Reports

Reports

Analysts’ Viewpoint

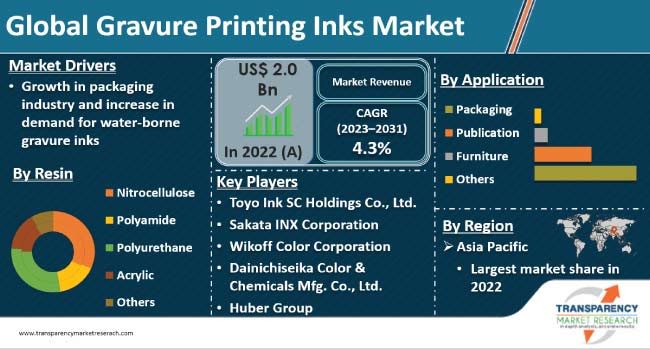

Growth of the packaging sector is expected to propel the global gravure printing inks market size during the forecast period. Rotogravure printing inks are gaining traction due to increase in demand for high-quality and visually captivating printing solutions across various industries. Surge in concerns about adverse environmental impact of traditional solvent-based inks is also augmenting market expansion.

Rise in demand for sustainable printing services in various industries is likely to offer lucrative opportunities to vendors in the global gravure printing inks industry. Companies are investing significantly in R&D activities to expand their product portfolio and increase gravure printing inks market share.

Gravure printing inks, a major part of gravure printing process, embody a perfect amalgamation of technical finesse and creative expression. These inks help produce images of high precision and detail. Gravure printing revolves around etching intricate designs onto cylindrical surfaces, each impression capturing the essence of the artwork.

Gravure printing inks possess optimal consistency, texture, and drying properties that seamlessly complement the engraved patterns. These inks can be used on an array of substrates such as paper and flexible packaging materials. Gravure printing inks come in various formulations to suit different substrates, applications, and printing conditions.

Engraved printing inks are a critical component of the gravure printing process, enabling the creation of high quality, detailed, and visually appealing prints used in a range of industries, including packaging, publishing, advertising, and decorative printing.

Packaging plays a major role in sectors such as food & beverages, pharmaceuticals, and consumer goods. Gravure printing is gaining traction as a preferred printing method for packaging materials such as labels, flexible packaging, and shrink sleeves. Surge in preference for gravure printing is ascribed to its capability to produce high-quality, intricate designs, and vibrant prints, thereby enhancing the visual appeal of packaging. Thus, expansion of the packaging sector is fueling the gravure printing inks market value.

Rapid urbanization and changes in lifestyle have led to rise in demand for packaged products. This, in turn, is anticipated to boost adoption of captivating and informative packaging. Brands are leveraging packaging as a means of establishing their identity and distinguishing themselves in a crowded marketplace. Gravure printing facilitates the realization of intricate branding elements and design nuances.

Expansion of the e-commerce sector is projected to spur the gravure printing inks market growth in the next few years. Packaging safeguards products during transit and provides an immersive unboxing experience. This, in turn, is fueling the need for high-quality printing. Gravure printing, with its ability to render lifelike images and intricate patterns, aligns seamlessly with this need.

Globalization is driving the need for packaging that can transcend language barriers and maintain consistent branding across diverse regions. The proficiency of gravure printing in reproducing intricate designs and texts makes it an ideal choice for achieving this global reach.

Water-borne gravure inks are gaining traction in the printing sector as vendors are adopting sustainable and environmentally conscious practices. Traditional solvent-based inks adversely affect the environment. Water-borne gravure inks offer an eco-friendlier alternative as they have a lower content of Volatile Organic Compounds (VOCs) and hazardous air pollutants, which helps reduce potential harm to human health and the environment. Hence, increase in concerns about adverse environmental impact of traditional solvent-based inks is augmenting the gravure printing inks market revenue.

Implementation of stringent environmental regulations and rise in preference for greener products are prompting manufacturers to seek alternatives that align with sustainable practices. Water-borne gravure inks meet these criteria by providing a safer and less toxic printing solution. These inks have reduced odor, which is advantageous in indoor printing environments, and contribute to improved air quality. This aligns with workplace safety concerns and community well-being.

Sustainability is a key consideration for consumer purchasing decisions. Thus, various end-users are increasingly adopting eco-friendly gravure inks for packaging to minimize their environmental impact and promote sustainable practices. Water-borne gravure inks align with this ethos, allowing brands to communicate their dedication to sustainability to their customers.

