Reports

Reports

Analysts’ Viewpoint

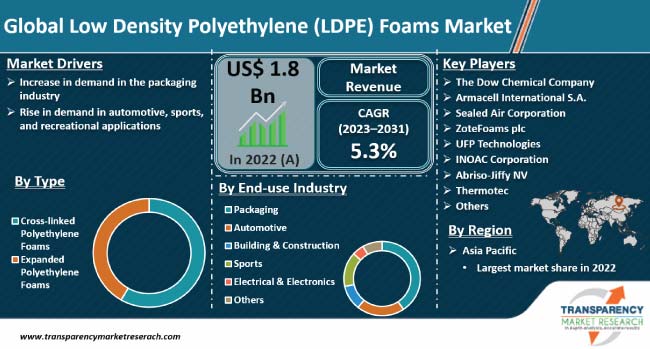

Excellent adaptability and broad range of uses in various sectors are expected to drive the global low density polyethylene (LDPE) foams market during the forecast period. LDPE foams, which are lightweight and have good insulating capabilities, are increasingly used in packaging, automotive, sports, and leisure industries. Surge in demand in automotive, sports, and recreational applications is another major factor propelling market expansion. Furthermore, rise in emphasis on sustainability, with LDPE foams emerging as favored environmentally-friendly material, is likely to bolster the global low density polyethylene (LDPE) foams market size in the near future.

Development of lightweight and high-performance solutions offers lucrative opportunities to market players. Manufacturers are focusing on introducing advanced raw materials and processing methods in order to increase market revenue.

Low density polyethylene (LDPE) foams' versatility has positioned them as a cornerstone material across sectors on a global scale. Their lightweight construction, combined with exceptional flexibility and insulating properties, makes them useful in a range of applications.

LDPE foams have demonstrated their utility in various industries, from protecting fragile items in packaging to improving safety features in vehicle design and even providing thermal insulation in building projects.

The global LDPE foams market offers a range of products, each precisely designed to meet the specific needs of their respective industries. LDPE foams, whether in sheets, rolls, or custom-molded components, provide a customized solution for various applications. This versatility has contributed to the widespread adoption and long-term importance of LDPE foams.

LDPE foam absorbs energy and could achieve varied levels of cushioning protection, depending on the exact density of the foam. It is largely utilized in the packaging sector to protect items from harm.

LDPE foam also has chemical resistant characteristics. This enables it to withstand common deterioration sources. Packaging covers customers' fundamental requirements as well as considerations of quality of life. It offers customers with information that could be vital to their health. This encompasses the freshness and ripeness of food, as well as its color, shelf life, contents, and nutritional value.

LDPE foams excel in insulation, acting as a barrier against temperature changes, moisture, and physical impacts. This is particularly useful for protecting fragile or temperature-sensitive commodities during shipping and storage. These characteristics combine to make LDPE foams an excellent choice for packaging applications across industries.

Increase in population and urbanization is driving the global packaging industry. This has resulted in greater economic activity, which has propelled demand for packaging solutions. Rise of e-commerce has led to a surge in demand for effective packaging.

The tendency of on-the-go consumption necessitates various container sizes as well as a requirement for food service packaging. LDPE foams have emerged as favored options in the packaging industry. Companies are rapidly understanding the advantages of using LDPE foams into their packaging strategy, not just for functional reasons, but also for favorable environmental effect. This trend is expected to continue, as companies prioritize sustainability and seek creative packaging solutions.

Surge in demand for sports equipment and products is driving the global low density polyethylene (LDPE) foams market demand. Moreover, urbanization and high consumer disposable income are projected to propel the global market.

LDPE foams are finding widespread usage in the sports sector because of their high flexibility. They are resistant to repeated shocks even when subjected to very high stresses. Furthermore, benefits such as water & chemical resistance, compressive strength, energy absorption, buoyancy, and cushioning qualities are bolstering the low density polyethylene (LDPE) foams market growth.

LDPE foams are widely used in vehicles for seats, headrests, armrests, and interior trim. Their low weight helps to reduce vehicle weight, which contributes to enhanced fuel economy. Furthermore, LDPE foams excel at shock absorption, a critical safety element that reduces impact forces during accidents and protects occupants. These attributes are driving the low density polyethylene (LDPE) foams industry growth.

LDPE foams are used in the manufacture of protective clothing, sporting equipment, and leisure items in the sports and recreational industries. Their strong shock-absorbing qualities soften the impact of physical activity, lowering the chance of damage.

The lightweight nature of LDPE foams keeps the equipment controllable and comfortable for users, boosting the whole athletic experience. LDPE foams are suited for outdoor and recreational applications because to their durability, weather resistance, and simplicity of manufacture. LDPE foams are durable and dependable in various applications, including boating, camping, and water sports equipment.

