Reports

Reports

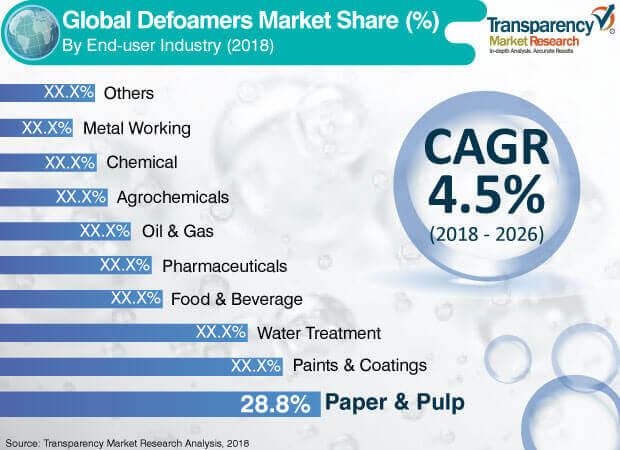

The growing popularity among numerous applications across a plethora of end-user industries may serve as a prominent growth factor for the defoamers market during the forecast period of 2018-2026. The major end-user industries of the defoamers market are paper and pulp, food and beverage, agrochemicals, water treatment, pharmaceuticals, metalworking, building and construction, chemical, and others. Defoamers are also known as antifoaming agents. They are chemical additives that help reduce foam formation in various processes across a variety of industries. The surface-active properties, viscosity and other characteristics may serve as a boon for the growth of the defoamers market during the forecast period.

The defoamers market has many aspects that can help the stakeholders design the future strategy of their business. Transparency Market Research presents the various aspects of the defoamers market such as competitive landscape, regional segmentation, latest trends, and others in a systematic manner to the stakeholders. Furthermore, the predictions are based on real-time data and extensive research. According to the analysts at Transparency Market Research, the defoamers market is anticipated to expand at a CAGR of 4.5% during the forecast period of 2018-2026. The defoamers market stood at US$ 7500.0 Mn in 2017.

Defoamers are used on a large scale in the paper and pulp industry. Numerous types of defoamers such as water-based defoamers, silicone-based defoamers, oil-based defoamers, alkyl polyacrylates defoamers, and powder defoamers are used in the paper and pulp industry. Defoamers help in addressing issues related to entrained air and surface foam. Even though digitalization is gaining pace across the globe, the demand for paper has not receded. According to the statistics from Statista, nearly 422 Mn metric tons of paper were consumed worldwide in 2018. Thus, the rising demand for paper is estimated to increase the growth rate of the defoamers market to a great extent.

The pharmaceutical industry is gaining considerable traction over the years. The use of defoamers is increasing in the manufacturing process of ointments and drugs for optimum production efficiency. Thus, these factors bode well for the growth of the defoamers market.

Water and wastewater management has become an important factor across various regions around the world. The problem of water scarcity has increased extensively in many countries. Water and wastewater management plays a crucial role in saving water. The use of hydrocarbon-based defoamers in sewage treatment application may bring profitable growth avenues for the defoamers market.

The growing rural-to-urban migration across various countries, especially in developing economies and densely populated regions like India and China may churn out substantial growth opportunities for the defoamers market. Due to rising urbanization, an increase in residential and commercial buildings is being observed, which is ultimately expanding the demand for paints. As defoamers are used in paints, the growth trajectory is expected to be strengthened during the forecast period. In addition, the government bodies of numerous countries are introducing smart city initiatives. These factors may boost the demand for new constructions and infrastructure, eventually propelling the growth opportunities across the defoamers market.

The defoamers market is largely consolidated. A few well-established players are responsible for a large growth share. Medium or small-sized manufacturers in the defoamers market are either acquired or merged with key players for decreasing the competition. Furthermore, R&D activities are crucial for the growth of the defoamers market. The key players invest in these activities for propelling novel formulations and strategies.