According to the latest gravure printing inks market trends, the nitrocellulose resin segment is expected to dominate the sector during the forecast period. Nitrocellulose-based inks are widely recognized for their versatility, fast-drying properties, and excellent adhesion to various substrates. This makes them a favored choice for gravure printing applications across industries.

Nitrocellulose-based inks adhere well to porous and non-porous surfaces such as paper, film, and metal. This versatility allows them to be employed in packaging materials, labels, magazines, and other printed products. The fast-drying nature of nitrocellulose inks significantly contributes to higher production speeds, making them ideal for high-volume printing operations.

Nitrocellulose-based inks are known for their versatility, fast-drying properties, vibrant color reproduction, and excellent adhesion to various substrates. While they offer several advantages, the sector’s increasing focus on sustainability is driving the exploration of alternative ink formulations that align with environmental standards and regulations.

According to the latest gravure printing inks market forecast, Asia Pacific is anticipated to account for the largest share from 2023 to 2031. The region held 42.5% share in 2022. Rapid industrialization and expansion in the manufacturing sector, particularly in countries such as China, India, Japan, and South Korea, are fueling market dynamics of the region.

Presence of a well-established packaging sector, surge in investment in product development, and strong emphasis on product presentation and branding are propelling market progress in North America. Food & beverages, pharmaceutical, cosmetics, and other industries in the region are adopting gravure printing inks for high-quality printing.

Mature packaging & labeling sectors and implementation of stringent regulations about packaging information & safety are driving market statistics in Europe. The industry in Latin America and Middle East & Africa is projected to grow at a sluggish pace during the forecast period.

The global industry is highly consolidated, with a small number of large-scale gravure printing ink companies controlling majority of the market share. Most gravure printing ink manufacturers are investing significantly in the R&D of new products to expand their product portfolio. These investments are aimed at improving print quality, enhancing environmental sustainability, and expanding the range of substrates & applications that gravure printing can address.

Toyo Ink SC Holdings Co., Ltd., Sakata INX Corporation, Wikoff Color Corporation, Dainichiseika Color & Chemicals Mfg. Co., Ltd., Siegwerk Druckfarben AG & Co. KGaA, Huber Group, Tokyo Printing Ink Mfg. Co., Ltd., DIC Corporation, FUJIFILM Holdings Corporation, Marabu GmbH & Co. KG, and Nutec Digital Ink are the prominent players in the market.

Each of these players has been profiled in the gravure printing inks market report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

| Attribute | Detail |

|---|---|

| Market Value in 2022 | US$ 2.0 Bn |

| Market Forecast Value in 2031 | US$ 2.9 Bn |

| Growth Rate (CAGR) | 4.3% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2022 |

| Quantitative Units | US$ Bn for Value and Kilo Tons for Volume |

| Market Analysis | It includes cross-segment analysis at the global as well as regional level. Furthermore, the qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation |

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

It was valued at US$ 2.0 Bn in 2022

It is projected to grow at a CAGR of 4.3% from 2023 to 2031

Growth of the packaging sector and surge in concerns about adverse environmental impact of traditional solvent-based inks

In terms of resin, nitrocellulose was the largest segment, with 32.4% share in 2022

Asia Pacific recorded the highest demand in 2022

Toyo Ink SC Holdings Co., Ltd., Sakata INX Corporation, Wikoff Color Corporation, Dainichiseika Color & Chemicals Mfg. Co., Ltd., Siegwerk Druckfarben AG & Co. KGaA, Huber Group, Tokyo Printing Ink Mfg. Co., Ltd., DIC Corporation, FUJIFILM Holdings Corporation, Marabu GmbH & Co. KG, and Nutec Digital Ink

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global Gravure Printing Inks Market Analysis and Forecast, 2023-2031

2.6.1. Global Gravure Printing Inks Market Volume (Kilo Tons)

2.6.2. Global Gravure Printing Inks Market Revenue (US$ Bn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Raw Technology Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealers/Distributors

2.9.4. List of Potential Customers

2.10. Production Overview

2.11. Product Specification Analysis

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on Supply Chain of Gravure Printing Inks

