Reports

Reports

Companies in the SFG measurement system market are placing high priority on maintaining business continuity in important industries such as optics, medical, and defense sectors during the ongoing COVID-19 crisis. Surface Measurement Systems - a developer of innovative experimental techniques and instrumentation for physico-chemical characterization of complex solids, is taking steps to meet mission-critical projects in essential industries with least amount of disruption as possible. Companies are implementing a series of policies to protect employees and their families, as well as clients & partners to safeguard their health during the pandemic.

The poor market sentiment is slowing down the growth of the SFG measurement system market. However, mass vaccination programs are anticipated to gradually revive market growth. Companies are focusing their business in countries where lockdown measures are being relaxed. They are adhering to National Government guidelines to avoid interruptions in business activities.

Companies in the SFG measurement system market are boosting their R&D efforts to study the properties of water with the help of an electrified graphene electrode via classical molecular dynamics simulations. It has been found that the value of the applied electrode potential has dramatic effects on the structure and dynamics of interfacial water molecules.

Vibrational sum-frequency generation (SFG) suggests itself as a tool, since it has been successfully used to characterize water molecules at a range of aqueous interfaces, including air/water, alkane/water, and silica/water interfaces. However, the buried interface between an aqueous solution and an electrochemical material presents a considerable challenge. Hence, companies are gaining a strong research in experiments encouraging SFG spectra at an uncharged graphene/water interface with its successful implementation in an electrochemical cell.

The application of SFG vibrational spectroscopy is growing popular in the investigation of surfaces and interfaces of solids, liquids, polymers, and biological membranes, among others. EKSPLA - a laser manufacturing company based in Lithuania, is capitalizing on this opportunity to provide SFG vibrational spectrometers that support studies of surface structure, chemical composition, and molecular orientation. These spectrometers help in characterization of vibrational bonds of molecules at surfaces or interfaces.

Companies in the SFG measurement system market are developing SFG vibrational spectrometers that are intrinsically surface specific and selective to adsorbed species. They are developing systems that are sensitive to submonolayer of molecules. SFG vibrational spectrometers that are applicable to all interfaces accessible to light and capable of high spectral & spatial resolution.

