Reports

Reports

Analyst Viewpoint

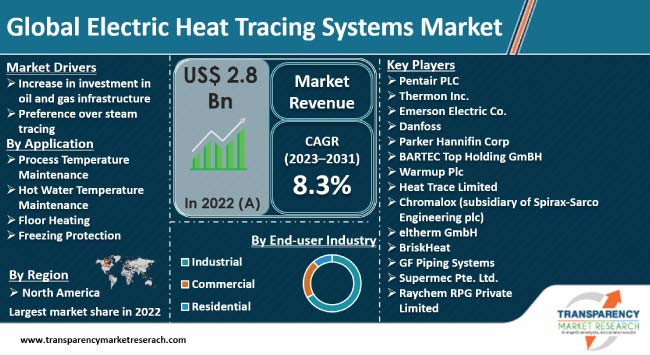

Increase in investment in oil and gas infrastructure is a prominent factor that is propelling the electric heat tracer systems market size. Surge in demand for energy is driving the expansion of hydrocarbon transportation networks such as vessels and pipelines. Electric thermal systems are installed to maintain temperature and avoid potential halts in transportation due to freezing or overheating. These systems are also deployed during the extraction and refining process for the smooth functioning of operations.

Preference over conventional steam tracing owing to electrical systems’ low maintenance costs and advanced monitoring capabilities is creating lucrative electric heat tracer system market opportunities for companies operating in the sector. Key players are following the latest global electric heat tracing systems market trends and investing substantially in the development of more durable and resistant heating systems.

Electric heat tracing systems are applied to maintain or raise the temperature of pipes and vessels by utilizing heat tracing cables. Resistive heating element in the form of cables runs along the length of the pipe and heats up when electricity passes through it.

Electrical heat tracing prevents tanks and pipelines from freezing and maintains the temperature as per vessel requirements. Heating cables must not overlap or overcross, as it can cause overheating and potential system failure.

Constant advancements in the electric heat tracing systems industry have led to introduction of several innovative products including self-regulating cables. These cables can adjust their wattage output based on exposed temperature and the environment.

Self-regulating feature of electric trace heating allows the energy output to match the requirements of the system while preventing the chances of high surface temperature. This negates any chances of a fire hazard and the presence of flammable fluids or gases.

Investments in oil and gas infrastructure in the form of vessels, pipelines, and tanks are increasing, as energy demand surges worldwide. As per the International Energy Agency, crude oil consumption rose to 99.5 million barrels every day in 2022.

China and the U.S. are the two largest consumers of energy in the world. In December 2023, the U.S. recorded its peak crude oil production numbers, producing more oil than any country in history.

Electric heat tracing systems are deployed in several processes of oil extraction and refining, as strict temperature control is vital for peak performance and smooth functioning. Heat tracing is also utilized to provide supplemental heat in case of sudden energy loss due to ambient air temperature.

Thermal tracing system assists in the prevention of a catastrophic pipeline shutdown due to environmental forces, while also reducing the chances of freezing of fluids. The global electric heat tracing systems market is set to gain significant traction, as oil exploration in certain regions, especially in the arctic polar region, becomes regular.

Electric heat tracing systems are cost-effective as compared to conventional steam tracing in the long term owing to low maintenance costs associated with electrical thermal insulation.

Steam tracing accounts for a majority of industrial heat control needs; however, electric heat tracing systems are gaining preference across sectors, as modern systems are more reliable and adaptive.

Electric systems allow for monitoring, process control, and efficient management of components. These features are complex and are not available in traditional steam-based tracing systems.

According to a report by nVent, the total installation cost of an electric tracing system is 75% of the total installation cost of a steam tracing system. The possibility of exposed circuits and burns is also significantly reduced in electric systems, while engineers can use thermal data gathered by the system to optimize functioning and performance.

Thus, rise in preference for electric trace heating over conventional steam tracing is augmenting the electric heat tracing systems market.

According to the latest electric heat tracing systems market analysis, North America accounted for the largest share of the global landscape in 2022. Rise in demand for oil and gas is boosting market dynamics of the region.