Some well-entrenched players in the defoamers market are Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Clariant International AG, Ashland Global Holdings Inc., Dow Corning Corporation, Momentive Performance Materials Inc., Evonik Industries AG, and BASF SE.

In 2017, Defoamers Market was valued at US$ 7500.0 Mn

Defoamers Market is estimated to rise at a CAGR of 4.5% during forecast period

Rising demand for paper is expected to drive the Defoamers Market

Asia Pacific is more attractive for vendors in the Defoamers Market

Key players of Defoamers Market are Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Clariant International AG, Ashland Global Holdings Inc., Dow Corning Corporation, Momentive Performance Materials Inc., Evonik Industries AG, and BASF SE

1. Preface

1.1. Report Scope and Market Segmentation

1.2. Research Highlights

2. Assumptions and Research Methodology

2.1. Report Assumptions

2.2. Secondary Sources and Acronyms Used

3. Executive Summary

3.1. Market Snapshot, Global Defoamers Market

3.2. Market Outlook, Volume Share, 2017

3.3. Market Share, Global Defoamers Market, by End-user Industry

3.4. Key Trends

3.5. Estimated Production, by Region, 2017

3.6. Market Share, by Company, 2017

4. Market Overview

4.1. Market Overview

4.2. Key Industry Developments

4.3. Drivers and Restraints Snapshot Analysis

4.3.1. Drivers

4.3.2. Restraints

4.3.3. Opportunities

4.4. Global Defoamers Market Analysis and Forecast

4.5. Porter’s Analysis

4.5.1. Threat of Substitutes

4.5.2. Bargaining Power of Buyers

4.5.3. Bargaining Power of Suppliers

4.5.4. Threat of New Entrants

4.5.5. Degree of Competition

4.6. Value Chain Analysis

4.7. Regulatory Scenario

4.8. Key Customer Analysis

4.9. Defoamers Market: SWOT Analysis

5. Price Trend Analysis

5.1. Defoamers Market Price Trend Analysis, by Product

5.2. Defoamers Market Price Trend Analysis, by End-user Industry

5.3. Defoamers Market Price Trend Analysis, by Region

6. Demand-Supply Scenario

6.1. Defoamers Market: Demand-Supply Scenario

6.2. Production Output at Regional Level (2017)

7. Global Defoamers Market Analysis and Forecast, by Product

7.1. Introduction

7.2. Key Findings

7.3. Global Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

7.4. Global Defoamers Market Forecast and Analysis, by Product, 2017–2026

7.4.1. Oil-based Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

7.4.2. Water-based Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

7.4.3. Silicone-based Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

7.4.4. Others Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

7.5. Global Defoamers Market Attractiveness Analysis, by Product

8. Defoamers Market Analysis and Forecast, by End-user Industry

8.1. Introduction

8.2. Key Findings

8.3. Global Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

8.4. Global Defoamers Market Forecast and Analysis, by End-user Industry, 2017–2026

8.4.1. Paper & Pulp Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.2. Water Treatment Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.3. Paints & Coatings Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.4. Food & Beverage Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.5. Oil & Gas Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.6. Agrochemicals Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.7. Pharmaceuticals Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.8. Chemical Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.9. Metal Working Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.4.10. Others Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, 2017–2026

