Reports

Reports

Analysts’ Viewpoint on Fluid Coupling Market Scenario

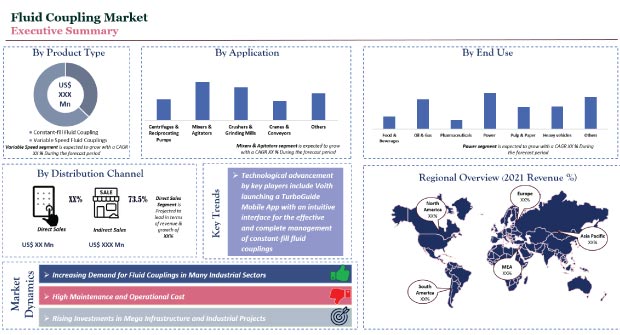

The global fluid coupling market is anticipated to expand at a significant CAGR during the forecast period due to increasing usage of centrifuges & reciprocating pumps, mixers & agitators, crushers & grinding mills, and mills, among others in several industrial areas. Moreover, rapid growth of the overall industrial sector, especially mining, food & beverages, construction, pharmacy, and power, among others, is expected to generate demand for fluid coupling. End users across the globe are generally procuring fluid coupling through various online and offline sales platforms. On the other hand, key users opting for customized fluid coupling of specific size, design, and material are likely to generate demand through direct sales. However, change in government policies and rise in geo-political tension affect the supply chain cycle and increase trade barriers. The high cost of technology and R&D is a key challenge for fluid coupling manufacturers across the global market. The presence of alternative options in several industrial sectors to perform light duty applications such as clutches, gear, and other coupling mats is also projected to pose a risk to the growth of the fluid coupling market.

Fluid couplings are heavy industrial devices. A growing trend in the global fluid coupling market is the rising demand for smaller-capacity fluid couplings. Fluid coupling is a device that allows a controlled amount of slip between input and output, between drive and drive, without the touch of a machine. As a result, fluid couplings offer engineers several benefits in many different types of power transfers. These advantages include control start, slower acceleration, overload protection, power saving, precision speed control, seamless grip, torsional isolation (important between a diesel engine and its load), and long-lasting reliability of the drive without mechanical contact between the transmission elements.

The fluid coupling is also known as a hydraulic coupling which is a hydrodynamic device used to transfer circulating energy from one shaft to another using transmission fluid. In the U.S., utilities are allowed to purchase energy from NUGs (Non-utility Generators). This enables NUGs to receive a reasonable to excellent price for the energy they produce and ensures that energy generated by small producers will not be wasted.

Another trend seen in the global fluid coupling market is the improvement in coupling technology. Manufacturing companies are also working closely with international OEMs, mine owners, and equipment operators to manufacture systems that meet industry needs and standards.

Although fluid couplings require periodic servicing, they are less replaceable in the short term. Additionally, the price of variable-speed fluid couplings is comparatively higher than constant-fill or constant speed fluid couplings. These factors are restraining the growth of the global fluid coupling market.

Fluid couplings have widespread usage in various industrial applications in railways, power transmission, marine, automotive, aviation, and cement industry. Demand for fluid coupling is increasing with the growth of these industries. Growing investment in renewable energy sources as compared to fossil fuels in many countries due to changing climate and renewable policies, increasing power market reforms, and initiatives taken by many corporations to procure clean energy is encouraging the growth of the renewable energy sector, which is leading to increase in demand for power transmission equipment that consists of components such as fluid coupling.

For instance, 48 countries of the Climate Vulnerable Forum pledged to achieve 100% domestic renewable energy production by 2050 at the COP22 in Marrakech, Morocco. This is expected to drive the fluid coupling market in the upcoming years.

In addition, end-use industries such as construction, food & beverages, pharmaceuticals, oil & gas, mining, and paper & pulp are continuously expanding. Fluid coupling plays a crucial role in equipment such as cranes, crushers, milling, centrifuges, mixers, and agitators, eventually leading to the growth of the market globally. Emerging countries such as India, China, and Brazil are continuously investing in several mega projects; for instance, China has invested in construction of three huge canals which are more than 600 miles in length to carry water to the north from China’s three largest rivers. This project has a 48-year construction schedule which may gain demand for a broad range of construction as well as power transmission equipment and is likely to generate demand for fluid couplings in the near future.