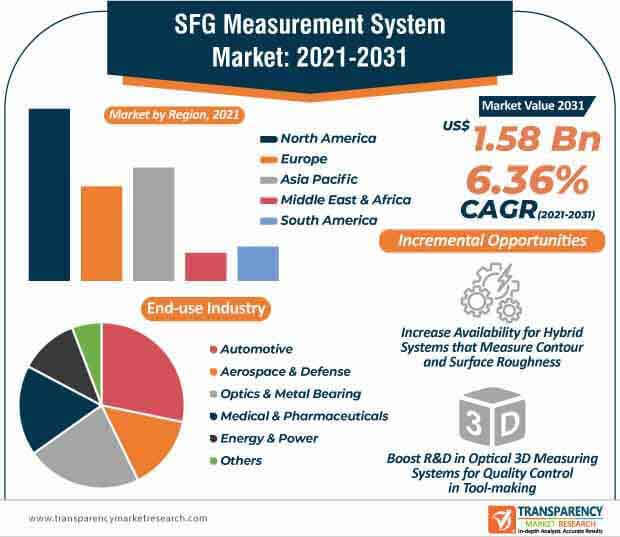

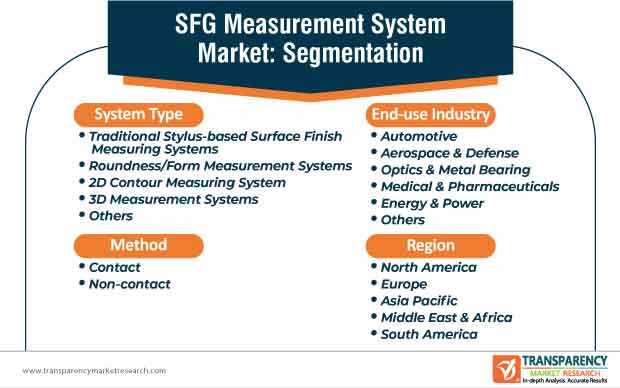

Revolutionary measuring systems are transforming the SFG measurement system market. Mitutoyo Corporation - a Japanese multinational corporation specializing in measuring instruments and metrological technology, is gaining recognition for its contour and surface roughness measuring systems called the FORMTRACER Avant Series. The SFG measurement system market is predicted to expand at a favorable CAGR of ~6% during the forecast period. Manufacturers are increasing the availability of hybrid measuring systems that allow measurements of contour and surface roughness.

Increased speed and operability is being preferred in contour and surface roughness measuring systems. Manufacturers are deploying expandability in contour and surface measurement systems, which allow upgrade to a complex system by integrating a detector. Continuous upper/lower surface measurement combined with a measurement adjustable feature is being achieved in contour measuring systems.

The SFG measurement system market is expected to reach the valuation of US$ 1.6 Bn by 2031. Manufacturers in the SFG measurement system market are building their portfolio in roundness, surface finish, and contour measuring systems to expand their income streams. Taylor Hobson - an ultra-precision technology company is being publicized for its contact and non-contact measurement systems that are ideal for precision components, including bearings, fuel injectors, turbocharger parts, and crankshafts.

Non-contact, optical 3D form measuring systems are being developed by manufacturers in the SFG measurement system market, and are suitable for the inspection of roundness, straightness, parallelism and roughness of precision components. These systems are being designed to deliver high accuracy measurement of injectors, lens barrels, hydraulic components, and precision bores, among others. On the other hand, the multi-part high precision roundness is a brand new inspection concept combining roughness, roundness, and contour on a fully automated inspection system.

Stakeholders in the SFG measurement system market are designing optical 3D measuring systems on the basis of modern imaging 3D measurement techniques. The Fraunhofer Institute for Applied Optics and Precision Engineering (IOF) is bolstering its research in optical 3D measuring systems for various applications on the basis of digital projection technology, modern imaging 3D measurement techniques, and novel microoptical projection-technology. Manufacturers are taking cues from such innovations to develop 3D measuring systems that are suitable for quality control in tool-making, mold making, and mechanical engineering industries.

Since automotive industry is projected to dominate the highest revenue among all end-use industries in the SFG measurement system market, it is evident that optical 3D measuring systems are in high demand for automotive applications.

In the industrial manufacturing metrology, there is a need for quick and easy measurement of work-piece profiles. A wide variety of measuring tasks is translating into revenue opportunities for companies in the SFG measurement system market. These tasks demand greater precision and optimum measuring strategies with the help of contour measurement systems. In order to reduce the cost and time associated with measuring tasks, there is a growing demand for a single machine for measuring form, position, roughness, and contour of precision components.

Mahr Metrology - an application specialist that offers an extensive range of products and solutions for measuring tasks, is combining decades of experience in contour metrology with the feedback of its customers to design contour measuring systems. Contour evaluation helps to record and document roughness parameters for testing workpieces.

Analysts’ Viewpoint

Companies in the SFG measurement system market are adopting contingency planning to deploy business continuity in optics, medical, and defense applications during the coronavirus pandemic. Optical 3D measuring systems are gaining prominence in medicine and forensic science applications. However, there is a demand to achieve time and cost efficiency for the testing of precision components. Hence, manufacturers should design a single machine for measuring form, roughness, and contour of work-pieces. On the other hand, manufacturers should increase focus in multi-part high precision roundness inspection concept with the help of fully automated inspection systems to reduce the number of inspection operations.

