Reports

Reports

Analysts’ Viewpoint on Market Scenario

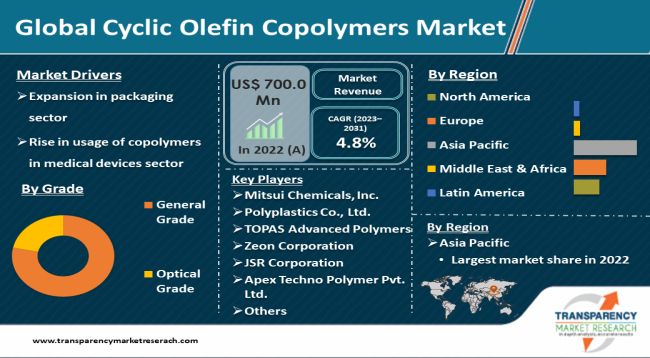

Cyclic olefin copolymers are used in the manufacture of packaging films, lenses, vials, displays, and medical devices. Growth in demand for high-performance materials in the electronics sector and rise in adoption of drug delivery systems are projected to augment the cyclic olefin copolymers market size in the near future.

Cyclic olefin copolymers are gaining traction in food & beverage and packaging sectors due to increase in demand for sustainable products across the globe. Vendors in the global cyclic olefin copolymer industry are using recyclable materials to meet their sustainability targets. They are also offering affordable products to expand their customer base. Surge in investment in R&D of new products is likely to increase the cyclic olefin copolymers market share of vendors in the near future.

Cyclic Olefin Copolymers (COCs) are a class of thermoplastic polymers that have a cyclic structure, which means that the monomer units of the polymer form a cyclic ring. COCs are made from the combination of two or more monomers. These monomers are cyclic olefins, which are unsaturated cyclic hydrocarbons, with one or more double bonds in the ring.

COCs have gained popularity in packaging and pharmaceutical sectors due to their outstanding characteristics and high level of purity. These copolymers are widely used in primary drug packaging, including prefilled syringes, vials, blisters, pouches, and lightweight wearables, as modern pharmaceutical compounds and formulations are more sensitive to various chemicals.

Cyclic olefin copolymers enable improved performance in multilayer polyolefin packaging sheets. The formability, optics, toughness, and puncture resistance of COC/linear low-density polyethylene (LLDPE) multilayer films are superior to EVA/ionomer co-extruded films at comparable price points.

Engineered COC/LLDPE multilayer films can be compared favorably to several nylon-based films while doing away with the need for adhesive tie layers. Removing tie layers and non-olefin resins simplifies manufacturing logistics and allows for the usage of recovered scrap film owing to the compatibility of COC and polyethylene. Thus, growth in the packaging sector is boosting cyclic olefin copolymers market development.

Prefilled syringes made from COC offer exceptional purity and subsequent medication stability. The purity and dimensional stability of COC make it possible to control drug dosage with high potency and accuracy in wearable insulin administration systems.

Increase in adoption of microfluidic devices and point-of-care (POC) diagnostics is expected to spur the cyclic olefin copolymers market growth in the near future.

Cyclic olefin copolymers are highly sought-after and practical microfluidic materials due to their excellent chemical resistance, including resistance to the most popular organic solvents used in chemical analysis, high optical and UV clarity, low water absorption, and exceptional moisture barrier.

According to the latest cyclic olefin copolymers market trends, the general grade segment held major share of 78.3% in 2022. General-grade cyclic olefin copolymers are popular for applications that require good mechanical, thermal, and chemical properties.

General grade cyclic olefin copolymers are generally less expensive than optical grade cyclic olefin copolymers. This makes them a cost-effective choice for applications that do not require exceptional optical properties.

Optical grade cyclic olefin copolymers are specifically designed for high-performance optical applications that require exceptional clarity, purity, and low birefringence.

According to the latest cyclic olefin copolymers market forecast, Asia Pacific is projected to account for the largest share from 2023 to 2031. The region constituted 47.5% share in 2022. Growth in several end-use industries is driving market dynamics of the region.

North America held 19.2% share in 2022. Expansion in the medical devices sector is augmenting cyclic olefin copolymers market statistics in the region. Middle East & Africa and Latin America cumulatively accounted for less than 10.0% share in 2022.

The global landscape is moderately consolidated, with a small number of large-scale vendors controlling majority of the share. Most of the businesses are investing substantially in R&D activities to expand their product portfolio.