Fluid couplings are widely used in the automotive sector in semi-automatic or fully automatic transmission systems. In automotive systems, the pump is usually connected to the engine flywheel. The enclosure may be part of the proper flywheel and thus be turned into the engine crankshaft. The turbine is connected to the transmission shaft. While the transmission is in gear, as the engine speed increases, the torque is transferred from the engine to the input shaft by liquid movement, which propels the motor. In this regard, the fluid coupling behavior is very similar to that of a mechanical clutch that drives a manual transmission. These applications are propelling the demand for fluid couplings in the global market.

Fluid couplings are used in belt conveyors, extruders, centrifuges, bucket elevators, ball mills, crushers, mixers, slurry pumps, compressors, industrial fans, feeders, diesel locomotives, wagon tipplers, boiler feed pumps, reciprocating pumps, process pumps, dryers etc. It possesses certain advantages. For instance, in conveyor belts, fluid couplings are used to gently accelerate belt drives. Fluid couplings limit torque, provide load sharing upon start-up, and dampen torsional vibrations, increasing a conveyor system’s productivity and longevity. Moreover, in fluid coupling, the power transmission is free from vibration & noise, and also power transmission is smooth in extreme conditions such as heat, pressure, and force. The maximum torque can be adjusted by varying the amount of oil filled in the casing.

Furthermore, recent innovations and product developments as per the requirement of users may drive the growth of the global fluid coupling market.

Fluid couplings are usually used for high-power transmission and made of steel or aluminum. In addition, the use of sensors in the fluid coupling has enabled manufacturers to detect abnormality in any fluid coupling and send signals to activate other devices, such as other safety couplings, torque limiters, and powertrain-connected devices. It is used in the automotive transfer system, the maritime system, and the power transmission industry and is also used as an alternative to the mechanical clutch.

The need for fossil fuels is growing as the number of power stations built for Independent Power Producers (IPP) grows. Services in the U.S. are allowed to receive electricity from NUGs (Non-utility Generators). Fluid couplings have critical applications, as they are used in power plants and are specially designed to ensure maximum life and operating time of machines in complex and demanding workplaces, which helps to expand the market worldwide.

In addition, investment in various projects in industries such as mining, paper plants, steel plants, automotive, and marine has been continuously increasing with growing industrialization and infrastructure projects in emerging economies. For instance, China’s investment in the automobile market has been rising in terms of both sales and manufacturing output, with domestic production estimated to exceed 35 million vehicles by 2025.

According to the Asia-Pacific Economic Cooperation, around 70% of all mining output produced globally is from Asia Pacific which may add more investment in several projects over the next few years. This also is an opportunity for the growth of the fluid coupling market.

Emerging countries of the globe such as India, China, South Africa, and Brazil, are continuously investing in energy sectors especially of oil & gas and power generation. This also offers an opportunity for investors to invest in its machineries which primarily require fluid coupling for operation.

In terms of product type, the fluid coupling market is likely to remain popular in the variable speed fluid coupling segment due to its better ability to control driveline speed and ensure consistency, which will directly impact performance and torque transmission. Moreover, variable speed couplings are found to be suitable for various application of pump, mixers, agitators, centrifuges, fan and compressor applications that ideally has application in every industrial area and may likely pull its demand in the coming years.

However, the constant-fill fluid coupling is used to limit start-up torque, and provide gentle acceleration control, maximum torque and torsional vibration which may also pull its demand by the users. Additionally, the increasing popularity of variable speed fluid coupling in centrifugal pumps and compressors, fans and blowers, centrifuges, and belt conveyors, among others may pull its demand in the foreseeable future.

Among the four biggest mining countries, two are in Asia Pacific: China and Australia. China is the largest producer of mining ores in the world. Thus, rising mining production in Asia Pacific is driving the demand for fluid couplings in this region. Furthermore, as per Elecon Engineering Company, the cement industry in India is growing at a significant rate. With growth in infrastructure, cement production in India is expected to reach 800 million tons by 2030. This increasing demand for cement, infrastructure, and residential, commercial, and industrial construction is subsequently driving the demand for fluid couplings across India.

The North American region is expected to hold the second largest share of the global fluid coupling market. End-use industries such as food & beverages and pharmaceuticals are expected to grow significantly in the region, which will eventually increase the demand for fluid coupling in the near future. The automobile industry is also expanding in this region which increases the demand for fluid coupling. Moreover, power generation is a major consumer of fluid couplings in North America. The fluid coupling market in North America, in terms of power generation, is projected to grow owing to the increasing investment in the U.S. and Canada power generation market, along with a focus on renewable power generation.

