Reports

Reports

Companies in the crusher backing materials market are maintaining clean production facilities and providing employees with necessary supplies for work-from-home routine. Canada’s distributor of maintenance, repair, and operational supplies has stepped in to maintain uninterrupted supply chains for its clients amidst the ongoing coronavirus (COVID-19) pandemic and emphasizes on social distancing norms in facilities. Thus, emerging market players are taking cues from such companies to establish signage and floor markings in production facilities amidst the COVID-19 pandemic.

Floor plan change and ensuring work-from-home supplies for employees is helping manufacturers to boost their credibility credentials in the global crusher backing materials market landscape. Companies are redesigning their facilities to reduce the density of occupants and minimize unsafe interaction. Moreover, clearly marked areas help remind employees to practice physical distancing and ensure interaction in a safe manner.

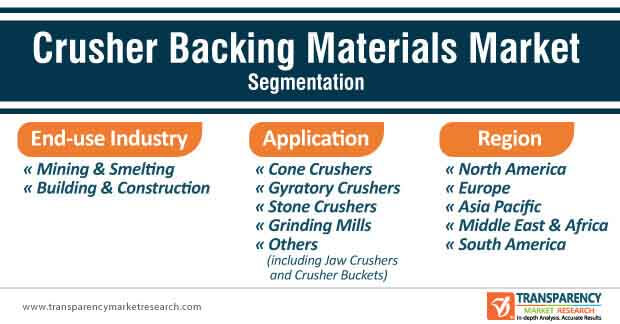

There is a growing demand for crusher backing materials for cone crushers and grinding mills operating under normal conditions. Manufacturers are innovating in 100% solids epoxy compounds for producing crusher backing materials that back wear plates in cone crushers. For instance, Henkel Adhesives-a specialist in adhesives, functional coatings, and sealants is gaining popularity for its LOCTITE® Nordbak Backing Material, which is made from 100% solids epoxy compounds, and offers high compressive strength and impact resistance in materials.

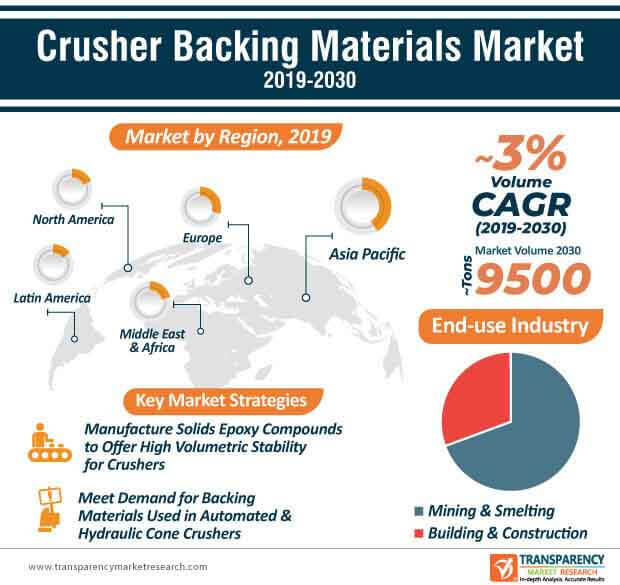

Advantageous attributes of crusher backing materials made from 100% solids epoxy compounds, such as high volumetric stability and non-flammable properties are being highly preferred by end users in the mining and smelting industries. This explains why the crusher backing materials market is projected to reach a value of US$ 33 Mn by the end of 2030. High volumetric stability of crusher backing materials made from solids epoxy compounds helps to eliminate gaps between liners.

The crusher backing materials market is slated to expand at a modest CAGR of ~4% during the assessment period. This is evident since certain companies are developing crushers and grinding mills that do not need crusher backing materials. This may affect revenue sales of crusher backing materials, thus lowering revenue collection. Thus, manufactures in the crusher backing materials market should leverage incremental opportunities in developing economies where there is high demand for these materials.

Engineering crushers and grinding mills that eliminate the need for crusher backing materials can be potentially cost-intensive. Since end users of the building and construction industry in developing economies are cash-strapped and have limited capital expenditure, they are more likely to opt for crushers and grinding mills that require crusher backing materials.

