Reports

Reports

Analysts’ Viewpoint

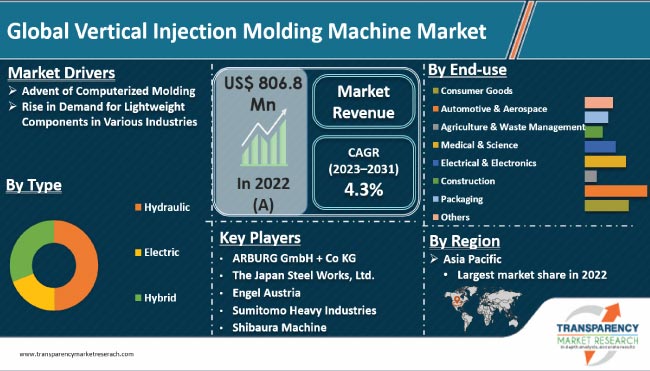

Rise in usage of robotics in the production of plastics, including injection molding related processes, and growth in demand for lightweight components in various industries are key factors driving the vertical injection molding machine market value. Vertical injection molding machines are more energy-efficient than horizontal machines, particularly in applications such as automotive parts, electronic components, and consumer goods. This is also augmenting market statistics.

Upright injection molding machines take advantage of gravity during the injection process. With vertical machines, the clamping unit and injection unit are typically in a stationary position for a significant portion of the molding cycle. This helps reduce energy consumption associated with continuous movement. Manufacturers of vertical injection molding equipment and vertical injection molding systems are investing significantly in R&D activities to introduce new and innovative technologies to increase their market share.

Vertical injection molding machine is used in the plastic manufacturing sector to produce molded plastic parts. Unlike horizontal injection molding machine, which has a horizontal clamping unit, vertical machine possesses a vertically oriented clamping unit and an injection unit that moves vertically.

Vertical machines are particularly suitable for insert molding applications. In insert molding, metal or other components are placed into the mold before plastic injection. Vertical machines have a smaller footprint compared to horizontal injection molding machines. They take up less floor space, which makes them ideal for manufacturing environments with limited space. The compact design allows for better optimization of factory layouts and increases overall efficiency.

Vertical injection molding press is particularly suitable for insert molding, where metal or other components are inserted into the mold before plastic injection. The vertical orientation allows gravity to assist in the insertion process.

Vertical injection molding machines are used to produce a wide range of plastic products, including automotive parts, medical devices, and consumer goods. Thus, rise in usage of these machines in the manufacture of various products is boosting vertical injection molding machine market size.

Industrial robots are being increasingly used in most areas of plastic production, from loading components into the injection molding machine to finishing and assembling of injection molded parts. Usage of robotics provides plastics manufacturers with a competitive advantage, with marked increase in productivity and quality of products.

Newbury's vertical molding machines are designed with features that lend themselves for automation. Having robotic integration as a standard option allows the customer to purchase a C-Frame rotary table machine complete with the necessary features required for tie-in of a robot.

The rotary table can present mold tooling directly to the molding press. This option is targeted towards customers who do not intend on running the machine initially with operators. The customer can send the machine directly to an automation source for immediate integration of robotics and other devices. The automation source can then provide the customer with a turn-key system, which includes insert presentation, molding, and part removal.

Thus, advent of computerized molding in plastics production is augmenting vertical injection molding machine market growth.

Vertical injection molding machines are used in the production of a wide range of lightweight plastic parts and components. Thus, these machines are essential equipment in industries such as automotive, electronics, packaging, healthcare, and consumer goods.

One of the key advantages of vertical injection molding machines is their ability to produce complex and intricate parts with high precision. These machines use a vertical clamping unit and an injection unit that moves vertically, thus allowing for efficient and accurate molding of plastic components. This capability is particularly valuable in industries such as electronics and medical, which require small and precise parts.

Growth in the automotive sector is a key factor driving vertical injection molding machine market demand. Plastic components are increasingly replacing metal parts in cars due to their lighter weight, improved fuel efficiency, and cost-effectiveness.

The packaging industry also relies on vertical injection molding machines for the production of plastic containers, caps, closures, and other packaging solutions. Rise in demand for packaged products, especially in the food and beverage sector, is encouraging companies in vertical injection machine market to develop efficient and reliable equipment to meet the production demands.