LDPE foams have emerged as a material of choice as sectors continue to place a premium on high-performance, lightweight materials that improve safety and comfort. Their versatility and efficacy in a range of applications in the automotive, sports, and recreational industries highlight their importance in modern production and consumer experiences.

Surge in demand for LDPE foams in various industries emphasizes their critical role in determining the future of these industries, highlighting the adaptable and dynamic character of LDPE foam technology. This factor is fueling the global LDPE foams market development.

The global LDPE foams market is expected to grow at a rapid pace during the forecast period. This is ascribed to increase in penetration of these foams in various sectors, particularly packaging, building & construction, and medical.

Growth of certain industries, such as protective packaging, where LDPE foams are being introduced; availability of advanced raw materials & processing methods that facilitate the manufacture of products with improved properties; and rise in number of LDPE foams being introduced are propelling the global market.

Asia Pacific is projected to account for the largest global LDPE foams market share of 44.82% during the forecast period. This is ascribed to growing industrialization and rise in demand for LDPE foams in the packaging and building & construction sectors. China is a prominent country for foams because of expansion of industries such as automotive. The country is a hub for automotive items that employ LDPE foam due to better qualities over other foams.

As per low density polyethylene (LDPE) foams market trends, Asia Pacific is projected to witness significant growth, led by China and India. China is expected to contribute considerably to global consumption by 2031. Surge in demand in the e-commerce retail industry across countries such as China, India, Australia, Singapore, Japan, and South Korea is driving the LDPE foams market development in the region.

Companies have adopted various strategies to increase market share in the global low density polyethylene (LDPE) foams market. According to the most recent low density polyethylene (LDPE) foams market analysis, the landscape is robust, with development and innovation driving the industry.

The Dow Chemical Company, Armacell International S.A, Sealed Air Corporation, ZoteFoams plc, UFP Technologies, INOAC Corporation, Abriso-Jiffy NV, Thermotec, American Excelsior, Inc., Ram Foam limited, Wisconsin Foam Products, Ultralon Foam Group, Sekisui Voltek LLC, PAR group, Zhuhai Newcean Technology Co. Ltd., and The Rubber Company are the prominent players in the market.

These firms were profiled in the low density polyethylene (LDPE) foams market research report based on parameters such as company overview, financial state, business strategies, product portfolio, business sectors, and recent developments. This comprehensive assessment contributes valuable information to the low density polyethylene (LDPE) foams market analysis.

| Attribute | Detail |

|---|---|

| Size in 2022 | US$ 1.8 Bn |

| Forecast (Value) in 2031 | US$ 2.8 Bn |

| Growth Rate (CAGR) | 5.3% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2020-2022 |

| Quantitative Tons | US$ Bn for Value and Kilo Tons for Volume |

| Market Analysis | It includes segment analysis as well as regional level analysis. Furthermore, the qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces Analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation |

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

It was valued at US$ 1.8 Bn in 2022

It is projected to expand at a CAGR of 5.3% from 2023 to 2031

Increase in demand in the packaging sector and rise in demand in automotive, sports, and recreational applications

The packaging end-use industry segment accounted for the largest share in 2022

Asia Pacific was the most lucrative region in 2022

The Dow Chemical Company, Armacell International S.A, Sealed Air Corporation, ZoteFoams plc, UFP Technologies, INOAC Corporation, Abriso-Jiffy NV, Thermotec, American Excelsior, Inc., Ram Foam limited, Wisconsin Foam Products, Ultralon Foam Group, Sekisui Voltek LLC, PAR group, Zhuhai Newcean Technology Co. Ltd, and The Rubber Company.

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Low Density Polyethylene (LDPE) Foams Market Analysis and Forecasts, 2023-2031

2.6.1. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons)

2.6.2. Low Density Polyethylene (LDPE) Foams Market Revenue (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Component Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealer/Distributors

2.9.4. List of Potential Customers

2.10. Product Specification Analysis

2.11. Production Overview

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on the Supply Chain of the Low Density Polyethylene (LDPE) Foams

3.2. Impact on the Demand of Low Density Polyethylene (LDPE) Foams - Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Tons)

