Reports

Reports

Analyst Viewpoint

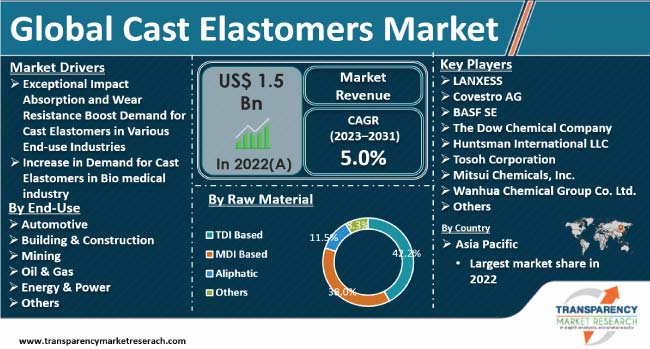

Cast elastomers offer exceptional wear resistance, impact absorption, and chemical compatibility, which makes them an important component in various industries, ranging from manufacturing to oil & gas. This is estimated to propel the cast elastomers market growth in the next few years.

The capacity of cast elastomers to tolerate high mechanical stress and retain performance in harsh environments is likely to offer lucrative cast elastomers market opportunities for manufacturers and stakeholders. Moreover, the desirable properties of cast elastomers are redefining how we approach innovation, dependability, and versatility across a wide range of applications.

Cast elastomers, noted for their outstanding resilience and versatility, are emerging as a critical component in modern material science, providing a formidable mix of durability, flexibility, and chemical resistance.

Cast elastomers possess an exceptional capacity to withstand extreme weather conditions, tolerate substantial mechanical stress, and provide long-lasting performance. Their outstanding features, including high wear resistance, impact absorption, and chemical compatibility, have firmly established cast elastomers as critical components in sectors where dependability and durability are critical.

These elastomers are designed to be precisely tailored to specific applications, such as conveyor belts and automotive components, as well as oilfield seals and hydraulic seals. Cast elastomers play an important role in improving the efficiency, safety, and resilience of innumerable products and applications.

These adaptable and extremely robust materials are gaining traction because of their unique capacity to suit the specialized requirements of a wide range of sectors, which in turn has been driving the cast elastomers market value for the last few years.

Cast elastomers are playing a crucial role in applications that require durability and endurance. In particular, they have been widely used in the automotive components such as suspension systems, tires, and gaskets, where their ability to withstand mechanical stress, abrasion, and severe temperatures is important. Cast elastomers have been a popular choice among manufacturers, as they strive to build more durable and long-lasting automobiles.

The oil & gas industry is witnessing a rising demand for cast elastomers for critical applications such as seals, gaskets, and pipelines in harsh environments. The energy sector values their resistance to chemicals, hydrocarbons, and high pressures, which safeguards equipment integrity and operational safety. Increased emphasis on infrastructure development, building, and mining operations further boosts the cast elastomers market demand.

Cast elastomers have become indispensable in industries such as automotive, manufacturing, oil and gas, mining, and construction due to their superior qualities. Expansion of these sectors and growing emphasis on durability and performance are anticipated to propel the cast elastomers market development in the next few years.

Outstanding properties of cast elastomers, such as biocompatibility, chemical resistance, and durability, make them ideal for medical applications. They are utilized in a variety of medical equipment components, such as gaskets, seals, diaphragms, and tubing, where high performance is required. Increase in adoption of these materials in the biomedical industry is one of the key factors driving the cast elastomers industry growth.

Cast elastomers can resist the effects of biological fluids and strong chemicals, survive sterilizing processes, and preserve their integrity over long periods. This is especially crucial when it comes to assuring the dependability and safety of medical equipment, particularly those used in vital operations and treatments.

Demand for cast elastomers is considerably high in prosthetics and orthopedic devices. These materials are used to make shock-absorbing insoles, padding for prosthetic limbs, and long-lasting orthopedic braces. Cast elastomers provide the required comfort, flexibility, and impact resistance in various medical devices.

The reliance on cast elastomers in the biomedical industry extends to the manufacture of pharmaceuticals as well. These elastomers are utilized in the manufacture of pharmaceutical processing equipment seals, gaskets, and diaphragms. Their biocompatibility guarantees that they do not contaminate delicate pharmaceutical items, thereby enabling compliance with demanding quality and safety requirements.

