Reports

Reports

Analysts’ Viewpoint on Case Packers Market Scenario

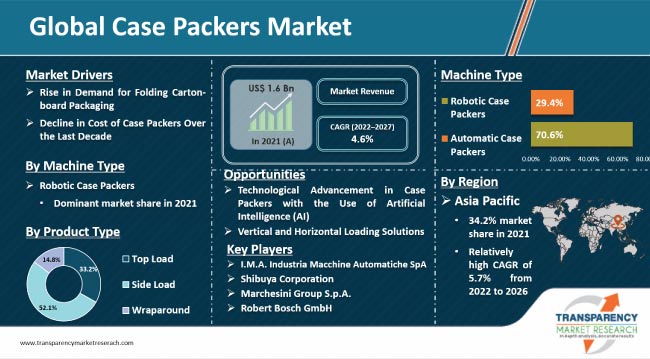

Increase in demand for folding carton-board packaging in various industries and product developments by manufacturers are the key factors expected to drive the global case packers market during the forecast period. Development of the case packer technology has also played a significant role in the growth of the case packers industry. Rise in application of case packers in industries such as food & beverages, pharmaceuticals, and personal care & cosmetics is likely to augment the global case packers market growth forecast. key players in the case packers market need to focus on maintaining the quality of products. They should also concentrate on manufacturing products in various capacities to increase their market share.

Carton-board packaging is widely preferred for secondary packaging over any other method, as it is completely biodegradable. Empty carton can be folded to save space. It does not necessarily require glue for sealing. Carton can be effectively sealed by tucking in the flaps. It provides a wide and easily printable surface for brand promotion and product details. According to an independent study, carton-board packaging crossed the US$ 130 Bn mark in 2018 in terms of value. Demand for carton-board packaging has increased across the globe. However, availability of labor has reduced, as case packing machines provide more productive results than human labor. The need for packaging more and more cartons in much lesser time is rising due to the increase in volume of carton-board packaging in most industries. Thus, rise in demand for carton-board packaging is boosting the case packers market.

The case packers market has been moderately impacted by the COVID-19 pandemic due to supply chain disruption and stringent government regulations. The packaging industry was significantly impacted, as it is directly associated with human interaction. However, food & beverages and pharmaceutical industries remained operational during the COVID-19 pandemic. Shortage in supply of materials resulted in lower production output. The case packers market recovered its losses in 2021 due to the decent rise in demand compared to that in 2020. The case packers market is expected to grow at a decent pace during the forecast period.

Around 50% of case packing machines sold every year are horizontal ones. Demand for horizontal case packing machines is higher across the globe. However, horizontal case packers occupy more shop floor area than vertical case packers. Shop floor consumption of a machine is a major concern for a packaging firm, as it affects shop floor planning, handling, and transport of the machine in case of changes required in the shop floor plan. Therefore, packaging machine manufacturers are striving to reduce the shop floor consumption area of machines and make them more compact, while maintaining the high speed of case packers.

Several packaging machinery manufacturers are focusing on developing technologically advanced case packers to target a large number of customers. The case packing operation is suitable for high volume of products. It costs much more compared to labor wages. Hence, case packer manufacturers are developing machines that are more economical in order to target packaging firms with small output. This is creating lucrative opportunities for manufacturers operating in the global market.

Case packers are ideal for food and beverage products. Based on end use, the food & beverages segment is expected to dominate the global case packers market during the forecast period. Consumption of food and beverages is increasing consistently across the globe. This is likely to directly boost the demand for case packers in the near future.

In terms of machine type, the global case packers market has been classified into robotic case packers and automatic case packers. The robotic case packers segment held major share of the global market in 2021. Robotic cases are preferred over automatic cases, since they are scalable, effective, and ideal for applications that need maximum flexibility.