Detailed profiles of providers of fluid coupling have been provided in the report to evaluate their financials, key product offerings, recent developments, and strategies. Key players operating in the global fluid coupling market are Premium Transmission, Fluiodmat Limited, Regal Rexnord Corporation, Flender, Voith GmbH & Co. KGaA, The VULKAN Group, Elecon Engineering Company Limited, Transfluid Industrial & Marine, Wichita Clutch, Nara Corporation among the others.

|

Attribute |

Detail |

|

Market Size Value in 2021 (Base Year) |

US$ 1 Bn |

|

Market Forecast Value in 2031 |

US$ 1.5 Bn |

|

Growth Rate (CAGR) |

4.3% |

|

Forecast Period |

2022-2031 |

|

Quantitative Units |

US$ Bn and Thousand Units |

|

Market Analysis |

Global qualitative analysis includes drivers, restraints, opportunities, key trends, upcoming key trends, Porter’s Five Forces analysis, value chain analysis, SWOT analysis, technology analysis, regulatory analysis, etc. Furthermore, at the regional level, qualitative analysis includes key trends, price trends, and key supplier analysis. |

|

Competition Landscape |

|

|

Regions Covered |

|

|

Market Segmentation |

|

|

Companies Profiled |

|

|

Customization Scope |

Available upon Request |

|

Pricing |

Available upon Request |

The market size fluid coupling was valued over US$ 1 Bn.

The fluid coupling market is estimated to grow at a CAGR of 4.3%.

The fluid coupling market is estimated to cross US$ 1.5 Bn.

Increasing demand for fluid couplings in many industrial sectors and advantages of using fluid couplings, along with rising investment in mega infrastructure & industrial projects are likely to drive the demand for fluid couplings in the global market.

Asia Pacific is a more attractive region for vendors in the fluid coupling market with the maximum market share.

Premium Transmission, Fluiodmat Limited, Regal Rexnord Corporation, Flender, Voith GmbH & Co. KGaA, The VULKAN Group, Elecon Engineering Company Limited, Transfluid Industrial & Marine, Wichita Clutch, and Nara Corporation, among others.

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions

3. Research Methodology

4. Executive Summary

5. Market Overview

5.1. Market Dynamics

5.1.1. Drivers

5.1.2. Restraints

5.1.3. Opportunities

5.2. Key Trends Analysis

5.2.1. Demand Side Analysis

5.2.2. Supply Side Analysis

5.3. Key Market Indicators

5.4. Industry SWOT Analysis

5.5. Raw Material Analysis

5.6. Porter’s Five Forces Analysis

5.7. Value Chain Analysis

5.8. COVID-19 Impact Analysis

5.9. Global Fluid Coupling Market Analysis and Forecast, 2017 - 2031

5.9.1. Market Revenue Projections (US$ Mn)

5.9.2. Market Revenue Projections (Thousand Units)

6. Global Fluid Coupling Market Analysis and Forecast, By Product Type

6.1. Global Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Product Type, 2017 - 2031

6.1.1. Constant-fill Fluid Coupling

6.1.2. Variable Speed Fluid Couplings

6.2. Incremental Opportunity, By Product Type

7. Global Fluid Coupling Market Analysis and Forecast, By Application

7.1. Global Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

7.1.1.1. Centrifuges & Reciprocating Pumps

7.1.1.2. Mixers & Agitators

7.1.1.3. Crushers & Grinding Mills

7.1.1.4. Cranes & Conveyors

7.1.1.5. Others

7.2. Incremental Opportunity, By Application

8. Global Fluid Coupling Market Analysis and Forecast, By End-use

8.1. Global Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

8.1.1. Food & Beverages

8.1.2. Oil & Gas

8.1.3. Pharmaceuticals

8.1.4. Power

8.1.5. Pulp & Paper

8.1.6. Heavy Vehicles

8.1.7. Others

8.2. Incremental Opportunity, By End-use

9. Global Fluid Coupling Market Analysis and Forecast, by Distribution Channel

9.1. Global Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

9.1.1. Direct Sales

9.1.2. Indirect Sales

9.2. Global Incremental Opportunity, by Distribution Channel

10. Global Fluid Coupling Market Analysis and Forecast, by Region

10.1. Global Fluid Coupling Market (US$ Mn and Thousand Units), by Region, 2017 - 2031

10.1.1. North America

10.1.2. Europe

10.1.3. Asia Pacific

10.1.4. Middle East & Africa

10.1.5. South America

10.2. India Incremental Opportunity, by Region

11. North America Fluid Coupling Market Analysis and Forecast

11.1. Regional Snapshot

11.2. Price Trend Analysis

11.2.1. Weighted Average Selling Price (US$)

11.3. Demographic Overview

11.4. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Product Type, 2017 - 2031

