Reports

Reports

The automotive sector is shifting gears and moving toward a greener future. The push for adoption and development of electric vehicles from local government authorities continues to play a key role in the development and adoption of hybrid and electric vehicles. Due to this, vehicle electrification technologies continue to evolve at a rapid pace. Sealants and electric vehicle adhesives are likely to remain at the forefront in terms of development of these technologies due to which, the electric vehicle adhesives market is starting at a bright future. In addition, electric vehicle adhesives are expected to play an integral role in the production of battery electric vehicle (BEV) and hybrid electric vehicle (HEV) battery cells, motors, and packs, among others.

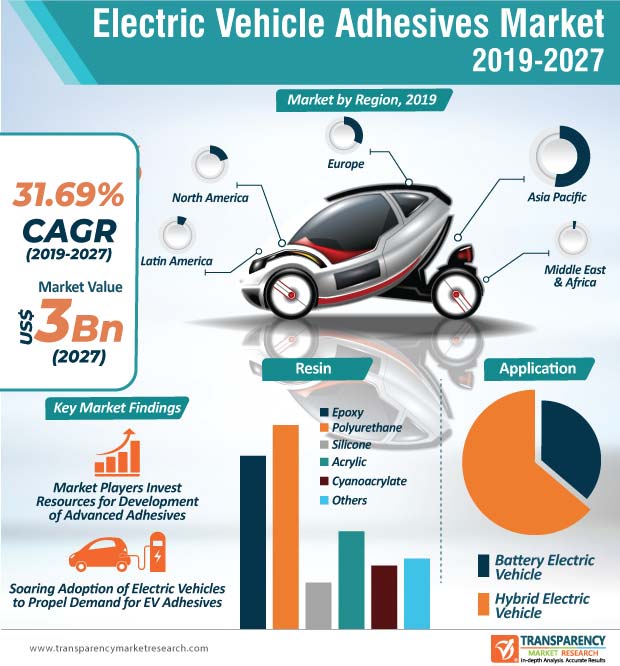

In the current scenario, the battery technology in the automotive sector is following the footsteps of the consumer electronics industry due to the advent of stringent regulatory requirements. Battery manufacturers are currently finding solutions to improve the durability of batteries that are required to operate at extreme temperatures. Electric vehicle adhesives have emerged as an excellent solution to address these challenges in multiple applications the BEV and HEV powertrain. Thus, the global electric vehicle adhesives market is expected to reach a market value of US$ 3 Bn by 2027.

With an undeniable surge in the number of electric vehicles worldwide, automakers are continually finding different ways to reduce vehicular weight and simultaneously improve the design aspects of their vehicles. Companies operating in the current electric vehicle adhesives market are expected to use their expertise to bring about these changes. Electric vehicle adhesives have emerged as an ideal solution to address these issues. In the current scenario, electric vehicle adhesives have come to light as an excellent replacement for heavy mechanical fasteners as far as the design of electric vehicle batteries is concerned. As electric vehicle adhesives play an imperative role in improving the range of electric vehicles, the demand for the same is expected to move in an upward trajectory in the upcoming years.

Companies such as 3M, DuPont, and Henkel Corp, among others, are increasingly focusing on the development of electric vehicle adhesives to enhance gap control and bond components such as battery module side panels, cooling plates, and battery cells among others. Furthermore, as structural adhesives assist in the overall assembly of battery modules and cells, the demand for electric vehicle adhesives is expected to witness significant growth in the upcoming years. Moreover, adhesive sticks also aid automotive manufacturers to attain their key objectives, including faster charging, cost-efficiency, and durability. Electric vehicle adhesives will play a key role in the development of cutting-edge high-voltage vehicle batteries. While automakers continue to prioritize improving the performance of their vehicles, innovations, and adoption of lightweight materials are expected to gain significant momentum during the assessment period.