1. Global SFG Measurement System Market - Executive Summary

1.1. Global SFG Measurement System Market Country Analysis

1.2. Competition Blueprint

1.3. Technology Time Line Mapping

1.4. TMR Analysis and Recommendations

2. Market Overview

2.1. Market Introduction

2.2. Market Definition

2.3. Market Taxonomy

3. Market Dynamics

3.1. Macro-economic Factors

3.2. Drivers

3.2.1. Economic Drivers

3.2.2. Supply Side Drivers

3.2.3. Demand Side Drivers

3.3. Market Restraints

3.4. Market Trends

3.5. Trend Analysis- Impact on Time Line (2021-2031)

4. Associated Industry and Key Indicator Assessment

4.1. Parent Industry Overview

4.2. Supply Chain Analysis

4.2.1. Profitability and Gross Margin Analysis, by Competition

4.2.2. List of Active Participants- By Region

4.2.2.1. Raw Type Suppliers

4.2.2.2. Key Manufacturers

4.2.2.3. Integrators

4.2.2.4. Key Distributor/Retailers

4.3. Technology Roadmap

4.4. Porter’s Five Forces Analysis

5. Global SFG Measurement System Market Pricing Analysis

5.1. Market Size Analysis (2018-2019) and Forecast (2021-2031)

5.1.1. Market Value (US$ Mn) and Y-o-Y Growth

5.2. Global SFG Measurement System Market Scenario Forecast (Optimistic, Likely and Conservative Market Conditions)

5.2.1. Forecast Factors and Relevance of Impact

5.2.2. Regional SFG Measurement System Market Business Performance Summary

6. Global SFG Measurement System Market Analysis, by System Type

6.1. Introduction

6.1.1. Y-o-Y Growth Comparison By System Type

6.2. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

6.2.1. Traditional Stylus Based Surface Finish Measuring Systems

6.2.2. Roundness/ Form Measurement Systems

6.2.3. 2D Contour Measuring System

6.2.4. 3D measurement systems

6.2.5. Others

6.3. Market Attractiveness Analysis, by System Type

7. Global SFG Measurement System Market Analysis, by Method

7.1. Introduction

7.1.1. Y-o-Y Growth Comparison By Method

7.2. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

7.2.1. Contact

7.2.2. Non-contact

7.3. Market Attractiveness Analysis, by Method

8. Global SFG Measurement System Market Analysis, by End-use Industry

8.1. Introduction

8.1.1. Y-o-Y Growth Comparison By End-use Industry

8.2. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

8.2.1. Automotive

8.2.2. Aerospace & Defense

8.2.3. Optics and Metal Bearing

8.2.4. Medical& Pharmaceuticals

8.2.5. Energy & Power

8.2.6. Others

8.3. Market Attractiveness Analysis, by End-use Industry

9. Global SFG Measurement System Market Analysis and Forecast, by Region

9.1. Introduction

9.1.1. Basis Point Share (BPS) Analysis, by Region

9.2. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Region, 2017-2031

9.2.1. North America

9.2.2. Europe

9.2.3. Asia Pacific

9.2.4. Middle East & Africa

9.2.5. South America

9.3. Market Attractiveness Analysis, by Region

10. North America SFG Measurement System Market Analysis and Forecast

10.1. Introduction

10.2. Drivers and Restraints: Impact Analysis

10.3. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

10.3.1. Traditional Stylus Based Surface Finish Measuring Systems

10.3.2. Roundness/ Form Measurement Systems

10.3.3. 2D Contour Measuring System

10.3.4. 3D measurement systems

10.3.5. Others

10.4. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

10.4.1. Contact

10.4.2. Non-contact

10.5. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

10.5.1. Automotive

10.5.2. Aerospace & Defense

10.5.3. Optics and Metal Bearing

10.5.4. Medical& Pharmaceuticals

10.5.5. Energy & Power

10.5.6. Others

10.6. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Country, 2017-2031

10.6.1. U.S.

10.6.2. Canada

10.6.3. Mexico

10.7. Market Attractiveness Analysis

10.7.1. System Type

