Reports

Reports

The production of knitting oil includes a combination of high-quality HVI solvent-extracted dual hydrogenated paraffin base oils with good lubricity, oxidation stability, and rust tolerance. The knitting oils have a long service life without the formation of sludge and acid that increases a machine’s wear. They are growing in popularity to their non-foaming, antirust qualities, and unique lubricity characteristics. Knitting oil is mostly used as an anti-staining lubricant for needles of various other types of knitting machines and is suitable for automatic oiling units on knitting machines. Presently, the knitting process has drastically grown, owing to the research and development by several manufacturers along the long way in the textile industry. In India, the textile industry has been rapidly expanding, leading the global market. This is most likely to drive the India knitting oil market during the forecast period.

Modern knitting machines can process several hundred kilograms of knitted material at maximum speeds daily. The needles and sinker can process several colorful threads into socks, sweaters, skirts, coats, wool bed covers, and other clothing in short time. Precise knitting requires sufficient yarn tension as well as the stable operation of bearings, sprockets, sliding elements, and needles. As even the smallest disparity in machines can reflect on the knitted fabric, the amount of substandard fabric, as well as the associated manufacturing expenses, is increased. Manufacturers in India now offer high-performance knitting oil for better reliability of machines. The oil helps to minimize wear and friction, and allows clean and low-maintenance production processes while saving costs. Moreover, knitting oils maintain high thermal resistance and remain water white when exposed to heat over a while. All these features are expected to drive the India knitting oil market in the upcoming future.

The outbreak of the COVID-19 has spread across the world declaring it a public health emergency. The global crisis will significantly affect the India knitting oil market in the near future. The pandemic has directly influenced production and trade by creating supply chain and market disruption, and by its economic impact on businesses and financial markets. It has also caused impressions on many features such as flight cancellations, travel prohibitions, quarantines, restricted activities, stock market volatility, dropping business spirit, and growing panic among the population. The business of knitting oil producers largely depends on the types of yarns they are producing and the machines required to create them. In India, the expenses of important domestic raw materials may not have witnessed a significant spike in prices. However, the prices of imported material increased incredibly, as international trade was allowed at a minimum amount in need.

The Indian textile industry witnessed enormous demand for products that support the medical community and essential workers. However, the demand only benefitted the players that had a presence in providing the textile businesses that make these types of products. Key producers, especially those that are multinational, had the means to remain viable during the crisis and will most likely resume operations with only minimal-to-moderate damage to their businesses. Smaller players are expected to struggle much more, and many of them may not survive after the pandemic. This is not only the case of the manufacturing sector, but many local businesses and end-use businesses such as textile, hospitality, and others were shutting doors to contain the spread of COVID-19. Nevertheless, Asia Pacific is expected to witness a boon in the production post COVID-19 pandemic, owing to the closure of several global manufacturers and others working on reduced schedules. This is most likely to create more opportunities for the India knitting oil market.

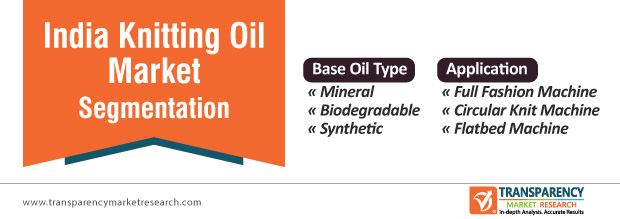

Knitting oil has been developed and researched for several years to become efficient and popular. The modern knitting oil can be used with all types of knitting machines, including full fashion machines and flatbed machines. The machines in textile production involve the use of needles, lifters, and sinkers. As these parts are needed to be properly maintained, it can make it easy for consumers to use knitting oil on these parts to ensure endurance. The knitting oil has been proven efficient for electronically and mechanically controlled machines. In addition, knitting oil is a specific name given to the lubricating oil when used in knitting machines in India. The knitting oil though finds its application in almost every machine that involves mechanical contacts. As textile business owners in India are increasingly preferring high oxidation resistance, excellent aging stability limiting stains, sludge, and sediment formation in the machine productivity, the India knitting oil market is expected to grow during the projected period.

The textile industry in India is one of the oldest industries, which has undergone a massive change in the past two decades. Old machines installed several years ago are still used and processed. The evolution of textile machines and advanced technology are expected t compel businesses to replace their old machines. Moreover, smart features and programmed machines have replaced skilled laborers, while increasing the productivity of the industry in the region. The advancement in technology also reduced the labor cost, as it can be operated with a limited number of people. Furthermore, the Government of India has allowed foreign investors to invest in full capacity. With many textile producers upgrading their facilities, the India knitting oil market is expected to witness several new opportunities in the near future.

