Reports

Reports

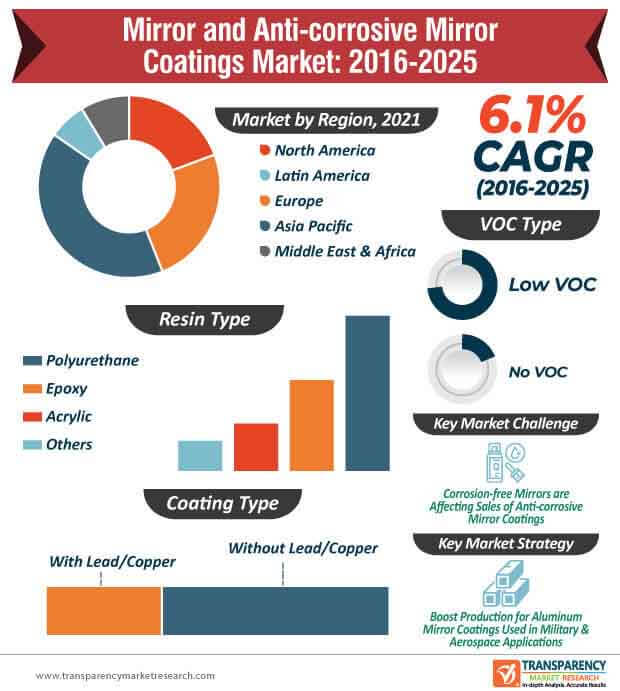

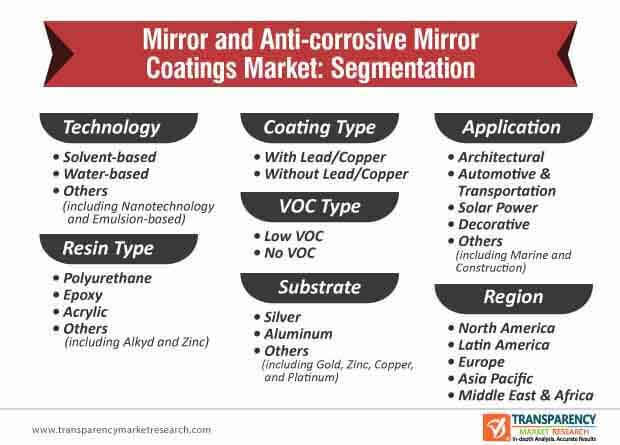

Despite challenging times created by the COVID-19 crisis, stakeholders in the mirror and anti-corrosive mirror coatings market are focusing on long-term objectives to consider economic factors and emergency response plans. In order to keep economies running, companies are tapping incremental opportunities in positive or limited negative impact industries such as architecture and decoration to offset losses incurred in the worse-hit global automotive sector.

Chemical companies in the mirror and anti-corrosive mirror coatings market are riding the crest of popularity in sustainable products that create low environmental impact such as low-VOC (volatile organic compound) coatings. They are increasing their innovation strength despite fluctuating supply and demand patterns in raw materials & products.

The mirror and anti-corrosive mirror coatings market is expected to reach the valuation of US$ 896.8 Mn by 2025. Even though aluminum mirror coatings are predicted to dominate the highest revenue share amongst all substrate types in the market, silver mirror coatings are anticipated to grow at an exponential CAGR during the forecast period.

Although in pure form aluminum can be weal, chemical treating and alloying processes drastically increase its strength. Aluminum mirror coatings are being used for military, aerospace, and defense applications. Silver mirror coatings, on the other hand, are being used for making telescopes. New mirror coating technologies are being developed by stakeholders for optical mirrors in new telescopes.

Solar thermal mirror coatings help to protect the invaluable parts of the system. Manufacturers in the mirror and anti-corrosive mirror coatings market are bolstering their production in these coatings to provide much-needed guarding against harsh environmental elements.

Intensive and precise reflection performance of solar thermal mirror coatings determines the efficiency of an entire solar power plant. However, efficiency and effectiveness of solar power plants are reduced, if conventional polymer corrosion protection coatings are used. Manufacturers are gaining awareness about proper and appropriate plasma coatings during the process of applying solar thermal mirror coatings. Companies in the mirror and anti-corrosive mirror coatings market are boosting production capabilities for nanocoatings or glass-like coating materials that offer corrosion protection that is reliable. These coatings are capable of offering long-term stability even at temperatures of a higher nature.