10.7.2. Method

10.7.3. End-use Industry

10.7.4. Country

11. Europe SFG Measurement System Market Analysis and Forecast

11.1. Introduction

11.2. Drivers and Restraints: Impact Analysis

11.3. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

11.3.1. Traditional Stylus Based Surface Finish Measuring Systems

11.3.2. Roundness/ Form Measurement Systems

11.3.3. 2D Contour Measuring System

11.3.4. 3D measurement systems

11.3.5. Others

11.4. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

11.4.1. Contact

11.4.2. Non-contact

11.5. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

11.5.1. Automotive

11.5.2. Aerospace & Defense

11.5.3. Optics and Metal Bearing

11.5.4. Medical& Pharmaceuticals

11.5.5. Energy & Power

11.5.6. Others

11.6. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Country/Sub-region, 2017-2031

11.6.1. U.K.

11.6.2. Germany

11.6.3. France

11.6.4. Italy

11.6.5. Russia

11.6.6. Rest of Europe

11.7. Market Attractiveness Analysis

11.7.1. System Type

11.7.2. Method

11.7.3. End-use Industry

11.7.4. Country/Sub-region

12. Asia Pacific SFG Measurement System Market Analysis and Forecast

12.1. Introduction

12.2. Drivers and Restraints: Impact Analysis

12.3. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

12.3.1. Traditional Stylus Based Surface Finish Measuring Systems

12.3.2. Roundness/ Form Measurement Systems

12.3.3. 2D Contour Measuring System

12.3.4. 3D measurement systems

12.3.5. Others

12.4. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

12.4.1. Contact

12.4.2. Non-contact

12.5. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

12.5.1. Automotive

12.5.2. Aerospace & Defense

12.5.3. Optics and Metal Bearing

12.5.4. Medical& Pharmaceuticals

12.5.5. Energy & Power

12.5.6. Others

12.6. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Country/Sub-region, 2017-2031

12.6.1. China

12.6.2. India

12.6.3. Japan

12.6.4. South Korea

12.6.5. Rest of Asia Pacific

12.7. Market Attractiveness Analysis

12.7.1. System Type

12.7.2. Method

12.7.3. End-use Industry

12.7.4. Country/Sub-region

13. Middle East & Africa (MEA) SFG Measurement System Market Analysis and Forecast

13.1. Introduction

13.2. Drivers and Restraints: Impact Analysis

13.3. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

13.3.1. Traditional Stylus Based Surface Finish Measuring Systems

13.3.2. Roundness/ Form Measurement Systems

13.3.3. 2D Contour Measuring System

13.3.4. 3D measurement systems

13.3.5. Others

13.4. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

13.4.1. Contact

13.4.2. Non-contact

13.5. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

13.5.1. Automotive

13.5.2. Aerospace & Defense

13.5.3. Optics and Metal Bearing

13.5.4. Medical& Pharmaceuticals

13.5.5. Energy & Power

13.5.6. Others

13.6. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Country/Sub-region, 2017-2031

13.6.1. GCC

13.6.2. South Africa

13.6.3. Rest of Middle East & Africa

13.7. Market Attractiveness Analysis

13.7.1. System Type

13.7.2. Method

13.7.3. End-use Industry

13.7.4. Country/Sub-region

14. South America SFG Measurement System Market Analysis and Forecast

14.1. Introduction

14.2. Drivers and Restraints: Impact Analysis

14.3. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by System Type, 2017-2031

14.3.1. Traditional Stylus Based Surface Finish Measuring Systems

14.3.2. Roundness/ Form Measurement Systems

14.3.3. 2D Contour Measuring System

14.3.4. 3D measurement systems

14.3.5. Others

14.4. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Method, 2017-2031

14.4.1. Contact

14.4.2. Non-contact

14.5. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by End-use Industry, 2017-2031