8.5. Global Defoamers Market Attractiveness Analysis, by End-user Industry

9. Global Defoamers Market Analysis and Forecast, by Region

9.1. Global Market Consumption (Kilo Tons) in 2017 and Growth Scenario, by Region

9.2. Key Findings

9.3. Global Defoamers Market Volume Share Analysis, by Region, 2017 and 2026

9.4. Global Defoamers Market Forecast, by Region, 2017–2026

9.4.1. North America

9.4.2. Latin America

9.4.3. Europe

9.4.4. Asia Pacific

9.4.5. Middle East and Africa

9.5. Global Defoamers Market Attractiveness Analysis, by Region

10. North America Defoamers Market Analysis and Forecast

10.1. Key Findings

10.2. North America Defoamers Market Overview

10.3. North America Defoamers Market Volume Share Analysis and Forecast, by Product, 2017 and 2026

10.4. North America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

10.4.1. Oil-based Defoamers

10.4.2. Water-based Defoamers

10.4.3. Silicone-based Defoamers

10.4.4. Others

10.5. North America Defoamers Market Volume Share Analysis and Forecast, by End-user Industry, 2017 and 2026

10.6. North America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

10.6.1. Paper & Pulp

10.6.2. Water Treatment

10.6.3. Paints & Coatings

10.6.4. Food & Beverage

10.6.5. Oil & Gas

10.6.6. Agrochemicals

10.6.7. Pharmaceuticals

10.6.8. Chemical

10.6.9. Metal Working

10.6.10. Others

10.7. North America Defoamers Market Volume Share Analysis and Forecast, by Country, 2017 and 2026

10.8. North America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country, 2017–2026

10.8.1. U.S. Defoamers Market Analysis

10.8.2. U.S. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

10.8.3. U.S. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

10.8.4. Canada Defoamers Market Analysis

10.8.5. Canada Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

10.8.6. Canada Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

10.8.7. North America Defoamers Market, Comparison Matrix, by Product

10.8.8. North America Defoamers Market, Comparison Matrix, by End-user Industry

11. Latin America Defoamers Market Analysis and Forecast

11.1. Key Findings

11.2. Latin America Defoamers Market Overview

11.3. Latin America - Market Trends

11.4. Latin America Defoamers Market Volume Share Analysis and Forecast, by Product, 2017 and 2026

11.5. Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

11.5.1. Oil-based Defoamers

11.5.2. Water-based Defoamers

11.5.3. Silicone-based Defoamers

11.5.4. Others

11.6. Latin America Defoamers Market Volume Share Analysis and Forecast, by End-user Industry, 2017 and 2026

11.7. Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

11.7.1. Paper & Pulp

11.7.2. Water Treatment

11.7.3. Paints & Coatings

11.7.4. Food & Beverage

11.7.5. Oil & Gas

11.7.6. Agrochemicals

11.7.7. Pharmaceuticals

11.7.8. Chemical

11.7.9. Metal Working

11.7.10. Others

11.8. Latin America Defoamers Market Volume Share Analysis and Forecast, by Country and Sub-region, 2017 and 2026

11.9. Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

11.9.1. Brazil Defoamers Market Analysis

11.9.2. Brazil Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

11.9.3. Brazil Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

11.9.4. Mexico Defoamers Market Analysis

11.9.5. Mexico Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

11.9.6. Mexico Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

11.9.7. Rest of Latin America Defoamers Market Analysis

11.9.8. Rest of Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

11.9.9. Rest of Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

11.10. Latin America Defoamers Market, Comparison Matrix, by Product

11.11. Latin America Defoamers Market, Comparison Matrix, by End-user Industry

12. Europe Defoamers Market Analysis and Forecast

12.1. Key Findings

12.2. Europe Defoamers Market Overview

12.3. Europe - Market Trends

12.4. Europe Defoamers Market Volume Share Analysis and Forecast, by Product, 2017 and 2026

12.5. Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.5.1. Oil-based Defoamers

12.5.2. Water-based Defoamers

12.5.3. Silicone-based Defoamers

12.5.4. Others

12.6. Europe Defoamers Market Volume Share Analysis and Forecast, by End-user Industry, 2017 and 2026

12.7. Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.7.1. Paper & Pulp

12.7.2. Water Treatment

12.7.3. Paints & Coatings

12.7.4. Food & Beverage

12.7.5. Oil & Gas

12.7.6. Agrochemicals

12.7.7. Pharmaceuticals

12.7.8. Chemical

12.7.9. Metal Working

12.7.10. Others

12.8. Europe Defoamers Market Volume Share Analysis and Forecast, by Country and Sub-region, 2017 and 2026

12.9. Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

12.9.1. Germany Defoamers Market Analysis

12.9.2. Germany Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.3. Germany Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.9.4. France Defoamers Market Analysis