Asia Pacific held major share of the global case packers market in 2021. It is estimated to maintain its dominance during the forecast period. Recent developments in emerging economies such as India and China have contributed to the growth of the market in the region. Rise in demand for food & beverages and pharmaceutical products; and entry of various regional and global case packer manufacturers are driving the market in India and China. Expanding base of professionals is also expected to augment the demand for case packers in Asia Pacific during the forecasted period. Consistent growth of the market in Asia Pacific can be ascribed to the expansion of the packaging machinery sector in India; low cost of case packers offered by manufacturers in the region; and high demand for case packers in small-scale industries operating in the region. Case packer manufacturers based in India are primarily importing robotic pick & place parts from Japan and China to create revenue streams. The market in North America and Europe is anticipated to witness moderate growth during the forecast period.

The global case packers market is fragmented, with the presence of large number of manufacturers that control majority of the share. Mergers and acquisitions and development of product portfolios are major strategies adopted by key players. The global case packers market assessment report includes various sections such as case packers market drivers, case packers market restraints, case packers market challenges, case packers market pricing analysis, case packers market sales analysis, and case packers market opportunities analysis. It also focuses on case packers market competition analysis, case packers market recent developments, and case packers market demand analysis. Leading players operating in the market include I.M.A. Industria Macchine Automatiche SpA, Shibuya Corporation, Robert Bosch GmbH, Omori Machinery Co. Ltd., and Marchesini Group S.p.A.

Each of these players has been profiled in the global case packers market report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

|

Attribute |

Detail |

|

Market Size Value in 2021 |

US$ 1.6 Bn |

|

Market Forecast Value in 2027 |

US$ 2.1 Bn |

|

Growth Rate (CAGR) |

4.6% (Year-to-Year) |

|

Forecast Period |

2022–2027 |

|

Quantitative Units |

US$ Bn for Value |

|

Market Analysis |

It includes cross-segment analysis at the global as well as regional levels. Moreover, the qualitative analysis includes drivers, restraints, opportunities, key trends, and a parent industry overview. |

|

Competition Landscape |

|

|

Format |

Electronic (PDF) + Excel |

|

Market Segmentation |

|

|

Regions Covered |

|

|

Countries Covered |

|

|

Companies Profiled |

|

|

Customization Scope |

Available upon request |

The global case packers market was valued at US$ 1.6 Bn in 2021

The global case packers market grew at a CAGR of 4.1% during 2014-2021

The global case packers market is projected to reach US$ 2.1 Bn by the end of 2027

The global case packers market is anticipated to grow at a CAGR of 4.6% during 2022-2027

Rise in demand for parenteral diabetic drug packaging solutions is expected to boost the case packers market

Robotic case packers are primarily preferred by case packer manufacturers due to their various benefits

Asia Pacific region is estimated to witness high demand for case packers during the forecast period

I.M.A. Industria Macchine Automatiche SpA, Robert Bosch GmbH, Shibuya Corporation, Omori Machinery Co. Ltd, and Marchesini Group S.p.A.

The China case packers market is anticipated to grow 1.5 times the current market value during the forecast period

The global case packers market is estimated to create a growth opportunity of US$ 498.7 Mn during the forecast period