Mitsui Chemicals, Inc., Polyplastics Co., Ltd., TOPAS Advanced Polymers, Zeon Corporation, JSR Corporation, and Apex Techno Polymer Pvt. Ltd. are key entities operating in this industry. Each of these players has been profiled in the cyclic olefin copolymers market report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

| Attribute | Detail |

|---|---|

|

Market Value in 2022 |

US$ 700.0 Mn |

|

Market Forecast Value in 2031 |

US$ 1.1 Bn |

|

Growth Rate (CAGR) |

4.8% |

|

Forecast Period |

2023-2031 |

|

Historical Data Available for |

2021 |

|

Quantitative Units |

US$ Mn/Bn for Value and Tons for Volume |

|

Market Analysis |

It includes cross-segment analysis at the global as well as regional level. Furthermore, the qualitative analysis includes drivers, restraints, and opportunities, key trends, Porter’s Five Forces analysis, value chain analysis, and key trend analysis. |

|

Competition Landscape |

|

|

Format |

Electronic (PDF) + Excel |

|

Market Segmentation |

|

|

Regions Covered |

|

|

Countries Covered |

|

|

Companies Profiled |

|

|

Customization Scope |

Available upon request |

|

Pricing |

Available upon request |

It was valued at US$ 700.0 Mn in 2022

It is projected to grow at a CAGR of 4.8% from 2023 to 2031

Expansion in the packaging sector and rise in usage of copolymers in the medical devices sector

The general grade segment held 78.3% share in 2022

Asia Pacific recorded the highest demand for cyclic olefin copolymers in 2022

Mitsui Chemicals, Inc., Polyplastics Co., Ltd., TOPAS Advanced Polymers, Zeon Corporation, JSR Corporation, and Apex Techno Polymer Pvt. Ltd.

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

2.6.1. Global Cyclic Olefin Copolymers Market Volume (Tons)

2.6.2. Global Cyclic Olefin Copolymers Market Revenue (US$ Bn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Grade Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealers/Distributors

2.9.4. List of Potential Customers

2.10. Production Overview

2.11. Product Specification Analysis

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on Supply Chain of Cyclic Olefin Copolymers

3.2. Impact on Demand for Cyclic Olefin Copolymers– Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Tons), 2022

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East & Africa

6. Price Trend Analysis and Forecast (US$/Ton), 2023-2031

6.1. Price Comparison Analysis by Grade

6.2. Price Comparison Analysis by Region

7. Global Cyclic Olefin Copolymers Market Analysis and Forecast, by Grade, 2023-2031

7.1. Introduction and Definitions

7.2. Global Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

7.2.1. Optical Grade

7.2.2. General Grade

7.3. Global Cyclic Olefin Copolymers Market Attractiveness, by Grade

8. Global Cyclic Olefin Copolymers Market Analysis and Forecast, by Application, 2023-2031

8.1. Introduction and Definitions

8.2. Global Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

8.2.1. Optical Plastic Lenses

8.2.1.1. Digital Camera Lenses

8.2.1.2. Optical Disks Lenses

8.2.1.3. Laser Beam Printers Lenses

8.2.1.4. Projector Lenses

8.2.1.5. Head Mounted Display Lenses

8.2.1.6. Automotive Camera Lenses

8.2.1.7. Others

8.2.2. Medical Packaging Materials

8.2.2.1. Press-through-Package (PTP) Sheets

8.2.2.2. Pre-filled Syringes

8.2.2.3. Medicine Bottles

8.2.2.4. Others

8.2.3. Cosmetic Packaging Materials

8.2.4. Food Packaging Materials

8.2.5. Electric and Electronic Components

8.2.6. Advanced Diagnostic and Microfluidic Applications

8.2.7. Others

8.3. Global Cyclic Olefin Copolymers Market Attractiveness, by Application

9. Global Cyclic Olefin Copolymers Market Analysis and Forecast, by End-use, 2023-2031

9.1. Introduction and Definitions

9.2. Global Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

9.2.1. Optics

9.2.2. Healthcare

9.2.3. Personal Care

9.2.4. Food & Beverage

9.2.5. Electrical & Electronics

9.2.6. Others

9.3. Global Cyclic Olefin Copolymers Market Attractiveness, by End-use

10. Global Cyclic Olefin Copolymers Market Analysis and Forecast, by Region, 2023-2031

10.1. Key Findings

10.2. Global Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Region, 2023-2031

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Global Cyclic Olefin Copolymers Market Attractiveness, by Region

11. North America Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

11.1. Key Findings

11.2. North America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

11.3. North America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.4. North America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

11.5. North America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Country, 2023-2031

11.5.1. U.S. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

11.5.2. U.S. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.5.3. U.S. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

11.5.4. Canada Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

11.5.5. Canada Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

11.5.6. Canada Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

11.6. North America Cyclic Olefin Copolymers Market Attractiveness Analysis

12. Europe Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.3. Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.4. Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5. Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