12.9.5. France Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.6. France Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.9.7. U.K. Defoamers Market Analysis

12.9.8. U.K. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.9. U.K. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.9.10. Spain Defoamers Market Analysis

12.9.11. Spain Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.12. Spain Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.9.13. Italy Defoamers Market Analysis

12.9.14. Italy Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.15. Italy Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.9.16. Rest of Europe Defoamers Market Analysis

12.9.17. Rest of Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

12.9.18. Rest of Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

12.10. Europe Defoamers Market, Comparison Matrix, by Product

12.11. Europe Defoamers Market, Comparison Matrix, by End-user Industry

13. Asia Pacific Defoamers Market Analysis and Forecast

13.1. Key Findings

13.2. Asia Pacific Defoamers Market Overview

13.3. Asia Pacific - Market Trends

13.4. Asia Pacific Defoamers Market Volume Share Analysis and Forecast, by Product, 2017 and 2026

13.5. Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.5.1. Oil-based Defoamers

13.5.2. Water-based Defoamers

13.5.3. Silicone-based Defoamers

13.5.4. Others

13.6. Asia Pacific Defoamers Market Volume Share Analysis and Forecast, by End-user Industry, 2017 and 2026

13.7. Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.7.1. Paper & Pulp

13.7.2. Water Treatment

13.7.3. Paints & Coatings

13.7.4. Food & Beverage

13.7.5. Oil & Gas

13.7.6. Agrochemicals

13.7.7. Pharmaceuticals

13.7.8. Chemical

13.7.9. Metal Working

13.7.10. Others

13.8. Asia Pacific Defoamers Market Volume Share Analysis and Forecast, by Country and Sub-region, 2017 and 2026

13.9. Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

13.9.1. China Defoamers Market Analysis

13.9.2. China Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.9.3. China Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.9.4. Japan Defoamers Market Analysis

13.9.5. Japan Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.9.6. Japan Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.9.7. India Defoamers Market Analysis

13.9.8. India Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.9.9. India Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.9.10. India - Market Trends

13.9.11. ASEAN Defoamers Market Analysis

13.9.12. ASEAN Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.9.13. ASEAN Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.9.14. Rest of Asia Pacific Defoamers Market Analysis

13.9.15. Rest of Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

13.9.16. Rest of Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

13.10. Asia Pacific Defoamers Market, Comparison Matrix, by Product

13.11. Asia Pacific Defoamers Market, Comparison Matrix, by End-user Industry

14. Middle East & Africa Defoamers Market Analysis and Forecast

14.1. Key Findings

14.2. Middle East & Africa Defoamers Market Overview

14.3. Middle East & Africa Defoamers Market Volume Share Analysis and Forecast, by Product, 2017 and 2026

14.4. Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.4.1. Oil-based Defoamers

14.4.2. Water-based Defoamers

14.4.3. Silicone-based Defoamers

14.4.4. Others

14.5. Middle East & Africa Defoamers Market Volume Share Analysis and Forecast, by End-user Industry, 2017 and 2026

14.6. Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.6.1. Paper & Pulp

14.6.2. Water Treatment

14.6.3. Paints & Coatings

14.6.4. Food & Beverage

14.6.5. Oil & Gas

14.6.6. Agrochemicals

14.6.7. Pharmaceuticals

14.6.8. Chemical

14.6.9. Metal Working

14.6.10. Others

14.7. Middle East & Africa Defoamers Market Volume Share Analysis and Forecast, by Country and Sub-region, 2017 and 2026

14.8. Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

14.8.1. Saudi Arabia Defoamers Market Analysis

14.8.2. Saudi Arabia Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.3. Saudi Arabia Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.4. U.A.E. Defoamers Market Analysis

14.8.5. U.A.E. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.6. U.A.E. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.7. Qatar Defoamers Market Analysis

14.8.8. Qatar Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.9. Qatar Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.10. Iran Defoamers Market Analysis