14.5.1. Automotive

14.5.2. Aerospace & Defense

14.5.3. Optics and Metal Bearing

14.5.4. Medical& Pharmaceuticals

14.5.5. Energy & Power

14.5.6. Others

14.6. SFG Measurement System Market Size (US$ Mn) Analysis & Forecast, by Country/Sub-region, 2017-2031

14.6.1. Brazil

14.6.2. Argentina

14.6.3. Rest of South America

14.7. Market Attractiveness Analysis

14.7.1. System Type

14.7.2. Method

14.7.3. End-use Industry

14.7.4. Country/Sub-region

15. Competition Assessment

15.1. Global SFG Measurement System Market Competition - a Dashboard View

15.2. Global SFG Measurement System Market Structure Analysis

15.3. Global SFG Measurement System Market Company Share Analysis, by Value (2020)

15.4. Key Participants Market Presence (Intensity Mapping) by Region

16. Competition Deep-dive (Manufacturers/Suppliers)

16.1. Mahr

16.1.1. Overview

16.1.2. Product Portfolio

16.1.3. Sales Footprint

16.1.4. Channel Footprint

16.1.4.1. Distributors List

16.1.5. Strategy Overview

16.1.5.1. Marketing Strategy

16.1.5.2. Culture Strategy

16.1.5.3. Channel Strategy

16.1.6. SWOT Analysis

16.1.7. Financial Analysis

16.1.8. Revenue Share

16.1.8.1. By Region

16.1.9. Key Clients

16.1.10. Analyst Comments

16.2. Carl Zeiss

16.2.1. Overview

16.2.2. Product Portfolio

16.2.3. Sales Footprint

16.2.4. Channel Footprint

16.2.4.1. Distributors List

16.2.5. Strategy Overview

16.2.5.1. Marketing Strategy

16.2.5.2. Culture Strategy

16.2.5.3. Channel Strategy

16.2.6. SWOT Analysis

16.2.7. Financial Analysis

16.2.8. Revenue Share

16.2.8.1. By Region

16.2.9. Key Clients

16.2.10. Analyst Comments

16.3. EXTECH

16.3.1. Overview

16.3.2. Product Portfolio

16.3.3. Sales Footprint

16.3.4. Channel Footprint

16.3.4.1. Distributors List

16.3.5. Strategy Overview

16.3.5.1. Marketing Strategy

16.3.5.2. Culture Strategy

16.3.5.3. Channel Strategy

16.3.6. SWOT Analysis

16.3.7. Financial Analysis

16.3.8. Revenue Share

16.3.8.1. By Region

16.3.9. Key Clients

16.3.10. Analyst Comments

16.4. Hexagon AB

16.4.1. Overview

16.4.2. Product Portfolio

16.4.3. Sales Footprint

16.4.4. Channel Footprint

16.4.4.1. Distributors List

16.4.5. Strategy Overview

16.4.5.1. Marketing Strategy

16.4.5.2. Culture Strategy

16.4.5.3. Channel Strategy

16.4.6. SWOT Analysis

16.4.7. Financial Analysis

16.4.8. Revenue Share

16.4.8.1. By Region

16.4.9. Key Clients

16.4.10. Analyst Comments

16.5. JENOPTIK AG

16.5.1. Overview

16.5.2. Product Portfolio

16.5.3. Sales Footprint

16.5.4. Channel Footprint

16.5.4.1. Distributors List

16.5.5. Strategy Overview

16.5.5.1. Marketing Strategy

16.5.5.2. Culture Strategy

16.5.5.3. Channel Strategy

16.5.6. SWOT Analysis

16.5.7. Financial Analysis

16.5.8. Revenue Share

16.5.8.1. By Region

16.5.9. Key Clients

16.5.10. Analyst Comments

16.6. KEYENCE Corporation

16.6.1. Overview

16.6.2. Product Portfolio

16.6.3. Sales Footprint

16.6.4. Channel Footprint

16.6.4.1. Distributors List

16.6.5. Strategy Overview

16.6.5.1. Marketing Strategy

16.6.5.2. Culture Strategy

16.6.5.3. Channel Strategy

16.6.6. SWOT Analysis

16.6.7. Financial Analysis

16.6.8. Revenue Share

16.6.8.1. By Region

16.6.9. Key Clients

16.6.10. Analyst Comments

16.7. Mitutoyo Corporation

16.7.1. Overview

16.7.2. Product Portfolio

16.7.3. Sales Footprint

16.7.4. Channel Footprint

16.7.4.1. Distributors List

16.7.5. Strategy Overview

16.7.5.1. Marketing Strategy

16.7.5.2. Culture Strategy

16.7.5.3. Channel Strategy

16.7.6. SWOT Analysis

16.7.7. Financial Analysis

