Reports

Reports

Analyst Viewpoint

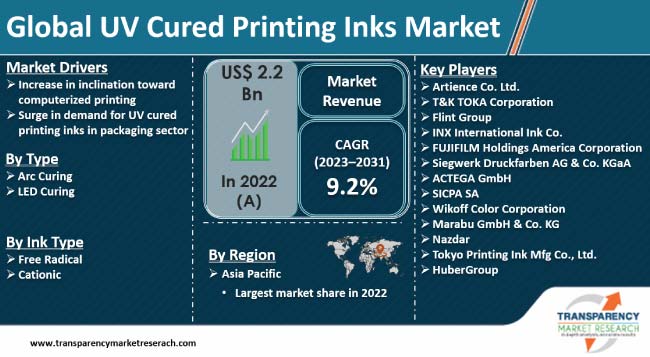

Increase in inclination toward computerized printing and surge in demand for UV cured printing inks in packaging sector are fueling the UV cured printing inks market size. UV cured printing inks are durable, high quality, and eco-friendly, thereby being extensively used in multiple industries. Increase in focus on sustainability and rise in demand for contamination-free packaging solutions from food and pharmaceutical sectors are bolstering market progress.

Technological advancements in printing processes offer lucrative UV cured printing inks market opportunities to the manufacturers in this sector. Leading players in the market are planning business expansion by introducing innovative products to enhance their product portfolio. Moreover, they invest in expansion of manufacturing capacities to meet global consumer demands.

UV-cured printing inks refer to a type of printing technology where ultraviolet (UV) light is used to instantly cure or dry the ink on a printed surface. UV-cured inks contain photoinitiators that react to UV light. These photoinitiators initiate a chemical reaction that rapidly polymerizes and solidifies the ink in UV light.

UV-LED printing inks are specifically designed for use with UV-Light-Emitting Diode (LED) curing systems. UV-LED technology is energy efficient, reduces heat generation, and holds environmental benefits.

High-performance UV inks ensure instant drying, high print quality, versatility, durability, and increased productivity. UV curable inks for industrial printing on non-porous surfaces allow companies to print graphically appealing logos on product packaging.

UV cured printing inks are extensively used in packaging, labeling, commercial printing, signage, and specialty printing applications. UV-curing requires less energy compared to other drying methods, contributing to energy efficiency and cost savings.

Digital printing technologies such as inkjet and UV inkjet, offer high precision and accuracy in reproducing intricate details and vibrant colors. UV-cured inks complement this precision by providing sharp and well-defined prints. Rise in demand for appealing and attractive brand packaging is driving the demand for computerized packaging.

Digital printing allows customization and UV cured inks have lower Volatile Organic Compound (VOC) emissions. Thus, increase in inclination toward computerized printing is fostering the UV cured printing inks market development.

As per the UV cured printing inks market forecast, technological advancements in UV curable ink systems are likely to drive the demand for digital printing in various sectors in the near future. Improved formulations for enhanced adhesion and flexibility, increased color gamut, reduced curing times, and compatibility with diverse substrates are some of the innovations in UV curable ink systems. Hence, innovation in UV cured printing inks is augmenting market dynamics.

UV-cured inks enhance print quality, contributing to sharp graphics and text. This printing technology is adopted in the packaging sector due to its rapid curing, vibrant colors, and exceptional adhesion on various substrates. The instant drying capability enables high-speed production and customization, meeting the demands of dynamic packaging designs.

UV LED cured printing inks for wide-format applications enable bulk printing on several materials, including paper, plastic, and others. Thus, rise in demand for UV cured printing inks in packaging sector is contributing to the UV cured printing inks industry growth.

Lower VOC emissions and energy efficiency make UV cured printing inks an eco-friendly and sustainable option, thereby being highly used in food packaging. According to the Packaging Industry Association of India (PIAI), packaging is the fifth largest sector in India's economy. The Indian food processing industry contributes 32% of the country's overall food market.