1. Executive Summary

1.1. Market Overview

1.2. Market Analysis

1.3. TMR Analysis and Recommendations

2. Market Viewpoint

2.1. Market Definition

2.2. Market Taxonomy

3. Case Packers Market Overview

3.1. Introduction

3.2. Global Case Packers Market Overview

3.3. Case Packers Market (US$ Mn) and Forecast

3.4. Value Chain Analysis

3.4.1. Exhaustive List of Active Participants

3.4.1.1. Raw Product Type Suppliers

3.4.1.2. Case Packers Manufacturers

3.4.1.3. End Users

3.4.2. Profitability Margins

3.5. Macro-economic Factors – Correlation Analysis

3.6. Forecast Factors – Relevance & Impact

4. Impact of COVID-19

4.1. Current Statistics and Probable Future Impact

4.2. Impact of COVID-19 on Target Market

5. Case Packers Market Analysis

5.1. Pricing Analysis

5.1.1. Pricing Assumption

5.1.2. Price Projections By Region

5.2. Market Size (US$ Mn) and Forecast

5.2.1. Market Size and Y-o-Y Growth

5.2.2. Absolute $ Opportunity

6. Case Packers Market Dynamics

6.1. Drivers

6.2. Restraints

6.3. Opportunity Analysis

6.4. Trends

7. Global Case Packers Market Analysis and Forecast, By Machine Type

7.1. Introduction

7.1.1. Market share and Basis Points (BPS) Analysis, By Machine Type

7.1.2. Y-o-Y Growth Projections, By Machine Type

7.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

7.2.1. Robotic Case Packers

7.2.2. Automatic Case Packers

7.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027, By Machine Type

7.3.1. Robotic Case Packers

7.3.2. Automatic Case Packers

7.4. Market Attractiveness Analysis, By Machine Type

8. Global Case Packers Market Analysis and Forecast, By Product Type

8.1. Introduction

8.1.1. Market share and Basis Points (BPS) Analysis, By Product Type

8.1.2. Y-o-Y Growth Projections, By Product Type

8.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

8.2.1. Top Load

8.2.2. Side Load

8.2.3. Wraparound

8.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027, By Product Type

8.3.1. Top Load

8.3.2. Side Load

8.3.3. Wraparound

8.4. Market Attractiveness Analysis, By Product Type

9. Global Case Packers Market Analysis and Forecast, By End Use

9.1. Introduction

9.1.1. Market share and Basis Points (BPS) Analysis, By End Use

9.1.2. Y-o-Y Growth Projections, By End Use

9.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

9.2.1. Food & Beverages

9.2.2. Pharmaceuticals

9.2.3. Personal Care and Cosmetics

9.2.4. Homecare

9.2.5. Others

9.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027, By End Use

9.3.1. Food & Beverages

9.3.2. Pharmaceuticals

9.3.3. Personal Care and Cosmetics

9.3.4. Homecare

9.3.5. Others

9.4. Market Attractiveness Analysis, By End Use

10. Global Case Packers Market Analysis and Forecast, By Region

10.1. Introduction

10.1.1. Market share and Basis Points (BPS) Analysis By Region

10.1.2. Y-o-Y Growth Projections By Region

10.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Region

10.2.1. North America

10.2.2. Latin America

10.2.3. Europe

10.2.4. Asia Pacific

10.2.5. Middle East and Africa

10.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 By Region

10.3.1. North America

10.3.2. Latin America

10.3.3. Europe

10.3.4. Asia Pacific

10.3.5. Middle East and Africa

10.4. Market Attractiveness Analysis By Region

11. North America Case Packers Market Analysis and Forecast

11.1. Introduction

11.1.1. Market share and Basis Points (BPS) Analysis, By Country

11.1.2. Y-o-Y Growth Projections, By Country

11.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Country

11.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027, By Country

11.3.1. U.S.

11.3.2. Canada

11.4. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

11.5. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Machine Type

11.5.1. Robotic Case Packers

11.5.2. Automatic Case Packers

11.6. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

11.7. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Product Type

11.7.1. Top Load

11.7.2. Side Load

11.7.3. Wraparound

11.8. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

11.9. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By End Use