Market Participants Develop New Thermal Conductive Interface Materials

The sustainability, safety, and durability of battery packs are expected to gain a huge amount of traction in the coming years. Companies operating in the current electric vehicle adhesives market are currently expected to focus on the development of new thermal-conductive interface materials for efficient assembly of EV/HEV batteries. For instance, in May 2019, DuPont unveiled new solutions for EV/HEV battery assembly. In addition, companies are also rolling out adhesive solutions for both – large-volume assemblies as well as smaller requirements. In addition, anticipating the surge in demand for electric and hybrid vehicles, electric vehicle adhesives market participants are increasingly investing resources on the development of innovative battery assembly solutions. In April 2019, Henkel announced the launch of new technologies that align with the requirements of modern-day battery architectures. The company is expected to use its existing technologies as the foundation to develop and introduce innovations that will play a pivotal role in accelerating the assembly speed.

The lack of standardization as far as design and production of batteries continue to raise alarm bells. Thus, the electric vehicle adhesives market is expected to witness innovations, development of new battery assembly solutions, and sustainability of next-generation vehicles.

Analysts’ Viewpoint

The global electric vehicle adhesives market is expected to grow at a staggering CAGR of 31.69% during the forecast period. The market growth can be primarily attributed to a range of factors of which, the significant rise in demand for electric and hybrid vehicles remains the most prominent factor. Moreover, advancements in technology, favorable government policies, and efforts to minimize the weight of vehicles are some of the other factors that will drive the growth of the electric vehicle adhesives market in the coming years. Opportunities are ripe in the Asia Pacific region and thus, participants in the electric vehicle adhesives market should align their operations to tap into the market in countries such as China and India wherein the demand for electric vehicles is on the rise at an impressive pace.

Major Challenges for Electric Vehicle Adhesives Market

Lucrative Opportunities for Electric Vehicle Adhesives Market

Asia Pacific to Dominate Electric Vehicle Adhesives Market

Polyurethane Resins to Witness High Demand

Leading Players Actively Engage in Joint Ventures and R&D Activities

Electric Vehicle Adhesives Market is projected to reach US$ 3 Bn by the end of 2019

Electric Vehicle Adhesives Market is expected to grow at a CAGR of 31.69% during 2019-2027

Increase in demand for epoxy liquid adhesives in fabrication of exterior and interior of vehicles and electric batteries is a key factor that is driving the Electric Vehicle Adhesives Market

Asia Pacific is a more attractive region for vendors in the Electric Vehicle Adhesives Market

Key vendors in the Electric Vehicle Adhesives Market are 3M, Henkel AG & Company KGaA, H.B. Fuller, DuPont de Nemours, Sika AG, and PPG Industries, Inc

