Reports

Reports

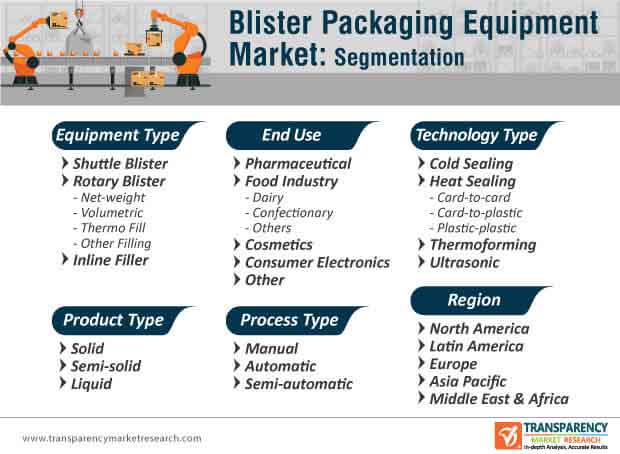

Pharmaceutical companies and their contract packagers are setting their collaboration wheels in motion by driving advancements in blister packaging equipment market. This is being achieved with faster changeover and compatibility with multiple blister formats. Currently, pharmaceutical end use segment dictates the highest revenue in the blister packaging equipment market. New trends such as prototype tooling for preliminary blister-card assessment of design and child-resistance are contributing to the growth of the market. As such, prototyping of blister cards facilitates design optimization, prior to making large investments in production tooling.

Manufacturers in the blister packaging equipment market are increasing their production capabilities to develop dedicated feeders for different products. Modern blister packaging equipment offer precise control over production parameters, especially PLC (Programmable Logic Controllers)-driven parameters associated with the human machine interface (HMI) for easier setup and adjustment. Manufacturers are focusing on smaller footprint and faster changeover for use in demanding applications in the pharmaceutical industry.

Apart from the pharmaceutical industry, manufacturers are increasing their production capacities to develop automatic blister packaging equipment for the cosmetic industry. This is evident since the automatic process type segment is expected to generate the highest revenue in the blister packaging equipment market. Meanwhile, automated blister packaging is a popular choice among pharmaceutical brand owners, owing to its attractive finish for consumer doses. Various benefits such as complete seal against contamination and effective protection of end products are helping to boost the credibility of equipment manufacturers worldwide.

Companies in the blister packaging equipment market are developing machines that support medium-volume production lines. For instance, Vekamaf— a provider of production technology solutions, has collaborated with FarmarTec, a provider of blistering and thermoforming solutions, to increase the availability of their medium-volume TF220 blister packaging machines for medium-volume production lines. Moreover, companies in the market for blister packaging equipment are designing equipment, which are compact and can be integrated in existing production lines.

After pharmaceutical applications, manufacturers in the blister packaging equipment market are eyeing opportunities in the food industry to establish strong business grounds. Blister products such as food blister tray (box), fruit packaging box (support), and the likes are generating value-grab opportunities for manufacturers. However, high price of environment-friendly materials pose as a challenge for companies and stakeholders in the food industry. Hence, companies in the blister packaging equipment market are targeting stakeholders dealing with high-grade plastic products to maintain continuous revenue streams from stakeholders in food and cosmetic industries.

Stakeholders in the market for blister packaging equipment are innovating through a variety of materials such as PVC (Poly Vinyl Chloride), since the novel material is easy to heat and can be easily sealed by sealing machines for the production of transparent plastic products. High transparency and good surface gloss of PVC sheets is grabbing the attention of stakeholders in the consumer electronics sector. PS (Polystyrene) is a novel introduction in the list of environment-friendly packaging materials in the market for blister packaging equipment, owing to the growing awareness about ecological footprint of plastic.

The blister packaging equipment market is set to trend positively in Europe and the U.S. over the next decade. This explains why engineers in the U.K. are innovating in thermoforming solutions. For instance, Shawpak-a revolutionary machine developed by the engineers of Riverside Medical Packaging, U.K., is gaining prominence in the medical industry, owing to the growing demand for blister packaging. The demand for blister packs is being met by the U.K. contract manufacturers, while multi-nationals are outsourcing blister packaging equipment.

Rising demand for serialization and FMD (Falsified Medicines Directive) solutions is surfacing in the blister packaging equipment market. This trend has helped to multiply the output in medical industries due to which, pharmaceutical brand owners are increasingly investing in fully-automated blister packaging lines.

Analysts’ Viewpoint

Pharmaceutical brand owners are preferring blister packaging for the protection against moisture and oxygen. On the other hand, 3D printed prototyping solutions for blister cavities are growing popular, owing to their cost efficiency. Stakeholders in the blister packaging equipment market are developing solutions with coding and die-cutting production.

Blister bulbs in Europe and the U.S. are creating a demand for PET (Polyethylene terephthalate) materials. However, their high thermal melting point poses great difficulties in high-frequency packaging. Hence, manufacturers should make use of PETG (Polyethylene terephthalate glycol-modified) materials to overcome issues associated with PET materials. On the other hand, medical companies are aiming to boost their serialization capabilities to gain global recognition.

are some of the key players of global blister packaging equipment market. Among these players, I.M.A. Industria Macchine Automatiche S.p.A., Korber AG, and Sonoco Products Company hold maximum market share of the global blister packaging equipment market. Tough rivalry among key players is witnessed in the blister packaging equipment market, attributable to the presence of small- and medium-sized manufacturers.