The consumer goods industry, including sectors such as appliances, toys, and electronics, relies significantly on plastic components for product manufacturing. Vertical injection molding machines offer versatility in producing a wide range of plastic parts, thus enabling manufacturers to meet diverse consumer demands.

Thus, increase in demand for plastic components in various industries, driven by factors such as light weight, cost-effectiveness, and precision requirements, is boosting vertical injection molding machine industry growth.

In terms of type, the vertical injection molding machine market segmentation entails hydraulic, electric, and hybrid segments. Of these, the hydraulic segment held large share of 50.0% in 2022. The segment is anticipated to grow at a significant pace during the forecast period.

Hydraulic systems can generate high clamping forces, thereby allowing the machine to securely hold the mold during the injection process. Hydraulic machines are generally more cost-effective compared to other types of injection molding machines such as all-electric machines. They have lower initial purchase cost and are often more affordable to maintain and repair.

Asia Pacific accounted for significant vertical injection molding machine market share in 2022. This trend is projected to continue during the forecast period.

Asia Pacific is anticipated to offer immense vertical injection molding machine market opportunities to manufacturers, due to substantial growth in automotive and consumer goods industries in the region. Increase in urbanization is also driving market progress in Asia Pacific.

As per the vertical injection molding machine market analysis, Europe constituted 32.4% share in 2022. The region is anticipated to hold market share of 31.8% by the end of the forecast period.

According to the vertical injection molding machine industry research report, the global landscape is highly fragmented, with the presence of various companies. Most of the businesses are spending significantly in R&D activities to introduce cutting-edge technologies in order to increase their vertical injection molding machine market share.

ARBURG GmbH + Co KG, The Japan Steel Works, Ltd., Engel Austria, Sumitomo Heavy Industries, and Shibaura Machine (Toshiba Machine Co., Ltd) are some of the prominent players operating in the global market.

Each of these companies has been summarized in the vertical injection molding machine market report based on parameters such as financial overview, business strategies, company overview, recent developments, and product portfolio.

| Attribute | Detail |

|---|---|

|

Market Size Value in 2022 |

US$ 806.8 Mn |

|

Market Forecast Value in 2031 |

US$ 1.2 Bn |

|

Growth Rate (CAGR) |

4.3% |

|

Forecast Period |

2023-2031 |

|

Historical Data Available for |

2021 |

|

Quantitative Units |

US$ Mn/Bn for Value and Units for Volume |

|

Market Analysis |

It includes cross-segment analysis at the global as well as regional level. Furthermore, the qualitative analysis includes drivers, restraints, business opportunities, key market trends, Porter’s Five Forces analysis, and value chain analysis. |

|

Competition Landscape |

|

|

Format |

Electronic (PDF) + Excel |

|

Market Segmentation |

|

|

Regions Covered |

|

|

Countries Covered |

|

|

Companies Profiled |

|

|

Customization Scope |

Available upon request |

|

Pricing |

Available upon request |

It was valued at US$ 806.8 Mn in 2022

It is likely to grow at a CAGR of 4.3% from 2023 to 2031

Advent of computerized molding and rise in demand for lightweight components in various industries

Hydraulic was the largest type segment in 2022

Asia Pacific was the highly lucrative region that held major share of 35.4% share in 2022

ARBURG GmbH + Co KG, The Japan Steel Works, Ltd., Engel Austria, Sumitomo Heavy Industries, and Shibaura Machine (Toshiba Machine Co., Ltd)

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

2.6.1. Global Vertical Injection Molding Machine Market Volume (Units)

2.6.2. Global Vertical Injection Molding Machine Market Revenue (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Raw Material Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealers/Distributors

2.9.4. List of Potential Customers

2.10. Production Overview

2.11. Product Specification Analysis

2.11.1. Cost Structure Analysis

3. Economic Recovery Post COVID-19 Impact

3.1. Impact on the Supply Chain of the Vertical Injection Molding Machine

3.2. Impact on the Demand of Vertical Injection Molding Machine- Pre & Post Crisis

4. Impact of Current Geopolitical Scenario

5. Production Output Analysis (Units), by Region, 2022

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East and Africa

6. Price Trend Analysis and Forecast (US$/Unit), 2023-2031

6.1. Price Comparison Analysis by Input Material Vs. Clamping Force

6.2. Price Comparison Analysis by Region

7. Global Vertical Injection Molding Machine Market Analysis and Forecast, by Input Material Vs. Clamping Force, 2023-2031