11.9.1. Food & Beverages

11.9.2. Pharmaceuticals

11.9.3. Personal Care and Cosmetics

11.9.4. Homecare

11.9.5. Others

11.10. Market Attractiveness Analysis

11.10.1. By Country

11.10.2. By Machine Type

11.10.3. By Product Type

11.10.4. By End Use

12. Latin America Case Packers Market Analysis and Forecast

12.1. Introduction

12.1.1. Market share and Basis Points (BPS) Analysis, By Country

12.1.2. Y-o-Y Growth Projections, By Country

12.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Country

12.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 By Country

12.3.1. Brazil

12.3.2. Mexico

12.3.3. Argentina

12.3.4. Rest of Latin America

12.4. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

12.5. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Machine Type

12.5.1. Robotic Case Packers

12.5.2. Automatic Case Packers

12.6. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

12.7. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Product Type

12.7.1. Top Load

12.7.2. Side Load

12.7.3. Wraparound

12.8. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

12.9. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By End Use

12.9.1. Food & Beverages

12.9.2. Pharmaceuticals

12.9.3. Personal Care and Cosmetics

12.9.4. Homecare

12.9.5. Others

12.10. Market Attractiveness Analysis

12.10.1. By Country

12.10.2. By Machine Type

12.10.3. By Product Type

12.10.4. By End Use

13. Europe Case Packers Market Analysis and Forecast

13.1. Introduction

13.1.1. Market share and Basis Points (BPS) Analysis, By Country

13.1.2. Y-o-Y Growth Projections, By Country

13.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Country

13.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 By Country

13.3.1. Germany

13.3.2. Italy

13.3.3. Spain

13.3.4. Russia

13.3.5. U.K.

13.3.6. France

13.3.7. Benelux

13.3.8. Rest of Europe

13.4. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

13.5. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Machine Type

13.5.1. Robotic Case Packers

13.5.2. Automatic Case Packers

13.6. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

13.7. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Product Type

13.7.1. Top Load

13.7.2. Side Load

13.7.3. Wraparound

13.8. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

13.9. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By End Use

13.9.1. Food & Beverages

13.9.2. Pharmaceuticals

13.9.3. Personal Care and Cosmetics

13.9.4. Homecare

13.9.5. Others

13.10. Market Attractiveness Analysis

13.10.1. By Country

13.10.2. By Machine Type

13.10.3. By Product Type

13.10.4. By End Use

14. Asia Pacific Case Packers Market Analysis and Forecast

14.1. Introduction

14.1.1. Market share and Basis Points (BPS) Analysis, By Country

14.1.2. Y-o-Y Growth Projections, By Country

14.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Country

14.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 By Country

14.3.1. China

14.3.2. India

14.3.3. ASEAN

14.3.4. Australia & New Zealand

14.3.5. Japan

14.3.6. Rest of Asia Pacific

14.4. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

14.5. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Machine Type

14.5.1. Robotic Case Packers

14.5.2. Automatic Case Packers

14.6. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

14.7. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Product Type

14.7.1. Top Load

14.7.2. Side Load

14.7.3. Wraparound

14.8. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

14.9. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By End Use

14.9.1. Food & Beverages

14.9.2. Pharmaceuticals

14.9.3. Personal Care and Cosmetics

14.9.4. Homecare

14.9.5. Others

14.10. Market Attractiveness Analysis

14.10.1. By Country

14.10.2. By Machine Type

14.10.3. By Product Type

14.10.4. By End Use

15. Middle East and Africa Case Packers Market Analysis and Forecast

15.1. Introduction

15.1.1. Market share and Basis Points (BPS) Analysis, By Country

15.1.2. Y-o-Y Growth Projections, By Country

15.2. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Country