16.7.8. Revenue Share

16.7.8.1. By Region

16.7.9. Key Clients

16.7.10. Analyst Comments

16.8. Starrett

16.8.1. Overview

16.8.2. Product Portfolio

16.8.3. Sales Footprint

16.8.4. Channel Footprint

16.8.4.1. Distributors List

16.8.5. Strategy Overview

16.8.5.1. Marketing Strategy

16.8.5.2. Culture Strategy

16.8.5.3. Channel Strategy

16.8.6. SWOT Analysis

16.8.7. Financial Analysis

16.8.8. Revenue Share

16.8.8.1. By Region

16.8.9. Key Clients

16.8.10. Analyst Comments

16.9. Taylor Hobson

16.9.1. Overview

16.9.2. Product Portfolio

16.9.3. Sales Footprint

16.9.4. Channel Footprint

16.9.4.1. Distributors List

16.9.5. Strategy Overview

16.9.5.1. Marketing Strategy

16.9.5.2. Culture Strategy

16.9.5.3. Channel Strategy

16.9.6. SWOT Analysis

16.9.7. Financial Analysis

16.9.8. Revenue Share

16.9.8.1. By Region

16.9.9. Key Clients

16.9.10. Analyst Comments

16.10. Tokyo Seimitsu Co., Ltd.

16.10.1. Overview

16.10.2. Product Portfolio

16.10.3. Sales Footprint

16.10.4. Channel Footprint

16.10.4.1. Distributors List

16.10.5. Strategy Overview

16.10.5.1. Marketing Strategy

16.10.5.2. Culture Strategy

16.10.5.3. Channel Strategy

16.10.6. SWOT Analysis

16.10.7. Financial Analysis

16.10.8. Revenue Share

16.10.8.1. By Region

16.10.9. Key Clients

16.10.10. Analyst Comments

16.11. Others (On additional Request)

17. Recommendation- Critical Success Factors

18. Research Methodology

19. Assumptions & Acronyms Used

List of Tables

Table 1: Global SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 2: Global SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 3: Global SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 4: Global SFG Measurement System Market Value (US$ Mn), by Region, 2017–2031

Table 5: North America SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 6: North America SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 7: North America SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 8: North America SFG Measurement System Market Value (US$ Mn), by Country, 2017–2031

Table 9: Europe SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 10: Europe SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 11: Europe SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 12: Europe SFG Measurement System Market Value (US$ Mn), by Country/Sub-region, 2017–2031

Table 13: Asia Pacific SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 14: Asia Pacific SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 15: Asia Pacific SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 16: Asia Pacific SFG Measurement System Market Value (US$ Mn), by Country/Sub-region, 2017–2031

Table 17: Middle East & Africa SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 18: Middle East & Africa SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 19: Middle East & Africa SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 20: Middle East & Africa SFG Measurement System Market Value (US$ Mn), by Country/Sub-region, 2017–2031

Table 21: South America SFG Measurement System Market Value (US$ Mn), by System Type, 2017–2031

Table 22: South America SFG Measurement System Market Value (US$ Mn), by Method, 2017–2031

Table 23: South America SFG Measurement System Market Value (US$ Mn), by End-use Industry, 2017–2031

Table 24: South America SFG Measurement System Market Value (US$ Mn), by Country/Sub-region, 2017–2031

List of Figures

Figure 1: Global SFG Measurement System Market Value (US$ Mn) Forecast, 2017–2031