In terms of value, Asia Pacific accounted for a notable share of the global elastomers market in 2022 due to growing demand for lightweight components in various industries such as steel and automotive, with large contributions from China, India, and Japan. The cast elastomer market forecast for Asia Pacific is highly positive, owing to the continuous need for these flexible materials in various sectors. Moreover, expansion of the construction, automotive, and mining sectors in Asia Pacific is projected to fuel the cast elastomers market value during the forecast period.

Europe was a mature market for cast elastomers in 2022. Growing emphasis of the automotive industry on the development of lightweight components, which is aligning with industry trends, is expected to boost the cast elastomers industry share held by the region.

Leading companies in the highly competitive cast elastomers industry are adopting various strategies to maintain and expand their market presence. The firms listed are key players in this industry. According to the most recent Cast Elastomers Market research, the landscape is healthy and these dynamics present significant opportunities for cast elastomers business growth.

LANXESS, Covestro AG, BASF SE, The Dow Chemical Company, Huntsman International LLC, Tosoh Corporation, Mitsui Chemicals, Inc., Wanhua Chemical Group Co. Ltd., Notedome Limited, Argonics, Inc., Coim Group, Era Polymers Pty Ltd are a few prominent players operating in the global market.

Key players in the cast elastomers market report, have been profiled based on various parameters such as company overview, financial state, business strategies, product portfolio, business sectors, and recent developments.

| Attribute | Detail |

|---|---|

| Size in 2022 | US$ 1.5 Bn |

| Forecast (Value) in 2031 | US$ 2.2 Bn |

| Growth Rate (CAGR) | 5.0% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2020-2022 |

| Quantitative Tons | US$ Bn for Value and Kilo Tons for Volume |

| Market Analysis | It includes segment analysis as well as regional level analysis. Furthermore, the qualitative analysis includes drivers, restraints, opportunities, key trends, Porter’s Five Forces Analysis, value chain analysis, and key trend analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Market Segmentation |

|

| Regions Covered |

|

| Countries Covered |

|

| Companies Profiled |

|

| Customization Scope | Available upon request |

| Pricing | Available upon request |

The global market was valued at US$ 1.5 Bn in 2022

It is expected to expand at a CAGR of 5.0% from 2023 to 2031

Exceptional impact absorption and wear resistance boost demand for cast elastomers in various end-use industries and increase in demand for cast elastomers in biomedical industry

In terms of raw material, the TDI based segment held largest share in 2022

Asia Pacific was the most lucrative region in 2022

LANXESS, Covestro AG, BASF SE, The Dow Chemical Company, Huntsman International LLC, Tosoh Corporation, Mitsui Chemicals, Inc., Wanhua Chemical Group Co. Ltd., Notedome Limited, Argonics, Inc., Coim Group, Era Polymers Pty Ltd

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Cast Elastomers Market Analysis and Forecast, 2023-2031

2.6.1. Cast Elastomers Market Volume (Kilo Tons)

2.6.2. Cast Elastomers Market Value (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Component Providers

2.9.2. List of Manufacturers

2.9.3. List of Dealer/Distributors

2.9.4. List of Potential Customers

2.10. Product Specification Analysis

2.11. Production Overview

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on the Supply Chain of the Cast Elastomers

3.2. Impact on the Demand of Cast Elastomers Market – Pre & Post Crisis

4. Impact of Current Geopolitical Scenario on Market

5. Production Output Analysis (Kilo Tons)

5.1. North America

5.2. Europe

5.3. Asia Pacific

5.4. Latin America

5.5. Middle East & Africa

6. Price Trend Analysis and Forecast (US$/Kilo Tons), 2023-2031

6.1. Price Comparison Analysis by Region

7. Cast Elastomers Market Analysis and Forecast, by Type, 2023-2031

7.1. Introduction and Definitions

7.2. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

7.2.1. Hot

7.2.2. Cold

7.3. Cast Elastomers Market Attractiveness, by Type

8. Cast Elastomers Market Analysis and Forecast, by Raw Material, 2023-2031

8.1. Introduction and Definitions

8.2. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

8.2.1. TDI Based

8.2.2. MDI Based

8.2.3. Aliphatic

8.2.4. Others

8.3. Cast Elastomers Market Attractiveness, by Raw Material

9. Cast Elastomers Market Analysis and Forecast, by End-use, 2023-2031

9.1. Introduction and Definitions

9.2. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

9.2.1. Automotive

9.2.2. Building & Construction

9.2.3. Industrial Process & Material Handling

9.2.4. Mining

9.2.5. Oil & Gas

9.2.6. Energy & Power

9.2.7. Others

9.3. Cast Elastomers Market Attractiveness, by End-use

10. Cast Elastomers Market Analysis and Forecast, by Region, 2023-2031

10.1. Key Findings

10.2. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Region, 2023-2031

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Cast Elastomers Market Attractiveness, by Region