The mirror and anti-corrosive mirror coatings market is projected to reach a volume of 478.9 kilo tons by 2031. Clearlight Designs - a provider of custom illuminated mirrors and custom frosted glass for residential & commercial clients, is broadening its portfolio in corrosion-free mirrors to expand its revenue streams.

Since copper is found to tarnish over time, market stakeholders are increasing efforts to innovate in corrosion-free mirrors. The growing awareness about copper-free manufacturing processes in mirrors is helping to increase reflectivity and uncompromising durability in mirrors. Manufacturers are increasing the availability of mirrors that provide unparalleled protection against corrosion, chemicals, moisture, and abrasion.

Analysts’ Viewpoint

Companies are increasing their focus on green investments via government stimulus packages in order to meet the UN sustainable development goals during the coronavirus pandemic. The market is slated to clock a CAGR of 6.1% during the forecast period. Even as aluminum mirror coatings dictate the highest revenue share among all substrate types in the mirror and anti-corrosive mirror coatings market, current telescopes are witnessing dramatic increase in efficiency and reflectiveness by switching from aluminum coatings to new silver coatings. Corrosion-free mirrors are helping to increase reflectivity in various end-use cases. Photovoltaic systems are fueling the demand for mirror and anti-corrosive mirror coatings.

1. Executive Summary

1.1. Mirror and Anti-corrosive Mirror Coatings Market Snapshot

1.2. Current Market and Future Potential

2. Market Overview

2.1. Market Segmentation

2.2. Market Indicators

2.3. Market Dynamics

2.3.1. Drivers

2.3.2. Restraints

2.3.3. Opportunities

2.4. Porter’s Five Forces Analysis

2.5. Regulatory Analysis

2.6. Value Chain Analysis

2.6.1. List of Potential Customers

2.6.2. List of Suppliers/Manufacturers

3. COVID-19 Impact Analysis

4. Production Output Analysis

5. Price Trend Analysis

6. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Resin Type, 2016-2025

6.1. Introduction and Definitions

6.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

6.2.1. Polyurethane Mirror and Anti-corrosive Mirror Coatings

6.2.2. Epoxy Mirror and Anti-corrosive Mirror Coatings

6.2.3. Acrylic Mirror and Anti-corrosive Mirror Coatings

6.2.4. Others

6.3. Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness, by Resin Type

7. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Technology, 2016–2025

7.1. Introduction and Definitions

7.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

7.2.1. Solvent-based

7.2.2. Water-based

7.2.3. Others

8. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Substrate, 2016–2025

8.1. Introduction and Definitions

8.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate , 2016–2025

8.2.1. Silver

8.2.2. Aluminum

8.2.3. Others

9. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by VOC Type, 2016–2025

9.1. Introduction and Definitions

9.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

9.2.1. Low VOC

9.2.2. No VOC

10. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Coating Type, 2016–2025

10.1. Introduction and Definitions

10.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

10.2.1. With Lead/Copper

10.2.2. Without Lead/Copper

11. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Application, 2016–2025

11.1. Introduction and Definitions

11.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

11.2.1. Architectural

11.2.2. Automotive & Transportation

11.2.3. Solar Power

11.2.4. Decorative

11.2.5. Others

11.3. Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness, by Application

12. Global Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, by Region, 2016–2025

12.1. Key Findings

12.2. Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Region, 2016–2025

12.2.1. North America

12.2.2. Europe

12.2.3. Asia Pacific

12.2.4. Latin America

12.2.5. Middle East & Africa

12.3. Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness, by Region

13. North America Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, 2016–2025

13.1. Key Findings

13.2. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

13.3. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

13.4. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

13.5. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

13.6. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

13.7. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

13.8. North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Country, 2016–2025

13.8.1. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

13.8.2. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

13.8.3. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

13.8.4. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

13.8.5. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

13.8.6. U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

13.8.7. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

13.8.8. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

13.8.9. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

13.8.10. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

13.8.11. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

13.8.12. Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

13.9. North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis

14. Europe Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, 2016–2025

14.1. Key Findings

14.2. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.3. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.4. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.5. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.6. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.7. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8. Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

14.8.1. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.2. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.3. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.4. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.5. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.8.6. Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.7. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.8. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.9. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.10. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.11. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Type, 2016–2025

