Reports

Reports

Over the past few decades, offshore corrosion protection technologies have evolved at a rapid pace due to which, the demand continues to grow at a consistent pace. The production of corrosion protection coatings specifically developed to protect metallic substrates, including magnesium, aluminum, iron, and steel has accelerated over the past decade. In addition, as the offshore infrastructure is largely prone to corrosion across different zones, including submerged, mud, and splash, the need for corrosion protection continues to gain considerable momentum. At present, organic coatings are gradually replacing expensive and ineffective conventional coatings and the trend is likely to stay over the course of the forecast period. Organic coatings are increasingly being used in hostile environmental and complex offshore conditions to prevent metallic degradation, depletion of resources, and structural failures to ensure optimum productivity in the drilling operations.

In the past couple of decades, within the offshore corrosion protection market, a considerable amount of resources have been invested in research & development activities to evaluate the efficacy of various organic coatings and offshore corrosion protection technologies. Manufacturers and participants operating in the supply side of the value chain are primarily focusing on the production of effective corrosion protection concepts to gain an advantage in the current market landscape. At the back of these factors, the global offshore corrosion protection market is projected to reach ~US$ 13 Bn by the end of 2030.

The global demand for electricity is currently growing at an exponential rate and the trend is set to continue in the upcoming years, owing to the large-scale emphasis on industrialization and modernization by the developing nations. The global demand for electricity is projected to grow by ~2% annually over the next decade due to which, the adoption of offshore renewables is expected to gain considerable traction. Over the forecast period, the market share of renewable-based electricity generation is likely to exceed that of coal-based electricity generation across the world due to which, the demand for offshore corrosion protection concepts and technologies is on the rise.

As a majority of this renewable energy is generated by wind turbines, offshore corrosion protection is gaining considerable importance across the offshore wind sector. In addition, as per the participants operating in the offshore wind sector, the long-term production of renewable energy will primarily depend on two important factors i.e. the maintenance and the installation costs. Offshore corrosion protection has emerged as an ideal solution to attain these objectives and thus, the demand for different types of offshore corrosion protection technologies is set to expand at a steady pace. While the offshore wind sector is expected to remain a prominent end-use industry, the oil & gas sector is also projected to provide abundant opportunities for players operating in the offshore corrosion protection market.

The oil & gas sector is expected to provide an array of opportunities for participants operating in the offshore corrosion protection market, as oil & gas operators continue to move toward hostile working environments. Although offshore production was treading through a minor slump, offshore exploration activities have increased over the past few years. As the oil & gas sector continues to recover from the recent oil crisis, market participants are increasingly focusing on offshore corrosion protection technologies.

At present, recent and development activities have paved the way for an array of offshore corrosion technologies. At present, nanotechnology has emerged as an ideal candidate that is set to redefine offshore protection in the upcoming years. The development of a new range of nanostructured coating materials is on course to redefine offshore corrosion protection. Advancements in nanotechnology coupled with the focus on upgrading the aging offshore rigs and infrastructure are anticipated to provide fertile grounds for growth to the players operating in the current market landscape.

The advent of the novel COVID-19 virus has led to a global economic slowdown and hampered the growth of a host of industrial sectors. The offshore corrosion protection market is expected to feel the impact of the COVID-19 pandemic amid the consistent decline in the demand for oil and disruptions in the supply chain. However, the demand for offshore corrosion protection technologies to complete the pending maintenance projects could witness a slight improvement during the COVID-19 pandemic. While the demand from the oil & gas sector is expected to likely to remain uncertain, the offshore wind generation sector could provide lucrative opportunities during the COVID-19 pandemic.

Analysts’ Viewpoint

The global offshore corrosion protection market is expected to grow at a sluggish CAGR of ~3% during the forecast period. Growing emphasis on upgrading the existing offshore infrastructure, developments in nanotechnology, consistent demand from the offshore wind generation sector, and research & development activities are some of the major factors that will provide a boost to the prospects of the offshore corrosion protection market during the forecast period. Market players should focus on research activities to introduce innovative and cost-effective corrosion protection techniques and concepts.