11.4.1. Constant-fill Fluid Coupling

11.4.2. Variable Speed Fluid Couplings

11.5. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

11.5.1. Centrifuges & Reciprocating Pumps

11.5.2. Mixers & Agitators

11.5.3. Crushers & Grinding Mills

11.5.4. Cranes & Conveyors

11.5.5. Others

11.6. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

11.6.1. Food & Beverages

11.6.2. Oil & Gas

11.6.3. Pharmaceuticals

11.6.4. Power

11.6.5. Pulp & Paper

11.6.6. Heavy Vehicles

11.6.7. Others

11.7. Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

11.7.1. Direct Sales

11.7.2. Indirect Sales

11.8. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Country & Sub-region, 2017 - 2031

11.8.1. U.S.

11.8.2. Canada

11.8.3. Rest of North America

11.9. Incremental Opportunity Analysis

12. Europe Fluid Coupling Market Analysis and Forecast

12.1. Regional Snapshot

12.2. Price Trend Analysis

12.2.1. Weighted Average Selling Price (US$)

12.3. Demographic Overview

12.4. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

12.4.1. Centrifuges & Reciprocating Pumps

12.4.2. Mixers & Agitators

12.4.3. Crushers & Grinding Mills

12.4.4. Cranes & Conveyors

12.4.5. Others

12.5. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

12.5.1. Food & Beverages

12.5.2. Oil & Gas

12.5.3. Pharmaceuticals

12.5.4. Power

12.5.5. Pulp & Paper

12.5.6. Heavy Vehicles

12.5.7. Others

12.6. Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

12.6.1. Direct Sales

12.6.2. Indirect Sales

12.7. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Country & Sub-region, 2017 - 2031

12.7.1. U.K.

12.7.2. Germany

12.7.3. France

12.7.4. Rest of Europe

12.8. Incremental Opportunity Analysis

13. Asia Pacific Fluid Coupling Market Analysis and Forecast

13.1. Regional Snapshot

13.2. Price Trend Analysis

13.2.1. Weighted Average Selling Price (US$)

13.3. Demographic Overview

13.4. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Product Type, 2017 - 2031

13.4.1. Constant-fill Fluid Coupling

13.4.2. Variable Speed Fluid Couplings

13.5. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

13.5.1. Centrifuges & Reciprocating Pumps

13.5.2. Mixers & Agitators

13.5.3. Crushers & Grinding Mills

13.5.4. Cranes & Conveyors

13.5.5. Others

13.6. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

13.6.1. Food & Beverages

13.6.2. Oil & Gas

13.6.3. Pharmaceuticals

13.6.4. Power

13.6.5. Pulp & Paper

13.6.6. Heavy Vehicles

13.6.7. Others

13.7. Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

13.7.1. Direct Sales

13.7.2. Indirect Sales

13.8. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Country & Sub-region, 2017 - 2031

13.8.1. China

13.8.2. India

13.8.3. Japan

13.8.4. Rest of Asia Pacific

13.9. Incremental Opportunity Analysis

14. Middle East & Africa Fluid Coupling Market Analysis and Forecast

14.1. Regional Snapshot

14.2. Price Trend Analysis

14.2.1. Weighted Average Selling Price (US$)

14.3. Demographic Overview

14.4. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Product Type, 2017 - 2031

14.4.1. Constant-fill Fluid Coupling

14.4.2. Variable Speed Fluid Couplings

14.5. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

14.5.1. Centrifuges & Reciprocating Pumps

14.5.2. Mixers & Agitators

14.5.3. Crushers & Grinding Mills

14.5.4. Cranes & Conveyors

14.5.5. Others

14.6. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

14.6.1. Food & Beverages

14.6.2. Oil & Gas

14.6.3. Pharmaceuticals

14.6.4. Power

14.6.5. Pulp & Paper

14.6.6. Heavy Vehicles

14.6.7. Others

14.7. Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

14.7.1. Direct Sales

14.7.2. Indirect Sales

14.8. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Country & Sub-region, 2017 - 2031