12.5.1. Germany Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.2. Germany Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.3. Germany Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5.4. France Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.5. France Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.6. France Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5.7. U.K. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.8. U.K. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.9. U.K. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5.10. Italy Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.11. Italy. Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.12. Italy Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5.13. Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.14. Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.15. Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.5.16. Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

12.5.17. Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

12.5.18. Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

12.6. Europe Cyclic Olefin Copolymers Market Attractiveness Analysis

13. Asia Pacific Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade

13.3. Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.4. Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.5. Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

13.5.1. China Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

13.5.2. China Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.3. China Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.5.4. Japan Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

13.5.5. Japan Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.6. Japan Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.5.7. India Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

13.5.8. India Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.9. India Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.5.10. ASEAN Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

13.5.11. ASEAN Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.12. ASEAN Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.5.13. Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

13.5.14. Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

13.5.15. Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

13.6. Asia Pacific Cyclic Olefin Copolymers Market Attractiveness Analysis

14. Latin America Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

14.3. Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.4. Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

14.5. Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

14.5.1. Brazil Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

14.5.2. Brazil Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5.3. Brazil Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

14.5.4. Mexico Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

14.5.5. Mexico Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5.6. Mexico Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

14.5.7. Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

14.5.8. Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

14.5.9. Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

14.6. Latin America Cyclic Olefin Copolymers Market Attractiveness Analysis

15. Middle East & Africa Cyclic Olefin Copolymers Market Analysis and Forecast, 2023-2031

15.1. Key Findings

15.2. Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

15.3. Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.4. Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

15.5. Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

15.5.1. GCC Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

15.5.2. GCC Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5.3. GCC Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

15.5.4. South Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

15.5.5. South Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5.6. South Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

15.5.7. Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Grade, 2023-2031

15.5.8. Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by Application, 2023-2031

15.5.9. Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) and Value (US$ Bn) Forecast, by End-use, 2023-2031

15.6. Middle East & Africa Cyclic Olefin Copolymers Market Attractiveness Analysis

16. Competition Landscape

16.1. Market Players - Competition Matrix (by Tier and Size of Companies)

16.2. Market Share Analysis, 2022

16.3. Market Footprint Analysis

16.3.1. By Grade

16.3.2. By End-use

16.4. Company Profiles

16.4.1. Mitsui Chemicals Inc.

16.4.1.1. Company Revenue

16.4.1.2. Business Overview

16.4.1.3. Grade Segments

16.4.1.4. Geographic Footprint

16.4.1.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.1.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.2. Polyplastics Co., Ltd.

16.4.2.1. Company Revenue

16.4.2.2. Business Overview

16.4.2.3. Grade Segments

16.4.2.4. Geographic Footprint

16.4.2.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.2.6. Strategic Partnership, Capacity Expansion, New Grade Innovation etc

16.4.3. TOPAS Advanced Polymers

16.4.3.1. Company Revenue

16.4.3.2. Business Overview

16.4.3.3. Grade Segments

16.4.3.4. Geographic Footprint

16.4.3.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.3.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.4. Zeon Corporation

16.4.4.1. Company Revenue

16.4.4.2. Business Overview

16.4.4.3. Grade Segments

16.4.4.4. Geographic Footprint

16.4.4.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.4.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.5. JSR Corporation

16.4.5.1. Company Revenue

16.4.5.2. Business Overview

16.4.5.3. Grade Segments

16.4.5.4. Geographic Footprint

16.4.5.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.5.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

16.4.6. Apex Techno Polymer Pvt. Ltd.

16.4.6.1. Company Revenue

16.4.6.2. Business Overview

16.4.6.3. Grade Segments

16.4.6.4. Geographic Footprint

16.4.6.5. Production Capacity/Plant Details, etc. (*As Applicable)

16.4.6.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

17. Primary Research: Key Insights

18. Appendix

List of Tables

Table 1: Global Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 2: Global Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 3: Global Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 4: Global Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 5: Global Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 6: Global Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 7: Global Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Region, 2023-2031

Table 8: Global Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Region, 2023-2031

Table 9: North America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 10: North America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 11: North America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 12: North America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 13: North America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 14: North America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 15: North America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Country, 2023-2031

Table 16: North America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Country, 2023-2031

Table 17: U.S. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 18: U.S. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 19: U.S. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 20: U.S. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 21: U.S. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 22: U.S. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 23: Canada Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 24: Canada Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 25: Canada Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 26: Canada Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 27: Canada Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 28: Canada Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 29: Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 30: Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 31: Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 32: Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 33: Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 34: Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 35: Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Country and Sub-region, 2023-2031