Epoxy crusher backing materials are gaining increased popularity in the crusher backing materials market. This can be attributed to the rise in sales and demand for epoxy products in the past few years. Hence, Copp Industries Inc. has strived to provide high-quality epoxy products, including epoxy crusher backing materials. Companies in the market for crusher backing materials are aiming to strengthen their supply chains in North America, Europe, and best-known countries in the Pacific Rim.

Manufacturers in the crusher backing materials market are focusing on standardized backing compounds to tap into revenue opportunities for supplies meant for gyratory and stone crushers. They are increasing the availability of materials made with enhanced compressive strength and can withstand various heat distortion temperatures. Companies are taking the extra mile by improving their secondary services such as R&D activities, testing, and prototyping.

Hi-tech crushers and powder grinding machinery are creating value-grab opportunities for companies in the crusher backing materials market. For instance, the Shanghai A&C Mining and Construction Machinery Co. Ltd., specializes in R&D for manufacturing state-of-the-art crushers and powder grinding machinery used in mining and construction industries. Lucrative opportunities for business expansion prevail in countries of Southeast Asia, Eastern Europe, and Latin America.

Companies are developing hydraulic cone crushers that significantly improve efficiency and production in mining and smelting industries. This is another key driver contributing toward the growth of the crusher backing materials market. Hydraulic crushing machinery with thin oil lubrication helps to improve the shelf life of crushers. This create a steady demand for crusher backing materials. Moreover, automation advancements in crusher machinery is creating a demand for crusher backing material products.

Manufacturers in the crusher backing materials market are experimenting with different crusher backing resins and crusher backing compounds to gain recognition in the mining industry. Various fleets of manganese cone crusher mantle liners are fueling the demand for crusher backing materials. Thus, companies in the crusher backing materials market are capitalizing on such opportunities to boost their production capacities. Cutting-edge series of jaw crushers, hydraulic gyratory crushers, and cone crushers are creating incremental opportunities for manufacturers.

Superfine grinding mills and vertical roller mills are being pervasively used in mining and smelting industries. High demand for primary crushers in India is another key driver for crusher backing material manufacturers. Primary applications in the mining industry such as crushing of mined ores and aggregate materials with the help of robust jaw crushers is surging worldwide.

Analysts’ Viewpoint

Maintaining air quality and special cleaning at production facilities is helping manufacturers to abide by the COVID-19 norms set by local and federal authorities. Apart from cone and stone crushers, manufacturers in the crusher backing materials market should make available products for jaw crushers and crusher buckets. However, advanced crushers that eliminate the need for crusher backing materials are potentially affecting the sales of these products. Hence, companies should focus on opportunities in developing economies, as end users opt for cost-efficient crushers and grinding mills that require crusher backing materials. They should increase production capabilities for epoxy products since these products are in high demand worldwide.

Crusher Backing Materials Market: Overview

Key Drivers of Crusher Backing Materials Market

Major Challenges for Crusher Backing Materials Market

Lucrative Opportunities for Crusher Backing Materials Market

Asia Pacific to Dominate Crusher Backing Materials Market

Cone Crushers to be Key Application of Crusher Backing Materials

Mining & Smelting End-use Industry Holds Major Share of Crusher Backing Materials Market

Key Players Operating in Crusher Backing Materials Market

Crusher Backing Materials Market is projected to reach US$ 33 Mn by the end of 2030

Crusher Backing Materials Market is expected to grow at a CAGR of 4% during 2020-2030

Rapid growth of the construction aggregates industry in developing countries expected to drive Crusher Backing Materials Market

Asia Pacific is a more attractive region for vendors in the Crusher Backing Materials Market

Key vendors in the Crusher Backing Materials Market are Henkel Corporation Engineering Adhesives, FLSmidth & Co. A/S, ITW Performance Polymers, ESCO Corporation