14.8.1. GCC

14.8.2. South Africa

14.8.3. Rest of Middle East & Africa

14.9. Incremental Opportunity Analysis

15. South America Fluid Coupling Market Analysis and Forecast

15.1. Regional Snapshot

15.2. Price Trend Analysis

15.2.1. Weighted Average Selling Price (US$)

15.3. Demographic Overview

15.4. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Product Type, 2017 - 2031

15.4.1. Constant-fill Fluid Coupling

15.4.2. Variable Speed Fluid Couplings

15.5. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Application, 2017 - 2031

15.5.1. Centrifuges & Reciprocating Pumps

15.5.2. Mixers & Agitators

15.5.3. Crushers & Grinding Mills

15.5.4. Cranes & Conveyors

15.5.5. Others

15.6. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By End-use, 2017 - 2031

15.6.1. Food & Beverages

15.6.2. Oil & Gas

15.6.3. Pharmaceuticals

15.6.4. Power

15.6.5. Pulp & Paper

15.6.6. Heavy Vehicles

15.6.7. Others

15.7. Fluid Coupling Market (US$ Mn and Thousand Units), by Distribution Channel, 2017 - 2031

15.7.1. Direct Sales

15.7.2. Indirect Sales

15.8. Fluid Coupling Market (US$ Mn and Thousand Units) Forecast, By Country & Sub-region, 2017 - 2031

15.8.1. Brazil

15.8.2. Rest of South America

15.9. Incremental Opportunity Analysis

16. Competition Landscape

16.1. Market Player – Competition Dashboard

16.2. Market Revenue Share Analysis (%), (2020)

16.3. Company Profiles (Details – Company Overview, Sales Area/Geographical Presence, Revenue, Strategy & Business Overview)

16.3.1. Premium Transmission

16.3.1.1. Company Overview

16.3.1.2. Sales Area/Geographical Presence

16.3.1.3. Revenue

16.3.1.4. Strategy & Business Overview

16.3.2. Fluiodmat Limited

16.3.2.1. Company Overview

16.3.2.2. Sales Area/Geographical Presence

16.3.2.3. Revenue

16.3.2.4. Strategy & Business Overview

16.3.3. Regal Rexnord Corporation

16.3.3.1. Company Overview

16.3.3.2. Sales Area/Geographical Presence

16.3.3.3. Revenue

16.3.3.4. Strategy & Business Overview

16.3.4. Flender

16.3.4.1. Company Overview

16.3.4.2. Sales Area/Geographical Presence

16.3.4.3. Revenue

16.3.4.4. Strategy & Business Overview

16.3.5. Voith GmbH & Co. KGaA

16.3.5.1. Company Overview

16.3.5.2. Sales Area/Geographical Presence

16.3.5.3. Revenue

16.3.5.4. Strategy & Business Overview

16.3.6. The VULKAN Group

16.3.6.1. Company Overview

16.3.6.2. Sales Area/Geographical Presence

16.3.6.3. Revenue

16.3.6.4. Strategy & Business Overview

16.3.7. Elecon Engineering Company Limited

16.3.7.1. Company Overview

16.3.7.2. Sales Area/Geographical Presence

16.3.7.3. Revenue

16.3.7.4. Strategy & Business Overview

16.3.8. Wichita Clutch

16.3.8.1. Company Overview

16.3.8.2. Sales Area/Geographical Presence

16.3.8.3. Revenue

16.3.8.4. Strategy & Business Overview

16.3.9. Transfluid Industrial & Marine

16.3.9.1. Company Overview

16.3.9.2. Sales Area/Geographical Presence

16.3.9.3. Revenue

16.3.9.4. Strategy & Business Overview

16.3.10. Nara Corporation

16.3.10.1. Company Overview

16.3.10.2. Sales Area/Geographical Presence

16.3.10.3. Revenue

16.3.10.4. Strategy & Business Overview

17. Key Takeaways

17.1. Identification of Potential Market Spaces

17.1.1. By Product Type

17.1.2. By Application

17.1.3. By End-use

17.1.4. By Distribution Channel

17.1.5. By Region

17.2. Understanding the Procurement Process of Customers

17.3. Preferred Sales & Marketing Strategy

17.4. Prevailing Market Risks

List of Tables

Table 1: Global Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 2: Global Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 3: Global Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 4: Global Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 5: Global Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 6: Global Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 7: Global Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 8: Global Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 9: Global Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 10: Global Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

