Reports

Reports

The medical device contract manufacturing market is relied upon to show extensive development because of variables, for example, expanding medical problems and the requirement for appropriate determination. Besides, the flare-up of the COVID-19 has attacked the world and the interest in testing units has shown a generous ascent. This pandemic has assumed an imperative part in speeding up the development of the medical device contract manufacturing market.

The agreement fabricating area helps with offering support in various limits like plan and creation. It assists with keeping up with center-around-center abilities and key preparation. The rising interest in clinical gadgets in the pandemic situation has shown vigorous development in the medical device contract manufacturing market. The developing interest for clinical hardware has likewise brought about the requirement for organizations producing clinical gadgets, which thusly, is helping the development of the medical device contract manufacturing market.

The clinical gadget fabricating industry is quickly developing across the globe and alongside that agreement producing administrations structure an enormous piece of the business. Throughout the last numerous many years, the agreement fabricating area alongside the clinical gadget producing industry has confronted the difficulties of satisfying the spiraling needs and has reshaped clinical innovation. Indeed, even presently, when COVID-19 is desolating the world, there is a deficiency of clinical units for testing the presence of an infection in a person. Worldwide pandemics, for example, COVID-19 alongside the typical expanding interest for clinical gadgets are probably going to reinforce the development of the worldwide medical device contract manufacturing market sooner rather than later. With the rising interest in clinical gadgets, it is normal that the requirement for individuals and organizations fabricating clinical gadgets will likewise rise. Accordingly, it is normal that agreement assembling will play a critical in the years to come.

The key elements driving the development of the medical device contract manufacturing market incorporates the general development of the clinical gadgets market, essentially because of rising infection pervasiveness, future, and the geriatric populace. Innovative progression has incited end clients to redesign or refresh their assembling frameworks. As this is an expensive interaction, they hope to contract fabricating. Furthermore, the COVID-19 flare-up has sped up the reception of cutting-edge diagnostics and patient consideration gadgets for better treatment of the executives. Nevertheless, market development is blocked by the developing combination in the clinical gadgets market. Bigger players, to foster their assembling capacities to save costs, center on the securing of more modest players and CMOs themselves.

The global medical device market is classified on the basis of device type, services type, type, class of device, and region. In terms of device type, the market is categorized into IVD devices, diagnostic imaging devices, cardiovascular devices, drug delivery devices, orthopedic devices, ophthalmic devices, ophthalmology devices, diabetes care devices, dental devices, endoscopy devices, respiratory care devices, surgical devices, gynecology or urology devices, personal care, neurology devices, and other devices. Among these, the drug delivery devices, and IVD devices segment are further sub-categorized. Based on type, the market is grouped into other packaging and assembling services, labeling, primary & secondary packaging, and other services. Further classification of class of device segment includes Classes I, II, and III. The gadget development and manufacturing administrations fragment overwhelmed this market. The expanding reception of agreement manufacturing administrations in the medical gadget industry, development in the medical devices market (particularly in the single-utilize dispensable medical devices market), and further developing gadget development and manufacturing abilities are the main considerations liable for the huge portion of this section.