1. Executive Summary

1.1. Global Crusher Backing Materials Market Snapshot

1.2. Key Market Trends

1.3. Current Market & Future Potential

1.4. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Market Indicators

2.3. Market Definitions

2.4. Market Dynamics

2.4.1. Drivers

2.4.2. Restraints

2.4.3. Opportunities

2.5. Porter’s Five Forces Analysis

2.6. Value Chain Analysis

2.6.1. List of Potential Customers

2.7. Global Crusher Backing Materials Market Analysis and Forecast, 2019–2030

3. COVIS-19 Impact on Global Crusher Backing Materials Market

4. Crusher Backing Materials Production Outlook, by Region

5. Crusher Backing Materials Price Trend Analysis, 2019–2030

5.1. By Region

6. Global Crusher Backing Materials Market Analysis and Forecast, by Application, 2019–2030

6.1. Introduction & Definitions

6.2. Global Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

6.2.1. Cone Crushers

6.2.2. Gyratory Crushers

6.2.3. Stone Crushers

6.2.4. Grinding Mills

6.2.5. Others

6.3. Global Crusher Backing Materials Market Attractiveness, by Application

7. Global Crusher Backing Materials Market Analysis and Forecast, by End-use Industry, 2019–2030

7.1. Introduction & Definitions

7.2. Global Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

7.2.1. Mining & Smelting

7.2.2. Building & Construction

7.3. Global Crusher Backing Materials Market Attractiveness, by End-use Industry

8. Global Crusher Backing Materials Market Analysis and Forecast, by Region, 2019–2030

8.1. Key Findings

8.2. Global Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Region, 2019–2030

8.2.1. North America

8.2.2. Europe

8.2.3. Asia Pacific

8.2.4. Middle East & Africa

8.2.5. Latin America

8.3. Global Crusher Backing Materials Market Attractiveness, by Region

9. North America Crusher Backing Materials Market Analysis and Forecast, 2019–2030

9.1. Key Findings

9.2. North America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.3. North America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

9.3.1. U.S. Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.3.2. U.S. Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

9.3.3. Canada Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

9.3.4. Canada Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

9.4. North America Crusher Backing Materials Market Attractiveness Analysis

10. Europe Crusher Backing Materials Market Analysis and Forecast, 2019–2030

10.1. Key Findings

10.2. Europe Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3. Europe Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.3.1. Germany Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3.2. Germany Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.3.3. France Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3.4. France Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.3.5. U.K. Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3.6. U.K. Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.3.7. Italy Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3.8. Italy Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.3.9. Rest of Europe Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

10.3.10. Rest of Europe Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

10.4. Europe Crusher Backing Materials Market Attractiveness Analysis

11. Asia Pacific Crusher Backing Materials Market Analysis and Forecast, 2019–2030

11.1. Key Findings

11.2. Asia Pacific Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3. Asia Pacific Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.3.1. China Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3.2. China Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.3.3. India Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3.4. India Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.3.5. Japan Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3.6. Japan Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.3.7. ASEAN Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3.8. ASEAN Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.3.9. Rest of Asia Pacific Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

11.3.10. Rest of Asia Pacific Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

11.4. Asia Pacific Crusher Backing Materials Market Attractiveness Analysis

12. Latin America Crusher Backing Materials Market Analysis and Forecast, 2019–2030

12.1. Key Findings

12.2. Latin America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.3. Latin America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

12.3.1. Brazil Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.3.2. Brazil Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

12.3.3. Mexico Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.3.4. Mexico Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

12.3.5. Rest of Latin America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

12.3.6. Rest of Latin America Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

12.4. Latin America Crusher Backing Materials Market Attractiveness Analysis

13. Middle East & Africa Crusher Backing Materials Market Analysis and Forecast, 2019–2030

13.1. Key Findings

13.2. Middle East & Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

13.3. Middle East & Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

13.3.1. GCC Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

13.3.2. GCC Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

13.3.3. South Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

13.3.4. South Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

13.3.5. Rest of Middle East & Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by Application, 2019–2030

13.3.6. Rest of Middle East & Africa Crusher Backing Materials Market Volume (Tons) and Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

13.4. Middle East & Africa Crusher Backing Materials Market Attractiveness Analysis

14. Competition Landscape

14.1. Global Crusher Backing Materials Market Share Analysis, by Company (2019)

14.2. Competition Matrix

14.2.1. Product Mapping

14.3. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

14.3.1. Henkel Corporation Engineering Adhesives

14.3.1.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.1.2. Company Description

14.3.1.3. Business Overview

14.3.1.4. Financial Overview

14.3.1.5. Strategic Overview

14.3.2. FLSmidth & Co. A/S

14.3.2.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.2.2. Company Description

14.3.2.3. Business Overview

14.3.2.4. Financial Overview

14.3.2.5. Strategic Overview

14.3.3. ITW Performance Polymers

14.3.3.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.3.2. Company Description