14.8.11. Iran Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.12. Iran Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.13. Nigeria Defoamers Market Analysis

14.8.14. Nigeria Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.15. Nigeria Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.16. South Africa Defoamers Market Analysis

14.8.17. South Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.18. South Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.8.19. Rest of Middle East & Africa Defoamers Market Analysis

14.8.20. Rest of Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

14.8.21. Rest of Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

14.9. Middle East & Africa Defoamers Market, Comparison Matrix, by Product

14.10. Middle East & Africa Defoamers Market, Comparison Matrix, by End-user Industry

15. Competition Landscape

15.1. Defoamers Market Share Analysis, by Company (2017)

15.2. Competition Matrix

15.3. Product Mapping

15.4. Company Profiles

15.4.1. Wacker Chemie AG

15.4.1.1. Company Description

15.4.1.2. Business Overview

15.4.1.3. Financial Details

15.4.1.4. Strategic Overview

15.4.1.5. Product Details

15.4.2. Elkem Silicones

15.4.3. DyStar Group

15.4.4. BASF SE

15.4.5. Clariant International AG

15.4.6. Synalloy Corporation

15.4.7. Evonik Industries AG

15.4.8. Accepta Ltd

15.4.9. Kemira Oyj

15.4.10. Ashland Global Holdings Inc

15.4.11. Momentive Performance Materials Inc

15.4.12. Shin-Etsu Chemical Co., Ltd.

15.4.13. Innospec

15.4.14. Air Products and Chemicals, Inc.

15.4.15. Elementis plc

15.4.16. Cytec Solvay Group

15.4.17. Emerald Performance Materials

15.4.18. BRB International B.V.

15.4.19. PMC Group, Inc.

15.4.20. LEVACO Chemicals GmbH

15.4.21. Kurita Water Industries Ltd.

15.4.22. Siltech Corporation

15.4.23. San Nopco Limited

15.4.24. Magrabar, LLC

15.4.25. Buckman Laboratories International, Inc.

15.4.26. Rudolf GmbH

15.4.27. CHT Group

15.4.28. Nalco Champion (An Ecolab company)

15.4.29. Dow Corning Corporation

15.4.30. Arysta LifeScience Magyarország Kft.

15.4.31. Archroma Packaging & Paper Specialties

15.4.32. CIMCOOL Fluid Technology, LLC

15.4.33. Banmark Oy

15.4.34. FUCHS

15.4.35. MÜNZING CHEMIE GmbH

15.4.36. BIM Kemi AB

15.4.37. Harcros Chemicals Inc.

15.4.38. SIXIN North America, Inc.

15.4.39. King Industries, Inc.

15.4.40. KCC Basildon

15.4.41. Enterprise Specialty Products

15.4.42. Bussetti & Co GmbH

15.4.43. Houghton International Inc.

15.4.44. Organic Defoamer Group

15.4.45. Nanjing Huaxing Defoamer Co., Ltd.

15.4.46. Elkay Chemicals Private Limited

15.4.47. K. K. Chempro India Pvt Ltd

15.4.48. Om Tex Chem Private Limited

15.4.49. Resil Chemicals Pvt. Ltd

15.4.50. Supreme Silicones

15.4.51. BYK

16. Primary Research – Key Insights

List of Tables

Table 01: Average Price Range of Defoamers, by Product, US$/Ton, 2017–2026

Table 02: Price Range of Styrenic Defoamers for Medical Applications, by End-user Industry, US$/Ton, 2017–2026

Table 03: Price Trend of Defoamers, by Product and Region, US$/Ton, 2017

Table 04: Estimated Production of Defoamers at Regional Level (2017)

Table 05: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 06: Global Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 07: Global Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 08: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Region, 2017–2026

Table 09: North America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 10: North America Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 11: North America Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 12: North America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country, 2017–2026

Table 13: U.S. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 14: U.S. Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 15: U.S. Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 16: Canada Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 17: Canada Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 18: Canada Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 19: Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 20: Latin America Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 21: Latin America Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 22: Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