1. Executive Summary

2. Blister Packaging Equipment Market Introduction

2.1. Blister Packaging Equipment Market Definition

2.2. Blister Packaging Equipment Market Taxonomy

3. Blister Packaging Equipment Market Overview

3.1. Introduction

3.1.1. Macroeconomic Indicators

3.1.2. Regional Packaging Machinery Market

3.1.3. Global Packaging Machinery Market Share

3.1.4. Case Studies

3.2. Blister Packaging Equipment Installed Base, By Region

3.2.1. Total Installed Base in North America

3.2.2. Total Installed Base in Latin America

3.2.3. Total Installed Base in Europe

3.2.4. Total Installed Base in Asia Pacific

3.2.5. Total Installed Base in MEA

3.3. Blister Packaging Equipment Market Value Chain Analysis

3.3.1. Profitability Margins

3.3.2. List of Active Participants

3.3.2.1. Part Suppliers

3.3.2.2. Integrators

3.3.2.3. Equipment Manufacturers

3.4. Global Blister Packaging Equipment Market Dynamics

3.4.1. Drivers

3.4.2. Restraints

3.4.3. Trends

3.4.4. Opportunities

4. Global Blister Packaging Equipment Market Analysis and Forecast, By Product Type

4.1. Introduction

4.1.1. Market Share and BPS Analysis By Product Type

4.1.2. Y-o-Y Growth Projections By Product Type

4.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

4.2.1. Solid Packaging Equipment

4.2.2. Semi-solid Packaging Equipment

4.2.3. Liquid Packaging Equipment

4.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

4.3.1. Solid Packaging Equipment

4.3.2. Semi-solid Packaging Equipment

4.3.3. Liquid Packaging Equipment

4.4. Market Attractiveness Analysis By Product Type

5. Global Blister Packaging Equipment Market Analysis and Forecast, By Process Type

5.1. Introduction

5.1.1. Market Share and BPS Analysis By Process Type

5.1.2. Y-o-Y Growth Projections By Process Type

5.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

5.2.1. Manual

5.2.2. Automatic

5.2.3. Semi-automatic

5.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

5.3.1. Manual

5.3.2. Automatic

5.3.3. Semi-automatic

5.4. Market Attractiveness Analysis By Process Type

6. Global Blister Packaging Equipment Market Analysis and Forecast, By Equipment Type

6.1. Introduction

6.1.1. Market Share and BPS Analysis By Equipment Type

6.1.2. Y-o-Y Growth Projections By Equipment Type

6.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

6.2.1. Shuttle Blister System

6.2.2. Rotary Blister System

6.2.2.1. Net-weight Fillers

6.2.2.2. Volumetric Fillers

6.2.2.3. Thermo fill-seal System

6.2.2.4. Other Filling Equipment

6.2.3. Inline Filler System

6.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

6.3.1. Shuttle Blister System

6.3.2. Rotary Blister System

6.3.2.1. Net-weight Fillers

6.3.2.2. Volumetric Fillers

6.3.2.3. Thermo fill-seal System

6.3.2.4. Other Filling Equipment

6.3.3. Inline Filler System

6.4. Market Attractiveness Analysis By Equipment Type

7. Global Blister Packaging Equipment Market Analysis and Forecast, By Technology Type

7.1. Introduction

7.1.1. Market Share and BPS Analysis By Technology Type

7.1.2. Y-o-Y Growth Projections By Technology Type

7.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

7.2.1. Cold Sealing

7.2.2. Heat Sealing

7.2.2.1. Card-to-card

7.2.2.2. Card-to-plastic

7.2.2.3. Plastic-to-plastic

7.2.3. Thermoforming

7.2.4. Ultrasonic Sealing

7.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

7.3.1. Cold Sealing

7.3.2. Heat Sealing

7.3.2.1. Card-to-card

7.3.2.2. Card-to-plastic

7.3.2.3. Plastic-to-plastic

7.3.3. Thermoforming

7.3.4. Ultrasonic Sealing

7.4. Market Attractiveness Analysis By Technology Type

8. Global Blister Packaging Equipment Market Analysis and Forecast, By End Use Type

8.1. Introduction

8.1.1. Market Share and BPS Analysis By End Use Type

8.1.2. Y-o-Y Growth Projections By End Use Type

8.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

8.2.1. Pharmaceutical Industry

8.2.2. Food Industry

8.2.2.1. Dairy

8.2.2.2. Confectionary

8.2.2.3. Others

8.2.3. Cosmetics & Personal Care

8.2.4. Consumer Electronics

8.2.5. Other Manufacturing

8.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

8.3.1. Pharmaceutical Industry

8.3.2. Food Industry

8.3.2.1. Dairy

8.3.2.2. Confectionary

8.3.2.3. Others

8.3.3. Cosmetics & Personal Care

8.3.4. Consumer Electronics

8.3.5. Other Manufacturing

8.4. Market Attractiveness Analysis By End Use Type

9. Global Blister Packaging Equipment Market Analysis and Forecast, By Region

9.1. Introduction

9.1.1. Market Share and BPS Analysis By Region

9.1.2. Y-o-Y Growth Projections By Region

9.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Region

9.2.1. North America

9.2.2. Latin America

9.2.3. Europe

9.2.4. Asia Pacific

9.2.5. Middle East and Africa (MEA)

9.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Region

9.3.1. North America

9.3.2. Latin America

9.3.3. Europe

9.3.4. Asia Pacific

9.3.5. Middle East and Africa (MEA)

9.4. Market Attractiveness Analysis By Region

10. North America Blister Packaging Equipment Market Analysis and Forecast

10.1. Introduction

10.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Country

10.2.1. U.S.

10.2.2. Canada

10.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Country

10.3.1. U.S.

10.3.2. Canada

10.4. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

10.4.1. Solid Packaging Equipment

10.4.2. Semi-solid Packaging Equipment

10.4.3. Liquid Packaging Equipment

10.5. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