11. North America Cast Elastomers Market Analysis and Forecast, 2023-2031

11.1. Key Findings

11.2. North America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.3. North America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

11.4. North America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

11.5. North America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country, 2023-2031

11.5.1. U.S. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.5.2. U.S. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

11.5.3. U.S. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use, 2023-2031

11.5.4. Canada Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

11.5.5. Canada Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

11.5.6. Canada Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use, 2023-2031

11.6. North America Cast Elastomers Market Attractiveness Analysis

12. Europe Cast Elastomers Market Analysis and Forecast, 2023-2031

12.1. Key Findings

12.2. Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.3. Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.4. Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.5. Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

12.5.1. Germany Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Material, 2023-2031

12.5.2. Germany Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.3. Germany. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use, 2023-2031

12.5.4. France Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.5.5. France Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.6. France. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, By End-use, 2023-2031

12.5.7. U.K. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.5.8. U.K. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.9. U.K. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.5.10. Italy Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.5.11. Italy. Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.12. Italy Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.5.13. Russia & CIS Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.5.14. Russia & CIS Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.15. Russia & CIS Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.5.16. Rest of Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

12.5.17. Rest of Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

12.5.18. Rest of Europe Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

12.6. Europe Cast Elastomers Market Attractiveness Analysis

13. Asia Pacific Cast Elastomers Market Analysis and Forecast, 2023-2031

13.1. Key Findings

13.2. Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type

13.3. Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.4. Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.5. Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

13.5.1. China Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.5.2. China Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.5.3. China Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.5.4. Japan Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.5.5. Japan Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.5.6. Japan Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.5.7. India Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.5.8. India Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.5.9. India Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.5.10. ASEAN Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.5.11. ASEAN Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.5.12. ASEAN Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.5.13. Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

13.5.14. Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

13.5.15. Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

13.6. Asia Pacific Cast Elastomers Market Attractiveness Analysis

14. Latin America Cast Elastomers Market Analysis and Forecast, 2023-2031

14.1. Key Findings

14.2. Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type Coat Type, 2023-2031

14.3. Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

14.4. Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

14.5. Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

14.5.1. Brazil Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.5.2. Brazil Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

14.5.3. Brazil Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

14.5.4. Mexico Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.5.5. Mexico Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

14.5.6. Mexico Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

14.5.7. Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

14.5.8. Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

14.5.9. Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

14.6. Latin America Cast Elastomers Market Attractiveness Analysis

15. Middle East & Africa Cast Elastomers Market Analysis and Forecast, 2023-2031

15.1. Key Findings

15.2. Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.3. Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

15.4. Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

15.5. Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2023-2031

15.5.1. GCC Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.5.2. GCC Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

15.5.3. GCC Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

15.5.4. South Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.5.5. South Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

15.5.6. South Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use,2023-2031

15.5.7. Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Type, 2023-2031

15.5.8. Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by Raw Material, 2023-2031

15.5.9. Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) and Value (US$ Mn) Forecast, by End-use, 2023-2031

15.6. Middle East & Africa Cast Elastomers Market Attractiveness Analysis

16. Competition Landscape

16.1. Market Players - Competition Matrix (by Tier and Size of Companies)

16.2. Market Share Analysis, 2021

16.3. Market Footprint Analysis

16.3.1. By Type

16.3.2. By Raw Material

16.4. Company Profiles

16.4.1. LANXESS

16.4.1.1. Company Revenue

16.4.1.2. Business Overview

16.4.1.3. Product Segments

16.4.1.4. Geographic Footprint

16.4.1.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.1.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.2. Covestro AG

16.4.2.1. Company Revenue

16.4.2.2. Business Overview

16.4.2.3. Product Segments

16.4.2.4. Geographic Footprint

16.4.2.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.2.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.3. BASF SE

16.4.3.1. Company Revenue

16.4.3.2. Business Overview

16.4.3.3. Product Segments

16.4.3.4. Geographic Footprint

16.4.3.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.3.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.4. The Dow Chemical Company

16.4.4.1. Company Revenue

16.4.4.2. Business Overview

16.4.4.3. Product Segments

16.4.4.4. Geographic Footprint

16.4.4.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.4.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.5. Huntsman International LLC

16.4.5.1. Company Revenue

16.4.5.2. Business Overview

16.4.5.3. Product Segments

16.4.5.4. Geographic Footprint

16.4.5.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.5.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.6. AKSA Power Generation

16.4.6.1. Company Revenue

16.4.6.2. Business Overview

16.4.6.3. Product Segments

16.4.6.4. Geographic Footprint

16.4.6.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.6.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.7. Tosoh Corporation

16.4.7.1. Company Revenue

16.4.7.2. Business Overview

16.4.7.3. Product Segments

16.4.7.4. Geographic Footprint

16.4.7.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.7.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.8. Mitsui Chemicals, Inc.