1. Preface

1.1. Market Definition and Scope

1.2. Market Segmentation

1.3. Key Research Objectives

1.4. Research Highlights

2. Assumptions and Research Methodology

2.1. Report Assumptions

2.2. Secondary Sources & Acronyms Used

2.3. Research Methodology

3. Executive Summary: Global Electric Vehicle Adhesives Market

4. Market Overview

4.1. Introduction

4.2. Key Market Developments

4.3. Key Market Indicators/Definitions

4.4. Market Dynamics

4.4.1. Drivers

4.4.2. Restraints

4.4.3. Opportunities

4.5. Global Electric Vehicle Adhesives Market Analysis and Forecast, 2018–2027

4.5.1. Global Electric Vehicle Adhesives Market Volume (Tons)

4.5.2. Global Electric Vehicle Adhesives Market Value (US$ Mn)

4.6. Porters Five Forces Analysis

4.7. Value Chain Analysis

4.8. Regulatory Landscape

4.9. List of Manufacturers

4.10. List of Potential Customers

5. Pricing Analysis, 2018

5.1. Price Comparison Analysis, by Resin

5.2. Price Comparison Analysis, by Region

6. Global Electric Vehicle Adhesives Market Analysis and Forecast, by Resin

6.1. Introduction and Key Findings

6.2. Global Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

6.2.1. Epoxy

6.2.2. Polyurethane

6.2.3. Silicone

6.2.4. Acrylic

6.2.5. Cyanoacrylate

6.2.6. Others (including Methyl Methacrylate, Polyolefin, and Polyester)

6.3. Global Electric Vehicle Adhesives Market Attractiveness, by Resin

7. Global Electric Vehicle Adhesives Market Analysis and Forecast, by Form

7.1. Introduction & Key Findings

7.2. Global Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

7.2.1. Liquid

7.2.2. Tapes & Films

7.2.3. Others (including Paste and Dry)

7.3. Global Electric Vehicle Adhesives Market Attractiveness, by Form

8. Global Electric Vehicle Adhesives Market Analysis and Forecast, by Application

8.1. Introduction

8.2. Global Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2028

8.2.1. Battery Electric Vehicle

8.2.1.1. Exterior

8.2.1.2. Interior

8.2.1.3. Electronics

8.2.1.4. Powertrain

8.2.1.5. Body in White

8.2.2. Hybrid Electric Vehicle

8.2.2.1. Exterior

8.2.2.2. Interior

8.2.2.3. Electronics

8.2.2.4. Powertrain

8.2.2.5. Body in White

8.2.2.6. Others

8.3. Global Electric Vehicle Adhesives Market Attractiveness, by Application

9. Global Electric Vehicle Adhesives Market Analysis and Forecast, by Region

9.1. Key Findings

9.2. Global Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Region, 2019–2027

9.2.1. North America

9.2.2. Europe

9.2.3. Asia Pacific

9.2.4. Latin America

9.2.5. Middle East & Africa

9.3. Global Electric Vehicle Adhesives Market Attractiveness, by Region

10. North America Electric Vehicle Adhesives Market Analysis and Forecast

10.1. Key Findings

10.2. North America Electric Vehicle Adhesives Market Overview

10.3. North America Electric Vehicle Adhesives Market Forecast, by Resin, 2018–2027

10.4. North America Electric Vehicle Adhesives Market Forecast, by Form, 2018–2027

10.5. North America Electric Vehicle Adhesives Forecast, by Application, 2018–2027

10.6. North America Electric Vehicle Adhesives Market Forecast, by Country, 2018–2027

10.6.1. U.S. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

10.6.2. U.S. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

10.6.3. U.S. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

10.6.4. Canada Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

10.6.5. Canada Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

10.6.6. Canada Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

10.7. North America Electric Vehicle Adhesives Market Attractiveness Analysis

11. Europe Electric Vehicle Adhesives Market Analysis and Forecast

11.1. Key Findings

11.2. Europe Electric Vehicle Adhesives Market Overview

11.3. Europe Electric Vehicle Adhesives Market Forecast, by Resin, 2018–2027

11.4. Europe Electric Vehicle Adhesives Market Forecast, by Form, 2018–2027

11.5. Europe Electric Vehicle Adhesives Forecast, by Application, 2018–2027

11.6. Europe Electric Vehicle Adhesives Market Forecast, by Country and Sub-region, 2018–2027

11.6.1. Germany Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.2. Germany Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.3. Germany Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.4. U.K. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.5. U.K. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.6. U.K. Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.7. France Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.8. France Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.9. France Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.10. Italy Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.11. Italy Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.12. Italy Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.13. Spain Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.14. Spain Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.15. Spain Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.16. Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.17. Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.18. Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.19. Netherlands Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.20. Netherlands Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.21. Netherlands Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.6.22. Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