3.2. Impact on Demand for Gravure Printing Inks- Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Kilo Tons), 2022

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East & Africa

6. Price Trend Analysis and Forecast (US$/Kilo Tons), 2023-2031

6.1. Price Comparison Analysis by Resin

6.2. Price Comparison Analysis by Region

7. Global Gravure Printing Inks Market Analysis and Forecast, by Resin, 2023-2031

7.1. Key Findings

7.2. Global Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

7.2.1. Nitrocellulose

7.2.2. Polyamide

7.2.3. Polyurethane

7.2.4. Acrylic

7.2.5. Others

7.3. Global Gravure Printing Inks Market Attractiveness, by Resin

8. Global Gravure Printing Inks Market Analysis and Forecast, by Technology, 2023-2031

8.1. Key Findings

8.2. Global Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

8.2.1. Water-based

8.2.2. Solvent-based

8.2.3. Others

8.3. Global Gravure Printing Inks Market Attractiveness, by Technology

9. Global Gravure Printing Inks Market Analysis and Forecast, Application, 2023-2031

9.1. Key Findings

9.2. Global Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

9.2.1. Packaging

9.2.2. Publication

9.2.3. Furniture

9.2.4. Others

9.3. Global Gravure Printing Inks Market Attractiveness, by Application

10. Global Gravure Printing Inks Market Analysis and Forecast, by Region, 2023-2031

10.1. Key Findings

10.2. Global Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Region, 2023-2031

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Global Gravure Printing Inks Market Attractiveness, by Region

11. North America Gravure Printing Inks Market Analysis and Forecast, 2023-2031

11.1. Key Findings

11.2. North America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

11.3. North America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

11.4. North America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.5. North America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Country, 2023-2031

11.5.1. U.S. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

11.5.2. U.S. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

11.5.3. U.S. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.5.4. Canada Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

11.5.5. Canada Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

11.5.6. Canada Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.6. North America Gravure Printing Inks Market Attractiveness Analysis

12. Europe Gravure Printing Inks Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.3. Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.4. Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5. Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

12.5.1. Germany Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.2. Germany Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.3. Germany Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.4. France Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.5. France Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.6. France Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.7. U.K. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.8. U.K. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.9. U.K. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.10. Italy Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.11. Italy. Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.12. Italy Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.13. Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.14. Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.15. Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.16. Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

12.5.17. Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

12.5.18. Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.6. Europe Gravure Printing Inks Market Attractiveness Analysis

13. Asia Pacific Gravure Printing Inks Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin

13.3. Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.4. Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5. Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

13.5.1. China Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

13.5.2. China Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.5.3. China Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.4. Japan Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

13.5.5. Japan Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.5.6. Japan Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.7. India Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

13.5.8. India Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.5.9. India Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.10. ASEAN Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

13.5.11. ASEAN Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.5.12. ASEAN Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.13. Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

13.5.14. Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

13.5.15. Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.6. Asia Pacific Gravure Printing Inks Market Attractiveness Analysis

14. Latin America Gravure Printing Inks Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

14.3. Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

14.4. Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5. Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

14.5.1. Brazil Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

14.5.2. Brazil Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

14.5.3. Brazil Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5.4. Mexico Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

14.5.5. Mexico Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

14.5.6. Mexico Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5.7. Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

14.5.8. Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

14.5.9. Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.6. Latin America Gravure Printing Inks Market Attractiveness Analysis

15. Middle East & Africa Gravure Printing Inks Market Analysis and Forecast, 2023-2031

15.1. Key Findings

15.2. Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

15.3. Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

15.4. Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5. Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

15.5.1. GCC Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

15.5.2. GCC Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

15.5.3. GCC Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5.4. South Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

15.5.5. South Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

15.5.6. South Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5.7. Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Resin, 2023-2031

15.5.8. Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Technology, 2023-2031

15.5.9. Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.6. Middle East & Africa Gravure Printing Inks Market Attractiveness Analysis

16. Competition Landscape

16.1. Market Players - Competition Matrix (by Tier and Size of Companies)

16.2. Market Share Analysis, 2022

16.3. Market Footprint Analysis

16.3.1. By Resin

16.3.2. By Technology

16.3.3. By Application

16.4. Company Profiles

16.4.1. Toyo Ink SC Holdings Co., Ltd.

16.4.1.1. Company Revenue

16.4.1.2. Business Overview

16.4.1.3. Product Segments

16.4.1.4. Geographic Footprint

16.4.1.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.1.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.2. Sakata INX Corporation

16.4.2.1. Company Revenue

16.4.2.2. Business Overview

16.4.2.3. Product Segments

16.4.2.4. Geographic Footprint

16.4.2.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.2.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.3. Wikoff Color Corporation

16.4.3.1. Company Revenue

16.4.3.2. Business Overview

16.4.3.3. Product Segments

16.4.3.4. Geographic Footprint

16.4.3.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.3.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.4. Dainichiseika Color & Chemicals Mfg. Co., Ltd.