1. Executive Summary

1.1. Market Outlook

1.2. Key Facts and Figures

1.3. Key Trends

2. Market Overview

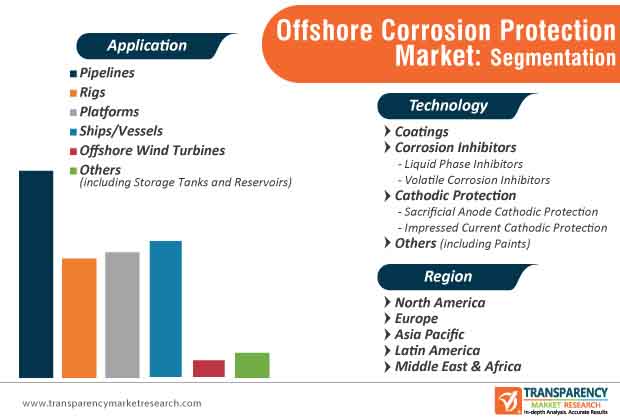

2.1. Market Segmentation

2.2. Market Indicators

3. Market Dynamics

3.1. Drivers and Restraints Snapshot Analysis

3.1.1.1. Drivers

3.1.1.2. Restraints

3.1.1.3. Opportunities

3.2. Porter’s Five Forces Analysis

3.2.1. Threat of Substitutes

3.2.2. Bargaining Power of Buyers

3.2.3. Bargaining Power of Suppliers

3.2.4. Threat of New Entrants

3.2.5. Degree of Competition

3.3. Regulatory Scenario

3.4. Value Chain Analysis

3.4.1. List of Offshore Corrosion Protection Manufacturers

3.4.2. List of Offshore Corrosion Protection Suppliers

3.4.3. List of Potential Customers

4. Global Offshore Corrosion Protection Market: Pricing, by Region, 2018

5. Global Offshore Corrosion Protection Market Value (US$ Mn) Analysis, by Technology

5.1. Key Findings and Introduction

5.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

5.2.1. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Coatings, 2019–2030

5.2.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Corrosion Inhibitors, 2019–2030

5.2.2.1. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Liquid Phase Inhibitors, 2019–2030

5.2.2.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Volatile Corrosion Inhibitors, 2019–2030

5.2.3. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Cathodic Protection, 2019–2030

5.2.3.1. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Sacrificial Anode Cathodic Protection, 2019–2030

5.2.3.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Impressed Current Cathodic Protection, 2019–2030

5.2.4. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Others, 2019–2030

5.3. Global Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

6. Global Offshore Corrosion Protection Market Value (US$ Mn) Analysis, by Application

6.1. Key Findings and Introduction

6.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

6.2.1. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Pipelines, 2019–2030

6.2.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Rigs, 2019–2030

6.2.3. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Platforms, 2019–2030

6.2.4. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Ships/Vessels, 2019–2030

6.2.5. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Offshore Wind Turbines, 2019–2030

6.2.6. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Others, 2019–2030

6.3. Global Offshore Corrosion Protection Market Attractiveness Analysis, by Application

7. Global Offshore Corrosion Protection Market Analysis, by Region

7.1. Key Findings

7.2. Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Region

7.2.1. North America

7.2.2. Europe

7.2.3. Asia Pacific

7.2.4. Latin America

7.2.5. Middle East & Africa

7.3. Global Offshore Corrosion Protection Market Attractiveness Analysis, by Region

8. North America Offshore Corrosion Protection Market Overview

8.1. Key Findings

8.2. North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

8.3. North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

8.4. North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country

8.4.1. U.S. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

8.4.2. U.S. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

8.4.3. Canada Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

8.4.4. Canada Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

8.5. North America Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

8.6. North America Offshore Corrosion Protection Market Attractiveness Analysis, by Application

8.7. North America Offshore Corrosion Protection Market Attractiveness Analysis, by Country

9. Europe Offshore Corrosion Protection Market Overview

9.1. Key Findings

9.2. Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.3. Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4. Europe Offshore Corrosion Protection Market Value (US$ Mn) and Forecast, by Country and Sub-region