Figure 2: Global SFG Measurement System Market Value (US$ Mn), by Traditional Stylus Based Surface Finish Measuring Systems

Figure 3: Global SFG Measurement System Market Value (US$ Mn), by Roundness/ Form Measurement Systems

Figure 4: Global SFG Measurement System Market Value (US$ Mn), by 2D Contour Measuring System

Figure 5: Global SFG Measurement System Market Value (US$ Mn), by 3D Measurement Systems

Figure 6: Global SFG Measurement System Market Value (US$ Mn), by Others

Figure 7: Global SFG Measurement System Market Comparison Matrix, by System Type

Figure 8: Global SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 9: Global SFG Measurement System Market Value (US$ Mn), by Contact

Figure 10: Global SFG Measurement System Market Value (US$ Mn), by Non-contact

Figure 11: Global SFG Measurement System Market Comparison Matrix, by Method

Figure 12: Global SFG Measurement System Market Attractiveness Analysis, by Method

Figure 13: Global SFG Measurement System Market Value (US$ Mn), by Automotive

Figure 14: Global SFG Measurement System Market Value (US$ Mn), by Aerospace & Defense

Figure 15: Global SFG Measurement System Market Value (US$ Mn), by Optics & Metal Bearing

Figure 16: Global SFG Measurement System Market Value (US$ Mn), by Medical & Pharmaceuticals

Figure 17: Global SFG Measurement System Market Value (US$ Mn), by Energy & Power

Figure 18: Global SFG Measurement System Market Value (US$ Mn), by Othersals

Figure 19: Global SFG Measurement System Market Comparison Matrix, by End-use Industry

Figure 20: Global SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 21: Global SFG Measurement System Market Value Share Analysis, by Region (2021F)

Figure 22: Global SFG Measurement System Market Value Share Analysis, by Region (2031F)

Figure 23: Global SFG Measurement System Market Attractiveness Analysis, by Region

Figure 24: North America SFG Measurement System Market Revenue Projection and Y-o-Y Growth, 2018–2031 (US$ Mn and %)

Figure 25: North America SFG Measurement System Market Value Share Analysis, by System Type (2021F)

Figure 26: North America SFG Measurement System Market Value Share Analysis, by System Type (2031F)

Figure 27: North America SFG Measurement System Market Value Share Analysis, by Method (2021F)

Figure 28: North America SFG Measurement System Market Value Share Analysis, by Method (2031F)

Figure 29: North America SFG Measurement System Market Value Share Analysis, by End-use Industry (2021F)

Figure 30: North America SFG Measurement System Market Value Share Analysis, by End-use Industry (2031F)

Figure 31: North America SFG Measurement System Market Value Share Analysis, by Country (2021F)

Figure 32: North America SFG Measurement System Market Value Share Analysis, by Country (2031F)

Figure 33: North America SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 34: North America SFG Measurement System Market Attractiveness Analysis, by Method

Figure 35: North America SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 36: North America SFG Measurement System Market Attractiveness Analysis, by Country

Figure 37: Europe SFG Measurement System Market Revenue Projection and Y-o-Y Growth, 2018–2031 (US$ Mn and %)

Figure 38: Europe SFG Measurement System Market Value Share Analysis, by System Type (2021F)

Figure 39: Europe SFG Measurement System Market Value Share Analysis, by System Type (2031F)

Figure 40: Europe SFG Measurement System Market Value Share Analysis, by Method (2021F)

Figure 41: Europe SFG Measurement System Market Value Share Analysis, by Method (2031F)

Figure 42: Europe SFG Measurement System Market Value Share Analysis, by End-use Industry (2021F)

Figure 43: Europe SFG Measurement System Market Value Share Analysis, by End-use Industry (2031F)

Figure 44: Europe SFG Measurement System Market Value Share Analysis, by Country (2021F)

Figure 45: Europe SFG Measurement System Market Value Share Analysis, by Country (2031F)