10.5.1. Solid Packaging Equipment

10.5.2. Semi-solid Packaging Equipment

10.5.3. Liquid Packaging Equipment

10.6. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

10.6.1. Manual

10.6.2. Automatic

10.6.3. Semi-automatic

10.7. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

10.7.1. Manual

10.7.2. Automatic

10.7.3. Semi-automatic

10.8. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

10.8.1. Shuttle Blister System

10.8.2. Rotary Blister System

10.8.2.1. Net-weight Fillers

10.8.2.2. Volumetric Fillers

10.8.2.3. Thermo fill-seal System

10.8.2.4. Other Filling Equipment

10.8.3. Inline Filler System

10.9. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

10.9.1. Shuttle Blister System

10.9.2. Rotary Blister System

10.9.2.1. Net-weight Fillers

10.9.2.2. Volumetric Fillers

10.9.2.3. Thermo fill-seal System

10.9.2.4. Other Filling Equipment

10.9.3. Inline Filler System

10.10. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

10.10.1. Cold Sealing

10.10.2. Heat Sealing

10.10.2.1. Card-to-card

10.10.2.2. Card-to-plastic

10.10.2.3. Plastic-to-plastic

10.10.3. Thermoforming

10.10.4. Ultrasonic Sealing

10.11. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

10.11.1. Cold Sealing

10.11.2. Heat Sealing

10.11.2.1. Card-to-card

10.11.2.2. Card-to-plastic

10.11.2.3. Plastic-to-plastic

10.11.3. Thermoforming

10.11.4. Ultrasonic Sealing

10.12. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

10.12.1. Pharmaceutical Industry

10.12.2. Food Industry

10.12.2.1. Dairy

10.12.2.2. Confectionary

10.12.2.3. Others

10.12.3. Cosmetics & Personal Care

10.12.4. Consumer Electronics

10.12.5. Other Manufacturing

10.13. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

10.13.1. Pharmaceutical Industry

10.13.2. Food Industry

10.13.2.1. Dairy

10.13.2.2. Confectionary

10.13.2.3. Others

10.13.3. Cosmetics & Personal Care

10.13.4. Consumer Electronics

10.13.5. Other Manufacturing

10.14. Market Attractiveness Analysis

10.14.1. By Country

10.14.2. By Product Type

10.14.3. By Process Type

10.14.4. By Equipment Type

10.14.5. By Technology Type

10.14.6. By End Use

11. Latin America Blister Packaging Equipment Market Analysis and Forecast

11.1. Introduction

11.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Country

11.2.1. Brazil

11.2.2. Mexico

11.2.3. Rest of Latin America

11.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Country

11.3.1. Brazil

11.3.2. Mexico

11.3.3. Rest of Latin America

11.4. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

11.4.1. Solid Packaging Equipment

11.4.2. Semi-solid Packaging Equipment

11.4.3. Liquid Packaging Equipment

11.5. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

11.5.1. Solid Packaging Equipment

11.5.2. Semi-solid Packaging Equipment

11.5.3. Liquid Packaging Equipment

11.6. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

11.6.1. Manual

11.6.2. Automatic

11.6.3. Semi-automatic

11.7. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

11.7.1. Manual

11.7.2. Automatic

11.7.3. Semi-automatic

11.8. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

11.8.1. Shuttle Blister System

11.8.2. Rotary Blister System

11.8.2.1. Net-weight Fillers

11.8.2.2. Volumetric Fillers

11.8.2.3. Thermo fill-seal System

11.8.2.4. Other Filling Equipment

11.8.3. Inline Filler System

11.9. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

11.9.1. Shuttle Blister System

11.9.2. Rotary Blister System

11.9.2.1. Net-weight Fillers

11.9.2.2. Volumetric Fillers

11.9.2.3. Thermo fill-seal System

11.9.2.4. Other Filling Equipment

11.9.3. Inline Filler System

11.10. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

11.10.1. Cold Sealing

11.10.2. Heat Sealing

11.10.2.1. Card-to-card

11.10.2.2. Card-to-plastic

11.10.2.3. Plastic-to-plastic

11.10.3. Thermoforming

11.10.4. Ultrasonic Sealing

11.11. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

11.11.1. Cold Sealing

11.11.2. Heat Sealing

11.11.2.1. Card-to-card

11.11.2.2. Card-to-plastic

11.11.2.3. Plastic-to-plastic

11.11.3. Thermoforming

11.11.4. Ultrasonic Sealing

11.12. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

11.12.1. Pharmaceutical Industry

11.12.2. Food Industry

11.12.2.1. Dairy

11.12.2.2. Confectionary

11.12.2.3. Others

11.12.3. Cosmetics & Personal Care

11.12.4. Consumer Electronics

11.12.5. Other Manufacturing

11.13. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

11.13.1. Pharmaceutical Industry

11.13.2. Food Industry

11.13.2.1. Dairy

11.13.2.2. Confectionary

11.13.2.3. Others

11.13.3. Cosmetics & Personal Care

11.13.4. Consumer Electronics

11.13.5. Other Manufacturing

11.14. Market Attractiveness Analysis

11.14.1. By Country

11.14.2. By Product Type

11.14.3. By Process Type

11.14.4. By Equipment Type

11.14.5. By Technology Type

11.14.6. By End Use

12. Europe Blister Packaging Equipment Market Analysis and Forecast

12.1. Introduction

12.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Country

12.2.1. Germany

12.2.2. Spain

12.2.3. Italy

12.2.4. France

12.2.5. U.K.

12.2.6. BENELUX

12.2.7. Nordic Countries

12.2.8. Russia

12.2.9. Rest of Europe

12.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Country

12.3.1. Germany

12.3.2. Spain

12.3.3. Italy

12.3.4. France

12.3.5. U.K.

12.3.6. BENELUX

12.3.7. Nordic Countries

12.3.8. Russia

12.3.9. Rest of Europe

12.4. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

12.4.1. Solid Packaging Equipment