7.1. Introduction and Definitions

7.2. Global Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

7.2.1. Plastic

7.2.1.1. Up to 20 Tons

7.2.1.2. 21 Tons to 40 Tons

7.2.1.3. 41 Tons to 50 Tons

7.2.1.4. 51 tons to 70 Tons

7.2.1.5. 71 Tons to 80 Tons

7.2.1.6. 81 Tons to 100 Tons

7.2.1.7. >100 Tons

7.2.2. Rubber

7.2.2.1. Up to 20 Tons

7.2.2.2. 21 Tons to 40 Tons

7.2.2.3. 41 Tons to 50 Tons

7.2.2.4. 51 tons to 70 Tons

7.2.2.5. 71 Tons to 80 Tons

7.2.2.6. 81 Tons to 100 Tons

7.2.2.7. >100 Tons

7.2.3. Others

7.2.3.1. Up to 20 Tons

7.2.3.2. 21 Tons to 40 Tons

7.2.3.3. 41 Tons to 50 Tons

7.2.3.4. 51 tons to 70 Tons

7.2.3.5. 71 Tons to 80 Tons

7.2.3.6. 81 Tons to 100 Tons

7.2.3.7. >100 Tons

7.3. Global Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

8. Global Vertical Injection Molding Machine Market Analysis and Forecast, by Type, 2023-2031

8.1. Introduction and Definitions

8.2. Global Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

8.2.1. Hydraulic

8.2.2. Electric

8.2.3. Hybrid

8.3. Global Vertical Injection Molding Machine Market Attractiveness, by Type

9. Global Vertical Injection Molding Machine Market Analysis and Forecast, Automation Grade, 2023-2031

9.1. Introduction and Definitions

9.2. Global Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

9.2.1. Automatic

9.2.2. Semi-automatic

9.3. Global Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

10. Global Vertical Injection Molding Machine Market Analysis and Forecast, End-use, 2023-2031

10.1. Introduction and Definitions

10.2. Global Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

10.2.1. Consumer Goods

10.2.2. Automotive & Aerospace

10.2.3. Agriculture & Waste Management

10.2.4. Medical & Science

10.2.5. Electrical & Electronics

10.2.6. Construction

10.2.7. Packaging

10.2.8. Others

10.3. Global Vertical Injection Molding Machine Market Attractiveness, by End-use

11. Global Vertical Injection Molding Machine Market Analysis and Forecast, by Region, 2023-2031

11.1. Key Findings

11.2. Global Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Region, 2023-2031

11.2.1. North America

11.2.2. Europe

11.2.3. Asia Pacific

11.2.4. Latin America

11.2.5. Middle East & Africa

11.3. Global Vertical Injection Molding Machine Market Attractiveness, by Region

12. North America Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. North America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

12.3. North America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4. North America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

12.5. North America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.6. North America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Country, 2023-2031

12.6.1. U.S. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

12.6.2. U.S. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.6.3. U.S. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

12.6.4. U.S. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

12.6.5. Canada Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

12.6.6. Canada Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.6.7. Canada Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

12.6.8. Canada Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

12.7. North America Vertical Injection Molding Machine Market Attractiveness Analysis

13. Europe Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.3. Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.4. Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.5. Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.6. Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

13.6.1. Germany Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.2. Germany Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.3. Germany Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.4. Germany Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.5. France Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.6. France Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.7. France Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.8. France Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.9. U.K. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.10. U.K. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.11. U.K. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.12. U.K. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.13. Italy Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.14. Italy. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.15. Italy Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.16. Italy Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.17. Spain Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.18. Spain. Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.19. Italy Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2022- Spain

13.6.20. Spain Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.21. Russia & CIS Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.22. Russia & CIS Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.23. Russia & CIS Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.24. Russia & CIS Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.6.25. Rest of Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

13.6.26. Rest of Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.6.27. Rest of Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