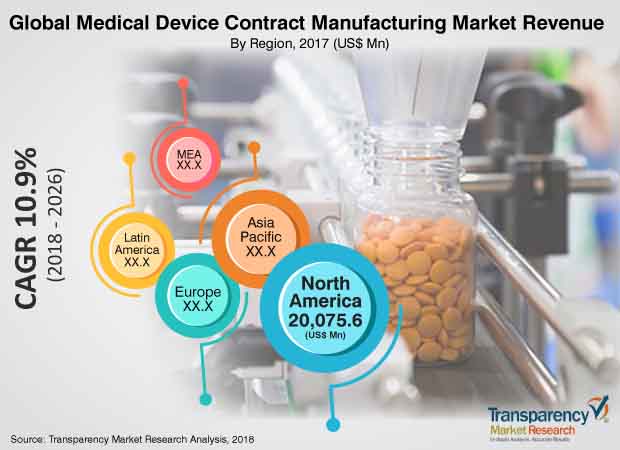

North America overwhelmed the worldwide medical gadget contract manufacturing market in 2017, inferable from a profoundly evolved medical services area, expansion in mindfulness among medical care suppliers about medical devices, and constant development of cutting edge medical gadget items. North America is likewise an alluring district of the market, as far as income. The ascent in the quantity of government drives and laws and expansion in populace drive the medical gadget contract manufacturing market in the area. Innovative progressions and an increment in manufacturing locales are relied upon to drive the medical gadget contract manufacturing market in the Asia Pacific, Latin America, and Middle East and Africa during the conjecture time frame.

Medical device contract manufacturing market to reach US$ 118.9 Bn by 2026

Medical device contract manufacturing market is projected to expand at a CAGR of 10.9% from 2018 to 2026

Medical device contract manufacturing market is driven by increase in the number of cases of various disorders across the globe

North America and Europe are projected to dominate the global medical devices contract manufacturing market, owing to a highly developed health care sector

Key players in the global medical devices contract manufacturing market include Flextronics International, LTD., Jabil Inc., Benchmark Electronics, Inc., Integer Holdings Corporation (Greatbatch), West Pharmaceutical Services, Inc.

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

3. Executive Summary : Global Medical Device Contract Manufacturing Market

4. Market Overview

4.1. Introduction

4.2. Overview

4.3. Market Dynamics

4.3.1. Drivers

4.3.2. Restraints

4.3.3. Opportunities

4.4. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, 2016–2026

5. Key Insights

5.1. Regulatory Scenario by Region

5.2. Selection Criteria for Medical Device Contract Manufacturing

5.3. Supply Chain Analysis

6. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, by Device Type

6.1. Introduction & Definition

6.2. Key Findings/Developments

6.3. Market Value Forecast, by Device Type, 2016–2026

6.3.1. In-vitro Diagnostic Medical Devices

6.3.2. Diagnostic Imaging & Medical Equipment

6.3.3. Drug Delivery Devices

6.3.4. Patient Monitoring Devices

6.3.5. Minimally Access Surgical Instruments

6.3.6. Therapeutic Patient Assistive Devices

6.3.7. Others

6.4. Market Attractiveness, by Device Type

7. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, by Type of Manufacturing

7.1. Introduction & Definition

7.2. Key Findings / Developments

7.3. Market Value Forecast, by Type of Manufacturing, 2016–2026

7.3.1. Raw Materials

7.3.2. Electronics

7.3.3. Finished Goods

7.4. Market Attractiveness, by Type of Manufacturing

8. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, by Services

8.1. Introduction & Definition

8.2. Key Findings / Developments

8.3. Market Value Forecast, by Services , 2016–2026

8.3.1. Prototype Development

8.3.2. Finished Device Manufacturing

8.3.3. Assembly & Packaging

8.3.4. Testing & Regulatory Support Services

8.3.5. Molding & Casting

8.3.6. Others

8.4. Market Attractiveness, by Service

9. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, by Application

9.1. Introduction & Definition

9.2. Key Findings/Developments

9.3. Market Value Forecast, by Application, 2016–2026

9.3.1. Cardiovascular

9.3.2. Orthopedic

9.3.3. Neurovascular

9.3.4. Pulmonary

9.3.5. Oncology

9.3.6. Laparoscopy

9.3.7. Urology & Gynecology

9.3.8. Radiology

9.3.9. Others

9.4. Market Attractiveness, by Application

10. Global Medical Device Contract Manufacturing Market Analysis and Forecasts, by Region

10.1. Key Findings

10.2. Market Value Forecast, by Region

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Market Attractiveness, by Country/Region