16.4.4.1. Company Revenue

16.4.4.2. Business Overview

16.4.4.3. Product Segments

16.4.4.4. Geographic Footprint

16.4.4.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.4.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.5. Siegwerk Druckfarben AG & Co. KGaA

16.4.5.1. Company Revenue

16.4.5.2. Business Overview

16.4.5.3. Product Segments

16.4.5.4. Geographic Footprint

16.4.5.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.5.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.6. Huber Group

16.4.6.1. Company Revenue

16.4.6.2. Business Overview

16.4.6.3. Product Segments

16.4.6.4. Geographic Footprint

16.4.6.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.6.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.7. Tokyo Printing Ink Mfg. Co., Ltd.

16.4.7.1. Company Revenue

16.4.7.2. Business Overview

16.4.7.3. Product Segments

16.4.7.4. Geographic Footprint

16.4.7.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.7.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.8. DIC Corporation

16.4.8.1. Company Revenue

16.4.8.2. Business Overview

16.4.8.3. Product Segments

16.4.8.4. Geographic Footprint

16.4.8.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.8.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.9. FUJIFILM Holdings Corporation

16.4.9.1. Company Revenue

16.4.9.2. Business Overview

16.4.9.3. Product Segments

16.4.9.4. Geographic Footprint

16.4.9.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.9.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.10. Marabu GmbH & Co. KG

16.4.10.1. Company Revenue

16.4.10.2. Business Overview

16.4.10.3. Product Segments

16.4.10.4. Geographic Footprint

16.4.10.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.10.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.11. Nutec Digital Ink

16.4.11.1. Company Revenue

16.4.11.2. Business Overview

16.4.11.3. Product Segments

16.4.11.4. Geographic Footprint

16.4.11.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.11.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17. Primary Research: Key Insights

18. Appendix

List of Tables

Table 1: Global Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 2: Global Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 3: Global Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 4: Global Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 5: Global Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 6: Global Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 7: Global Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Region, 2023-2031

Table 8: Global Gravure Printing Inks Market Value (US$ Bn) Forecast, by Region, 2023-2031

Table 9: North America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 10: North America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 11: North America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 12: North America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 13: North America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 14: North America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 15: North America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Country, 2023-2031

Table 16: North America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Country, 2023-2031

Table 17: U.S. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 18: U.S. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 19: U.S. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 20: U.S. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 21: U.S. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 22: U.S. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 23: Canada Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 24: Canada Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 25: Canada Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 26: Canada Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 27: Canada Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 28: Canada Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 29: Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 30: Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 31: Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 32: Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 33: Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 34: Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 35: Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 36: Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 37: Germany Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 38: Germany Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 39: Germany Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 40: Germany Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 41: Germany Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 42: Germany Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 43: France Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 44: France Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 45: France Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 46: France Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 47: France Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 48: France Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 49: U.K. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 50: U.K. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 51: U.K. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 52: U.K. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 53: U.K. Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 54: U.K. Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 55: Italy Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 56: Italy Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 57: Italy Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 58: Italy Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 59: Italy Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 60: Italy Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 61: Spain Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 62: Spain Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 63: Spain Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 64: Spain Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 65: Spain Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 66: Spain Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 67: Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 68: Russia & CIS Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 69: Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 70: Russia & CIS Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 71: Russia & CIS Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 72: Russia & CIS Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 73: Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 74: Rest of Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 75: Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 76: Rest of Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 77: Rest of Europe Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 78: Rest of Europe Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 79: Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 80: Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 81: Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 82: Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 83: Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 84: Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 85: Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 86: Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 87: China Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 88: China Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin 2023-2031

Table 89: China Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 90: China Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 91: China Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 92: China Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 93: Japan Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 94: Japan Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 95: Japan Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 96: Japan Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 97: Japan Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 98: Japan Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 99: India Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 100: India Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 101: India Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 102: India Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 103: India Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 104: India Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 105: India Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 106: India Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application 2023-2031