9.4.1. Germany Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.2. Germany Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.3. U.K. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.4. U.K. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.5. France Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.6. France Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.7. Italy Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.8. Italy Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.9. Spain Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.10. Spain Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.11. Russia & CIS Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.12. Russia & CIS Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.4.13. Rest of Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

9.4.14. Rest of Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

9.5. Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

9.6. Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Application

9.7. Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

10. Asia Pacific Offshore Corrosion Protection Market Overview

10.1. Key Findings

10.2. Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

10.3. Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4. Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region

10.4.1. China Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

10.4.2. China Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4.3. India Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology

10.4.4. India Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4.5. Japan Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology

10.4.6. Japan Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4.7. ASEAN Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology

10.4.8. ASEAN Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4.9. South Korea Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology

10.4.10. South Korea Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.4.11. Rest of Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology

10.4.12. Rest of Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

10.5. Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

10.6. Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Application

10.7. Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

11. Latin America Offshore Corrosion Protection Market Overview

11.1. Key Findings

11.2. Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

11.3. Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

11.4. Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region

11.4.1. Brazil Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

11.4.2. Brazil Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

11.4.3. Mexico Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

11.4.4. Mexico Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

11.4.5. Rest of Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

11.4.6. Rest of Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

11.5. Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

11.6. Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Application

11.7. Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

12. Middle East & Africa Offshore Corrosion Protection Market Overview

12.1. Key Findings

12.2. Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

12.3. Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

12.4. Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region

12.4.1. GCC Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

12.4.2. GCC Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

12.4.3. South Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

12.4.4. South Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

12.4.5. Rest of Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

12.4.6. Rest of Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

12.5. Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

12.6. Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Application

12.7. Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

13. Competition Landscape

13.1. Competition Matrix

13.2. Global Offshore Corrosion Protection Market Share Analysis, by Company (2019)

13.3. Market Footprint Analysis

13.4. Company Profiles

13.4.1. Southern Cathodic Protection

13.4.1.1. Company Details

13.4.1.2. Company Description

13.4.1.3. Business Overview

13.4.2. RPM International Inc.

13.4.2.1. Company Details

13.4.2.2. Company Description

13.4.2.3. Business Overview

13.4.2.4. Financial Details

13.4.3. Ashland

13.4.3.1. Company Details

13.4.3.2. Company Description

13.4.3.3. Business Overview

13.4.3.4. Financial Details

13.4.4. 3M

13.4.4.1. Company Details

13.4.4.2. Company Description

13.4.4.3. Business Overview

13.4.4.4. Financial Details

13.4.5. Akzo Nobel N.V.

13.4.5.1. Company Details

13.4.5.2. Company Description

13.4.5.3. Business Overview

13.4.5.4. Financial Details

13.4.6. Akzo Nobel N.V.

13.4.6.1. Company Details

13.4.6.2. Company Description

13.4.6.3. Business Overview

13.4.6.4. Financial Details

13.4.7. Hempel A/S

13.4.7.1. Company Details

13.4.7.2. Company Description

13.4.7.3. Business Overview

13.4.7.4. Financial Details

13.4.8. Axalta Coating Systems Ltd.

13.4.8.1. Company Details

13.4.8.2. Company Description

13.4.8.3. Business Overview

13.4.8.4. Financial Details

13.4.9. Kansai Paint Co., Ltd.

13.4.9.1. Company Details

13.4.9.2. Company Description

13.4.9.3. Business Overview

13.4.9.4. Financial Details

13.4.10. The Sherwin-Williams Company

13.4.10.1. Company Details

13.4.10.2. Company Description

13.4.10.3. .Business Overview

13.4.10.4. Financial Details

13.4.11. BASF SE

13.4.11.1. Company Details

13.4.11.2. Company Description

13.4.11.3. Business Overview

13.4.11.4. Financial Details

13.4.12. Aegion Corporation

13.4.12.1. Company Details

13.4.12.2. Company Description

13.4.12.3. Business Overview

13.4.12.4. Financial Details

13.4.13. Chase Corp

13.4.13.1. Company Details

13.4.13.2. Company Description

13.4.13.3. Business Overview

13.4.13.4. Financial Details

14. Primary Research – Key Insights

15. Appendix

15.1. Research Methodology and Assumptions

List of Tables

Table 01: Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 02: Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 03: Global Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Region, 2019–2030

Table 04: North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country, 2019–2030