Table 36: Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 37: Germany Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 38: Germany Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 39: Germany Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 40: Germany Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 41: Germany Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 42: Germany Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 43: France Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 44: France Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 45: France Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 46: France Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 47: France Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 48: France Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 49: U.K. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 50: U.K. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 51: U.K. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 52: U.K. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 53: U.K. Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 54: U.K. Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 55: Italy Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 56: Italy Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 57: Italy Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 58: Italy Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 59: Italy Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 60: Italy Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 61: Spain Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 62: Spain Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 63: Spain Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 64: Spain Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 65: Spain Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 66: Spain Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 67: Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 68: Russia & CIS Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 69: Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 70: Russia & CIS Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 71: Russia & CIS Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 72: Russia & CIS Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 73: Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 74: Rest of Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 75: Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 76: Rest of Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 77: Rest of Europe Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 78: Rest of Europe Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 79: Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 80: Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 81: Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 82: Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 83: Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 84: Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 85: Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Country and Sub-region, 2023-2031

Table 86: Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 87: China Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 88: China Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade 2023-2031

Table 89: China Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 90: China Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 91: China Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 92: China Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 93: Japan Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 94: Japan Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 95: Japan Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 96: Japan Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 97: Japan Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 98: Japan Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 99: India Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 100: India Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 101: India Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 102: India Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 103: India Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 104: India Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 105: India Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 106: India Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use 2023-2031

Table 107: ASEAN Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 108: ASEAN Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 109: ASEAN Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 110: ASEAN Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 111: ASEAN Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 112: ASEAN Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 113: Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 114: Rest of Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 115: Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 116: Rest of Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 117: Rest of Asia Pacific Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 118: Rest of Asia Pacific Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 119: Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 120: Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 121: Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 122: Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 123: Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 124: Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 125: Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Country and Sub-region, 2023-2031

Table 126: Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 127: Brazil Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 128: Brazil Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 129: Brazil Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 130: Brazil Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 131: Brazil Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 132: Brazil Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 133: Mexico Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 134: Mexico Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 135: Mexico Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 136: Mexico Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 137: Mexico Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 138: Mexico Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 139: Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 140: Rest of Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 141: Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 142: Rest of Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 143: Rest of Latin America Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 144: Rest of Latin America Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 145: Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 146: Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 147: Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 148: Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 149: Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 150: Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 151: Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Country and Sub-region, 2023-2031

Table 152: Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Country and Sub-region, 2023-2031

Table 153: GCC Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 154: GCC Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 155: GCC Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 156: GCC Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 157: GCC Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 158: GCC Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 159: South Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 160: South Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 161: South Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 162: South Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 163: South Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 164: South Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

Table 165: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Grade, 2023-2031

Table 166: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Grade, 2023-2031

Table 167: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by Application, 2023-2031

Table 168: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by Application, 2023-2031

Table 169: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Volume (Tons) Forecast, by End-use, 2023-2031

Table 170: Rest of Middle East & Africa Cyclic Olefin Copolymers Market Value (US$ Bn) Forecast, by End-use, 2023-2031

List of Figures

Figure 1: Global Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 2: Global Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 3: Global Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 4: Global Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 5: Global Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 6: Global Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 7: Global Cyclic Olefin Copolymers Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 8: Global Cyclic Olefin Copolymers Market Attractiveness, by Region

Figure 9: North America Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 10: North America Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 11: North America Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 12: North America Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 13: North America Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 14: North America Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 15: North America Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 16: North America Cyclic Olefin Copolymers Market Attractiveness, by Country and Sub-region

Figure 17: Europe Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 18: Europe Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 19: Europe Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 20: Europe Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 21: Europe Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 22: Europe Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 23: Europe Cyclic Olefin Copolymers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Europe Cyclic Olefin Copolymers Market Attractiveness, by Country and Sub-region

Figure 25: Asia Pacific Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 26: Asia Pacific Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 27: Asia Pacific Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 28: Asia Pacific Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 29: Asia Pacific Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 30: Asia Pacific Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 31: Asia Pacific Cyclic Olefin Copolymers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 32: Asia Pacific Cyclic Olefin Copolymers Market Attractiveness, by Country and Sub-region

Figure 33: Latin America Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 34: Latin America Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 35: Latin America Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 36: Latin America Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 37: Latin America Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 38: Latin America Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 39: Latin America Cyclic Olefin Copolymers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Latin America Cyclic Olefin Copolymers Market Attractiveness, by Country and Sub-region

Figure 41: Middle East & Africa Cyclic Olefin Copolymers Market Volume Share Analysis, by Grade, 2022, 2027, and 2031

Figure 42: Middle East & Africa Cyclic Olefin Copolymers Market Attractiveness, by Grade

Figure 43: Middle East & Africa Cyclic Olefin Copolymers Market Volume Share Analysis, by Application, 2022, 2027, and 2031

Figure 44: Middle East & Africa Cyclic Olefin Copolymers Market Attractiveness, by Application

Figure 45: Middle East & Africa Cyclic Olefin Copolymers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 46: Middle East & Africa Cyclic Olefin Copolymers Market Attractiveness, by End-use

Figure 47: Middle East & Africa Cyclic Olefin Copolymers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 48: Middle East & Africa Cyclic Olefin Copolymers Market Attractiveness, by Country and Sub-region