According to the market insights, Asia Pacific dominated the global market in 2022. Increase in consumer spending on packaged food and rise in demand for frozen food products are likely to propel the UV cured printing inks market share during the forecast period. Growth in working population and rapid industrialization are fueling the demand for on-the-go food products among consumers.

Moreover, expansion of pharmaceutical sector is creating a high demand for high-quality packaging solutions. UV cured printing ink is used in pharmaceutical packaging to avoid product contamination, thereby boosting market expansion. As per the India Brand Equity Foundation (IBEF), India is an emerging key exporter of packaging materials globally. The packaging materials export from India grew at a CAGR of 9.9% to US$ 1,119 million in 2021-22.

As per the latest UV cured printing inks market trends, sustainability and innovative packaging solutions offer lucrative opportunities to the companies operating in this sector. Leading players in the market are focusing on launching new products to meet sustainability standards and consumer demands from the packaging sector.

Moreover, increase in investments in research and development activities allows companies to enhance their product portfolio and increase global brand presence.

Some of the leading companies in the UV cured printing inks market are DIC Corporation, Artience Co. Ltd., T&K TOKA Corporation, Flint Group, INX International Ink Co., FUJIFILM Holdings America Corporation, Siegwerk Druckfarben AG & Co. KGaA, ACTEGA GmbH, SICPA SA, Wikoff Color Corporation, Marabu GmbH & Co. KG, Nazdar, Tokyo Printing Ink Mfg Co., Ltd., and HuberGroup.

These companies have been profiled in the UV cured printing inks market report based on parameters, such as business strategies, financial overview, product portfolio, company overview, recent developments, and business segments.

| Attribute | Detail |

|---|---|

| Market Size in 2022 | US$ 2.2 Bn |

| Market Forecast (Value) in 2031 | US$ 4.9 Bn |

| Growth Rate (CAGR) | 9.2% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2021 |

| Quantitative Tons | US$ Bn for Value and Tons for Volume |

| Market Analysis | It includes segment analysis as well as regional level analysis. Furthermore, qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces Analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation |

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

It was valued at US$ 2.2 Bn in 2022

It is projected to grow at a CAGR of 9.2% from 2023 to 2031

Increase in inclination toward computerized printing and surge in demand for UV cured printing inks in packaging sector

Asia Pacific was the most lucrative region in 2022

DIC Corporation, Artience Co. Ltd., T&K TOKA Corporation, Flint Group, INX International Ink Co., FUJIFILM Holdings America Corporation, Siegwerk Druckfarben AG & Co. KGaA, ACTEGA GmbH, SICPA SA, Wikoff Color Corporation, Marabu GmbH & Co. KG, Nazdar, Tokyo Printing Ink Mfg Co., Ltd., and HuberGroup

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global UV Cured Printing Inks Market Analysis and Forecast, 2020-2031

2.6.1. Global UV Cured Printing Inks Market Volume (Tons)

2.6.2. Global UV Cured Printing Inks Market Revenue (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Manufacturers

2.9.2. List of Dealers/Distributors

2.9.3. List of Potential Customers

2.10. Product Specification Analysis

2.11. Production Overview

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on Supply Chain of UV Cured Printing Inks