As per the U.S Energy Information Administration (EIA), there are 160 operational oil pipelines in the U.S., and a further 22 are under development. The U.S. has more than 200 oil pipelines running across the country, which is more than the number of pipelines in Russia, China, and Canada combined.

As per the latest electric heat tracing systems market forecast, the industry in Asia Pacific is expected to grow at a steady pace during the forecast period. According to the Ministry of Petroleum and Natural Gas, natural gas pipelines run a length of more than 17,000 kilometers in India.

Rapid urbanization in Asia Pacific, especially in India and China, is likely to augment the demand for energy. In turn, this is anticipated to propel electric heat tracing systems market share of Asia Pacific in the near future.

According to recent electric heat tracing systems market insights, prominent manufacturers of electric heat tracing systems are investing significantly in development of advanced electric pipe heating and resistance heating systems.

Close collaborations within the industry and mergers & acquisitions are key strategies to build a better product portfolio and maintain a strong footprint in the global landscape.

Pentair PLC, Thermon Inc., Emerson Electric Co., Danfoss, Parker Hannifin Corp, BARTEC Top Holding GmBH, Warmup Plc, eltherm GmbH, BriskHeat, GF Piping Systems, and Supermec Pte. Ltd. are the leading companies operating in the global landscape.

The electric heat tracing systems market report covers these companies in terms of parameters such as company overview, business strategies, product portfolio, financial overview, and business segments.

| Attribute | Detail |

|---|---|

| Market Value in 2022 (Base Year) | US$ 2.8 Bn |

| Market Forecast Value in 2031 | US$ 5.7 Bn |

| Growth Rate (CAGR) | 8.3% |

| Forecast Period | 2023 to 2031 |

| Historical Data Available for | 2021 |

| Quantitative Units | US$ Bn for Value |

| Market Analysis | Qualitative analysis includes drivers, restraints, opportunities, key trends, key market indicators, Porter’s Five Forces analysis, value chain analysis, and SWOT analysis. Furthermore, at the regional level, the qualitative analysis includes key trends, price trends, and key supplier analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Regions Covered |

|

| Countries Covered |

|

| Market Segmentation |

|

| Companies Profiled |

|

| Customization Scope | Available upon Request |

| Pricing | Available upon Request |

It was valued at US$ 2.8 Bn in 2022

It is projected to grow at a CAGR of 8.3% from 2023 to 2031

Increase in investment in oil and gas infrastructure and preference over steam tracing

The industrial segment held the largest share in 2022

North America was the leading region in 2022

Pentair PLC, Thermon Inc., Emerson Electric Co., Danfoss, Parker Hannifin Corp, BARTEC Top Holding GmBH, Warmup Plc, eltherm GmbH, BriskHeat, GF Piping Systems, Supermec Pte. Ltd., and Raychem RPG Private Limited