15.3. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027, By Country

15.3.1. North Africa

15.3.2. GCC countries

15.3.3. South Africa

15.3.4. Rest of MEA

15.4. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Machine Type

15.5. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Machine Type

15.5.1. Robotic Case Packers

15.5.2. Automatic Case Packers

15.6. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By Product Type

15.7. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By Product Type

15.7.1. Top Load

15.7.2. Side Load

15.7.3. Wraparound

15.8. Historical Market Value (US$ Mn) and Volume (Units), 2014-2021, By End Use

15.9. Market Size (US$ Mn) and Volume (Units) Forecast Analysis 2022-2027 Analysis 2022-2027, By End Use

15.9.1. Food & Beverages

15.9.2. Pharmaceuticals

15.9.3. Personal Care and Cosmetics

15.9.4. Homecare

15.9.5. Others

15.10. Market Attractiveness Analysis

15.10.1. By Country

15.10.2. By Machine Type

15.10.3. By Product Type

15.10.4. By End Use

16. Country wise Case Packers Market Analysis, 2022-2027

16.1. U.S. Case Packers Market Analysis

16.1.1. By Machine Type

16.1.2. By Product Type

16.1.3. By End Use

16.2. Canada Case Packers Market Analysis

16.2.1. By Machine Type

16.2.2. By Product Type

16.2.3. By End Use

16.3. Brazil Case Packers Market Analysis

16.3.1. By Machine Type

16.3.2. By Product Type

16.3.3. By End Use

16.4. Mexico Case Packers Market Analysis

16.4.1. By Machine Type

16.4.2. By Product Type

16.4.3. By End Use

16.5. Argentina Case Packers Market Analysis

16.5.1. By Machine Type

16.5.2. By Product Type

16.5.3. By End Use

16.6. Germany Case Packers Market Analysis

16.6.1. By Machine Type

16.6.2. By Product Type

16.6.3. By End Use

16.7. Spain Case Packers Market Analysis

16.7.1. By Machine Type

16.7.2. By Product Type

16.7.3. By End Use

16.8. France Case Packers Market Analysis

16.8.1. By Machine Type

16.8.2. By Product Type

16.8.3. By End Use

16.9. U.K. Case Packers Market Analysis

16.9.1. By Machine Type

16.9.2. By Product Type

16.9.3. By End Use

16.10. Italy Case Packers Market Analysis

16.10.1. By Machine Type

16.10.2. By Product Type

16.10.3. By End Use

16.11. Benelux Case Packers Market Analysis

16.11.1. By Machine Type

16.11.2. By Product Type

16.11.3. By End Use

16.12. Russia Case Packers Market Analysis

16.12.1. By Machine Type

16.12.2. By Product Type

16.12.3. By End Use

16.13. China Case Packers Market Analysis

16.13.1. By Machine Type

16.13.2. By Product Type

16.13.3. By End Use

16.14. India Case Packers Market Analysis

16.14.1. By Machine Type

16.14.2. By Product Type

16.14.3. By End Use

16.15. Japan Case Packers Market Analysis

16.15.1. By Machine Type

16.15.2. By Product Type

16.15.3. By End Use

17. Competitive Landscape

17.1. Market Structure

17.2. Competition Dashboard

17.3. Company Market Share Analysis

17.4. Company Profiles (Details – Overview, Financials, Strategy, Recent Developments, SWOT analysis)

17.5. Competition Deep Dive (Key Global Market Players)

17.5.1. I.M.A. Industria Machine Automatiche SpA

17.5.1.1. Overview

17.5.1.2. Financials

17.5.1.3. Strategy

17.5.1.4. Recent Developments

17.5.1.5. SWOT Analysis

17.5.2. Shibuya Corporation

17.5.2.1. Overview

17.5.2.2. Financials

17.5.2.3. Strategy

17.5.2.4. Recent Developments

17.5.2.5. SWOT Analysis

17.5.3. Robert Bosch GmbH

17.5.3.1. Overview

17.5.3.2. Financials

17.5.3.3. Strategy

17.5.3.4. Recent Developments

17.5.3.5. SWOT Analysis

17.5.4. Omori Machinery Co. Ltd.

17.5.4.1. Overview

17.5.4.2. Financials

17.5.4.3. Strategy

17.5.4.4. Recent Developments

17.5.4.5. SWOT Analysis

17.5.5. Marchesini Group S.p.A.

17.5.5.1. Overview

17.5.5.2. Financials

17.5.5.3. Strategy

17.5.5.4. Recent Developments

17.5.5.5. SWOT Analysis

17.5.6. Rovema GmbH

17.5.6.1. Overview

17.5.6.2. Financials

17.5.6.3. Strategy

17.5.6.4. Recent Developments

17.5.6.5. SWOT Analysis

17.5.7. Tetra Pak International S.A.

17.5.7.1. Overview

17.5.7.2. Financials

17.5.7.3. Strategy

17.5.7.4. Recent Developments

17.5.7.5. SWOT Analysis

17.5.8. Smurfit Kappa Group