3.2. Impact on Demand for UV Cured Printing Inks – Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Tons)

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East & Africa

6. Price Trend Analysis and Forecast (US$/Ton), 2020-2031

6.1. Price Comparison Analysis by Type

6.2. Price Comparison Analysis by Region

7. Global UV Cured Printing Inks Market Analysis and Forecast, by Type, 2020–2031

7.1. Introduction and Definitions

7.2. Global UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

7.2.1. Arc Curing

7.2.2. LED Curing

7.3. Global UV Cured Printing Inks Market Attractiveness, by Type

8. Global UV Cured Printing Inks Market Analysis and Forecast, by Ink Type, 2020–2031

8.1. Introduction and Definitions

8.2. Global UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

8.2.1. Free Radical

8.2.2. Cationic

8.3. Global UV Cured Printing Inks Market Attractiveness, by Ink Type

9. Global UV Cured Printing Inks Market Analysis and Forecast, by Application, 2020–2031

9.1. Introduction and Definitions

9.2. Global UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

9.2.1. Flexographic

9.2.2. Gravure Printing

9.2.3. Offset Printing

9.2.4. Digital Printing

9.2.5. Screen Printing

9.3. Global UV Cured Printing Inks Market Attractiveness, by Application

10. Global UV Cured Printing Inks Market Analysis and Forecast, by End-use Industry, 2020–2031

10.1. Introduction and Definitions

10.2. Global UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

10.2.1. Publication & Commercial Printing

10.2.2. Packaging

10.2.3. Others

10.3. Global UV Cured Printing Inks Market Attractiveness, by End-use Industry

11. Global UV Cured Printing Inks Market Analysis and Forecast, by Region, 2020–2031

11.1. Key Findings

11.2. Global UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Region, 2020–2031

11.2.1. North America

11.2.2. Europe

11.2.3. Asia Pacific

11.2.4. Latin America

11.2.5. Middle East & Africa

11.3. Global UV Cured Printing Inks Market Attractiveness, by Region

12. North America UV Cured Printing Inks Market Analysis and Forecast, 2020–2031

12.1. Key Findings

12.2. North America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

12.3. North America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

12.4. North America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

12.5. North America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

12.6. North America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Country, 2020–2031

12.6.1. U.S. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

12.6.2. U.S. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

12.6.3. U.S. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

12.6.4. U.S. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

12.6.5. Canada UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

12.6.6. Canada UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

12.6.7. Canada UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

12.6.8. Canada UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

12.7. North America UV Cured Printing Inks Market Attractiveness Analysis

13. Europe UV Cured Printing Inks Market Analysis and Forecast, 2020–2031

13.1. Key Findings

13.2. Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.3. Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.4. Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.5. Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6. Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

13.6.1. Germany UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.2. Germany UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.3. Germany UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.4. Germany. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6.5. France UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.6. France UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.7. France UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.8. France UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6.9. U.K. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.10. U.K. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.11. U.K. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.12. U.K. UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6.13. Italy UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.14. Italy UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.15. Italy UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.16. Italy UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6.17. Russia & CIS UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.18. Russia & CIS UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.19. Russia & CIS UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.20. Russia & CIS UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.6.21. Rest of Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

13.6.22. Rest of Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

13.6.23. Rest of Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

13.6.24. Rest of Europe UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

13.7. Europe UV Cured Printing Inks Market Attractiveness Analysis

14. Asia Pacific UV Cured Printing Inks Market Analysis and Forecast, 2020–2031

14.1. Key Findings

14.2. Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type

14.3. Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.4. Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.5. Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.6. Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

14.6.1. China UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

14.6.2. China UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.6.3. China UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.6.4. China UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.6.5. Japan UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

14.6.6. Japan UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.6.7. Japan UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.6.8. Japan UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.6.9. India UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

14.6.10. India UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.6.11. India UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.6.12. India UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.6.13. ASEAN UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

14.6.14. ASEAN UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.6.15. ASEAN UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.6.16. ASEAN UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.6.17. Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