12.4.2. Semi-solid Packaging Equipment

12.4.3. Liquid Packaging Equipment

12.5. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

12.5.1. Solid Packaging Equipment

12.5.2. Semi-solid Packaging Equipment

12.5.3. Liquid Packaging Equipment

12.6. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

12.6.1. Manual

12.6.2. Automatic

12.6.3. Semi-automatic

12.7. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

12.7.1. Manual

12.7.2. Automatic

12.7.3. Semi-automatic

12.8. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

12.8.1. Shuttle Blister System

12.8.2. Rotary Blister System

12.8.2.1. Net-weight Fillers

12.8.2.2. Volumetric Fillers

12.8.2.3. Thermo fill-seal System

12.8.2.4. Other Filling Equipment

12.8.3. Inline Filler System

12.9. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

12.9.1. Shuttle Blister System

12.9.2. Rotary Blister System

12.9.2.1. Net-weight Fillers

12.9.2.2. Volumetric Fillers

12.9.2.3. Thermo fill-seal System

12.9.2.4. Other Filling Equipment

12.9.3. Inline Filler System

12.10. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

12.10.1. Cold Sealing

12.10.2. Heat Sealing

12.10.2.1. Card-to-card

12.10.2.2. Card-to-plastic

12.10.2.3. Plastic-to-plastic

12.10.3. Thermoforming

12.10.4. Ultrasonic Sealing

12.11. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

12.11.1. Cold Sealing

12.11.2. Heat Sealing

12.11.2.1. Card-to-card

12.11.2.2. Card-to-plastic

12.11.2.3. Plastic-to-plastic

12.11.3. Thermoforming

12.11.4. Ultrasonic Sealing

12.12. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

12.12.1. Pharmaceutical Industry

12.12.2. Food Industry

12.12.2.1. Dairy

12.12.2.2. Confectionary

12.12.2.3. Others

12.12.3. Cosmetics & Personal Care

12.12.4. Consumer Electronics

12.12.5. Other Manufacturing

12.13. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

12.13.1. Pharmaceutical Industry

12.13.2. Food Industry

12.13.2.1. Dairy

12.13.2.2. Confectionary

12.13.2.3. Others

12.13.3. Cosmetics & Personal Care

12.13.4. Consumer Electronics

12.13.5. Other Manufacturing

12.14. Market Attractiveness Analysis

12.14.1. By Country

12.14.2. By Product Type

12.14.3. By Process Type

12.14.4. By Equipment Type

12.14.5. By Technology Type

12.14.6. By End Use

13. Asia Pacific Blister Packaging Equipment Market Analysis and Forecast

13.1. Introduction

13.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Country

13.2.1. China

13.2.2. India

13.2.3. Japan

13.2.4. ASEAN

13.2.5. Australia and New Zealand

13.2.6. Rest of APAC

13.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Country

13.3.1. China

13.3.2. India

13.3.3. Japan

13.3.4. ASEAN

13.3.5. Australia and New Zealand

13.3.6. Rest of APAC

13.4. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

13.4.1. Solid Packaging Equipment

13.4.2. Semi-solid Packaging Equipment

13.4.3. Liquid Packaging Equipment

13.5. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

13.5.1. Solid Packaging Equipment

13.5.2. Semi-solid Packaging Equipment

13.5.3. Liquid Packaging Equipment

13.6. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

13.6.1. Manual

13.6.2. Automatic

13.6.3. Semi-automatic

13.7. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

13.7.1. Manual

13.7.2. Automatic

13.7.3. Semi-automatic

13.8. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

13.8.1. Shuttle Blister System

13.8.2. Rotary Blister System

13.8.2.1. Net-weight Fillers

13.8.2.2. Volumetric Fillers

13.8.2.3. Thermo fill-seal System

13.8.2.4. Other Filling Equipment

13.8.3. Inline Filler System

13.9. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

13.9.1. Shuttle Blister System

13.9.2. Rotary Blister System

13.9.2.1. Net-weight Fillers

13.9.2.2. Volumetric Fillers

13.9.2.3. Thermo fill-seal System

13.9.2.4. Other Filling Equipment

13.9.3. Inline Filler System

13.10. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

13.10.1. Cold Sealing

13.10.2. Heat Sealing

13.10.2.1. Card-to-card

13.10.2.2. Card-to-plastic

13.10.2.3. Plastic-to-plastic

13.10.3. Thermoforming

13.10.4. Ultrasonic Sealing

13.11. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

13.11.1. Cold Sealing

13.11.2. Heat Sealing

13.11.2.1. Card-to-card

13.11.2.2. Card-to-plastic

13.11.2.3. Plastic-to-plastic

13.11.3. Thermoforming

13.11.4. Ultrasonic Sealing

13.12. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

13.12.1. Pharmaceutical Industry

13.12.2. Food Industry

13.12.2.1. Dairy

13.12.2.2. Confectionary

13.12.2.3. Others

13.12.3. Cosmetics & Personal Care

13.12.4. Consumer Electronics

13.12.5. Other Manufacturing

13.13. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

13.13.1. Pharmaceutical Industry

13.13.2. Food Industry

13.13.2.1. Dairy

13.13.2.2. Confectionary

13.13.2.3. Others

13.13.3. Cosmetics & Personal Care

13.13.4. Consumer Electronics

13.13.5. Other Manufacturing

13.14. Market Attractiveness Analysis

13.14.1. By Country

13.14.2. By Product Type

13.14.3. By Process Type

13.14.4. By Equipment Type

13.14.5. By Technology Type

13.14.6. By End Use

14. Middle East and Africa Blister Packaging Equipment Market Analysis and Forecast

14.1. Introduction

14.2. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Country

14.2.1. North Africa

14.2.2. South Africa

14.2.3. GCC countries

14.2.4. Rest of MEA

14.3. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Country

14.3.1. North Africa

14.3.2. South Africa

14.3.3. GCC countries

14.3.4. Rest of MEA