16.4.8.1. Company Revenue

16.4.8.2. Business Overview

16.4.8.3. Product Segments

16.4.8.4. Geographic Footprint

16.4.8.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.8.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.9. Wanhua Chemical Group Co. Ltd.

16.4.9.1. Company Revenue

16.4.9.2. Business Overview

16.4.9.3. Product Segments

16.4.9.4. Geographic Footprint

16.4.9.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.9.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.10. Notedome Limited

16.4.10.1. Company Revenue

16.4.10.2. Business Overview

16.4.10.3. Product Segments

16.4.10.4. Geographic Footprint

16.4.10.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.10.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.11. Argonics, Inc.

16.4.11.1. Company Revenue

16.4.11.2. Business Overview

16.4.11.3. Product Segments

16.4.11.4. Geographic Footprint

16.4.11.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.11.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.12. Coim Group

16.4.12.1. Company Revenue

16.4.12.2. Business Overview

16.4.12.3. Product Segments

16.4.12.4. Geographic Footprint

16.4.12.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.12.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

16.4.13. Era Polymers Pty Ltd

16.4.13.1. Company Revenue

16.4.13.2. Business Overview

16.4.13.3. Product Segments

16.4.13.4. Geographic Footprint

16.4.13.5. Production Type/Plant Details, etc. (*As Applicable)

16.4.13.6. Strategic Partnership, Type Expansion, New Product Innovation etc.

17. Primary Research: Key Insights

18. Appendix

List of Tables

Table 1: Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 2: Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 3: Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 4: Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 5: Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 6: Cast Elastomers Market Value (US$ Mn) Forecast, by End-use, 2023–2031

Table 7: Cast Elastomers Market Volume (Kilo Tons) Forecast, by Region, 2023–2031

Table 8: Cast Elastomers Market Value (US$ Mn) Forecast, by Region, 2023–2031

Table 9: North America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 10: North America Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 11: North America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 12: North America Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 13: North America Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 14: North America Cast Elastomers Market Value (US$ Mn) Forecast, by End-use, 2023–2031

Table 15: North America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Country, 2023–2031

Table 16: North America Cast Elastomers Market Value (US$ Mn) Forecast, by Country, 2023–2031

Table 17: U.S. Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 18: U.S. Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 19: U.S. Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 20: U.S. Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 21: U.S. Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 22: U.S. Cast Elastomers Market Value (US$ Mn) Forecast, by End-use, 2023–2031

Table 23: Canada Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 24: Canada Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 25: Canada Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 26: Canada Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 27: Canada Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 28: Canada Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 29: Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 30: Europe Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 31: Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 32: Europe Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 33: Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 34: Europe Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 35: Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023–2031

Table 36: Europe Cast Elastomers Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 37: Germany Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 38: Germany Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 39: Germany Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 40: Germany Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 41: Germany Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 42: Germany Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 43: France Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 44: France Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 45: France Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 46: France Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 47: France Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 48: France Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 49: U.K. Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 50: U.K. Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 51: U.K. Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 52: U.K. Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 53: U.K. Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 54: U.K. Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 55: Italy Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 56: Italy Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 57: Italy Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 58: Italy Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 59: Italy Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 60: Italy Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 61: Spain Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 62: Spain Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 63: Spain Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 64: Spain Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 65: Spain Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 66: Spain Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 67: Russia & CIS Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 68: Russia & CIS Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 69: Russia & CIS Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 70: Russia & CIS Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 71: Russia & CIS Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 72: Russia & CIS Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 73: Rest of Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 74: Rest of Europe Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 75: Rest of Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 76: Rest of Europe Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 77: Rest of Europe Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 78: Rest of Europe Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 79: Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 80: Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 81: Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 82: Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 83: Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 84: Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 85: Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023–2031

Table 86: Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 87: China Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 88: China Cast Elastomers Market Value (US$ Mn) Forecast, by Type 2023–2031