14.6.18. Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

14.6.19. Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

14.6.20. Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

14.7. Asia Pacific UV Cured Printing Inks Market Attractiveness Analysis

15. Latin America UV Cured Printing Inks Market Analysis and Forecast, 2020–2031

15.1. Key Findings

15.2. Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

15.3. Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

15.4. Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

15.5. Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

15.6. Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

15.6.1. Brazil UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

15.6.2. Brazil UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

15.6.3. Brazil UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

15.6.4. Brazil UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

15.6.5. Mexico UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

15.6.6. Mexico UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

15.6.7. Mexico UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

15.6.8. Mexico UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

15.6.9. Rest of Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

15.6.10. Rest of Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

15.6.11. Rest of Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

15.6.12. Rest of Latin America UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

15.7. Latin America UV Cured Printing Inks Market Attractiveness Analysis

16. Middle East & Africa UV Cured Printing Inks Market Analysis and Forecast, 2020–2031

16.1. Key Findings

16.2. Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

16.3. Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

16.4. Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

16.5. Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

16.6. Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

16.6.1. GCC UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

16.6.2. GCC UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

16.6.3. GCC UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

16.6.4. GCC UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

16.6.5. South Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

16.6.6. South Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

16.6.7. South Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

16.6.8. South Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

16.6.9. Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2020–2031

16.6.10. Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Ink Type, 2020–2031

16.6.11. Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020–2031

16.6.12. Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

16.7. Middle East & Africa UV Cured Printing Inks Market Attractiveness Analysis

17. Competition Landscape

17.1. Market Players - Competition Matrix (by Tier and Size of Companies)

17.2. Market Share Analysis, 2022

17.3. Market Footprint Analysis

17.3.1. By Type

17.3.2. By End-use Industry

17.4. Company Profiles

17.4.1. DIC Corporation

17.4.1.1. Company Revenue

17.4.1.2. Business Overview

17.4.1.3. Product Segments

17.4.1.4. Geographic Footprint

17.4.1.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.1.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.2. Artience Co. Ltd.

17.4.2.1. Company Revenue

17.4.2.2. Business Overview

17.4.2.3. Product Segments

17.4.2.4. Geographic Footprint

17.4.2.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.2.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.3. T&K TOKA Corporation

17.4.3.1. Company Revenue

17.4.3.2. Business Overview

17.4.3.3. Product Segments

17.4.3.4. Geographic Footprint

17.4.3.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.3.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.4. Flint Group

17.4.4.1. Company Revenue

17.4.4.2. Business Overview

17.4.4.3. Product Segments

17.4.4.4. Geographic Footprint

17.4.4.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.4.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.5. INX International Ink Co.

17.4.5.1. Company Revenue

17.4.5.2. Business Overview

17.4.5.3. Product Segments

17.4.5.4. Geographic Footprint

17.4.5.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.5.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.6. FUJIFILM Holdings America Corporation

17.4.6.1. Company Revenue

17.4.6.2. Business Overview

17.4.6.3. Product Segments

17.4.6.4. Geographic Footprint

17.4.6.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.6.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.7. Siegwerk Druckfarben AG & Co. KGaA

17.4.7.1. Company Revenue

17.4.7.2. Business Overview

17.4.7.3. Product Segments

17.4.7.4. Geographic Footprint

17.4.7.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.7.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.8. ACTEGA GmbH

17.4.8.1. Company Revenue

17.4.8.2. Business Overview

17.4.8.3. Product Segments

17.4.8.4. Geographic Footprint

17.4.8.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.8.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.9. SICPA SA

17.4.9.1. Company Revenue

17.4.9.2. Business Overview

17.4.9.3. Product Segments

17.4.9.4. Geographic Footprint

17.4.9.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.9.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.10. Wikoff Color Corporation

17.4.10.1. Company Revenue

17.4.10.2. Business Overview

17.4.10.3. Product Segments

17.4.10.4. Geographic Footprint

17.4.10.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.10.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.11. Marabu GmbH & Co. KG

17.4.11.1. Company Revenue

17.4.11.2. Business Overview

17.4.11.3. Product Segments

17.4.11.4. Geographic Footprint

17.4.11.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.11.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.12. Nazdar

17.4.12.1. Company Revenue

17.4.12.2. Business Overview

17.4.12.3. Product Segments

17.4.12.4. Geographic Footprint

17.4.12.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.12.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.13. Tokyo Printing Ink Mfg Co., Ltd.