14.4. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Product Type

14.4.1. Solid Packaging Equipment

14.4.2. Semi-solid Packaging Equipment

14.4.3. Liquid Packaging Equipment

14.5. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Product Type

14.5.1. Solid Packaging Equipment

14.5.2. Semi-solid Packaging Equipment

14.5.3. Liquid Packaging Equipment

14.6. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Process Type

14.6.1. Manual

14.6.2. Automatic

14.6.3. Semi-automatic

14.7. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Process Type

14.7.1. Manual

14.7.2. Automatic

14.7.3. Semi-automatic

14.8. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Equipment Type

14.8.1. Shuttle Blister System

14.8.2. Rotary Blister System

14.8.2.1. Net-weight Fillers

14.8.2.2. Volumetric Fillers

14.8.2.3. Thermo fill-seal System

14.8.2.4. Other Filling Equipment

14.8.3. Inline Filler System

14.9. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Equipment Type

14.9.1. Shuttle Blister System

14.9.2. Rotary Blister System

14.9.2.1. Net-weight Fillers

14.9.2.2. Volumetric Fillers

14.9.2.3. Thermo fill-seal System

14.9.2.4. Other Filling Equipment

14.9.3. Inline Filler System

14.10. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By Technology Type

14.10.1. Cold Sealing

14.10.2. Heat Sealing

14.10.2.1. Card-to-card

14.10.2.2. Card-to-plastic

14.10.2.3. Plastic-to-plastic

14.10.3. Thermoforming

14.10.4. Ultrasonic Sealing

14.11. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By Technology Type

14.11.1. Cold Sealing

14.11.2. Heat Sealing

14.11.2.1. Card-to-card

14.11.2.2. Card-to-plastic

14.11.2.3. Plastic-to-plastic

14.11.3. Thermoforming

14.11.4. Ultrasonic Sealing

14.12. Historical Market Value (US$ Mn) and Volume (Units) 2015-2019, By End Use Type

14.12.1. Pharmaceutical Industry

14.12.2. Food Industry

14.12.2.1. Dairy

14.12.2.2. Confectionary

14.12.2.3. Others

14.12.3. Cosmetics & Personal Care

14.12.4. Consumer Electronics

14.12.5. Other Manufacturing

14.13. Market Value (US$ Mn) and Volume (Units) Forecast Analysis 2020-2025, By End Use Type

14.13.1. Pharmaceutical Industry

14.13.2. Food Industry

14.13.2.1. Dairy

14.13.2.2. Confectionary

14.13.2.3. Others

14.13.3. Cosmetics & Personal Care

14.13.4. Consumer Electronics

14.13.5. Other Manufacturing

14.14. Market Attractiveness Analysis

14.14.1. By Country

14.14.2. By Product Type

14.14.3. By Process Type

14.14.4. By Equipment Type

14.14.5. By Technology Type

14.14.6. By End Use

15. Competitive Landscape

15.1. Competition Dashboard

15.2. Company Profiles (Details – Overview, Financials, Strategy, SWOT Analysis, Recent Developments)

15.3. Company Names

15.3.1. Marchesini Group S.p.A.

15.3.1.1. Overview

15.3.1.2. Financials

15.3.1.3. Strategy

15.3.1.4. SWOT Analysis

15.3.1.5. Recent Developments

15.3.2. Bosch Packaging Technology

15.3.2.1. Overview

15.3.2.2. Financials

15.3.2.3. Strategy

15.3.2.4. SWOT Analysis

15.3.2.5. Recent Developments

15.3.3. IMA Industria Macchine Automatiche S.p.A.

15.3.3.1. Overview

15.3.3.2. Financials

15.3.3.3. Strategy

15.3.3.4. SWOT Analysis

15.3.3.5. Recent Developments

15.3.4. Körber AG

15.3.4.1. Overview

15.3.4.2. Financials

15.3.4.3. Strategy

15.3.4.4. SWOT Analysis

15.3.4.5. Recent Developments

15.3.5. Gebo Cermex

15.3.5.1. Overview

15.3.5.2. Financials

15.3.5.3. Strategy

15.3.5.4. SWOT Analysis

15.3.5.5. Recent Developments

15.3.6. ULMA Packaging, S. Coop

15.3.6.1. Overview

15.3.6.2. Financials

15.3.6.3. Strategy

15.3.6.4. SWOT Analysis

15.3.6.5. Recent Developments

15.3.7. Sonoco Products Company

15.3.7.1. Overview

15.3.7.2. Financials

15.3.7.3. Strategy

15.3.7.4. SWOT Analysis

15.3.7.5. Recent Developments

15.3.8. Uhlmann Pac-Systeme GmbH & Co. KG

15.3.8.1. Overview

15.3.8.2. Financials

15.3.8.3. Strategy

15.3.8.4. SWOT Analysis

15.3.8.5. Recent Developments

15.3.9. Romaco Pharmatechnik GmbH

15.3.9.1. Overview

15.3.9.2. Financials

15.3.9.3. Strategy

15.3.9.4. SWOT Analysis

15.3.9.5. Recent Developments

15.3.10. Fabrima Maquinas Automaticas Ltda

15.3.10.1. Overview

15.3.10.2. Financials

15.3.10.3. Strategy

15.3.10.4. SWOT Analysis

15.3.10.5. Recent Developments

15.3.11. Zed Industries Inc.

15.3.11.1. Overview

15.3.11.2. Financials

15.3.11.3. Strategy

15.3.11.4. SWOT Analysis

15.3.11.5. Recent Developments

15.3.12. Jornen Machinery Co., Ltd.

15.3.12.1. Overview

15.3.12.2. Financials

15.3.12.3. Strategy

15.3.12.4. SWOT Analysis

15.3.12.5. Recent Developments

15.3.13. Illig Maschinenbau GmbH & Co. KG

15.3.13.1. Overview

15.3.13.2. Financials

15.3.13.3. Strategy

15.3.13.4. SWOT Analysis

15.3.13.5. Recent Developments

15.3.14. CAM Packaging Solutions

15.3.14.1. Overview

15.3.14.2. Financials

15.3.14.3. Strategy

15.3.14.4. SWOT Analysis

15.3.14.5. Recent Developments

15.3.15. Starview Packaging Machinery, Inc.

15.3.15.1. Overview

15.3.15.2. Financials

15.3.15.3. Strategy

15.3.15.4. SWOT Analysis

15.3.15.5. Recent Developments

15.3.16. Royal Pharmaceutical Machinery Co., Ltd.

15.3.16.1. Overview

15.3.16.2. Financials

15.3.16.3. Strategy

15.3.16.4. SWOT Analysis

15.3.16.5. Recent Developments

16. Assumption and Acronyms

17. Research Methodology

List of Tables

Table 01: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 02: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 03: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 04: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 05: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