Table 107: ASEAN Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 108: ASEAN Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 109: ASEAN Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 110: ASEAN Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 111: ASEAN Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 112: ASEAN Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 113: Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 114: Rest of Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 115: Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 116: Rest of Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 117: Rest of Asia Pacific Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 118: Rest of Asia Pacific Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 119: Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 120: Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 121: Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 122: Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 123: Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 124: Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 125: Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 126: Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 127: Brazil Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 128: Brazil Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 129: Brazil Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 130: Brazil Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 131: Brazil Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 132: Brazil Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 133: Mexico Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 134: Mexico Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 135: Mexico Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 136: Mexico Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 137: Mexico Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 138: Mexico Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 139: Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 140: Rest of Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 141: Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 142: Rest of Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 143: Rest of Latin America Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 144: Rest of Latin America Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 145: Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 146: Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 147: Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 148: Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 149: Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 150: Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 151: Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023-2031

Table 152: Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 153: GCC Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 154: GCC Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 155: GCC Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 156: GCC Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 157: GCC Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 158: GCC Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 159: South Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 160: South Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 161: South Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 162: South Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 163: South Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 164: South Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 165: Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Resin, 2023-2031

Table 166: Rest of Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Resin, 2023-2031

Table 167: Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Technology, 2023-2031

Table 168: Rest of Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Technology, 2023-2031

Table 169: Rest of Middle East & Africa Gravure Printing Inks Market Volume (Kilo Tons) Forecast, by Application, 2023-2031

Table 170: Rest of Middle East & Africa Gravure Printing Inks Market Value (US$ Bn) Forecast, by Application, 2023-2031

List of Figures

Figure 1: Global Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 2: Global Gravure Printing Inks Market Attractiveness, by Resin

Figure 3: Global Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 4: Global Gravure Printing Inks Market Attractiveness, by Technology

Figure 5: Global Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 6: Global Gravure Printing Inks Market Attractiveness, by Application

Figure 7: Global Gravure Printing Inks Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 8: Global Gravure Printing Inks Market Attractiveness, by Region

Figure 9: North America Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 10: North America Gravure Printing Inks Market Attractiveness, by Resin

Figure 11: North America Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 12: North America Gravure Printing Inks Market Attractiveness, by Technology

Figure 13: North America Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 14: North America Gravure Printing Inks Market Attractiveness, by Application

Figure 15: North America Gravure Printing Inks Market Volume Share Analysis, by Country, 2022, 2027, and 2031

Figure 16: North America Gravure Printing Inks Market Attractiveness, by Country

Figure 17: Europe Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 18: Europe Gravure Printing Inks Market Attractiveness, by Resin

Figure 19: Europe Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 20: Europe Gravure Printing Inks Market Attractiveness, by Technology

Figure 21: Europe Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 22: Europe Gravure Printing Inks Market Attractiveness, by Application

Figure 23: Europe Gravure Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Europe Gravure Printing Inks Market Attractiveness, by Country and Sub-region

Figure 25: Asia Pacific Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 26: Asia Pacific Gravure Printing Inks Market Attractiveness, by Resin

Figure 27: Asia Pacific Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 28: Asia Pacific Gravure Printing Inks Market Attractiveness, by Technology

Figure 29: Asia Pacific Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 30: Asia Pacific Gravure Printing Inks Market Attractiveness, by Application

Figure 31: Asia Pacific Gravure Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 32: Asia Pacific Gravure Printing Inks Market Attractiveness, by Country and Sub-region

Figure 33: Latin America Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 34: Latin America Gravure Printing Inks Market Attractiveness, by Resin

Figure 35: Latin America Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 36: Latin America Gravure Printing Inks Market Attractiveness, by Technology

Figure 37: Latin America Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 38: Latin America Gravure Printing Inks Market Attractiveness, by Application

Figure 39: Latin America Gravure Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Latin America Gravure Printing Inks Market Attractiveness, by Country and Sub-region

Figure 41: Middle East & Africa Gravure Printing Inks Market Volume Share Analysis, by Resin, 2022, 2027, and 2031

Figure 42: Middle East & Africa Gravure Printing Inks Market Attractiveness, by Resin

Figure 43: Middle East & Africa Gravure Printing Inks Market Volume Share Analysis, by Technology, 2022, 2027, and 2031

Figure 44: Middle East & Africa Gravure Printing Inks Market Attractiveness, by Technology

Figure 45: Middle East & Africa Gravure Printing Inks Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 46: Middle East & Africa Gravure Printing Inks Market Attractiveness, by Application

Figure 47: Middle East & Africa Gravure Printing Inks Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 48: Middle East & Africa Gravure Printing Inks Market Attractiveness, by Country and Sub-region