17.5.8.1. Overview

17.5.8.2. Financials

17.5.8.3. Strategy

17.5.8.4. Recent Developments

17.5.8.5. SWOT Analysis

17.5.9. Fuji Machinery Co. Ltd.

17.5.9.1. Overview

17.5.9.2. Financials

17.5.9.3. Strategy

17.5.9.4. Recent Developments

17.5.9.5. SWOT Analysis

17.5.10. Hangzhou Youngsun Intelligent Equipment Co Ltd

17.5.10.1. Overview

17.5.10.2. Financials

17.5.10.3. Strategy

17.5.10.4. Recent Developments

17.5.10.5. SWOT Analysis

17.5.11. Cama Group

17.5.11.1. Overview

17.5.11.2. Financials

17.5.11.3. Strategy

17.5.11.4. Recent Developments

17.5.11.5. SWOT Analysis

17.5.12. Douglas Machine Inc.

17.5.12.1. Overview

17.5.12.2. Financials

17.5.12.3. Strategy

17.5.12.4. Recent Developments

17.5.12.5. SWOT Analysis

17.5.13. Econocorp Inc.

17.5.13.1. Overview

17.5.13.2. Financials

17.5.13.3. Strategy

17.5.13.4. Recent Developments

17.5.13.5. SWOT Analysis

17.5.14. PMI Cartoning Inc.

17.5.14.1. Overview

17.5.14.2. Financials

17.5.14.3. Strategy

17.5.14.4. Recent Developments

17.5.14.5. SWOT Analysis

17.5.15. Bradman Lake Group Ltd.

17.5.15.1. Overview

17.5.15.2. Financials

17.5.15.3. Strategy

17.5.15.4. Recent Developments

17.5.15.5. SWOT Analysis

17.5.16. Jacob White Packaging Ltd

17.5.16.1. Overview

17.5.16.2. Financials

17.5.16.3. Strategy

17.5.16.4. Recent Developments

17.5.16.5. SWOT Analysis

17.5.17. ADCO Manufacturing

17.5.17.1. Overview

17.5.17.2. Financials

17.5.17.3. Strategy

17.5.17.4. Recent Developments

17.5.17.5. SWOT Analysis

17.5.18. Premier Tech Chronos

17.5.18.1. Overview

17.5.18.2. Financials

17.5.18.3. Strategy

17.5.18.4. Recent Developments

17.5.18.5. SWOT Analysis

17.5.19. Schneider Packaging Equipment Co. Inc.

17.5.19.1. Overview

17.5.19.2. Financials

17.5.19.3. Strategy

17.5.19.4. Recent Developments

17.5.19.5. SWOT Analysis

17.5.20. Brenton LLC

17.5.20.1. Overview

17.5.20.2. Financials

17.5.20.3. Strategy

17.5.20.4. Recent Developments

17.5.20.5. SWOT Analysis

18. Assumptions and Acronyms Used

19. Research Methodology

List of Tables

Table 01: Global Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 02: Global Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 03: Global Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 04: Global Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 05: Global Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 06: Global Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 07: Global Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 08: Global Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 09: Global Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 10: Global Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 11: Global Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 12: Global Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 13: Global Case Packers Market Historic Value (US$ Mn), By Region 2014(H)-2021(A)

Table 14: Global Case Packers Market Forecast Value (US$ Mn), By Region 2022(E)-2027(F)

Table 15: Global Case Packers Market Historic Volume (Units), By Region 2014(H)-2021(A)

Table 16: Global Case Packers Market Forecast Volume (Units), By Region 2022(E)-2027(F)

Table 17: North America Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 18: North America Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 19: North America Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 20: North America Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 21: North America Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 22: North America Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 23: North America Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 24: North America Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 25: North America Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 26: North America Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 27: North America Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 28: North America Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 29: North America Case Packers Market Historic Value (US$ Mn), By Country 2014(H)-2021(A)