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East & Africa

6. Price Trend Analysis and Forecast (US$/Ton), 2023-2031

6.1. Price Comparison Analysis by Type

6.2. Price Comparison Analysis by Region

7. Global Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, by Type, 2023-2031

7.1. Introduction and Definitions

7.2. Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

7.2.1. Cross-linked Polyethylene Foams

7.2.2. Expanded Polyethylene

7.3. Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

8. Global Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, by End-use Industry, 2023-2031

8.1. Introduction and Definitions

8.2. Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

8.2.1. Packaging

8.2.2. Automotive

8.2.3. Building & construction

8.2.4. Sport

8.2.5. Electrical & Electronics

8.2.6. Others

8.3. Global Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

9. Global Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, by Region, 2023-2031

9.1. Key Findings

9.2. Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Region, 2023-2031

9.2.1. North America

9.2.2. Europe

9.2.3. Asia Pacific

9.2.4. Latin America

9.2.5. Middle East & Africa

9.3. Global Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Region

10. North America Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, 2023-2031

10.1. Key Findings

10.2. North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

10.3. North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

10.4. North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country, 2023-2031

10.4.1. U.S. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

10.4.2. U.S. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

10.4.3. Canada Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

10.4.4. Canada Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

10.5. North America Low Density Polyethylene (LDPE) Foams Market Attractiveness Analysis

11. Europe Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, 2023-2031

11.1. Key Findings

11.2. Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.3. Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

11.4. Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

11.4.1. Germany Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.2. Germany. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.4.3. France Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.4. France. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.4.5. U.K. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.6. U.K. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.4.7. Italy Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.8. Italy Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.4.9. Russia & CIS Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.10. Russia & CIS Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.4.11. Rest of Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.4.12. Rest of Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

11.5. Europe Low Density Polyethylene (LDPE) Foams Market Attractiveness Analysis

12. Asia Pacific Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.3. Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

12.4. Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

12.4.1. China Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4.2. China Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

12.4.3. Japan Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4.4. Japan Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

12.4.5. India Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4.6. India Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

12.4.7. ASEAN Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4.8. ASEAN Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

12.4.9. Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.4.10. Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

12.5. Asia Pacific Low Density Polyethylene (LDPE) Foams Market Attractiveness Analysis

13. Latin America Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.3. Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

13.4. Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

13.4.1. Brazil Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.4.2. Brazil Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

13.4.3. Mexico Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.4.4. Mexico Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

13.4.5. Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.4.6. Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

13.5. Latin America Low Density Polyethylene (LDPE) Foams Market Attractiveness Analysis

14. Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.3. Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

14.4. Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

14.4.1. GCC Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.4.2. GCC Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

14.4.3. South Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.4.4. South Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

14.4.5. Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.4.6. Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use Industry, 2023-2031

14.5. Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Attractiveness Analysis

15. Competition Landscape

15.1. Market Players - Competition Matrix (by Tier and Size of Companies)

15.2. Market Share Analysis, 2021

15.3. Market Footprint Analysis

15.3.1. By Type

15.4. Company Profiles

15.4.1. The Dow Chemical Company

15.4.1.1. Company Revenue

15.4.1.2. Business Overview

15.4.1.3. Product Segments

15.4.1.4. Geographic Footprint

15.4.1.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.1.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.2. Armacell International S.A.

15.4.2.1. Company Revenue

15.4.2.2. Business Overview

15.4.2.3. Product Segments

15.4.2.4. Geographic Footprint

15.4.2.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.2.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.3. Sealed Air Corporation

15.4.3.1. Company Revenue

15.4.3.2. Business Overview

15.4.3.3. Product Segments

15.4.3.4. Geographic Footprint

15.4.3.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.3.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.4. ZoteFoams plc

15.4.4.1. Company Revenue

15.4.4.2. Business Overview

15.4.4.3. Product Segments

15.4.4.4. Geographic Footprint

15.4.4.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.4.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.5. UFP Technologies

15.4.5.1. Company Revenue

15.4.5.2. Business Overview

15.4.5.3. Product Segments

15.4.5.4. Geographic Footprint

15.4.5.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.5.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.6. INOAC Corporation

15.4.6.1. Company Revenue

15.4.6.2. Business Overview

15.4.6.3. Product Segments

15.4.6.4. Geographic Footprint

15.4.6.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.6.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.7. Abriso-Jiffy NV

15.4.7.1. Company Revenue

15.4.7.2. Business Overview

15.4.7.3. Product Segments

15.4.7.4. Geographic Footprint

15.4.7.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.7.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.8. Thermotec

15.4.8.1. Company Revenue

15.4.8.2. Business Overview

15.4.8.3. Product Segments

15.4.8.4. Geographic Footprint

15.4.8.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.8.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.9. American Excelsior, Inc.