13.6.28. Rest of Europe Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

13.7. Europe Vertical Injection Molding Machine Market Attractiveness Analysis

14. Asia Pacific Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force

14.3. Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.4. Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.5. Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

14.6. Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

14.6.1. China Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

14.6.2. China Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.6.3. China Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.6.4. China Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

14.6.5. Japan Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

14.6.6. Japan Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.6.7. Japan Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.6.8. Japan Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

14.6.9. India Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

14.6.10. India Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.6.11. India Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.6.12. India Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

14.6.13. ASEAN Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

14.6.14. ASEAN Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.6.15. ASEAN Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.6.16. ASEAN Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

14.6.17. Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

14.6.18. Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.6.19. Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

14.6.20. Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

14.7. Asia Pacific Vertical Injection Molding Machine Market Attractiveness Analysis

15. Latin America Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

15.1. Key Findings

15.2. Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

15.3. Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.4. Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

15.5. Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

15.6. Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

15.6.1. Brazil Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

15.6.2. Brazil Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.6.3. Brazil Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

15.6.4. Brazil Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

15.6.5. Mexico Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

15.6.6. Mexico Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.6.7. Mexico Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

15.6.8. Mexico Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

15.6.9. Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

15.6.10. Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.6.11. Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

15.6.12. Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

15.7. Latin America Vertical Injection Molding Machine Market Attractiveness Analysis

16. Middle East & Africa Vertical Injection Molding Machine Market Analysis and Forecast, 2023-2031

16.1. Key Findings

16.2. Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

16.3. Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

16.4. Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

16.5. Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2023-2031

16.6. Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

16.6.1. GCC Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

16.6.2. GCC Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

16.6.3. GCC Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

16.6.4. GCC Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

16.6.5. South Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

16.6.6. South Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

16.6.7. South Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

16.6.8. South Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

16.6.9. Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

16.6.10. Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Type, 2023-2031

16.6.11. Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

16.6.12. Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) and Value (US$ Mn) Forecast, End-use, 2023-2031

16.7. Middle East & Africa Vertical Injection Molding Machine Market Attractiveness Analysis

17. Competition Landscape

17.1. Market Players - Competition Matrix (by Tier and Size of Companies)

17.2. Market Share Analysis, 2022

17.3. Market Footprint Analysis

17.3.1. By Automation Grade

17.3.2. By End-use

17.4. Company Profiles (Details - Overview, Financials, Recent Developments, and Strategy)

17.4.1. ARBURG GmbH + Co KG

17.4.1.1. Company Revenue

17.4.1.2. Business Overview

17.4.1.3. Product Segments

17.4.1.4. Geographic Footprint

17.4.1.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.1.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.2. The Japan Steel Works, LTD.

17.4.2.1. Company Revenue

17.4.2.2. Business Overview

17.4.2.3. Product Segments

17.4.2.4. Geographic Footprint

17.4.2.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.2.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.3. Nissei Plastic Industrial Co., Ltd

17.4.3.1. Company Revenue

17.4.3.2. Business Overview

17.4.3.3. Product Segments

17.4.3.4. Geographic Footprint

17.4.3.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.3.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.4. Sumitomo Heavy Industries

17.4.4.1. Company Revenue

17.4.4.2. Business Overview

17.4.4.3. Product Segments

17.4.4.4. Geographic Footprint

17.4.4.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.4.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.5. Engel Austria

17.4.5.1. Company Revenue

17.4.5.2. Business Overview

17.4.5.3. Product Segments

17.4.5.4. Geographic Footprint

17.4.5.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.5.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.6. Milacron Holdings Corp

17.4.6.1. Company Revenue

17.4.6.2. Business Overview

17.4.6.3. Product Segments

17.4.6.4. Geographic Footprint

17.4.6.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.6.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.7. Tayu Machinery Co., Ltd

17.4.7.1. Company Revenue

17.4.7.2. Business Overview

17.4.7.3. Product Segments

17.4.7.4. Geographic Footprint

17.4.7.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.7.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.8. Wittmann Battenfeld GmbH

17.4.8.1. Company Revenue

17.4.8.2. Business Overview

17.4.8.3. Product Segments

17.4.8.4. Geographic Footprint

17.4.8.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.8.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.9. Shibaura Machine (Toshiba Machine Co., Ltd)