11.6.23. Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

11.6.24. Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

11.7. Europe Electric Vehicle Adhesives Market Attractiveness Analysis

12. Asia Pacific Electric Vehicle Adhesives Market Analysis and Forecast

12.1. Key Findings

12.2. Asia Pacific Electric Vehicle Adhesives Market Overview

12.3. Asia Pacific Electric Vehicle Adhesives Market Forecast, by Resin, 2018–2027

12.4. Asia Pacific Electric Vehicle Adhesives Market Forecast, by Form, 2018–2027

12.5. Asia Pacific Electric Vehicle Adhesives Forecast, by Application, 2018–2027

12.6. Asia Pacific Electric Vehicle Adhesives Market Forecast, by Country and Sub-region, 2018–2027

12.6.1. China Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

12.6.2. China Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

12.6.3. China Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

12.6.4. Japan Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

12.6.5. Japan Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

12.6.6. Japan Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

12.6.7. India Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

12.6.8. India Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

12.6.9. India Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

12.6.10. ASEAN Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

12.6.11. ASEAN Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

12.6.12. ASEAN Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

12.6.13. Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

12.6.14. Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

12.6.15. Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

12.7. Asia Pacific Electric Vehicle Adhesives Market Attractiveness Analysis

13. Latin America Electric Vehicle Adhesives Market Analysis and Forecast

13.1. Key Findings

13.2. Latin America Electric Vehicle Adhesives Market Overview

13.3. Latin America Electric Vehicle Adhesives Market Forecast, by Resin, 2018–2027

13.4. Latin America Electric Vehicle Adhesives Forecast, by Form, 2018–2027

13.5. Latin America Electric Vehicle Adhesives Forecast, by Application, 2018–2027

13.6. Latin America Electric Vehicle Adhesives Market Forecast, by Country and Sub-region, 2018–2027

13.6.1. Brazil Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

13.6.2. Brazil Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

13.6.3. Brazil Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

13.6.4. Mexico Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

13.6.5. Mexico Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

13.6.6. Mexico Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

13.6.7. Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

13.6.8. Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

13.6.9. Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

13.7. Latin America Electric Vehicle Adhesives Market Attractiveness Analysis

14. Middle East & Africa Electric Vehicle Adhesives Market Analysis and Forecast

14.1. Key Findings

14.2. Middle East & Africa Electric Vehicle Adhesives Market Overview

14.3. Middle East & Africa Electric Vehicle Adhesives Market Forecast, by Resin, 2018–2027

14.4. Middle East & Africa Electric Vehicle Adhesives Forecast, by Form, 2018–2027

14.5. Middle East & Africa Electric Vehicle Adhesives Market Forecast, by Application, 2018–2027

14.6. Middle East & Africa Electric Vehicle Adhesives Market Forecast, by Country and Sub-region, 2018–2027

14.6.1. GCC Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

14.6.2. GCC Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

14.6.3. GCC Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.6.4. South Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

14.6.5. South Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

14.6.6. South Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.6.7. Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin, 2018–2027