Table 06: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Region, 2015 (H) – 2025 (F)

Table 07: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Country, 2015 (H) – 2025 (F)

Table 08: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 09: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 10: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 11: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 12: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

Table 13: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Country, 2015 (H) – 2025 (F)

Table 14: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 15: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 16: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 17: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 18: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

Table 19: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Country, 2015 (H) – 2025 (F)

Table 20: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 21: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 22: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 23: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 24: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

Table 25: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Country, 2015 (H) – 2025 (F)

Table 26: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 27: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 28: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 29: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 30: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

Table 31: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Country, 2015 (H) – 2025 (F)

Table 32: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Product Type, 2015 (H) – 2025 (F)

Table 33: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Process Type, 2015 (H) – 2025 (F)

Table 34: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Equipment Type, 2015 (H) – 2025 (F)

Table 35: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by Technology Type, 2015 (H) – 2025 (F)

Table 36: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units) Forecast, by End Use Type, 2015 (H) – 2025 (F)

List of Figure

Figure 1: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by Product Type, 2020(E) & 2025 (F)

Figure 2: Global Blister Packaging Equipment Market Y-o-Y Growth, by Product Type, 2019 (A) – 2025 (F)

Figure 3: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Solid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 4: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Solid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 5: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Semi-Solid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 6: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Semi-Solid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 7: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Liquid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 8: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Liquid Packaging Equipment Segment, 2019 (A) – 2025 (F)

Figure 9: Global Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) -2025 (F)

Figure 10: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by Process Type, 2020(E) & 2025 (F)

Figure 11: Global Blister Packaging Equipment Market Y-o-Y Growth, by Process Type, 2019 (A) – 2025 (F)

Figure 12: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Manual Segment, 2019 (A) – 2025 (F)

Figure 13: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Manual Segment, 2019 (A) – 2025 (F)

Figure 14: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Automatic Segment, 2019 (A) – 2025 (F)

Figure 15: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Automatic Segment, 2019 (A) – 2025 (F)

Figure 16: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Semi-Automatic Segment, 2019 (A) – 2025 (F)

Figure 17: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Semi-Automatic Segment, 2019 (A) – 2025 (F)

Figure 18: Global Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 19: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by Equipment Type, 2020(E) & 2025 (F)

Figure 20: Global Blister Packaging Equipment Market Y-o-Y Growth, by Equipment Type, 2019 (A) – 2025 (F)

Figure 21: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Shuttle Blister System Segment, 2019 (A) – 2025 (F)

Figure 22: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Shuttle Blister System Segment, 2019 (A) – 2025 (F)

Figure 23: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Rotary Blister System Segment, 2019 (A) – 2025 (F)

Figure 24: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Rotary Blister System Segment, 2019 (A) – 2025 (F)

Figure 25: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Net-weight Fillers, 2019 (A) – 2025 (F)

Figure 26: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Net-weight Fillers, 2019 (A) – 2025 (F)

Figure 27: Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Volumetric Fillers, 2019 (A) – 2025 (F)

Figure 28: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Volumetric Fillers, 2019 (A) – 2025 (F)

Figure 29: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Thermo fill-seal System, 2019 (A) – 2025 (F)

Figure 30: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Thermo fill-seal System, 2019 (A) – 2025 (F)

