 2020 to 2035

Table 243 GCC Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 244 GCC Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 245 GCC Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 246 GCC Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 247 GCC Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 248 GCC Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 249 GCC Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 250 GCC Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 251 GCC Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 252 GCC Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 253 South Africa Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 254 South Africa Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 255 South Africa Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 256 South Africa Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 257 South Africa Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 258 South Africa Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 259 South Africa Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 260 South Africa Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 261 South Africa Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 262 South Africa Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Table 263 Rest of Middle East & Africa Coil Coating Market Volume (Tons) Forecast, By Resin, 2020 to 2035

Table 264 Rest of Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, By Resin, 2020 to 2035

Table 265 Rest of Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Method, 2020 to 2035

Table 266 Rest of Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Method, 2020 to 2035

Table 267 Rest of Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Metal Type, 2020 to 2035

Table 268 Rest of Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Metal Type, 2020 to 2035

Table 269 Rest of Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by Finish, 2020 to 2035

Table 270 Rest of Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by Finish 2020 to 2035

Table 271 Rest of Middle East & Africa Coil Coating Market Volume (Tons) Forecast, by End-use, 2020 to 2035

Table 272 Rest of Middle East & Africa Coil Coating Market Value (US$ Bn) Forecast, by End-use, 2020 to 2035

Figure 1 Global Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 2 Global Coil Coating Market Attractiveness, By Resin

Figure 3 Global Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 4 Global Coil Coating Market Attractiveness, by Method

Figure 5 Global Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 6 Global Coil Coating Market Attractiveness, by Metal Type

Figure 7 Global Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 8 Global Coil Coating Market Attractiveness, by Finish

Figure 9 Global Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 10 Global Coil Coating Market Attractiveness, by End-use

Figure 11 Global Coil Coating Market Volume Share Analysis, by Region, 2024, 2027, and 2035

Figure 12 Global Coil Coating Market Attractiveness, by Region

Figure 13 North America Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 14 North America Coil Coating Market Attractiveness, By Resin

Figure 15 North America Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 16 North America Coil Coating Market Attractiveness, by Method

Figure 17 North America Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 18 North America Coil Coating Market Attractiveness, by Metal Type

Figure 19 North America Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 20 North America Coil Coating Market Attractiveness, by Finish

Figure 21 North America Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 22 North America Coil Coating Market Attractiveness, by End-use

Figure 23 North America Coil Coating Market Volume Share Analysis, by Country and Sub-region, 2024, 2027, and 2035

Figure 24 North America Coil Coating Market Attractiveness, by Country and Sub-region

Figure 25 Europe Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 26 Europe Coil Coating Market Attractiveness, By Resin

Figure 27 Europe Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 28 Europe Coil Coating Market Attractiveness, by Method

Figure 29 Europe Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 30 Europe Coil Coating Market Attractiveness, by Metal Type

Figure 31 Europe Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 32 Europe Coil Coating Market Attractiveness, by Finish

Figure 33 Europe Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 34 Europe Coil Coating Market Attractiveness, by End-use

Figure 35 Europe Coil Coating Market Volume Share Analysis, by Country and Sub-region, 2024, 2027, and 2035

Figure 36 Europe Coil Coating Market Attractiveness, by Country and Sub-region

Figure 37 Asia Pacific Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 38 Asia Pacific Coil Coating Market Attractiveness, By Resin

Figure 39 Asia Pacific Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 40 Asia Pacific Coil Coating Market Attractiveness, by Method

Figure 41 Asia Pacific Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 42 Asia Pacific Coil Coating Market Attractiveness, by Metal Type

Figure 43 Asia Pacific Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 44 Asia Pacific Coil Coating Market Attractiveness, by Finish

Figure 45 Asia Pacific Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 46 Asia Pacific Coil Coating Market Attractiveness, by End-use

Figure 47 Asia Pacific Coil Coating Market Volume Share Analysis, by Country and Sub-region, 2024, 2027, and 2035

Figure 48 Asia Pacific Coil Coating Market Attractiveness, by Country and Sub-region

Figure 49 Latin America Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 50 Latin America Coil Coating Market Attractiveness, By Resin

Figure 51 Latin America Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 52 Latin America Coil Coating Market Attractiveness, by Method

Figure 53 Latin America Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 54 Latin America Coil Coating Market Attractiveness, by Metal Type

Figure 55 Latin America Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 56 Latin America Coil Coating Market Attractiveness, by Finish

Figure 57 Latin America Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 58 Latin America Coil Coating Market Attractiveness, by End-use

Figure 59 Latin America Coil Coating Market Volume Share Analysis, by Country and Sub-region, 2024, 2027, and 2035

Figure 60 Latin America Coil Coating Market Attractiveness, by Country and Sub-region

Figure 61 Middle East & Africa Coil Coating Market Volume Share Analysis, By Resin, 2024, 2027, and 2035

Figure 62 Middle East & Africa Coil Coating Market Attractiveness, By Resin

Figure 63 Middle East & Africa Coil Coating Market Volume Share Analysis, by Method, 2024, 2027, and 2035

Figure 64 Middle East & Africa Coil Coating Market Attractiveness, by Method

Figure 65 Middle East & Africa Coil Coating Market Volume Share Analysis, by Metal Type, 2024, 2027, and 2035

Figure 66 Middle East & Africa Coil Coating Market Attractiveness, by Metal Type

Figure 67 Middle East & Africa Coil Coating Market Volume Share Analysis, by Finish, 2024, 2027, and 2035

Figure 68 Middle East & Africa Coil Coating Market Attractiveness, by Finish

Figure 69 Middle East & Africa Coil Coating Market Volume Share Analysis, by End-use, 2024, 2027, and 2035

Figure 70 Middle East & Africa Coil Coating Market Attractiveness, by End-use

Figure 71 Middle East & Africa Coil Coating Market Volume Share Analysis, by Country and Sub-region, 2024, 2027, and 2035

Figure 72 Middle East & Africa Coil Coating Market Attractiveness, by Country and Sub-region