14.6.8. Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Form, 2018–2027

14.6.9. Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2018–2027

14.7. Middle East & Africa Electric Vehicle Adhesives Market Attractiveness Analysis

15. Competition Landscape

15.1. Global Electric Vehicle Adhesives Market Share Analysis, by Company, 2018

15.2. Market Players-Competition Matrix

15.2.1. 3M

15.2.2. Henkel AG & Company, KGaA

15.2.3. H.B. Fuller

15.2.4. DuPont de Nemours, Inc.

15.3. Competitive Business Strategies

15.4. Global Electric Vehicle Adhesives Market Footprint Analysis, by Resin

16. Company Profiles

16.1. 3M

16.1.1. Company Description

16.1.2. Business Overview

16.1.3. Financial Details

16.1.4. Strategic Overview

16.2. Henkel AG & Company, KGaA

16.2.1. Company Description

16.2.2. Business Overview

16.2.3. Financial Details

16.2.4. Strategic Overview

16.3. H.B. Fuller

16.3.1. Company Description

16.3.2. Business Overview

16.3.3. Financial Details

16.3.4. Strategic Overview

16.4. DuPont de Nemours, Inc.

16.4.1. Company Description

16.4.2. Business Overview

16.4.3. Financial Details

16.4.4. Strategic Overview

16.5. Arkema S.A.

16.5.1. Company Description

16.5.2. Business Overview

16.5.3. Financial Details

16.5.4. Strategic Overview

16.6. Permabond LLC

16.6.1. Company Description

16.6.2. Business Overview

16.7. Ashland Inc.

16.7.1. Company Description

16.7.2. Business Overview

16.7.3. Financial Details

16.7.4. Strategic Overview

16.8. LORD Corporation

16.8.1. Company Description

16.8.2. Business Overview

16.9. PPG Industries, Inc.

16.9.1. Company Description

16.9.2. Business Overview

16.9.3. Financial Details

16.9.4. Strategic Overview

16.10. Avery Dennison Corporation

16.10.1. Company Description

16.10.2. Business Overview

16.10.3. Financial Details

16.10.4. Strategic Overview

16.11. Evonik Industries AG

16.11.1. Company Description

16.11.2. Business Overview

16.11.3. Financial Details

16.11.4. Strategic Overview

16.12. Illinois Tool Works Inc.

16.12.1. Company Description

16.12.2. Business Overview

16.13. Dymax Corporation

16.13.1. Company Description

16.13.2. Business Overview

16.14. Wacker Chemie AG

16.14.1. Company Description

16.14.2. Business Overview

16.14.3. Financial Details

16.14.4. Strategic Overview

16.15. Sika AG

16.15.1. Company Description

16.15.2. Business Overview

16.15.3. Financial Details

16.15.4. Strategic Overview

List of Tables

Table 01: Global Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 02: Global Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 03: Global Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 04: Global Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 05: Global Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 06: Global Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 07: Global Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Region, 2018–2027

Table 08: Global Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Region, 2018–2027

Table 09: North America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 10: North America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 11: North America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 12: North America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 13: North America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 14: North America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 15: North America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 16: North America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 17: U.S. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 18: U.S. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 19: U.S. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 20: U.S. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 21: U.S. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 22: U.S. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 23: Canada Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 24: Canada Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 25: Canada Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 26: Canada Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 27: Canada Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 28: Canada Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 29: Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 30: Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 31: Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 32: Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 33: Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 34: Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 35: Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Country and Sub-region, 2018–2027

Table 36: Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 37: Germany Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 38: Germany Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 39: Germany Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 40: Germany Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 41: Germany Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 42: Germany Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 43: France Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 44: France Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 45: France Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 46: France Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 47: France Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 48: France Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 49: U.K. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 50: U.K. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 51: U.K. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 52: U.K. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 53: U.K. Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 54: U.K. Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 55: Italy Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 56: Italy Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 57: Italy Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 58: Italy Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 59: Italy Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 60: Italy Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 61: Spain Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 62: Spain Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 63: Spain Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 64: Spain Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 65: Spain Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 66: Spain Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 67: Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 68: Russia & CIS Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 69: Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 70: Russia & CIS Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 71: Russia & CIS Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 72: Russia & CIS Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 73: Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 74: Rest of Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 75: Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 76: Rest of Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 77: Rest of Europe Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 78: Rest of Europe Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 79: Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 80: Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 81: Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 82: Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 83: Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 84: Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 85: Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Country and Sub-region, 2018–2027

Table 86: Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 87: China Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 88: China Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 89: China Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 90: China Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 91: China Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 92: China Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 93: India Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 94: India Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 95: India Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 96: India Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 97: India Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 98: India Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 99: Japan Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 100: Japan Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 101: Japan Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 102: Japan Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 103: Japan Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 104: Japan Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 105: ASEAN Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 106: ASEAN Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 107: ASEAN Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 108: ASEAN Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 109: ASEAN Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 110: ASEAN Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 111: Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 112: Rest of Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 113: Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 114: Rest of Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 115: Rest of Asia Pacific Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 116: Rest of Asia Pacific Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 117: Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 118: Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 119: Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 120: Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 121: Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 122: Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 123: Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Country and Sub-region, 2018–2027