Figure 31: Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Other Filling Equipment, 2019 (A) – 2025 (F)

Figure 32: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Other Filling Equipment, 2019 (A) – 2025 (F)

Figure 33: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Inline Filler System Segment, 2019 (A) – 2025 (F)

Figure 34: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Inline Filler System Segment, 2019 (A) – 2025 (F)

Figure 35: Global Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 36: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by Technology Type, 2020(E) & 2025 (F)

Figure 37: Global Blister Packaging Equipment Market Y-o-Y Growth, by Technology Type, 2019 (A) – 2025 (F)

Figure 38: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Cold Sealing Segment, 2019 (A) – 2025 (F)

Figure 39: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Cold Sealing Segment, 2019 (A) – 2025 (F)

Figure 40: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Heat Sealing Segment, 2019 (A) – 2025 (F)

Figure 41: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Heat Sealing Segment, 2019 (A) – 2025 (F)

Figure 42: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Card-to-card, 2019 (A) – 2025 (F)

Figure 43: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Card-to-card, 2019 (A) – 2025 (F)

Figure 44: Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Card-to-plastic, 2019 (A) – 2025 (F)

Figure 45: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Card-to-plastic, 2019 (A) – 2025 (F)

Figure 46: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Plastic-to-plastic, 2019 (A) – 2025 (F)

Figure 47: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Plastic-to-plastic, 2019 (A) – 2025 (F)

Figure 48: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Thermoforming Segment, 2019 (A) – 2025 (F)

Figure 49: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Thermoforming Segment, 2019 (A) – 2025 (F)

Figure 50: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Ultrasonic Sealing Segment, 2019 (A) – 2025 (F)

Figure 51: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Ultrasonic Sealing Segment, 2019 (A) – 2025 (F)

Figure 52: Global Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 53: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by End Use Type, 2020(E) & 2025 (F)

Figure 54: Global Blister Packaging Equipment Market Y-o-Y Growth, by End Use Type, 2019 (A) – 2025 (F)

Figure 55: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Pharmaceutical Industry Segment, 2019 (A) – 2025 (F)

Figure 56: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Pharmaceutical Industry Segment, 2019 (A) – 2025 (F)

Figure 57: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Food Industry Segment, 2019 (A) – 2025 (F)

Figure 58: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Food Industry Segment, 2019 (A) – 2025 (F)

Figure 59: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Dairy, 2019 (A) – 2025 (F)

Figure 60: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Dairy, 2019 (A) – 2025 (F)

Figure 61: Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), & Confectionary, 2019 (A) – 2025 (F)

Figure 62: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, & Confectionary, 2019 (A) – 2025 (F)

Figure 63: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Others, 2019 (A) – 2025 (F)

Figure 64: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Others, 2019 (A) – 2025 (F)

Figure 65: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Cosmetics & Personal Care Segment, 2019 (A) – 2025 (F)

Figure 66: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Cosmetics & Personal Care Segment, 2019 (A) – 2025 (F)

Figure 67: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Consumer Electronics Segment, 2019 (A) – 2025 (F)

Figure 68: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Consumer Electronics Segment, 2019 (A) – 2025 (F)

Figure 69: Global Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), Other Manufacturing Segment, 2019 (A) – 2025 (F)

Figure 70: Global Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, Other Manufacturing Segment, 2019 (A) – 2025 (F)

Figure 71: Global Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 72: Global Blister Packaging Equipment Market Share & Basis Points (BPS) Analysis, by Region, 2020(E) & 2025 (F)

Figure 73: Global Blister Packaging Equipment Market Y-o-Y Growth, by Region, 2019 (A) – 2025 (F)

Figure 74: Global Blister Packaging Equipment Market Attractiveness Index, by Region, 2019 (A) – 2025 (F)

Figure 75: North America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), 2019 (A) – 2025 (F)

Figure 76: North America Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, 2019 (A) – 2025 (F)

Figure 77: North America Blister Packaging Equipment Market Share and BPS Analysis, by Country, 2020(E) & 2025 (F)

Figure 78: North America Blister Packaging Equipment Market Y-o-Y Growth, by Country, 2019 (A) – 2025 (F)

Figure 79: North America Blister Packaging Equipment Market Attractiveness Analysis, by Country, 2019 (A) – 2025 (F)

Figure 80: North America Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) – 2025 (F)

Figure 81: North America Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 82: North America Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 83: North America Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 84: North America Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 85: North America Blister Packaging Equipment Market Value (US$ Mn) by Product Type, 2015 (H) – 2025 (F)

Figure 86: North America Blister Packaging Equipment Market Value (US$ Mn) by Process Type, 2015 (H) – 2025 (F)

Figure 87: North America Blister Packaging Equipment Market Value (US$ Mn) by Equipment Type, 2015 (H) – 2025 (F)

Figure 88: North America Blister Packaging Equipment Market Value (US$ Mn) by Technology Type, 2015 (H) – 2025 (F)

Figure 89: North America Blister Packaging Equipment Market Value (US$ Mn) by End Use Type, 2015 (H) – 2025 (F)

Figure 90: Latin America Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), 2019 (A) – 2025 (F)

Figure 91: Latin America Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, 2019 (A) – 2025 (F)

Figure 92: Latin America Blister Packaging Equipment Market Share and BPS Analysis, by Country, 2020(E) & 2025 (F)

Figure 93: Latin America Blister Packaging Equipment Market Y-o-Y Growth, by Country, 2019 (A) – 2025 (F)

Figure 94: Latin America Blister Packaging Equipment Market Attractiveness Analysis, by Country, 2019 (A) – 2025 (F)-2025