14.3.3.3. Business Overview

14.3.3.4. Financial Overview

14.3.3.5. Strategic Overview

14.3.4. ESCO Corporation

14.3.4.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.4.2. Company Description

14.3.4.3. Business Overview

14.3.4.4. Financial Overview

14.3.4.5. Strategic Overview

14.3.5. Columbia Steel Casting Co., Inc.

14.3.5.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.5.2. Company Description

14.3.5.3. Business Overview

14.3.6. Copps Industries

14.3.6.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.6.2. Company Description

14.3.6.3. Business Overview

14.3.7. Monarch Industrial Product (I) Pvt Ltd.

14.3.7.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.7.2. Company Description

14.3.7.3. Business Overview

14.3.8. Micor Company, Inc.

14.3.8.1. Headquarters, Year of Establishment, Revenue, Key Management, Number of Employees

14.3.8.2. Company Description

14.3.8.3. Business Overview

14.3.8.4. Product Portfolio

14.3.9. HPZ Crusher Services Inc.

14.3.9.1. Headquarters, Year of Establishment, Key Management

14.3.9.2. Company Description

14.3.9.3. Business Overview

14.3.10. Unnathi Enterprises

14.3.10.1. Headquarters, Year of Establishment, Key Management

14.3.10.2. Company Description

14.3.10.3. Business Overview

14.3.11. FINSAD Group Oy

14.3.11.1. Headquarters, Year of Establishment, Key Management

14.3.11.2. Company Description

14.3.11.3. Business Overview

14.3.12. G & S Chemicals

14.3.12.1. Headquarters, Year of Establishment, Key Management

14.3.12.2. Company Description

14.3.12.3. Business Overview

14.3.13. Epoxa US

14.3.13.1. Headquarters, Year of Establishment, Key Management

14.3.13.2. Company Description

14.3.13.3. Business Overview

14.3.14. SkySpring Nanomaterials, Inc.

14.3.14.1. Headquarters, Year of Establishment, Key Management

14.3.14.2. Company Description

14.3.14.3. Business Overview

14.3.15. BSB DEVELOPMENT & INVESTMENT CO. LTD.

14.3.15.1. Headquarters, Year of Establishment, Key Management

14.3.15.2. Company Description

14.3.15.3. Business Overview

14.3.15.4. Strategic Overview

14.3.16. Ion Exchange Ltd.

14.3.16.1. Headquarters, Year of Establishment, Key Management

14.3.16.2. Company Description

14.3.16.3. Business Overview

15. Primary Research: Key Insights

16. Appendix

List of Tables

Table 1 Global Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 2 Global Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 3 Global Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 4 Global Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 5 Global Crusher Backing Materials Market Volume (Tons) Forecast, by Region, 2019–2030

Table 6 Global Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Region, 2019–2030

Table 7 North America Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 8 North America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 9 North America Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 10 North America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 11 North America Crusher Backing Materials Market Volume (Tons) Forecast, by Country, 2019–2030

Table 12 North America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Country, 2019–2030

Table 13 U.S. Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 14 U.S. Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 15 U.S. Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 16 U.S. Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 17 Canada Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 18 Canada Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 19 Canada Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 20 Canada Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 21 Europe Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 22 Europe Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 23 Europe Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 24 Europe Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 25 Europe Crusher Backing Materials Market Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 26 Europe Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 27 Germany Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 28 Germany Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 29 Germany Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 30 Germany Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 31 U.K. Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 32 U.K. Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 33 U.K. Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 34 U.K. Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 35 France Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 36 France Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 37 France Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 38 France Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 39 Italy Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 40 Italy Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 41 Italy Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 42 Italy Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 43 Spain Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 44 Spain Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 45 Spain Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 46 Spain Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 47 Russia & CIS Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 48 Russia & CIS Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 49 Russia & CIS Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 50 Russia & CIS Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 51 Rest of Europe Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 52 Rest of Europe Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 53 Rest of Europe Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 54 Rest of Europe Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 55 Asia Pacific Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 56 Asia Pacific Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 57 Asia Pacific Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 58 Asia Pacific Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 59 Asia Pacific Crusher Backing Materials Market Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 60 Asia Pacific Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 61 China Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 62 China Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 63 China Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 64 China Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 65 Japan Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 66 Japan Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 67 Japan Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 68 Japan Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 69 India Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 70 India Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 71 India Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 72 India Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 73 ASEAN Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 74 ASEAN Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 75 ASEAN Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 76 ASEAN Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 77 Rest of Asia Pacific Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 78 Rest of Asia Pacific Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 79 Rest of Asia Pacific Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 80 Rest of Asia Pacific Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 81 Latin America Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 82 Latin America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 83 Latin America Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 84 Latin America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 85 Latin America Crusher Backing Materials Market Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 86 Latin America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 87 Brazil Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 88 Brazil Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 89 Brazil Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 90 Brazil Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 91 Mexico Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 92 Mexico Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 93 Mexico Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 94 Mexico Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 95 Rest of Latin America Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 96 Rest of Latin America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 97 Rest of Latin America Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 98 Rest of Latin America Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 99 Middle East & Africa Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 100 Middle East & Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 101 Middle East & Africa Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 102 Middle East & Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 103 Middle East & Africa Crusher Backing Materials Market Volume (Tons) Forecast, by Country and Sub-region, 2019–2030