Table 30: North America Case Packers Market Forecast Value (US$ Mn), By Country 2022(E)-2027(F)

Table 31: North America Case Packers Market Historic Volume (Units), By Country 2014(H)-2021(A)

Table 32: North America Case Packers Market Forecast Volume (Units), By Country 2022(E)-2027(F)

Table 33: Latin America Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 34: Latin America Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 35: Latin America Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 36: Latin America Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 37: Latin America Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 38: Latin America Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 39: Latin America Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 40: Latin America Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 41: Latin America Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 42: Latin America Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 43: Latin America Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 44: Latin America Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 45: Latin America Case Packers Market Historic Value (US$ Mn), By Country 2014(H)-2021(A)

Table 46: Latin America Case Packers Market Forecast Value (US$ Mn), By Country 2022(E)-2027(F)

Table 47: Latin America Case Packers Market Historic Volume (Units), By Country 2014(H)-2021(A)

Table 48: Latin America Case Packers Market Forecast Volume (Units), By Country 2022(E)-2027(F)

Table 49: Europe Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 50: Europe Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 51: Europe Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 52: Europe Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 53: Europe Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 54: Europe Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 55: Europe Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 56: Europe Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 57: Europe Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 58: Europe Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 59: Europe Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 60: Europe Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 61: Europe Case Packers Market Historic Value (US$ Mn), By Country 2014(H)-2021(A)

Table 62: Europe Case Packers Market Forecast Value (US$ Mn), By Country 2022(E)-2027(F)

Table 63: Europe Case Packers Market Historic Volume (Units), By Country 2014(H)-2021(A)

Table 64: Europe Case Packers Market Forecast Volume (Units), By Country 2022(E)-2027(F)

Table 65: Asia Pacific Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 66: Asia Pacific Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 67: Asia Pacific Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 68: Asia Pacific Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 69: Asia Pacific Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 70: Asia Pacific Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 71: Asia Pacific Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 72: Asia Pacific Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 73: Asia Pacific Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 74: Asia Pacific Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 75: Asia Pacific Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 76: Asia Pacific Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 77: Asia Pacific Case Packers Market Historic Value (US$ Mn), By Country 2014(H)-2021(A)

Table 78: Asia Pacific Case Packers Market Forecast Value (US$ Mn), By Country 2022(E)-2027(F)

Table 79: Asia Pacific Case Packers Market Historic Volume (Units), By Country 2014(H)-2021(A)

Table 80: Asia Pacific Case Packers Market Forecast Volume (Units), By Country 2022(E)-2027(F)

Table 81: MEA Case Packers Market Historic Value (US$ Mn), By Machine Type 2014(H)-2021(A)

Table 82: MEA Case Packers Market Forecast Value (US$ Mn), By Machine Type 2022(E)-2027(F)

Table 83: MEA Case Packers Market Historic Volume (Units), By Machine Type 2014(H)-2021(A)

Table 84: MEA Case Packers Market Forecast Volume (Units), By Machine Type 2022(E)-2027(F)

Table 85: MEA Case Packers Market Historic Value (US$ Mn), By Product Type 2014(H)-2021(A)

Table 86: MEA Case Packers Market Forecast Value (US$ Mn), By Product Type 2022(E)-2027(F)

Table 87: MEA Case Packers Market Historic Volume (Units), By Product Type 2014(H)-2021(A)

Table 88: MEA Case Packers Market Forecast Volume (Units), By Product Type 2022(E)-2027(F)

Table 89: MEA Case Packers Market Historic Value (US$ Mn), By End Use 2014(H)-2021(A)

Table 90: MEA Case Packers Market Forecast Value (US$ Mn), By End Use 2022(E)-2027(F)

Table 91: MEA Case Packers Market Historic Volume (Units), By End Use 2014(H)-2021(A)

Table 92: MEA Case Packers Market Forecast Volume (Units), By End Use 2022(E)-2027(F)

Table 93: MEA Case Packers Market Historic Value (US$ Mn), By Country 2014(H)-2021(A)