11. North America Medical Device Contract Manufacturing Market Analysis and Forecast

11.1.Introduction

11.2.Market Value Forecast, by Device Type, 2016–2026

11.2.1. In-vitro Diagnostic Medical Devices

11.2.2. Diagnostic Imaging & Medical Equipment

11.2.3. Drug Delivery Devices

11.2.4. Patient Monitoring Devices

11.2.5. Minimally Access Surgical Instruments

11.2.6. Therapeutic Patient Assistive Devices

11.2.7. Others

11.3.Market Value Forecast, by Type of Manufacturing, 2016–2026

11.3.1. Raw Materials

11.3.2. Electronics

11.3.3. Finished Goods

11.4.Market Value Forecast, by Services , 2016–2026

11.4.1. Prototype Development

11.4.2. Finished Device Manufacturing

11.4.3. Assembly & Packaging

11.4.4. Testing & Regulatory Support Services

11.4.5. Molding & Casting

11.4.6. Others

11.5.Market Value Forecast, by Application, 2016–2026

11.5.1. Cardiovascular

11.5.2. Orthopedic

11.5.3. Neurovascular

11.5.4. Pulmonary

11.5.5. Oncology

11.5.6. Laparoscopy

11.5.7. Urology & Gynecology

11.5.8. Radiology

11.5.9. Others

11.6.Market Value Forecast, by Country, 2016–2026

11.6.1. U.S.

11.6.2. Canada

11.7.Market Attractiveness Analysis

11.7.1. By Device Type

11.7.2. By Type of Manufacturing

11.7.3. By Services

11.7.4. By Application

11.7.5. By Country

12. Europe Medical Device Contract Manufacturing Market Analysis and Forecast

12.1.Introduction

12.2.Market Value Forecast, by Device Type, 2016–2026

12.2.1. In-vitro Diagnostic Medical Devices

12.2.2. Diagnostic Imaging & Medical Equipment

12.2.3. Drug Delivery Devices

12.2.4. Patient Monitoring Devices

12.2.5. Minimally Access Surgical Instruments

12.2.6. Therapeutic Patient Assistive Devices

12.2.7. Others

12.3.Market Value Forecast, by Type of Manufacturing, 2016–2026

12.3.1. Raw Materials

12.3.2. Electronics

12.3.3. Finished Goods

12.4.Market Value Forecast, by Service , 2016–2026

12.4.1. Prototype Development

12.4.2. Finished Device Manufacturing

12.4.3. Assembly & Packaging

12.4.4. Testing & Regulatory Support Services

12.4.5. Molding & Casting

12.4.6. Others

12.5.Market Value Forecast, by Application, 2016–2026

12.5.1. Cardiovascular

12.5.2. Orthopedic

12.5.3. Neurovascular

12.5.4. Pulmonary

12.5.5. Oncology

12.5.6. Laparoscopy

12.5.7. Urology & Gynecology

12.5.8. Radiology

12.5.9. Others

12.6.Market Value Forecast, by Country, 2016–2026

12.6.1. Germany

12.6.2. U.K.

12.6.3. France

12.6.4. Spain

12.6.5. Italy

12.6.6. Rest of Europe

12.7.Market Attractiveness Analysis

12.7.1. By Device Type

12.7.2. By Type of Manufacturing

12.7.3. By Services

12.7.4. By Application

12.7.5. By Country

13. Asia Pacific Medical Device Contract Manufacturing Market Analysis and Forecast

13.1.Introduction

13.2.Market Value Forecast, by Device Type, 2016–2026

13.2.1. In-vitro Diagnostic Medical Devices

13.2.2. Diagnostic Imaging & Medical Equipment

13.2.3. Drug Delivery Devices

13.2.4. Patient Monitoring Devices

13.2.5. Minimally Access Surgical Instruments

13.2.6. Therapeutic Patient Assistive Devices

13.2.7. Others

13.3.Market Value Forecast, by Type of Manufacturing, 2016–2026

13.3.1. Raw Materials

13.3.2. Electronics

13.3.3. Finished Goods

13.4.Market Value Forecast, by Services , 2016–2026

13.4.1. Prototype Development

13.4.2. Finished Device Manufacturing

13.4.3. Assembly & Packaging

13.4.4. Testing & Regulatory Support Services