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Market Trends

2.3. Market Dynamics

2.3.1. Drivers

2.3.2. Restraints

2.3.3. Opportunities

2.4. Porter’s Five Forces Analysis

2.5. Regulatory Analysis

2.6. Value Chain Analysis

2.6.1. List of Raw Component Suppliers

2.6.2. List of Key Manufacturers

2.6.3. List of Suppliers/ Distributors

2.6.4. List of Potential Customers

2.7. End-user Industry Specification Analysis

2.8. Overview of Manufacturing Process

2.9. Cost Structure Analysis

3. COVID-19 Impact Analysis

4. Production Output Analysis, 2022

5. Price Trend Analysis

6. Global Electric Heat Tracing Systems Market Analysis and Forecast, by Component, 2020–2031

6.1. Introduction and Definitions

6.2. Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

6.2.1. Electric Heat Tracing Cables

6.2.2. Power Connection Kits

6.2.3. RTD Sensors (Thermostat)

6.2.4. Other Accessories

6.3. Global Electric Heat Tracing Systems Market Attractiveness, by Component

7. Global Electric Heat Tracing Systems Market Analysis and Forecast, by End-user Industry, 2020–2031

7.1. Introduction and Definitions

7.2. Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

7.2.1. Industrial

7.2.2. Commercial

7.2.3. Residential

7.3. Global Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

8. Global Electric Heat Tracing Systems Market Analysis and Forecast, by Application, 2020–2031

8.1. Introduction and Definitions

8.2. Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

8.2.1. Process Temperature Maintenance

8.2.2. Hot Water Temperature Maintenance

8.2.3. Floor Heating

8.2.4. Freezing Protection

8.3. Global Electric Heat Tracing Systems Market Attractiveness, by Application

9. Global Electric Heat Tracing Systems Market Analysis and Forecast, by Region, 2020–2031

9.1. Key Findings

9.2. Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Region, 2020–2031

9.2.1. North America

9.2.2. Europe

9.2.3. Asia Pacific

9.2.4. Middle East & Africa

9.2.5. Latin America

9.3. Global Electric Heat Tracing Systems Market Attractiveness, by Region

10. North America Electric Heat Tracing Systems Market Analysis and Forecast, 2020–2031

10.1. Key Findings

10.2. North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

10.3. North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

10.4. North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

10.5. North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country, 2020–2031

10.5.1. U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

10.5.2. U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

10.5.3. U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

10.5.4. Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

10.5.5. Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

10.5.6. Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

10.6. North America Electric Heat Tracing Systems Market Attractiveness Analysis

11. Europe Electric Heat Tracing Systems Market Analysis and Forecast, 2020–2031

11.1. Key Findings

11.2. Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.3. Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.4. Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5. Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

11.5.1. Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.2. Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.3. Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5.4. France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.5. France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.6. France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5.7. U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.8. U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.9. U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5.10. Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.11. Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.12. Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5.13. Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.14. Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.15. Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.5.16. Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

11.5.17. Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

11.5.18. Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

11.6. Europe Electric Heat Tracing Systems Market Attractiveness Analysis

12. Asia Pacific Electric Heat Tracing Systems Market Analysis and Forecast, 2020–2031

12.1. Key Findings

12.2. Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component

12.3. Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.4. Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.5. Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

12.5.1. China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

12.5.2. China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.5.3. China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.5.4. Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

12.5.5. Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.5.6. Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.5.7. India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

12.5.8. India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.5.9. India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.5.10. ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

12.5.11. ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.5.12. ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.5.13. Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