17.4.9.1. Company Revenue

17.4.9.2. Business Overview

17.4.9.3. Product Segments

17.4.9.4. Geographic Footprint

17.4.9.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.9.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.10. Pratishna Engineers Ltd

17.4.10.1. Company Revenue

17.4.10.2. Business Overview

17.4.10.3. Product Segments

17.4.10.4. Geographic Footprint

17.4.10.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.10.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.11. Toyo Machinery & Metal Co., Ltd

17.4.11.1. Company Revenue

17.4.11.2. Business Overview

17.4.11.3. Product Segments

17.4.11.4. Geographic Footprint

17.4.11.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.11.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.12. Husky Injection Molding Systems Ltd

17.4.12.1. Company Revenue

17.4.12.2. Business Overview

17.4.12.3. Product Segments

17.4.12.4. Geographic Footprint

17.4.12.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.12.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

17.4.13. Niigata Machine Techno Co., Ltd.

17.4.13.1. Company Revenue

17.4.13.2. Business Overview

17.4.13.3. Product Segments

17.4.13.4. Geographic Footprint

17.4.13.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.13.6. Strategic Partnership, Capacity Expansion, New Product Innovation etc.

18. Primary Research: Key Insights

19. Appendix

List of Tables

Table 1: Global Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 2: Global Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 3: Global Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 4: Global Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 5: Global Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 6: Global Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 7: Global Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 8: Global Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use, 2023-2031

Table 9: Global Vertical Injection Molding Machine Market Volume (Units) Forecast, by Region, 2023-2031

Table 10: Global Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Region, 2023-2031

Table 11: North America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 12: North America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 13: North America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 14: North America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 15: North America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 16: North America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 17: North America Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 18: North America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use, 2023-2031

Table 19: North America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Country, 2023-2031

Table 20: North America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Country, 2023-2031

Table 21: U.S. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 22: U.S. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 23: U.S. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 24: U.S. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 25: U.S. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 26: U.S. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 27: U.S. Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 28: U.S. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use, 2023-2031

Table 29: Canada Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 30: Canada Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 31: Canada Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 32: Canada Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 33: Canada Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 34: Canada Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 35: Canada Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 36: Canada Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 37: Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 38: Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 39: Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 40: Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 41: Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 42: Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 43: Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 44: Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 45: Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Country and Sub-region, 2023-2031

Table 46: Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 47: Germany Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 48: Germany Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 49: Germany Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 50: Germany Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 51: Germany Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 52: Germany Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 53: Germany Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 54: Germany Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 55: France Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 56: France Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 57: France Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 58: France Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 59: France Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 60: France Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 61: France Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 62: France Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 63: U.K. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 64: U.K. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 65: U.K. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 66: U.K. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 67: U.K. Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 68: U.K. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 69: U.K. Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 70: U.K. Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 71: Italy Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 72: Italy Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 73: Italy Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 74: Italy Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 75: Italy Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 76: Italy Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 77: Italy Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 78: Italy Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 79: Spain Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 80: Spain Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 81: Spain Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 82: Spain Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 83: Spain Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 84: Spain Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 85: Spain Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 86: Spain Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 87: Russia & CIS Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 88: Russia & CIS Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 89: Russia & CIS Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 90: Russia & CIS Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 91: Russia & CIS Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 92: Russia & CIS Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 93: Russia & CIS Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 94: Russia & CIS Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 95: Rest of Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 96: Rest of Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 97: Rest of Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 98: Rest of Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 99: Rest of Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 100: Rest of Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 101: Rest of Europe Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 102: Rest of Europe Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 103: Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 104: Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 105: Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 106: Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 107: Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 108: Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 109: Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 110: Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 111: Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Country and Sub-region, 2023-2031

Table 112: Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 113: China Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 114: China Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force 2023-2031

Table 115: China Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 116: China Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 117: China Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 118: China Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 119: China Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 120: China Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 121: Japan Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 122: Japan Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 123: Japan Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 124: Japan Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 125: Japan Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 126: Japan Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 127: Japan Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 128: Japan Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 129: India Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 130: India Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 131: India Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 132: India Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 133: India Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 134: India Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 135: India Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 136: India Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 137: ASEAN Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 138: ASEAN Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 139: ASEAN Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 140: ASEAN Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 141: ASEAN Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 142: ASEAN Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 143: ASEAN Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 144: ASEAN Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 145: Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 146: Rest of Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 147: Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 148: Rest of Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 149: Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 150: Rest of Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 151: Rest of Asia Pacific Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 152: Rest of Asia Pacific Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 153: Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 154: Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 155: Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 156: Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 157: Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 158: Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 159: Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 160: Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 161: Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Country and Sub-region, 2023-2031