13.4.5. Molding & Casting

13.4.6. Others

13.5.Market Value Forecast, by Application, 2016–2026

13.5.1. Cardiovascular

13.5.2. Orthopedic

13.5.3. Neurovascular

13.5.4. Pulmonary

13.5.5. Oncology

13.5.6. Laparoscopy

13.5.7. Urology & Gynecology

13.5.8. Radiology

13.5.9. Others

13.6.Market Value Forecast, by Country, 2016–2026

13.6.1. China

13.6.2. Japan

13.6.3. India

13.6.4. Australia & New Zealand

13.6.5. Rest of Asia Pacific

13.7.Market Attractiveness Analysis

13.7.1. By by Device Type

13.7.2. By by Type of Manufacturing

13.7.3. By by Services

13.7.4. By by Application

13.7.5. By by Country

14. Latin America Medical Device Contract Manufacturing Market Analysis and Forecast

14.1.Introduction

14.2.Market Value Forecast, by Device Type, 2016–2026

14.2.1. In-vitro Diagnostic Medical Devices

14.2.2. Diagnostic Imaging & Medical Equipment

14.2.3. Drug Delivery Devices

14.2.4. Patient Monitoring Devices

14.2.5. Minimally Access Surgical Instruments

14.2.6. Therapeutic Patient Assistive Devices

14.2.7. Others

14.3.Market Value Forecast, by Type of Manufacturing, 2016–2026

14.3.1. Raw Materials

14.3.2. Electronics

14.3.3. Finished Goods

14.4.Market Value Forecast, by Services , 2016–2026

14.4.1. Prototype Development

14.4.2. Finished Device Manufacturing

14.4.3. Assembly & Packaging

14.4.4. Testing & Regulatory Support Services

14.4.5. Molding & Casting

14.4.6. Others

14.5.Market Value Forecast, by Application, 2016–2026

14.5.1. Cardiovascular

14.5.2. Orthopedic

14.5.3. Neurovascular

14.5.4. Pulmonary

14.5.5. Oncology

14.5.6. Laparoscopy

14.5.7. Urology & Gynecology

14.5.8. Radiology

14.5.9. Others

14.6.Market Value Forecast, by Country, 2016–2026

14.6.1. Brazil

14.6.2. Mexico

14.6.3. Rest of Latin America

14.7.Market Attractiveness Analysis

14.7.1. By Device Type

14.7.2. By Type of Manufacturing

14.7.3. By Services

14.7.4. By Application

14.7.5. By Country

15. Middle East & Africa Medical Device Contract Manufacturing Market Analysis and Forecast

15.1.Introduction

15.2.Market Value Forecast, by Device Type, 2016–2026

15.2.1. In-vitro Diagnostic Medical Devices

15.2.2. Diagnostic Imaging & Medical Equipment

15.2.3. Drug Delivery Devices

15.2.4. Patient Monitoring Devices

15.2.5. Minimally Access Surgical Instruments

15.2.6. Therapeutic Patient Assistive Devices

15.2.7. Others

15.3.Market Value Forecast, by Type of Manufacturing, 2016–2026

15.3.1. Raw Materials

15.3.2. Electronics

15.3.3. Finished Goods

15.4.Market Value Forecast, by Services , 2016–2026

15.4.1. Prototype Development

15.4.2. Finished Device Manufacturing

15.4.3. Assembly & Packaging

15.4.4. Testing & Regulatory Support Services

15.4.5. Molding & Casting

15.4.6. Others

15.5.Market Value Forecast, by Application, 2016–2026

15.5.1. Cardiovascular

15.5.2. Orthopedic

15.5.3. Neurovascular

15.5.4. Pulmonary

15.5.5. Oncology

15.5.6. Laparoscopy

15.5.7. Urology & Gynecology

15.5.8. Radiology

15.5.9. Others

15.6.Market Value Forecast, by Country, 2016–2026

15.6.1. GCC Countries

15.6.2. South Africa

15.6.3. Rest of Middle East & Africa

15.7.Market Attractiveness Analysis

15.7.1. By Device Type

15.7.2. By Type of Manufacturing

15.7.3. By Services

15.7.4. By Application

15.7.5. By Country

16. Competition Landscape

16.1.Market Share Analysis by Company (2017)