12.5.14. Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

12.5.15. Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

12.6. Asia Pacific Electric Heat Tracing Systems Market Attractiveness Analysis

13. Latin America Electric Heat Tracing Systems Market Analysis and Forecast, 2020–2031

13.1. Key Findings

13.2. Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

13.3. Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

13.4. Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

13.5. Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

13.5.1. Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

13.5.2. Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

13.5.3. Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

13.5.4. Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

13.5.5. Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

13.5.6. Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

13.5.7. Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

13.5.8. Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

13.5.9. Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

13.6. Latin America Electric Heat Tracing Systems Market Attractiveness Analysis

14. Middle East & Africa Electric Heat Tracing Systems Market Analysis and Forecast, 2020–2031

14.1. Key Findings

14.2. Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

14.3. Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

14.4. Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

14.5. Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

14.5.1. GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

14.5.2. GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

14.5.3. GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

14.5.4. South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

14.5.5. South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

14.5.6. South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

14.5.7. Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

14.5.8. Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

14.5.9. Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

14.6. Middle East & Africa Electric Heat Tracing Systems Market Attractiveness Analysis

15. Competition Landscape

15.1. Global Electric Heat Tracing Systems Market Company Share Analysis, 2022

15.2. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

15.2.1. Pentair PLC

15.2.1.1. Company Description

15.2.1.2. Business Overview

15.2.1.3. Financial Overview

15.2.1.4. Strategic Overview

15.2.2. Thermon Inc.

15.2.2.1. Company Description

15.2.2.2. Business Overview

15.2.2.3. Financial Overview

15.2.2.4. Strategic Overview

15.2.3. Emerson Electric Co.

15.2.3.1. Company Description

15.2.3.2. Business Overview

15.2.3.3. Financial Overview

15.2.3.4. Strategic Overview

15.2.4. Danfoss

15.2.4.1. Company Description

15.2.4.2. Business Overview

15.2.4.3. Financial Overview

15.2.4.4. Strategic Overview

15.2.5. Parker Hannifin Corp

15.2.5.1. Company Description

15.2.5.2. Business Overview

15.2.5.3. Financial Overview

15.2.5.4. Strategic Overview

15.2.6. BARTEC Top Holding GmBH

15.2.6.1. Company Description

15.2.6.2. Business Overview

15.2.6.3. Financial Overview

15.2.6.4. Strategic Overview

15.2.7. Warmup Plc

15.2.7.1. Company Description

15.2.7.2. Business Overview

15.2.7.3. Financial Overview

15.2.7.4. Strategic Overview

15.2.8. Heat Trace Limited

15.2.8.1. Company Description

15.2.8.2. Business Overview

15.2.8.3. Financial Overview

15.2.8.4. Strategic Overview

15.2.9. Chromalox (Subsidiary of Spirax-Sarco Engineering plc)

15.2.9.1. Company Description

15.2.9.2. Business Overview

15.2.9.3. Financial Overview

15.2.9.4. Strategic Overview

15.2.10. eltherm GmbH

15.2.10.1. Company Description

15.2.10.2. Business Overview

15.2.10.3. Financial Overview

15.2.10.4. Strategic Overview

15.2.11. BriskHeat

15.2.11.1. Company Description

15.2.11.2. Business Overview

15.2.11.3. Financial Overview

15.2.11.4. Strategic Overview

15.2.12. GF Piping Systems

15.2.12.1. Company Description

15.2.12.2. Business Overview

15.2.12.3. Financial Overview

15.2.12.4. Strategic Overview

15.2.13. Supermec Pte. Ltd.

15.2.13.1. Company Description

15.2.13.2. Business Overview

15.2.13.3. Financial Overview

15.2.13.4. Strategic Overview

15.2.14. Raychem RPG Private Limited

15.2.14.1. Company Description

15.2.14.2. Business Overview

15.2.14.3. Financial Overview

15.2.14.4. Strategic Overview

16. Primary Research: Key Insights

17. Appendix

List of Tables

Table 1: Global Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 2: Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 3: Global Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 4: Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 5: Global Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 6: Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 7: Global Electric Heat Tracing Systems Market Forecast, by Region, 2020–2031

Table 8: Global Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Region, 2020–2031

Table 9: North America Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 10: North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 11: North America Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 12: North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 13: North America Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 14: North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 15: North America Electric Heat Tracing Systems Market Forecast, by Country, 2020–2031

Table 16: North America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country, 2020–2031

Table 17: U.S. Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 18: U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 19: U.S. Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 20: U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 21: U.S. Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 22: U.S. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 23: Canada Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 24: Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 25: Canada Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 26: Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 27: Canada Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 28: Canada Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 29: Europe Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 30: Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 31: Europe Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 32: Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 33: Europe Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 34: Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 35: Europe Electric Heat Tracing Systems Market Forecast, by Country and Sub-region, 2020–2031

Table 36: Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 37: Germany Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 38: Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 39: Germany Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 40: Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 41: Germany Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 42: Germany Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 43: France Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 44: France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 45: France Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 46: France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 47: France Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 48: France Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 49: U.K. Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 50: U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 51: U.K. Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 52: U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 53: U.K. Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 54: U.K. Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 55: Italy Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 56: Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 57: Italy Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 58: Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 59: Italy Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 60: Italy Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 61: Spain Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 62: Spain Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 63: Spain Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 64: Spain Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 65: Spain Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 66: Spain Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 67: Russia & CIS Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 68: Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 69: Russia & CIS Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 70: Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 71: Russia & CIS Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 72: Russia & CIS Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 73: Rest of Europe Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 74: Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 75: Rest of Europe Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 76: Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 77: Rest of Europe Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 78: Rest of Europe Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 79: Asia Pacific Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 80: Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 81: Asia Pacific Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 82: Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 83: Asia Pacific Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 84: Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 85: Asia Pacific Electric Heat Tracing Systems Market Forecast, by Country and Sub-region, 2020–2031

Table 86: Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 87: China Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 88: China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component 2020–2031

Table 89: China Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 90: China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 91: China Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 92: China Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 93: Japan Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 94: Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 95: Japan Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 96: Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 97: Japan Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 98: Japan Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 99: India Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 100: India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 101: India Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 102: India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 103: India Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 104: India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 105: India Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 106: India Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application 2020–2031