Table 94: MEA Case Packers Market Forecast Value (US$ Mn), By Country 2022(E)-2027(F)

Table 95: MEA Case Packers Market Historic Volume (Units), By Country 2014(H)-2021(A)

Table 96: MEA Case Packers Market Forecast Volume (Units), By Country 2022(E)-2027(F)

List of Figures

Figure 01: Global Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 02: Global Case Packers Market Attractiveness Analysis by Machine Type, 2022E-2027F

Figure 03: Global Case Packers Market Y-o-Y Analysis by Machine Type, 2019H-2027F

Figure 04: Global Case Packers Market Share Analysis by Product Type, 2022E & 2027F

Figure 05: Global Case Packers Market Attractiveness Analysis by Product Type, 2022E-2027F

Figure 06: Global Case Packers Market Y-o-Y Analysis by Product Type, 2019H-2027F

Figure 07: Global Case Packers Market Share Analysis by End Use, 2022E & 2027F

Figure 08: Global Case Packers Market Attractiveness Analysis by End Use, 2022E-2027F

Figure 09: Global Case Packers Market Y-o-Y Analysis by End Use, 2019H-2027F

Figure 10: Global Case Packers Market Share Analysis by Region, 2022E & 2027F

Figure 11: Global Case Packers Market Attractiveness Analysis by Region, 2022E-2027F

Figure 12: Global Case Packers Market Y-o-Y Analysis by Region, 2019H-2027F

Figure 13: North America Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 14: North America Case Packers Market Value Share Analysis by Product Type 2022(E)

Figure 15: North America Case Packers Market Value Share Analysis by End Use 2022(E)

Figure 16: North America Case Packers Market Value Share Analysis by Country 2022(E)

Figure 17: Latin America Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 18: Latin America Case Packers Market Value Share Analysis by Product Type 2022(E)

Figure 19: Latin America Case Packers Market Value Share Analysis by End Use 2022(E)

Figure 20: Latin America Case Packers Market Value Share Analysis by Country 2022(E)

Figure 21: Europe Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 22: Europe Case Packers Market Value Share Analysis by Product Type 2022(E)

Figure 23: Europe Case Packers Market Value Share Analysis by End Use 2022(E)

Figure 24: Europe Case Packers Market Value Share Analysis by Country 2022(E)

Figure 25: Asia Pacific Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 26: Asia Pacific Case Packers Market Value Share Analysis by Product Type 2022(E)

Figure 27: Asia Pacific Case Packers Market Value Share Analysis by End Use 2022(E)

Figure 28: Asia Pacific Case Packers Market Value Share Analysis by Country 2022(E)

Figure 29: MEA Case Packers Market Share Analysis by Machine Type, 2022E & 2027F

Figure 30: MEA Case Packers Market Value Share Analysis by Product Type 2022(E)

Figure 31: MEA Case Packers Market Value Share Analysis by End Use 2022(E)

Figure 32: MEA Case Packers Market Value Share Analysis by Country 2022(E)

Figure 33: U.S. Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 34: U.S. Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 35: U.S. Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 36: Canada Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 37: Canada Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 38: Canada Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 39: Brazil Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 40: Brazil Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 41: Brazil Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 42: Mexico Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 43: Mexico Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 44: Mexico Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 45: Argentina Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 46: Argentina Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 47: Argentina Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 48: Germany Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 49: Germany Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 50: Germany Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 51: Spain Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 52: Spain Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 53: Spain Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 54: France Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 55: France Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 56: France Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 57: U.K. Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 58: U.K. Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 59: U.K. Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 60: Italy Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 61: Italy Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 62: Italy Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 63: Russia Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 64: Russia Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 65: Russia Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 66: China Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 67: China Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 68: China Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 69: India Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 70: India Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 71: India Case Packers Market Value Share Analysis, by End Use, 2022E

Figure 72: Japan Case Packers Market Value Share Analysis, by Machine Type, 2022E & 2027F

Figure 73: Japan Case Packers Market Value Share Analysis, by Product Type, 2022E

Figure 74: Japan Case Packers Market Value Share Analysis, by Product Type, 2022E