Table 23: Brazil Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 24: Brazil Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 25: Brazil Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 26: Mexico Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 27: Mexico Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 28: Mexico Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 29: Rest of Latin America Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 30: Rest of Latin America Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 31: Rest of Latin America Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 32: Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 33: Europe Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 34: Europe Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 35: Europe Defoamers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2017–2026

Table 36: Europe Defoamers Market Volume Revenue (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

Table 37: Germany Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 38: Germany Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 39: Germany Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 40: France Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 41: France Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 42: France Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 43: U.K. Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 44: U.K. Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 45: U.K. Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 46: Spain Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 47: Spain Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 48: Spain Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 49: Italy Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 50: Italy Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 51: Italy Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 52: Rest of Europe Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 53: Rest of Europe Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 54: Rest of Europe Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 55: Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 56: Asia Pacific Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 57: Asia Pacific Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 58: Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

Table 60: China Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 61: China Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 62: China Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 63: Japan Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 64: Japan Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 65: Japan Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 66: India Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 67: India Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 68: India Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 69: ASEAN Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 70: ASEAN Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 71: ASEAN Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 72: Rest of Asia Pacific Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 73: Rest of Asia Pacific Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 74: Rest of Asia Pacific Defoamers Market Value (US$ Mn) Forecast, by End-user industry, 2017–2026

Table 75: Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 76: Middle East & Africa Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 77: Middle East & Africa Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 78: Middle East & Africa Defoamers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2017–2026

Table 79: Middle East & Africa Defoamers Market Volume Revenue (US$ Mn) Forecast, by Country and Sub-region, 2017–2026

Table 80: Saudi Arabia Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 81: Saudi Arabia Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 82: Saudi Arabia Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 83: UAE Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 84: UAE Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 85: UAE Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 86: Qatar Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 87: Qatar Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 88: Qatar Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 89: Iran Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 90: Iran Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 91: Iran Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 92: Nigeria Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 93: Nigeria Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 94: Nigeria Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 95: South Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 96: South Africa Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 97: South Africa Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

Table 98: Rest of Middle East & Africa Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Product, 2017–2026

Table 99: Rest of Middle East & Africa Defoamers Market Volume (Kilo Tons) Forecast, by End-user Industry, 2017–2026

Table 100: Rest of Middle East & Africa Defoamers Market Value (US$ Mn) Forecast, by End-user Industry, 2017–2026

List of Figures

Figure 01: Market Snapshot, Global Defoamers Market

Figure 02: Global Defoamers Market Volume Share, by Product, 2017

Figure 03: Global Defoamers Market Volume Share, by Region, 2017

Figure 04: Global Defoamers Market Volume Share, by End-user Industry, 2017

Figure 05: Market Snapshot, Global Defoamers Market, by End-user Industry, 2018 (E) and 2026 (F)

Figure 06: Estimated Production of Defoamers at Regional Level, 2017

Figure 07: Global Defoamers Market Share Analysis, by Company, 2017

Figure 08: Global Defoamers Market Volume (Kilo Tons) and Size (US$ Mn) Analysis, 2017–2026

Figure 09: Global Defoamers Market Size and Volume, Y-o-Y Growth Projection, 2017–2026

Figure 10: Price Trend of Defoamers, by Product and Region, US$/Ton, 2017

Figure 11: Estimated Production of Defoamers at Regional Level (2017), Kilo Tons

Figure 12: Global Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 13: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Oil-based Defoamers, 2017–2026

Figure 14: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Water-based Defoamers, 2017–2026

Figure 15: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Silicone-based Defoamers, 2017–2026

Figure 16: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Other Defoamers, 2017–2026

Figure 17: Global Defoamers Market Attractiveness Analysis, by Product

Figure 18: Global Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 19: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Paper & Pulp, 2017–2026

Figure 20: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Water Treatment, 2017–2026

Figure 21: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Paints & Coatings, 2017–2026

Figure 22: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Food & Beverage, 2017–2026

Figure 23: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Oil & Gas, 2017–2026