Table 162: Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 163: Brazil Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 164: Brazil Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 165: Brazil Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 166: Brazil Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 167: Brazil Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 168: Brazil Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 169: Brazil Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 170: Brazil Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 171: Mexico Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 172: Mexico Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 173: Mexico Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 174: Mexico Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 175: Mexico Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 176: Mexico Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 177: Mexico Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 178: Mexico Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 179: Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 180: Rest of Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 181: Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 182: Rest of Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 183: Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 184: Rest of Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 185: Rest of Latin America Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 186: Rest of Latin America Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 187: Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 188: Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 189: Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 190: Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 191: Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 192: Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 193: Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 194: Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 195: Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Country and Sub-region, 2023-2031

Table 196: Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 197: GCC Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 198: GCC Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 199: GCC Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 200: GCC Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 201: GCC Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 202: GCC Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 203: GCC Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 204: GCC Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 205: South Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 206: South Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 207: South Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 208: South Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 209: South Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 210: South Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 211: South Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 212: South Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

Table 213: Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 214: Rest of Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Input Material Vs. Clamping Force, 2023-2031

Table 215: Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Type, 2023-2031

Table 216: Rest of Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 217: Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by Automation Grade, 2023-2031

Table 218: Rest of Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by Automation Grade, 2023-2031

Table 219: Rest of Middle East & Africa Vertical Injection Molding Machine Market Volume (Units) Forecast, by End-use, 2023-2031

Table 220: Rest of Middle East & Africa Vertical Injection Molding Machine Market Value (US$ Mn) Forecast, by End-use 2023-2031

List of Figures

Figure 1: Global Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 2: Global Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 3: Global Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 4: Global Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 5: Global Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 6: Global Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 7: Global Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 8: Global Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 9: Global Vertical Injection Molding Machine Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 10: Global Vertical Injection Molding Machine Market Attractiveness, by Region

Figure 11: North America Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 12: North America Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 13: North America Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 14: North America Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 15: North America Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 16: North America Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 17: North America Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 18: North America Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 19: North America Vertical Injection Molding Machine Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 20: North America Vertical Injection Molding Machine Market Attractiveness, by Country and Sub-region

Figure 21: Europe Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 22: Europe Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 23: Europe Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 24: Europe Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 25: Europe Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 26: Europe Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 27: Europe Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 28: Europe Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 29: Europe Vertical Injection Molding Machine Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 30: Europe Vertical Injection Molding Machine Market Attractiveness, by Country and Sub-region

Figure 31: Asia Pacific Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 32: Asia Pacific Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 33: Asia Pacific Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 34: Asia Pacific Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 35: Asia Pacific Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 36: Asia Pacific Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 37: Asia Pacific Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 38: Asia Pacific Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 39: Asia Pacific Vertical Injection Molding Machine Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Asia Pacific Vertical Injection Molding Machine Market Attractiveness, by Country and Sub-region

Figure 41: Latin America Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 42: Latin America Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 43: Latin America Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 44: Latin America Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 45: Latin America Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 46: Latin America Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 47: Latin America Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 48: Latin America Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 49: Latin America Vertical Injection Molding Machine Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 50: Latin America Vertical Injection Molding Machine Market Attractiveness, by Country and Sub-region

Figure 51: Middle East & Africa Vertical Injection Molding Machine Market Volume Share Analysis, by Input Material Vs. Clamping Force, 2022, 2027, and 2031

Figure 52: Middle East & Africa Vertical Injection Molding Machine Market Attractiveness, by Input Material Vs. Clamping Force

Figure 53: Middle East & Africa Vertical Injection Molding Machine Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 54: Middle East & Africa Vertical Injection Molding Machine Market Attractiveness, by Type

Figure 55: Middle East & Africa Vertical Injection Molding Machine Market Volume Share Analysis, by Automation Grade, 2022, 2027, and 2031

Figure 56: Middle East & Africa Vertical Injection Molding Machine Market Attractiveness, by Automation Grade

Figure 57: Middle East & Africa Vertical Injection Molding Machine Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 58: Middle East & Africa Vertical Injection Molding Machine Market Attractiveness, by End-use

Figure 59: Middle East & Africa Vertical Injection Molding Machine Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 60: Middle East & Africa Vertical Injection Molding Machine Market Attractiveness, by Country and Sub-region