17.4.13.1. Company Revenue

17.4.13.2. Business Overview

17.4.13.3. Product Segments

17.4.13.4. Geographic Footprint

17.4.13.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.13.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17.4.14. HuberGroup

17.4.14.1. Company Revenue

17.4.14.2. Business Overview

17.4.14.3. Product Segments

17.4.14.4. Geographic Footprint

17.4.14.5. Production Capacity/Plant Details, etc. (*As Applicable)

17.4.14.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

18. Primary Research: Key Insights

19. Appendix

List of Tables

Table 1: Global UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 2: Global UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 3: Global UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 4: Global UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 5: Global UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 6: Global UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 7: Global UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 8: Global UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

Table 9: Global UV Cured Printing Inks Market Volume (Tons) Forecast, by Region, 2020–2031

Table 10: Global UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Region, 2020–2031

Table 11: North America UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 12: North America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 13: North America UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 14: North America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 15: North America UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 16: North America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 17: North America UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 18: North America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

Table 19: North America UV Cured Printing Inks Market Volume (Tons) Forecast, by Country, 2020–2031

Table 20: North America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Country, 2020–2031

Table 21: U.S. UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 22: U.S. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 23: U.S. UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 24: U.S. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 25: U.S. UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 26: U.S. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 27: U.S. UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 28: U.S. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry, 2020–2031

Table 29: Canada UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 30: Canada UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 31: Canada UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 32: Canada UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 33: Canada UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 34: Canada UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 35: Canada UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 36: Canada UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 37: Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 38: Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 39: Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 40: Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 41: Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 42: Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 43: Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 44: Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 45: Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Country and Sub-region, 2020–2031

Table 46: Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 47: Germany UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 48: Germany UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 49: Germany UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 50: Germany UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 51: Germany UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 52: Germany UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 53: Germany UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 54: Germany UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 55: France UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 56: France UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 57: France UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 58: France UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 59: France UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 60: France UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 61: France UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 62: France UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 63: U.K. UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 64: U.K. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 65: U.K. UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 66: U.K. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 67: U.K. UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 68: U.K. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 69: U.K. UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 70: U.K. UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 71: Italy UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 72: Italy UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 73: Italy UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 74: Italy UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 75: Italy UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 76: Italy UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 77: Italy UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 78: Italy UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 79: Spain UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 80: Spain UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 81: Spain UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 82: Spain UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 83: Spain UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 84: Spain UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 85: Spain UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 86: Spain UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 87: Russia & CIS UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 88: Russia & CIS UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 89: Russia & CIS UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 90: Russia & CIS UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 91: Russia & CIS UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 92: Russia & CIS UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 93: Russia & CIS UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 94: Russia & CIS UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 95: Rest of Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 96: Rest of Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 97: Rest of Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 98: Rest of Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 99: Rest of Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 100: Rest of Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 101: Rest of Europe UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 102: Rest of Europe UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 103: Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 104: Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 105: Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 106: Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 107: Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 108: Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 109: Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 110: Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 111: Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Country and Sub-region, 2020–2031

Table 112: Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 113: China UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 114: China UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type 2020–2031

Table 115: China UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 116: China UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 117: China UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 118: China UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 119: China UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 120: China UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 121: Japan UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 122: Japan UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 123: Japan UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 124: Japan UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 125: Japan UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 126: Japan UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 127: Japan UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 128: Japan UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 129: India UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 130: India UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 131: India UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 132: India UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 133: India UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 134: India UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 135: India UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 136: India UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 137: ASEAN UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 138: ASEAN UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 139: ASEAN UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 140: ASEAN UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 141: ASEAN UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 142: ASEAN UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 143: ASEAN UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 144: ASEAN UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 145: Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 146: Rest of Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 147: Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 148: Rest of Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 149: Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 150: Rest of Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 151: Rest of Asia Pacific UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 152: Rest of Asia Pacific UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 153: Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 154: Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 155: Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 156: Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 157: Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 158: Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 159: Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 160: Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 161: Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Country and Sub-region, 2020–2031

Table 162: Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 163: Brazil UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 164: Brazil UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 165: Brazil UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 166: Brazil UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 167: Brazil UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 168: Brazil UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 169: Brazil UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 170: Brazil UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 171: Mexico UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 172: Mexico UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 173: Mexico UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 174: Mexico UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 175: Mexico UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 176: Mexico UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 177: Mexico UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 178: Mexico UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 179: Rest of Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 180: Rest of Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 181: Rest of Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 182: Rest of Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 183: Rest of Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 184: Rest of Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 185: Rest of Latin America UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 186: Rest of Latin America UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 187: Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 188: Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 189: Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 190: Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 191: Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 192: Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 193: Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 194: Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 195: Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Country and Sub-region, 2020–2031