16.2. Company Profiles

16.2.1. Flextronics International, LTD.

16.2.2. Jabil Inc.

16.2.3. Benchmark Electronics, Inc.

16.2.4. Integer Holdings Corporation (Greatbatch)

16.2.5. West Pharmaceutical Services, Inc.

16.2.6. Tecomet, Inc.

16.2.7. Nortech Systems

16.2.8. TE Connectivity (Creganna Medical)

16.2.9. Forefront Medical Technologies

16.2.10. Nordson Corporation

List of Tables

Table 01: Global Medical Device Contract Manufacturing Market Size (US$ Mn) Forecast, by Device Type, 2016–2026

Table 02: Global Medical Device Contract Manufacturing Market Size (US$ Mn) Forecast, by Type of Manufacturing , 2016–2026

Table 03: Global Medical Device Contract Manufacturing Market Size (US$ Mn) Forecast, by Service, 2016–2026

Table 04: Global Medical Device Contract Manufacturing Market Size (US$ Mn) Forecast, by Application, 2016–2026

Table 05: Global Medical Device Contract Manufacturing Market Value (US$ Mn) Forecast, by Region , 2016–2026

Table 06: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Country, 2016–2026

Table 07: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Device Type, 2016–2026

Table 08: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Type of Manufacturing, 2016–2026

Table 09: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Services, 2016–2026

Table 10: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Application, 2016–2026

Table 11: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2016–2026

Table 12: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Device Type, 2016–2026

Table 13: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Type of Manufacturing, 2016–2026

Table 14: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Services, 2016–2026

Table 15: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Application, 2016–2026

Table 16: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2016–2026

Table 17: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Device Type, 2016–2026

Table 18: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Type of Manufacturing, 2016–2026

Table 19: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Services, 2016–2026

Table 20: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Application, 2016–2026

Table 21: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2016–2026

Table 22: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Device Type, 2016–2026

Table 23: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Type of Manufacturing, 2016–2026

Table 24: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Services, 2016–2026

Table 25: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Application, 2016–2026

Table 26: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Country/Sub-region, 2016–2026

Table 27: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Type of Manufacturing, 2016–2026

Table 28: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Services, 2016–2026

Table 29: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Application, 2016–2026

Table 30: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast, by Device Type, 2016–2026

List of Figures

Figure 01: Global Medical Device Contract Manufacturing Market Value (US$ Mn) Forecast, 2016–2026

Figure 02: Global Medical Device Contract Manufacturing Market Value Share Analysis, by Device Type, 2017 and 2026

Figure 03: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by In-vitro Diagnostic

Figure 04: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Diagnostic Imaging &

Figure 05: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Drug Delivery Devices, 2016–2026

Figure 06: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Patient Monitoring Devices, 2016–2026

Figure 07: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Minimally Access

Figure 08: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Therapeutic Patient

Figure 09: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Other Device Types, 2016–2026

Figure 10: Global Medical Device Contract Manufacturing Market Attractiveness Analysis, by Device Type, 2018–2026

Figure 11: Global Medical Device Contract Manufacturing Market Value Share Analysis, by Type of Manufacturing, 2018 and 2026

Figure 12: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Raw Materials, 2016-2026

Figure 13: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Electronics, 2016-2026

Figure 14: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Finished Goods, 2016-2026

Figure 15: Global medical device contract Manufacturing Market Attractiveness Analysis, by Type of Manufacturing, 2018–2026

Figure 16: Global Medical Device Contract Manufacturing Market Value Share Analysis, by Services, 2017 and 2026

Figure 17: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Prototype Development, 2016–2026

Figure 18: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Finished Device Manufacturing, 2016–2026

Figure 19: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Assembly & Packaging, 2016–2026

Figure 20: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Testing & Regulatory Support Services, 2016–2026