Figure 46: Europe SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 47: Europe SFG Measurement System Market Attractiveness Analysis, by Method

Figure 48: Europe SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 49: Europe SFG Measurement System Market Attractiveness Analysis, by Country

Figure 50: Asia Pacific SFG Measurement System Market Revenue Projection and Y-o-Y Growth, 2018–2031 (US$ Mn and %)

Figure 51: Asia Pacific SFG Measurement System Market Value Share Analysis, by System Type (2021F)

Figure 52: Asia Pacific SFG Measurement System Market Value Share Analysis, by System Type (2031F)

Figure 53: Asia Pacific SFG Measurement System Market Value Share Analysis, by Method (2021F)

Figure 54: Asia Pacific SFG Measurement System Market Value Share Analysis, by Method (2031F)

Figure 55: Asia Pacific SFG Measurement System Market Value Share Analysis, by End-use Industry (2021F)

Figure 56: Asia Pacific SFG Measurement System Market Value Share Analysis, by End-use Industry (2031F)

Figure 57: Asia Pacific SFG Measurement System Market Value Share Analysis, by Country (2021F)

Figure 58: Asia Pacific SFG Measurement System Market Value Share Analysis, by Country (2031F)

Figure 59: Asia Pacific SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 60: Asia Pacific SFG Measurement System Market Attractiveness Analysis, by Method

Figure 61: Asia Pacific SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 62: Asia Pacific SFG Measurement System Market Attractiveness Analysis, by Country

Figure 63: Middle East & Africa SFG Measurement System Market Revenue Projection and Y-o-Y Growth, 2018–2031 (US$ Mn and %)

Figure 64: Middle East & Africa SFG Measurement System Market Value Share Analysis, by System Type (2021F)

Figure 65: Middle East & Africa SFG Measurement System Market Value Share Analysis, by System Type (2031F)

Figure 66: Middle East & Africa SFG Measurement System Market Value Share Analysis, by Method (2021F)

Figure 67: Middle East & Africa SFG Measurement System Market Value Share Analysis, by Method (2031F)

Figure 68: Middle East & Africa SFG Measurement System Market Value Share Analysis, by End-use Industry (2021F)

Figure 69: Middle East & Africa SFG Measurement System Market Value Share Analysis, by End-use Industry (2031F)

Figure 70: Middle East & Africa SFG Measurement System Market Value Share Analysis, by Country (2021F)

Figure 71: Middle East & Africa SFG Measurement System Market Value Share Analysis, by Country (2031F)

Figure 72: Middle East & Africa SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 73: Middle East & Africa SFG Measurement System Market Attractiveness Analysis, by Method

Figure 74: Middle East & Africa SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 75: Middle East & Africa SFG Measurement System Market Attractiveness Analysis, by Country

Figure 76: South America SFG Measurement System Market Revenue Projection and Y-o-Y Growth, 2018–2031 (US$ Mn and %)

Figure 77: South America SFG Measurement System Market Value Share Analysis, by System Type (2021F)

Figure 78: South America SFG Measurement System Market Value Share Analysis, by System Type (2031F)

Figure 79: South America SFG Measurement System Market Value Share Analysis, by Method (2021F)

Figure 80: South America SFG Measurement System Market Value Share Analysis, by Method (2031F)

Figure 81: South America SFG Measurement System Market Value Share Analysis, by End-use Industry (2021F)

Figure 82: South America SFG Measurement System Market Value Share Analysis, by End-use Industry (2031F)

Figure 83: South America SFG Measurement System Market Value Share Analysis, by Country (2021F)

Figure 84: South America SFG Measurement System Market Value Share Analysis, by Country (2031F)

Figure 85: South America SFG Measurement System Market Attractiveness Analysis, by System Type

Figure 86: South America SFG Measurement System Market Attractiveness Analysis, by Method

Figure 87: South America SFG Measurement System Market Attractiveness Analysis, by End-use Industry

Figure 88: South America SFG Measurement System Market Attractiveness Analysis, by Country