Table 11: North America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 12: North America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 13: North America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 14: North America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 15: North America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 16: North America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 17: North America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 18: North America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 19: North America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 20: North America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

Table 21: Europe Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 22: Europe Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 23: Europe Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 24: Europe Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 25: Europe Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 26: Europe Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 27: Europe Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 28: Europe Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 29: Europe Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 30: Europe Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

Table 31: Asia Pacific Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 32: Asia Pacific Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 33: Asia Pacific Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 34: Asia Pacific Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 35: Asia Pacific Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 36: Asia Pacific Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 37: Asia Pacific Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 38: Asia Pacific Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 39: Asia Pacific Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 40: Asia Pacific Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

Table 41: Middle East & Africa Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 42: Middle East & Africa Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 43: Middle East & Africa Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 44: Middle East & Africa Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 45: Middle East & Africa Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 46: Middle East & Africa Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 47: Middle East & Africa Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 48: Middle East & Africa Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 49: Middle East & Africa Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 50: Middle East & Africa Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

Table 51: South America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, by Product Type

Table 52: South America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, by Product Type

Table 53: South America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Application

Table 54: South America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Application

Table 55: South America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By End Use

Table 56: South America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By End Use

Table 57: South America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Distribution Channel

Table 58: South America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Distribution Channel

Table 59: South America Fluid Coupling Market Value (US$ Mn) Forecast, 2017-2031, By Region

Table 60: South America Fluid Coupling Market Volume (Thousand Units) Forecast, 2017-2031, By Region

List of Figures

Figure 1: Global Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 2: Global Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 3: Global Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 3: Global Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 4: Global Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 6: Global Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 7: Global Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 8: Global Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 9: Global Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 10: Global Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 11: Global Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 12: Global Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 13: Global Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Region

Figure 14: Global Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Region

Figure 15: Global Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Region

Figure 16: North America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 17: North America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 18: North America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 19: North America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 20: North America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 21: North America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 22: North America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 23: North America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 24: North America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 25: North America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 26: North America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 27: North America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 28: North America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Country

Figure 29: North America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Country

Figure 30: North America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Country

Figure 31: Europe Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 32: Europe Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 33: Europe Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 34: Europe Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 35: Europe Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 36: Europe Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 37: Europe Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 38: Europe Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 39: Europe Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 40: Europe Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 41: Europe Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 42: Europe Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 43: Europe Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Country

Figure 44: Europe Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Country

Figure 45: Europe Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Country

Figure 46: Asia Pacific Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 47: Asia Pacific Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 48: Asia Pacific Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 49: Asia Pacific Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 50: Asia Pacific Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 51: Asia Pacific Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 52: Asia Pacific Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 53: Asia Pacific Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 54: Asia Pacific Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 55: Asia Pacific Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 56: Asia Pacific Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 57: Asia Pacific Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 58: Asia Pacific Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Country

Figure 59: Asia Pacific Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Country

Figure 60: Asia Pacific Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Country

Figure 61: Middle East & Africa Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 62: Middle East & Africa Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 63: Middle East & Africa Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 64: Middle East & Africa Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 65: Middle East & Africa Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 66: Middle East & Africa Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 67: Middle East & Africa Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 68: Middle East & Africa Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 69: Middle East & Africa Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 70: Middle East & Africa Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 71: Middle East & Africa Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 72: Middle East & Africa Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 73: Middle East & Africa Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Country

Figure 74: Middle East & Africa Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Country

Figure 75: Middle East & Africa Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Country

Figure 76: South America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, by Type

Figure 77: South America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, by Type

Figure 78: South America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, by Type

Figure 79: South America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Resolution

Figure 80: South America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Resolution

Figure 81: South America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Resolution

Figure 82: South America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Technology

Figure 83: South America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Technology

Figure 84: South America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Technology

Figure 85: South America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Distribution Channel

Figure 86: South America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Distribution Channel

Figure 87: South America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Distribution Channel

Figure 88: South America Fluid Coupling Market Value (US$ Bn) Forecast, 2017-2031, By Country

Figure 89: South America Fluid Coupling Market Volume (Million units) Forecast, 2017-2031, By Country

Figure 90: South America Fluid Coupling Market, Incremental Opportunities, Forecast, 2017-2031, By Country