Figure 21: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Molding & Casting, 2016–2026

Figure 22: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Others, 2016–2026

Figure 23: Global Medical Device Contract Manufacturing Market Attractiveness Analysis, by Services, 2018–2026

Figure 24: Global Medical Device Contract Manufacturing Market Value Share Analysis, by Application, 2017 and 2026

Figure 25: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Cardiovascular, 2016–2026

Figure 26: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Orthopedic, 2016–2026

Figure 27: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Neurovascular, 2016–2026

Figure 28: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Pulmonary, 2016–2026

Figure 29: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Oncology, 2016–2026

Figure 30: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Laparoscopy, 2016–2026

Figure 31: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Urology & Gynecology, 2016–2026

Figure 32: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Radiology, 2016–2026

Figure 33: Global Medical Device Contract Manufacturing Market Revenue (US$ Mn), by Others, 2016–2026

Figure 34: Global Medical Device Contract Manufacturing Market Attractiveness Analysis, by Application, 2018–2026

Figure 35: Global Medical Device Contract Manufacturing Market Value Share Analysis, by Region, 2017 and 2026

Figure 36: Global Medical Device Contract Manufacturing Market Attractiveness Analysis, by Region

Figure 37: North America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast and Y-o-Y Growth (%) Projection, 2016–2026

Figure 38: North America Medical Device Contract Manufacturing Market Value Share (%), by Country, 2017 and 2026

Figure 39: North America Medical Device Contract Manufacturing Market Attractiveness, by Country, 2018–2026

Figure 40: North America Medical Device Contract Manufacturing Market Value Share (%), by Device Type, 2017 and 2026

Figure 41: North America Medical Device Contract Manufacturing Market Attractiveness, by Device Type, 2018–2026

Figure 42: North America Medical Device Contract Manufacturing Market Value Share (%), by Type of Manufacturing, 2017 and 2026

Figure 43: North America Medical Device Contract Manufacturing Market Attractiveness, by Type of Manufacturing, 2018–2026

Figure 44: North America Medical Device Contract Manufacturing Market Value Share (%), by Services, 2017 and 2026

Figure 45: North America Medical Device Contract Manufacturing Market Attractiveness, by Service, 2018–2026

Figure 46: North America Medical Device Contract Manufacturing Market Value Share (%), by Application, 2017 and 2026

Figure 47: North America Medical Device Contract Manufacturing Market Attractiveness, by Application, 2018–2026

Figure 48: Europe Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast and Y-o-Y Growth (%) Projection, 2016–2026

Figure 49: Europe Medical Device Contract Manufacturing Market Value Share (%), by Country, 2017 and 2026

Figure 50: Europe Medical Device Contract Manufacturing Market Attractiveness, by Country/Sub-region, 2018–2026

Figure 51: Europe Medical Device Contract Manufacturing Market Value Share (%), by Device Type, 2017 and 2026

Figure 52: Europe Medical Device Contract Manufacturing Market Attractiveness, by Device Type, 2018–2026

Figure 53: Europe Medical Device Contract Manufacturing Market Value Share (%), by Type of Manufacturing, 2017 and 2026

Figure 54: Europe Medical Device Contract Manufacturing Market Attractiveness, by Type of Manufacturing, 2018–2026

Figure 55: Europe Medical Device Contract Manufacturing Market Value Share (%), by Service, 2017 and 2026

Figure 56: Europe Medical Device Contract Manufacturing Market Attractiveness, by Service, 2018–2026

Figure 57: Europe Medical Device Contract Manufacturing Market Value Share (%), by Application, 2017 and 2026

Figure 58: Europe Medical Device Contract Manufacturing Market Attractiveness, by Application, 2018–2026

Figure 59: Asia Pacific Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast and Y-o-Y Growth (%) Projection, 2016–2026

Figure 60: Asia Pacific Medical Device Contract Manufacturing Market Value Share (%), by Country/Sub-region, 2017 and 2026