15.4.9.1. Company Revenue

15.4.9.2. Business Overview

15.4.9.3. Product Segments

15.4.9.4. Geographic Footprint

15.4.9.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.9.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.10. Ram Foam limited

15.4.10.1. Company Revenue

15.4.10.2. Business Overview

15.4.10.3. Product Segments

15.4.10.4. Geographic Footprint

15.4.10.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.10.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.11. Wisconsin Foam Products

15.4.11.1. Company Revenue

15.4.11.2. Business Overview

15.4.11.3. Product Segments

15.4.11.4. Geographic Footprint

15.4.11.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.11.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.12. Ultralon Foam Group

15.4.12.1. Company Revenue

15.4.12.2. Business Overview

15.4.12.3. Product Segments

15.4.12.4. Geographic Footprint

15.4.12.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.12.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.13. Sekisui Voltek LLC

15.4.13.1. Company Revenue

15.4.13.2. Business Overview

15.4.13.3. Product Segments

15.4.13.4. Geographic Footprint

15.4.13.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.13.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.14. PAR group

15.4.14.1. Company Revenue

15.4.14.2. Business Overview

15.4.14.3. Product Segments

15.4.14.4. Geographic Footprint

15.4.14.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.14.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.15. Zhuhai Newcean Technology Co. Ltd

15.4.15.1. Company Revenue

15.4.15.2. Business Overview

15.4.15.3. Product Segments

15.4.15.4. Geographic Footprint

15.4.15.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.15.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

15.4.16. The Rubber Company

15.4.16.1. Company Revenue

15.4.16.2. Business Overview

15.4.16.3. Product Segments

15.4.16.4. Geographic Footprint

15.4.16.5. Production Type/Plant Details, etc. (*As Applicable)

15.4.16.6. Strategic Partnership, Coat Type Expansion, New Product Innovation etc.

16. Primary Research: Key Insights

17. Appendix

List of Tables

Table 1: Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 2: Global Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 3: Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 4: Global Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

Table 5: Global Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Region, 2023-2031

Table 6: Global Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Region, 2023-2031

Table 7: North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 8: North America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 9: North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 10: North America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

Table 11: North America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Country, 2023-2031

Table 12: North America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Country, 2023-2031

Table 13: U.S. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 14: U.S. Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 15: U.S. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 16: U.S. Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry, 2023-2031

Table 17: Canada Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 18: Canada Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 19: Canada Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 20: Canada Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 21: Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 22: Europe Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 23: Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 24: Europe Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 25: Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 26: Europe Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 27: Germany Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 28: Germany Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 29: Germany Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 30: Germany Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 31: France Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 32: France Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 33: France Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 34: France Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 35: U.K. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 36: U.K. Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 37: U.K. Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 38: U.K. Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 39: Italy Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 40: Italy Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 41: Italy Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 42: Italy Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 43: Spain Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 44: Spain Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 45: Spain Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 46: Spain Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 47: Russia & CIS Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 48: Russia & CIS Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 49: Russia & CIS Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 50: Russia & CIS Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 51: Rest of Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 52: Rest of Europe Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 53: Rest of Europe Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 54: Rest of Europe Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 55: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 56: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 61: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 62: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 63: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 64: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 65: China Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 66: China Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type 2023-2031

Table 67: China Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 68: China Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 69: Japan Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 70: Japan Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 71: Japan Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 72: Japan Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 73: India Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 74: India Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 75: India Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 76: India Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 77: ASEAN Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 78: ASEAN Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 79: ASEAN Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 80: ASEAN Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 81: Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 82: Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 83: Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 84: Rest of Asia Pacific Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 85: Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 86: Latin America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 87: Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 88: Latin America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 89: Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 90: Latin America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 91: Brazil Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 92: Brazil Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 93: Brazil Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 94: Brazil Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 95: Mexico Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 96: Mexico Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 97: Mexico Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 98: Mexico Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 99: Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 100: Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 101: Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 102: Rest of Latin America Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 103: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 104: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 105: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 106: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 107: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 108: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

Table 109: GCC Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 110: GCC Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 111: GCC Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 112: GCC Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 113: South Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 114: South Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 115: South Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 116: South Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

Table 117: Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by Type, 2023-2031

Table 118: Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by Type, 2023-2031

Table 119: Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume (Kilo Tons) Forecast, by End-use Industry, 2023-2031

Table 120: Rest of Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Value (US$ Mn) Forecast, by End-use Industry 2023-2031

List of Figures

Figure 1: Global Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 2: Global Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 3: Global Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 4: Global Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 5: Global Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 6: Global Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Region

Figure 7: North America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 8: North America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 9: North America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 10: North America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 11: North America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Country, 2022, 2027, and 2031

Figure 12: North America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Country

Figure 13: Europe Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 14: Europe Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 15: Europe Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 16: Europe Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 17: Europe Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 18: Europe Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Country and Sub-region

Figure 19: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 20: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 21: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 22: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 23: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Asia Pacific Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Country and Sub-region

Figure 25: Latin America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 26: Latin America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 27: Latin America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 28: Latin America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 29: Latin America Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 30: Latin America Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Country and Sub-region

Figure 31: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 32: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Type

Figure 33: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by End-use Industry, 2022, 2027, and 2031

Figure 34: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Attractiveness, by End-use Industry

Figure 35: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 36: Middle East & Africa Low Density Polyethylene (LDPE) Foams Market Attractiveness, by Country and Sub-region