Table 107: ASEAN Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 108: ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 109: ASEAN Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 110: ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 111: ASEAN Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 112: ASEAN Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 113: Rest of Asia Pacific Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 114: Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 115: Rest of Asia Pacific Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 116: Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 117: Rest of Asia Pacific Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 118: Rest of Asia Pacific Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 119: Latin America Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 120: Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 121: Latin America Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 122: Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 123: Latin America Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 124: Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 125: Latin America Electric Heat Tracing Systems Market Forecast, by Country and Sub-region, 2020–2031

Table 126: Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 127: Brazil Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 128: Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 129: Brazil Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 130: Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 131: Brazil Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 132: Brazil Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 133: Mexico Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 134: Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 135: Mexico Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 136: Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 137: Mexico Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 138: Mexico Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 139: Rest of Latin America Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 140: Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 141: Rest of Latin America Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 142: Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 143: Rest of Latin America Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 144: Rest of Latin America Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 145: Middle East & Africa Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 146: Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 147: Middle East & Africa Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 148: Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 149: Middle East & Africa Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 150: Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 151: Middle East & Africa Electric Heat Tracing Systems Market Forecast, by Country and Sub-region, 2020–2031

Table 152: Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 153: GCC Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 154: GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 155: GCC Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 156: GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 157: GCC Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 158: GCC Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 159: South Africa Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 160: South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 161: South Africa Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 162: South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 163: South Africa Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 164: South Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

Table 165: Rest of Middle East & Africa Electric Heat Tracing Systems Market Forecast, by Component, 2020–2031

Table 166: Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Component, 2020–2031

Table 167: Rest of Middle East & Africa Electric Heat Tracing Systems Market Forecast, by End-user Industry, 2020–2031

Table 168: Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by End-user Industry, 2020–2031

Table 169: Rest of Middle East & Africa Electric Heat Tracing Systems Market Forecast, by Application, 2020–2031

Table 170: Rest of Middle East & Africa Electric Heat Tracing Systems Market Value (US$ Mn) Forecast, by Application, 2020–2031

List of Figures

Figure 1: Global Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 2: Global Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 3: Global Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 4: Global Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 5: Global Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 6: Global Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 7: Global Electric Heat Tracing Systems Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 8: Global Electric Heat Tracing Systems Market Attractiveness, by Region

Figure 9: North America Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 10: North America Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 11: North America Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 12: North America Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 13: North America Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 14: North America Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 15: North America Electric Heat Tracing Systems Market Volume Share Analysis, by Country, 2022, 2027, and 2031

Figure 16: North America Electric Heat Tracing Systems Market Attractiveness, by Country

Figure 17: Europe Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 18: Europe Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 19: Europe Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 20: Europe Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 21: Europe Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 22: Europe Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 23: Europe Electric Heat Tracing Systems Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Europe Electric Heat Tracing Systems Market Attractiveness, by Country and Sub-region

Figure 25: Asia Pacific Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 26: Asia Pacific Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 27: Asia Pacific Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 28: Asia Pacific Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 29: Asia Pacific Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 30: Asia Pacific Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 31: Asia Pacific Electric Heat Tracing Systems Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 32: Asia Pacific Electric Heat Tracing Systems Market Attractiveness, by Country and Sub-region

Figure 33: Latin America Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 34: Latin America Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 35: Latin America Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 36: Latin America Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 37: Latin America Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 38: Latin America Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 39: Latin America Electric Heat Tracing Systems Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Latin America Electric Heat Tracing Systems Market Attractiveness, by Country and Sub-region

Figure 41: Middle East & Africa Electric Heat Tracing Systems Market Volume Share Analysis, by Component, 2022, 2027, and 2031

Figure 42: Middle East & Africa Electric Heat Tracing Systems Market Attractiveness, by Component

Figure 43: Middle East & Africa Electric Heat Tracing Systems Market Volume Share Analysis, by End-user Industry, 2022, 2027, and 2031

Figure 44: Middle East & Africa Electric Heat Tracing Systems Market Attractiveness, by End-user Industry

Figure 45: Middle East & Africa Electric Heat Tracing Systems Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 46: Middle East & Africa Electric Heat Tracing Systems Market Attractiveness, by Application

Figure 47: Middle East & Africa Electric Heat Tracing Systems Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 48: Middle East & Africa Electric Heat Tracing Systems Market Attractiveness, by Country and Sub-region