Figure 61: Asia Pacific Medical Device Contract Manufacturing Market Attractiveness, by Country/Sub-region, 2018–2026

Figure 62: Asia Pacific Medical Device Contract Manufacturing Market Value Share (%), by Device Type, 2017 and 2026

Figure 63: Asia Pacific Medical Device Contract Manufacturing Market Attractiveness, by Device Type, 2018–2026

Figure 64: Asia Pacific Medical Device Contract Manufacturing Market Value Share (%), by Type of Manufacturing, 2017 and 2026

Figure 65: Asia Pacific Medical Device Contract Manufacturing Market Attractiveness, by Type of Manufacturing, 2018–2026

Figure 66: Asia Pacific Medical Device Contract Manufacturing Market Value Share (%), by Service, 2017 and 2026

Figure 67: Asia Pacific Medical Device Contract Manufacturing Market Attractiveness, by Service, 2018–2026

Figure 68: Asia Pacific Medical Device Contract Manufacturing Market Value Share (%), by Application, 2017 and 2026

Figure 69: Asia Pacific Medical Device Contract Manufacturing Market Attractiveness, by Application, 2018–2026

Figure 70: Latin America Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast and Y-o-Y Growth (%) Projection, 2016–2026

Figure 71: Latin America Medical Device Contract Manufacturing Market Value Share (%), by Country/Sub-region, 2017 and 2026

Figure 72: Latin America Medical Device Contract Manufacturing Market Attractiveness, by Country/Sub-region, 2018–2026

Figure 73: Latin America Medical Device Contract Manufacturing Market Value Share (%), by Device Type, 2017 and 2026

Figure 74: Latin America Medical Device Contract Manufacturing Market Attractiveness, by Device Type, 2018–2026

Figure 75: Latin America Medical Device Contract Manufacturing Market Value Share (%), by Type of Manufacturing, 2017 and 2026

Figure 76: Latin America Medical Device Contract Manufacturing Market Attractiveness, by Type of Manufacturing, 2018–2026

Figure 77: Latin America Medical Device Contract Manufacturing Market Value Share (%), by Service, 2017 and 2026

Figure 78: Latin America Medical Device Contract Manufacturing Market Attractiveness, by Service, 2018–2026

Figure 79: Latin America Medical Device Contract Manufacturing Market Value Share (%), by Application, 2017 and 2026

Figure 80: Latin America Medical Device Contract Manufacturing Market Attractiveness, by Application, 2018–2026

Figure 81: Middle East & Africa Medical Device Contract Manufacturing Market Revenue (US$ Mn) Forecast and Y-o-Y Growth (%) Projection, 2016–2026

Figure 82: Middle East & Africa Medical Device Contract Manufacturing Market Value Share (%), by Country, 2017 and 2026

Figure 83: Middle East & Africa Medical Device Contract Manufacturing Market Attractiveness, by Country/Sub-region, 2018–2026

Figure 84: Middle East & Africa Medical Device Contract Manufacturing Market Value Share (%), by Type of Manufacturing, 2017 and 2026

Figure 85: Middle East & Africa Medical Device Contract Manufacturing Market Attractiveness, by Type of Manufacturing, 2018–2026

Figure 86: Middle East & Africa Medical Device Contract Manufacturing Market Value Share (%), by Service, 2017 and 2026

Figure 87: Middle East & Africa Medical Device Contract Manufacturing Market Attractiveness, by Service, 2018–2026

Figure 88: Middle East & Africa Medical Device Contract Manufacturing Market Value Share (%), by Application, 2017 and 2026

Figure 89: Middle East & Africa Medical Device Contract Manufacturing Market Attractiveness, by Application, 2018–2026

Figure 90: Middle East & Africa Medical Device Contract Manufacturing Market Value Share (%), by Device Type, 2017 and 2026

Figure 91: Middle East & Africa Medical Device Contract Manufacturing Market Attractiveness, by Device Type, 2018–2026

Figure 92: Global Medical Device Contract Manufacturing Market Analysis, by Top Company Ranking, 2017