Table 196: Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 197: GCC UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 198: GCC UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 199: GCC UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 200: GCC UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 201: GCC UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 202: GCC UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 203: GCC UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 204: GCC UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 205: South Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 206: South Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 207: South Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 208: South Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 209: South Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 210: South Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 211: South Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 212: South Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

Table 213: Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Type, 2020–2031

Table 214: Rest of Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Type, 2020–2031

Table 215: Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Ink Type, 2020–2031

Table 216: Rest of Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Ink Type, 2020–2031

Table 217: Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by Application, 2020–2031

Table 218: Rest of Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 219: Rest of Middle East & Africa UV Cured Printing Inks Market Volume (Tons) Forecast, by End-use Industry, 2020–2031

Table 220: Rest of Middle East & Africa UV Cured Printing Inks Market Value (US$ Mn) Forecast, by End-use Industry 2020–2031

List of Figures

Figure 1: Global UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 2: Global UV Cured Printing Inks Market Attractiveness, by Type

Figure 3: Global UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 4: Global UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 5: Global UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 6: Global UV Cured Printing Inks Market Attractiveness, by Application

Figure 7: Global UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 8: Global UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 9: Global UV Cured Printing Inks Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 10: Global UV Cured Printing Inks Market Attractiveness, by Region

Figure 11: North America UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 12: North America UV Cured Printing Inks Market Attractiveness, by Type

Figure 13: North America UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 14: North America UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 15: North America UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 16: North America UV Cured Printing Inks Market Attractiveness, by Application

Figure 17: North America UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 18: North America UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 19: North America UV Cured Printing Inks Market Volume Share Analysis, by Country, 2022, 2027, and 2031

Figure 20: North America UV Cured Printing Inks Market Attractiveness, by Country

Figure 21: Europe UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 22: Europe UV Cured Printing Inks Market Attractiveness, by Type

Figure 23: Europe UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 24: Europe UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 25: Europe UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 26: Europe UV Cured Printing Inks Market Attractiveness, by Application

Figure 27: Europe UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 28: Europe UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 29: Europe UV Cured Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 30: Europe UV Cured Printing Inks Market Attractiveness, by Country and Sub-region

Figure 31: Asia Pacific UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 32: Asia Pacific UV Cured Printing Inks Market Attractiveness, by Type

Figure 33: Asia Pacific UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 34: Asia Pacific UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 35: Asia Pacific UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 36: Asia Pacific UV Cured Printing Inks Market Attractiveness, by Application

Figure 37: Asia Pacific UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 38: Asia Pacific UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 39: Asia Pacific UV Cured Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Asia Pacific UV Cured Printing Inks Market Attractiveness, by Country and Sub-region

Figure 41: Latin America UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 42: Latin America UV Cured Printing Inks Market Attractiveness, by Type

Figure 43: Latin America UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 44: Latin America UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 45: Latin America UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 46: Latin America UV Cured Printing Inks Market Attractiveness, by Application

Figure 47: Latin America UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 48: Latin America UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 49: Latin America UV Cured Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 50: Latin America UV Cured Printing Inks Market Attractiveness, by Country and Sub-region

Figure 51: Middle East & Africa UV Cured Printing Inks Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 52: Middle East & Africa UV Cured Printing Inks Market Attractiveness, by Type

Figure 53: Middle East & Africa UV Cured Printing Inks Market Volume Share Analysis, by Ink Type, 2022, 2027, and 2031

Figure 54: Middle East & Africa UV Cured Printing Inks Market Attractiveness, by Ink Type

Figure 55: Middle East & Africa UV Cured Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 56: Middle East & Africa UV Cured Printing Inks Market Attractiveness, by Application

Figure 57: Middle East & Africa UV Cured Printing Inks Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 58: Middle East & Africa UV Cured Printing Inks Market Attractiveness, by End-use Industry

Figure 59: Middle East & Africa UV Cured Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 60: Middle East & Africa UV Cured Printing Inks Market Attractiveness, by Country and Sub-region