In India, knitting oil is produced using various base oils including mineral oil, biodegradable oil, and synthetic oil. Developing research and upgrades in knitting oil have spiked the price. This contributes to an increase in the overall production cost, thereby hampering the growth of the India knitting oil market. Moreover, key players that operate in the market have patented technologies for developing knitting oil. This is limiting new entrants in the market. The excellent properties of knitting oil can be unaffordable to various players, especially with the economic decline in the pandemic. However, increasing foreign direct investments and growing international mergers with local players are likely to reduce the overall cost of production, thus fueling the growth of the India knitting oil market.

Analysts’ Viewpoint

The textile industry in India is rapidly growing, owing to lifestyle trends and increased demand for functional clothing. Moreover, knitting oil is used in full fashion machines to avoid damage to components of knit machines. Moreover, the textiles and apparel industry in India is popularly growing across the entire value chain from fiber, yarn, and fabric to apparel. Thus, the rising clothing demand in India is expected to propel the knitting oil market in India. The India knitting oil market is projected to reach US$ 43 Mn by 2031, at a CAGR of ~5% during the forecast period.

India Knitting Oil Market: Overview

Key Drivers of India Knitting Oil Market

Major Challenges for India Knitting Oil Market

Lucrative Opportunities for Players Operating in India Knitting Oil Market

Leading Players in India Knitting Oil Market

India knitting oil market to reach valuation of US$ 43 Mn by 2031

India knitting oil market is expanding at a CAGR of 5% during the forecast period

Rising clothing demand in India is expected to propel the knitting oil market in India

Key players of knitting oil in India are Indian Oil Corporation Ltd, Paras Lubricants Ltd, Eastern Petroleum Pvt. Ltd., Carl Bechem Lubricants India Private Limited, DANA Lubricants Factory LLC

The forecast period considered for the India knitting oil market is 2021-2031

1. Executive Summary

1.1. India Knitting Oil Market Snapshot

1.2. Key Market Trends

1.3. Current Market and Future Potential

1.4. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Market Indicators

2.3. Market Definitions

2.4. Market Dynamics

2.4.1. Drivers

2.4.2. Restraints

2.4.3. Opportunities

2.5. Porter’s Five Forces Analysis

2.6. Value Chain Analysis

2.6.1. List of Potential Customers

3. COVID-19 Impact Analysis

4. India Knitting Oil Market Production Outlook

5. India Knitting Oil Market Price Trend Analysis, 2020-2031

5.1. By Base Oil Type

6. India Knitting Oil Market Analysis and Forecast, 2020-2031

6.1. Key Findings

6.2. India Knitting Oil Market Volume (Tons) and Value (US$ Mn) Forecast, by Base Oil Type, 2020-2031

6.3. India Knitting Oil Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2020-2031

6.4. India Knitting Oil Market Attractiveness Analysis

7. Competition Landscape

7.1. India Knitting Oil Market Share Analysis, 2019

7.2. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

7.2.1. Klueber Lubrication

7.2.1.1. Company Description

7.2.1.2. Business Overview

7.2.1.3. Financial Overview

7.2.1.4. Strategic Overview

7.2.2. DANA Lubricants Factory LLC

7.2.2.1. Company Description

7.2.2.2. Business Overview

7.2.2.3. Financial Overview

7.2.2.4. Strategic Overview

7.2.3. Eastern Petroleum Pvt Ltd

7.2.3.1. Company Description

7.2.3.2. Business Overview

7.2.3.3. Financial Overview

7.2.3.4. Strategic Overview

7.2.4. Witmans Industries Private Limited

7.2.4.1. Company Description

7.2.4.2. Business Overview

7.2.5. Total Lubricants

7.2.5.1. Company Description

7.2.5.2. Business Overview

7.2.5.3. Financial Overview

7.2.5.4. Strategic Overview

7.2.6. Vickers Oils

7.2.6.1. Company Description

7.2.6.2. Business Overview

7.2.6.3. Financial Overview

7.2.6.4. Strategic Overview

7.2.7. Klueber Lubrication

7.2.7.1. Company Description

7.2.7.2. Business Overview

7.2.7.3. Financial Overview

7.2.7.4. Strategic Overview

8. Primary Research: Key Insights

9. Appendix

List of Tables

Table 1: India Knitting Oil Market Volume (Tons) Forecast, by Base Oil Type, 2020–2031

Table 2: India Knitting Oil Market Value (US$ Mn) Forecast, by Base Oil Type, 2020–2031

Table 3: India Knitting Oil Market Volume Share, by Application, 2020–2031

Table 4: India Knitting Oil Market Value Share, by Application, 2020–2031

List of Figures

Figure 1: India Knitting Oil Market Volume Share, by Base Oil Type, 2020, 2025, and 2031

Figure 2: India Knitting Oil Market Attractiveness, by Base Oil Type

Figure 3: India Knitting Oil Market Volume Share, by Application, 2020, 2025, and 2031

Figure 4: India Knitting Oil Market Attractiveness, by Application