Table 104 Middle East & Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Country and Sub-region, 2019–2030

Table 105 GCC Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 106 GCC Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 107 GCC Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 108 GCC Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 109 South Africa Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 110 South Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 111 South Africa Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 112 South Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

Table 113 Rest of Middle East & Africa Crusher Backing Materials Market Volume (Tons) Forecast, by Application, 2019–2030

Table 114 Rest of Middle East & Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by Application, 2019–2030

Table 115 Rest of Middle East & Africa Crusher Backing Materials Market Volume (Tons) Forecast, by End-use Industry, 2019–2030

Table 116 Rest of Middle East & Africa Crusher Backing Materials Market Value (US$ Thousand) Forecast, by End-use Industry, 2019–2030

List of Figures

Figure 1 Global Crusher Backing Materials Price Trend, by Region, 2019–2030 (US$/Ton)

Figure 2 Global Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 3 Global Crusher Backing Materials Market Attractiveness, by Application

Figure 4 Global Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 5 Global Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 6 Global Crusher Backing Materials Market Volume Share, by Region, 2019, 2025, and 2030

Figure 7 Global Crusher Backing Materials Market Attractiveness, by Region

Figure 8 North America Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 9 North America Crusher Backing Materials Market Attractiveness, by Application

Figure 10 North America Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 11 North America Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 12 North America Crusher Backing Materials Market Volume Share, by Country, 2019, 2025, and 2030

Figure 13 North America Crusher Backing Materials Market Attractiveness, by Country

Figure 14 Europe Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 15 Europe Crusher Backing Materials Market Attractiveness, by Application

Figure 16 Europe Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 17 Europe Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 18 Europe Crusher Backing Materials Market Volume Share, by Country and Sub-region, 2019, 2025, and 2030

Figure 19 Europe Crusher Backing Materials Market Attractiveness, by Country and Sub-region

Figure 20 Asia Pacific Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 21 Asia Pacific Crusher Backing Materials Market Attractiveness, by Application

Figure 22 Asia Pacific Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 23 Asia Pacific Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 24 Asia Pacific Crusher Backing Materials Market Volume Share, by Country and Sub-region, 2019, 2025, and 2030

Figure 25 Asia Pacific Crusher Backing Materials Market Attractiveness, by Country and Sub-region

Figure 26 Latin America Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 27 Latin America Crusher Backing Materials Market Attractiveness, by Application

Figure 28 Latin America Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 29 Latin America Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 30 Latin America Crusher Backing Materials Market Volume Share, by Country and Sub-region, 2019, 2025, and 2030

Figure 31 Latin America Crusher Backing Materials Market Attractiveness, by Country and Sub-region

Figure 32 Middle East & Africa Crusher Backing Materials Market Volume Share, by Application, 2019, 2025, and 2030

Figure 33 Middle East & Africa Crusher Backing Materials Market Attractiveness, by Application

Figure 34 Middle East & Africa Crusher Backing Materials Market Volume Share, by End-use Industry, 2019, 2025, and 2030

Figure 35 Middle East & Africa Crusher Backing Materials Market Attractiveness, by End-use Industry

Figure 36 Middle East & Africa Crusher Backing Materials Market Volume Share, by Country and Sub-region, 2019, 2025, and 2030

Figure 37 Middle East & Africa Crusher Backing Materials Market Attractiveness, by Country and Sub-region

Figure 38 Global Crusher Backing Materials Market Share Analysis, by Company, 2019