Reports

Reports

Mechanical springs are devices that deflect under absorb, load and store energy and release the equivalent amount of energy when load is released. Mechanical springs are used in a wide range of applications because they have the ability to store and release energy. For instance, in automobiles, they work as shock absorbers; in machine tools, they are used for mechanical clamping; and in IC engines, they are utilized in outlet and inlet valves. Furthermore, mechanical springs are employed in the field of machine design to maintain contact between machine components, to store energy, and control of vibrations.

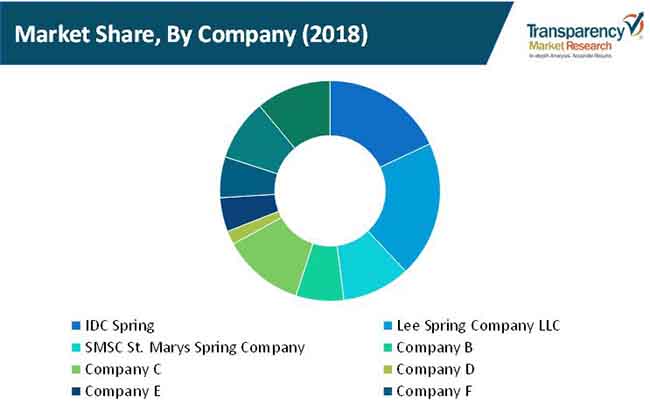

IDC Spring

Founded in 1974, IDC Spring is headquartered in Coon Rapids, Minnesota, U.S. The company manufactures and sells high quality springs and garage door products. It provides various types of mechanical springs such as torsion springs, extension springs, compression springs, barrel springs, and specialty springs. The company’s mechanical springs are used in various applications such as agriculture, dock levels, farming equipment, and furniture.

Lee Spring Company LLC

Incorporated in 1918, Lee Spring Company LLC is based in Brooklyn, New York, U.S. The company is engaged in manufacturing and distribution of wire forms, mechanical springs and stampings, and fourslide parts across the globe. The company offers numerous types of springs such as stock springs, custom springs, battery springs, Belleville washers compression springs, constant force springs, continuous length springs, extension springs, HEFTY (die springs), LeeP (plastic composite springs), compression springs, wave springs, and torsion springs. It provides services to various industry sectors including aerospace, military, automotive & transportation, electronics, energy, industrial machine manufacturing & metal working, medical & pharmaceutical, and packaging & material handling equipment.

SMSC St. Marys Spring Company

Established in 1946, SMSC St. Marys Spring Company is headquartered in Saint Marys, Pennsylvania, U.S. The company manufactures a wide range of springs, wire forms, flat forms, and stampings. It provides compression springs, torsion springs, flat form springs, extension springs, precision stampings, constant force springs, fine wire springs, and double torsion springs. The company provides its products to many industries such as aerospace, agriculture, automotive, electrical, medical, military, and telecommunication.

Bohne Spring Industries Ltd

Incorporated in 1891, Bohne Spring Industries Ltd is based in Ontario, Canada. The company develops and designs mechanical springs and machinery equipment. It provides various products such as compression springs, extension springs, torsion springs, four-slide stampings, and wire forms.

Other prominent players operating in the mechanical springs market include Precision Global Springs Pvt. Ltd, M. Coil Spring Manufacturing Company, Barnes Group Inc., and WCS Industries.

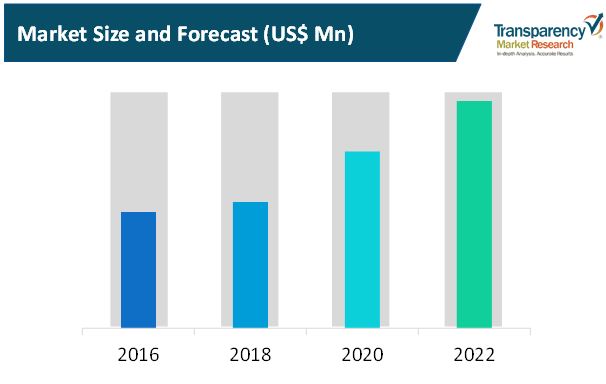

Increase in Automation in Manufacturing Industry Drives the Market

Rise in automation in the industrial sector is projected to be a major factor driving the mechanical springs market. Additionally, increase in enhancements in manufacturing process in terms of product quality and efficiency due to the rise in globalization has resulted in implementation of new products, this, in turn, is likely to propel the market in the next few years. Furthermore, growth in penetration of Computer Numerical Control (CNC) machines is another key factor estimated to boost the demand for mechanical springs across the globe. Moreover, increase in consumer disposable income and growth in automotive and aerospace industries are some of the key factors driving the demand for mechanical springs across the globe. Also, the integration of Internet of Things (IoT) in manufacturing is projected to be a major trend likely to gain traction in this market in the next few years.

Increase in Use of Plastic and Fiber Restraining Mechanical Spring Market

Rise in usage of plastic and fiber-made products due to the low cost of these products is expected to hamper the market in the next few years. Furthermore, mechanical spring market faces competition from increasing demand for non-mechanical or non-wire springs such as plastic products and gas springs. This is another key factor restraining the mechanical spring market.

Mechanical Springs Market: Segmentation

The mechanical springs market can be segmented based on:

Mechanical Springs Market Segmentation – By Shape

Based on shape, the mechanical springs market can be classified into:

Mechanical Springs Market Segmentation – By Load Force

In terms of load force, the mechanical springs market can be divided into:

Mechanical Springs Market Segmentation – By Material

In terms of material, the mechanical springs market can be segregated into:

Mechanical Springs Market Segmentation – By Application

Based on application, the mechanical springs market can be divided into:

The report on the mechanical springs market is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, and inputs from industry experts and industry participants across the value chain. The mechanical springs market report provides in-depth analysis of parent market trends, macroeconomic indicators, and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on mechanical springs market segments and geographies.

N/A