Table 124: Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 125: Brazil Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 126: Brazil Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 127: Brazil Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 128: Brazil Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 129: Brazil Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 130: Brazil Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 131: Mexico Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 132: Mexico Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 133: Mexico Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 134: Mexico Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 135: Mexico Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 136: Mexico Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 137: Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 138: Rest of Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 139: Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 140: Rest of Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 141: Rest of Latin America Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 142: Rest of Latin America Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 143: Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 144: Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 145: Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 146: Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 147: Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 148: Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 149: Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Country and Sub-region, 2018–2027

Table 150: Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Country and Sub-region, 2018–2027

Table 151: GCC Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 152: GCC Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 153: GCC Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 154: GCC Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 155: GCC Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 156: GCC Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 157: South Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 158: South Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 159: South Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 160: South Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 161: South Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 162: South Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

Table 163: Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Resin, 2018–2027

Table 164: Rest of Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Resin, 2018–2027

Table 165: Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Form, 2018–2027

Table 166: Rest of Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Form, 2018–2027

Table 167: Rest of Middle East & Africa Electric Vehicle Adhesives Market Volume (Tons) Forecast, by Application, 2018–2027

Table 168: Rest of Middle East & Africa Electric Vehicle Adhesives Market Value (US$ Mn) Forecast, by Application, 2018–2027

List of Figures

Figure 01: Price Trend Analysis (US$/Ton), by Resin, 2018–2027

Figure 02: Price Trend Analysis (US$/Ton), by Region, 2018–2027

Figure 03: Global Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 04: Global Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 05: Global Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 06: Global Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 07: Global Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 08: Global Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 09: Global Electric Vehicle Adhesives Market Volume Share Analysis, by Region

Figure 10: Global Electric Vehicle Adhesives Market Attractiveness Analysis, by Region

Figure 11: North America Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 12: North America Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 13: North America Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 14: North America Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 15: North America Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 16: North America Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 17: North America Electric Vehicle Adhesives Market Volume Share Analysis, by Country

Figure 18: North America Electric Vehicle Adhesives Market Attractiveness Analysis, by Country

Figure 19: Europe Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 20: Europe Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 21: Europe Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 22: Europe Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 23: Europe Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 24: Europe Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 25: Europe Electric Vehicle Adhesives Market Volume Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 26: Europe Electric Vehicle Adhesives Market Attractiveness Analysis, by Country and Sub-region

Figure 27: Asia Pacific Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 28: Asia Pacific Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 29: Asia Pacific Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 30: Asia Pacific Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 31: Asia Pacific Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 32: Asia Pacific Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 33: Asia Pacific Electric Vehicle Adhesives Market Volume Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 34: Asia Pacific Electric Vehicle Adhesives Market Attractiveness Analysis, by Country and Sub-region

Figure 35: Latin America Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 35: Latin America Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 37: Latin America Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 38: Latin America Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 39: Latin America Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 40: Latin America Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 41: Latin America Electric Vehicle Adhesives Market Volume Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 42: Latin America Electric Vehicle Adhesives Market Attractiveness Analysis, by Country and Sub-region

Figure 43: Middle East & Africa Electric Vehicle Adhesives Market Volume Share Analysis, by Resin

Figure 44: Middle East & Africa Electric Vehicle Adhesives Market Attractiveness Analysis, by Resin

Figure 45: Middle East & Africa Electric Vehicle Adhesives Market Volume Share Analysis, by Form

Figure 46: Middle East & Africa Electric Vehicle Adhesives Market Attractiveness Analysis, by Form

Figure 47: Middle East & Africa Electric Vehicle Adhesives Market Volume Share Analysis, by Application

Figure 48: Middle East & Africa Electric Vehicle Adhesives Market Attractiveness Analysis, by Application

Figure 49: Middle East & Africa Electric Vehicle Adhesives Market Volume Share Analysis, by Country and Sub-region, 2018 and 2027

Figure 50: Middle East & Africa Electric Vehicle Adhesives Market Attractiveness Analysis, by Country and Sub-region

Figure 56: Global Electric Vehicle Adhesives Market share analysis, by Company, 2018