Figure 24: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Agrochemicals, 2017–2026

Figure 25: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Pharmaceuticals, 2017–2026

Figure 26: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Chemical, 2017–2026

Figure 27: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Metal working, 2017–2026

Figure 28: Global Defoamers Market Volume (Kilo Tons) and Value (US$ Mn) Analysis for Others, 2017–2026

Figure 29: Global Defoamers Market Attractiveness Analysis, by End-user Industry

Figure 30: Global Defoamers Market Volume Share Analysis, by Region, 2017 and 2026

Figure 31: Global Defoamers Market Attractiveness Analysis, by Region

Figure 32: North America Defoamers Market Size (US$ Mn) and Volume (Kilo Tons) Forecast, 2017–2026

Figure 33: North America Defoamers Market Attractiveness Analysis, by Country

Figure 34: North America Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 35: North America Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 36: North America Defoamers Market Volume Share Analysis, by Country, 2017 and 2026

Figure 37: U.S. Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 38: U.S. Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 39: Canada Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 40: Canada Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 41: Latin America Defoamers Market Size (US$ Mn) and Volume (Kilo Tons) Forecast, 2017–2026

Figure 42: Latin America Defoamers Market Attractiveness Analysis, by Country and Sub-region

Figure 43: Latin America Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 44: Latin America Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 45: Latin America Defoamers Market Volume Share Analysis, by Country and Sub-region, 2017 and 2026

Figure 46: Brazil Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 47: Brazil Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 48: Mexico Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 49: Mexico Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 50: Rest of Latin America Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 51: Rest of Latin America Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 52: Europe Defoamers Market Size (US$ Mn) and Volume (Kilo Tons) Forecast, 2017–2026

Figure 53: Europe Defoamers Market Attractiveness Analysis, by Country and Sub-region

Figure 54: Europe Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 55: Europe Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 56: Europe Defoamers Market Volume Share Analysis, by Country and Sub-region, 2017 and 2026

Figure 57: Germany Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 58: Germany Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 59: France Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 60: France Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 61: U.K. Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 62: U.K. Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 63: Spain Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 64: Spain Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 65: Italy Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 66: Italy Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 67: Rest of Europe Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 68: Rest of Europe Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 69: Asia Pacific Defoamers Market Size (US$ Mn) and Volume (Kilo Tons) Forecast, 2017–2026

Figure 70: Asia Pacific Defoamers Market Attractiveness Analysis, by Country and Sub-region

Figure 71: Asia Pacific Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 72: Asia Pacific Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 73: Asia Pacific Defoamers Market Volume Share Analysis, by Country and Sub-region, 2017 and 2026

Figure 74: China Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 75: China Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 76: Japan Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 77: Japan Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 78: India Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 79: India Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 80: ASEAN Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 81: ASEAN Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 82: Rest of Asia Pacific Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 83: Rest of Asia Pacific Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 84: Middle East & Africa Defoamers Market Size (US$ Mn) and Volume (Kilo Tons) Forecast, 2017–2026

Figure 85: Middle East & Africa Defoamers Market Attractiveness Analysis, by Country and Sub-region

Figure 86: Middle East & Africa Defoamers Market Volume Share Analysis, by Product, 2017 and 2026

Figure 87: Middle East & Africa Defoamers Market Volume Share Analysis, by End-user Industry, 2017 and 2026

Figure 88: Middle East & Africa Defoamers Market Volume Share Analysis, by Country and Sub-region, 2017 and 2026

Figure 89: Saudi Arabia Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 90: Saudi Arabia Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 91: UAE Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 92: UAE Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 93: Qatar Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 94: Qatar Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 95: Iran Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 96: Iran Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 97: Nigeria Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 98: Nigeria Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 99: South Africa Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 100: South Africa Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 101: Rest of Middle East & Africa Defoamers Market Volume (Kilo Tons) Forecast, 2017–2026

Figure 102: Rest of Middle East & Africa Defoamers Market Size (US$ Mn) Forecast, 2017–2026

Figure 103: Global Defoamers Market Share Analysis, by Company, 2017