Table 05: North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 06: North America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 07: U.S. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 08: U.S. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 09: Canada Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 10: Canada Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 11: Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region, 2019–2030

Table 12: Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 13: Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 14: Germany Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 15: Germany Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 16: France Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 17: France Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 18: U.K. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 19: U.K. Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 20: Italy Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 21: Italy Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 22: Spain Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 23: Spain Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 24: Russia & CIS Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 25: Russia & CIS Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 26: Rest of Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 27: Rest of Europe Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 28: Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region, 2019–2030

Table 29: Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 30: Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 31: China Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 32: China Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 33: Japan Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 34: Japan Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 35: India Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 36: India Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 37: ASEAN Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 38: ASEAN Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 39: South Korea Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 40: South Korea Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 41: Rest of Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 42: Rest of Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 43: Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region, 2019–2030

Table 44: Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 45: Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 46: Brazil Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 47: Brazil Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 48: Mexico Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 49: Mexico Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 50: Rest of Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 51: Rest of Latin America Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 52: Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Country and Sub-region, 2019–2030

Table 53: Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 54: Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 55: GCC Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 56: GCC Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 57: South Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 58: South Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

Table 59: Rest of Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Technology, 2019–2030

Table 60: Rest of Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn) Forecast, by Application, 2019–2030

List of Figures

Figure 01: Global Offshore Corrosion Protection Value Analysis, by Technology

Figure 02: Global Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 03: Global Offshore Corrosion Protection Value Analysis, by Application

Figure 04: Global Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 05: Global Offshore Corrosion Protection Value Share Analysis, by Region

Figure 06: Global Offshore Corrosion Protection Market Attractiveness Analysis, by Region

Figure 07: North America Offshore Corrosion Protection Market Value (US$ Mn), 2019–2030

Figure 08: North America Offshore Corrosion Protection Market Value Share Analysis, by Country

Figure 09: North America Offshore Corrosion Protection Market Attractiveness Analysis, by Country

Figure 10: North America Offshore Corrosion Protection Market Value Share Analysis, by Technology

Figure 11: North America Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 12: North America Offshore Corrosion Protection Market Value Share Analysis, by Application

Figure 13: North America Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 14: Europe Offshore Corrosion Protection Market Value (US$ Mn), 2019–2030

Figure 15: Europe Offshore Corrosion Protection Market Value Share Analysis, by Country and Sub-region

Figure 16: Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

Figure 17: Europe Offshore Corrosion Protection Market Value Share Analysis, by Technology

Figure 18: Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 19: Europe Offshore Corrosion Protection Market Value Share Analysis, by Application

Figure 20: Europe Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 21: Asia Pacific Offshore Corrosion Protection Market Value (US$ Mn), 2019–2030

Figure 22: Asia Pacific Offshore Corrosion Protection Market Value Share Analysis, by Country and Sub-region

Figure 23: Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

Figure 24: Asia Pacific Offshore Corrosion Protection Market Value Share Analysis, by Technology

Figure 25: Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 26: Asia Pacific Offshore Corrosion Protection Market Value Share Analysis, by Application

Figure 27: Asia Pacific Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 28: Latin America Offshore Corrosion Protection Market Value (US$ Mn), 2019–2030

Figure 29: Latin America Offshore Corrosion Protection Market Value Share Analysis, by Country and Sub-region

Figure 30: Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Country and Sub-region

Figure 31: Latin America Offshore Corrosion Protection Market Value Share Analysis, by Technology

Figure 32: Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 33: Latin America Offshore Corrosion Protection Market Value Share Analysis, by Application

Figure 34: Latin America Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 35: Middle East & Africa Offshore Corrosion Protection Market Value (US$ Mn), 2019–2030

Figure 36: Middle East & Africa Offshore Corrosion Protection Market Value Share Analysis, by Country

Figure 37: Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Country &Sub-region

Figure 38: Middle East & Africa Offshore Corrosion Protection Market Value Share Analysis, by Technology

Figure 39: Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Technology

Figure 40: Middle East & Africa Offshore Corrosion Protection Market Value Share Analysis, by Application

Figure 41: Middle East & Africa Offshore Corrosion Protection Market Attractiveness Analysis, by Application

Figure 42: Global Offshore Corrosion Protection Market Share Analysis, by Company, 2019