Figure 95: Latin America Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) – 2025 (F)

Figure 96: Latin America Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 97: Latin America Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 98: Latin America Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 99: Latin America Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 100: Latin America Blister Packaging Equipment Market Value (US$ Mn) by Product Type, 2015 (H) – 2025 (F)

Figure 101: Latin America Blister Packaging Equipment Market Value (US$ Mn) by Process Type, 2015 (H) – 2025 (F)

Figure 102: Latin America Blister Packaging Equipment Market Value (US$ Mn) by Equipment Type, 2015 (H) – 2025 (F)

Figure 103: Latin America Blister Packaging Equipment Market Value (US$ Mn) by Technology Type, 2015 (H) – 2025 (F)

Figure 104: Latin America Blister Packaging Equipment Market Value (US$ Mn) by End Use Type, 2015 (H) – 2025 (F)

Figure 105: Europe Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), 2019 (A) – 2025 (F)

Figure 106: Europe Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, 2019 (A) – 2025 (F)

Figure 107: Europe Blister Packaging Equipment Market Share and BPS Analysis, by Country, 2020(E) & 2025 (F)

Figure 108: Europe Blister Packaging Equipment Market Y-o-Y Growth, by Country, 2019 (A) – 2025 (F)

Figure 109: Europe Blister Packaging Equipment Market Attractiveness Analysis, by Country, 2019 (A) – 2025 (F)-2025

Figure 110: Europe Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) – 2025 (F)

Figure 111: Europe Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 112: Europe Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 113: Europe Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 114: Europe Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 115: Europe Blister Packaging Equipment Market Value (US$ Mn) by Product Type, 2015 (H) – 2025 (F)

Figure 116: Europe Blister Packaging Equipment Market Value (US$ Mn) by Process Type, 2015 (H) – 2025 (F)

Figure 117: Europe Blister Packaging Equipment Market Value (US$ Mn) by Equipment Type, 2015 (H) – 2025 (F)

Figure 118: Europe Blister Packaging Equipment Market Value (US$ Mn) by Technology Type, 2015 (H) – 2025 (F)

Figure 119: Europe Blister Packaging Equipment Market Value (US$ Mn) by End Use Type, 2015 (H) – 2025 (F)

Figure 120: APAC Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), 2019 (A) – 2025 (F)

Figure 121: APAC Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, 2019 (A) – 2025 (F)

Figure 122: APAC Blister Packaging Equipment Market Share and BPS Analysis, by Country, 2020(E) & 2025 (F)

Figure 123: APAC Blister Packaging Equipment Market Y-o-Y Growth, by Country, 2019 (A) – 2025 (F)

Figure 124: APAC Blister Packaging Equipment Market Attractiveness Analysis, by Country, 2019 (A) – 2025 (F)-2025

Figure 125: APAC Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) – 2025 (F)

Figure 126: APAC Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 127: APAC Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 128: APAC Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 129: APAC Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 130: APAC Blister Packaging Equipment Market Value (US$ Mn) by Product Type, 2015 (H) – 2025 (F)

Figure 131: APAC Blister Packaging Equipment Market Value (US$ Mn) by Process Type, 2015 (H) – 2025 (F)

Figure 132: APAC Blister Packaging Equipment Market Value (US$ Mn) by Equipment Type, 2015 (H) – 2025 (F)

Figure 133: APAC Blister Packaging Equipment Market Value (US$ Mn) by Technology Type, 2015 (H) – 2025 (F)

Figure 134: APAC Blister Packaging Equipment Market Value (US$ Mn) by End Use Type, 2015 (H) – 2025 (F)

Figure 135: MEA Blister Packaging Equipment Market Value (US$ Mn) and Volume (Units), 2019 (A) – 2025 (F)

Figure 136: MEA Blister Packaging Equipment Market, Absolute $ Opportunity Analysis, 2019 (A) – 2025 (F)

Figure 137: MEA Blister Packaging Equipment Market Share and BPS Analysis, by Country, 2020(E) & 2025 (F)

Figure 138: MEA Blister Packaging Equipment Market Y-o-Y Growth, by Country, 2019 (A) – 2025 (F)

Figure 139: MEA Blister Packaging Equipment Market Attractiveness Analysis, by Country, 2019 (A) – 2025 (F)-2025

Figure 140: MEA Blister Packaging Equipment Market Attractiveness Index, by Product Type, 2019 (A) – 2025 (F)

Figure 141: MEA Blister Packaging Equipment Market Attractiveness Index, by Process Type, 2019 (A) – 2025 (F)

Figure 142: MEA Blister Packaging Equipment Market Attractiveness Index, by Equipment Type, 2019 (A) – 2025 (F)

Figure 143: MEA Blister Packaging Equipment Market Attractiveness Index, by Technology Type, 2019 (A) – 2025 (F)

Figure 144: MEA Blister Packaging Equipment Market Attractiveness Index, by End Use Type, 2019 (A) – 2025 (F)

Figure 145: MEA Blister Packaging Equipment Market Value (US$ Mn) by Product Type, 2015 (H) – 2025 (F)

Figure 146: MEA Blister Packaging Equipment Market Value (US$ Mn) by Process Type, 2015 (H) – 2025 (F)

Figure 147: MEA Blister Packaging Equipment Market Value (US$ Mn) by Equipment Type, 2015 (H) – 2025 (F)

Figure 148: MEA Blister Packaging Equipment Market Value (US$ Mn) by Technology Type, 2015 (H) – 2025 (F)

Figure 149: MEA Blister Packaging Equipment Market Value (US$ Mn) by End Use Type, 2015 (H) – 2025 (F)