Table 89: China Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 90: China Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 91: China Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 92: China Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 93: Japan Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 94: Japan Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 95: Japan Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 96: Japan Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 97: Japan Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 98: Japan Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 99: India Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 100: India Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 101: India Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 102: India Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 103: India Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 104: India Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 105: ASEAN Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 106: ASEAN Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 107: ASEAN Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 108: ASEAN Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 109: ASEAN Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 110: ASEAN Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 111: Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 112: Rest of Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 113: Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 114: Rest of Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 115: Rest of Asia Pacific Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 116: Rest of Asia Pacific Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 117: Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 118: Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 119: Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 120: Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 121: Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 122: Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 123: Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023–2031

Table 124: Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 125: Brazil Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 126: Brazil Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 127: Brazil Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 128: Brazil Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 129: Mexico Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 130: Mexico Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 131: Mexico Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 132: Mexico Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 133: Mexico Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 134: Mexico Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 135: Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 136: Rest of Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 137: Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 138: Rest of Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 139: Rest of Latin America Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 140: Rest of Latin America Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 141: Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 142: Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 143: Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 144: Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 145: Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 146: Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 147: Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Country and Sub-region, 2023–2031

Table 148: Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 149: GCC Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 150: GCC Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 151: GCC Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 152: GCC Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 153: GCC Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 154: GCC Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 155: South Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 156: South Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 157: South Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 158: South Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 159: South Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 160: South Africa Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

Table 161: Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Type, 2023–2031

Table 162: Rest of Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Type, 2023–2031

Table 163: Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by Raw Material, 2023–2031

Table 164: Rest of Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by Raw Material, 2023–2031

Table 165: Rest of Middle East & Africa Cast Elastomers Market Volume (Kilo Tons) Forecast, by End-use, 2023–2031

Table 166: Rest of Middle East & Africa Cast Elastomers Market Value (US$ Mn) Forecast, by End-use 2023–2031

List of Figures

Figure 1: Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 2: Cast Elastomers Market Attractiveness, by Type

Figure 3: Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 4: Cast Elastomers Market Attractiveness, by Raw Material

Figure 5: Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 6: Cast Elastomers Market Attractiveness, by End-use

Figure 7: Cast Elastomers Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 8: Cast Elastomers Market Attractiveness, by Region

Figure 9: North America Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 10: North America Cast Elastomers Market Attractiveness, by Type

Figure 11: North America Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 12: North America Cast Elastomers Market Attractiveness, by Raw Material

Figure 13: North America Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 14: North America Cast Elastomers Market Attractiveness, by End-use

Figure 15: North America Cast Elastomers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 16: North America Cast Elastomers Market Attractiveness, by Country and Sub-region

Figure 17: Europe Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 18: Europe Cast Elastomers Market Attractiveness, by Type

Figure 19: Europe Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 20: Europe Cast Elastomers Market Attractiveness, by Raw Material

Figure 21: Europe Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 22: Europe Cast Elastomers Market Attractiveness, by End-use

Figure 23: Europe Cast Elastomers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Europe Cast Elastomers Market Attractiveness, by Country and Sub-region

Figure 25: Asia Pacific Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 26: Asia Pacific Cast Elastomers Market Attractiveness, by Type

Figure 27: Asia Pacific Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 28: Asia Pacific Cast Elastomers Market Attractiveness, by Raw Material

Figure 29: Asia Pacific Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 30: Asia Pacific Cast Elastomers Market Attractiveness, by End-use

Figure 31: Asia Pacific Cast Elastomers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 32: Asia Pacific Cast Elastomers Market Attractiveness, by Country and Sub-region

Figure 33: Latin America Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 34: Latin America Cast Elastomers Market Attractiveness, by Type

Figure 35: Latin America Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 36: Latin America Cast Elastomers Market Attractiveness, by Raw Material

Figure 37: Latin America Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 38: Latin America Cast Elastomers Market Attractiveness, by End-use

Figure 39: Latin America Cast Elastomers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 40: Latin America Cast Elastomers Market Attractiveness, by Country and Sub-region

Figure 41: Middle East & Africa Cast Elastomers Market Volume Share Analysis, by Type, 2022, 2027, and 2031

Figure 42: Middle East & Africa Cast Elastomers Market Attractiveness, by Type

Figure 43: Middle East & Africa Cast Elastomers Market Volume Share Analysis, by Raw Material, 2022, 2027, and 2031

Figure 44: Middle East & Africa Cast Elastomers Market Attractiveness, by Raw Material

Figure 45: Middle East & Africa Cast Elastomers Market Volume Share Analysis, by End-use, 2022, 2027, and 2031

Figure 46: Middle East & Africa Cast Elastomers Market Attractiveness, by End-use

Figure 47: Middle East & Africa Cast Elastomers Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 48: Middle East & Africa Cast Elastomers Market Attractiveness, by Country and Sub-region