14.8.12. France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.13. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.14. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.15. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.16. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.17. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.8.18. U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.19. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.20. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.21. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.22. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.23. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.8.24. Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.25. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.26. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.27. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.28. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.29. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.8.30. Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.31. Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.32. Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.33. Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

14.8.34. Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.8.35. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

14.8.36. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

14.8.37. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate , 2016–2025

14.8.38. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

14.8.39. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

14.8.40. Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

14.9. Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis

15. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, 2016–2025

15.1. Key Findings

15.2. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.3. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.4. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.5. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.6. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.7. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.8. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

15.8.1. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.8.2. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.8.3. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.8.4. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.8.5. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.8.6. China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.8.7. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.8.8. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.8.9. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.8.10. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.8.11. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.8.12. Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.8.13. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.8.14. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.8.15. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.8.16. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.8.17. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.8.18. India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.8.19. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.8.20. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.8.21. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.8.22. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.8.23. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.8.24. ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.8.25. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

15.8.26. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

15.8.27. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

15.8.28. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

15.8.29. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

15.8.30. Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

15.9. Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis

16. Latin America Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, 2016–2025

16.1. Key Findings

16.2. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

16.3. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

16.4. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

16.5. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

16.6. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

16.7. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

16.8. Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

16.8.1. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

16.8.2. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

16.8.3. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

16.8.4. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

16.8.5. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

16.8.6. Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

16.8.7. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

16.8.8. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

16.8.9. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

16.8.10. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

16.8.11. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

16.8.12. Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

16.8.13. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

16.8.14. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

16.8.15. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

16.8.16. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

16.8.17. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

16.8.18. Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

16.9. Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis

17. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Analysis and Forecast, 2016–2025

17.1. Key Findings

17.2. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

17.3. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

17.4. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

17.5. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

17.6. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

17.7. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

17.8. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

17.8.1. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

17.8.2. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

17.8.3. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

17.8.4. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

17.8.5. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

17.8.6. GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

17.8.7. South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

17.8.8. South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

17.8.9. South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

17.8.10. South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

17.8.11. South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

17.8.12. South Africa Mirror and Anti-corrosive Mirror Coatings s Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

17.8.13. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Resin Type, 2016–2025

17.8.14. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Technology, 2016–2025

17.8.15. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Substrate, 2016–2025

17.8.16. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by VOC Type, 2016–2025

17.8.17. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Coating Type, 2016–2025

17.8.18. Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) and Value (US$ Mn) Forecast, by Application, 2016–2025

17.9. Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis

18. Competition Landscape

18.1. Global Mirror and Anti-corrosive Mirror Coatings Company Market Share Analysis, 2020

18.2. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

18.2.1. FENZI S.p.A.

18.2.1.1. Company Description

18.2.1.2. Technology Overview

18.2.1.3. Financial Overview

18.2.1.4. Strategic Overview

18.2.2. Thorlabs Inc.

18.2.2.1. Company Description

18.2.2.2. Technology Overview

18.2.2.3. Financial Overview

18.2.2.4. Strategic Overview

18.2.3. JENOPTIK

18.2.3.1. Company Description

18.2.3.2. Technology Overview

18.2.3.3. Financial Overview

18.2.3.4. Strategic Overview

18.2.4. Dynasil Corporation

18.2.4.1. Company Description

18.2.4.2. Technology Overview

18.2.4.3. Financial Overview

18.2.4.4. Strategic Overview

18.2.5. Tianjin Xin Lihua Color Materials Co., Ltd

18.2.5.1. Company Description

18.2.5.2. Technology Overview

18.2.5.3. Financial Overview

18.2.5.4. Strategic Overview

18.2.6. AGC Inc

18.2.6.1. Company Description

18.2.6.2. Technology Overview

18.2.6.3. Financial Overview

18.2.6.4. Strategic Overview

18.2.7. The Sherwin-Williams Company

18.2.7.1. Company Description

18.2.7.2. Technology Overview

18.2.7.3. Financial Overview

18.2.7.4. Strategic Overview

18.2.8. Newport Thin Film Laboratory, Inc.

18.2.8.1. Company Description

18.2.8.2. Technology Overview

18.2.8.3. Financial Overview

18.2.8.4. Strategic Overview

18.2.9. AccuCoat inc.

18.2.9.1. Company Description

18.2.9.2. Technology Overview

18.2.9.3. Financial Overview

18.2.9.4. Strategic Overview

18.2.10. Evaporated Coatings, Inc.

18.2.10.1. Company Description

18.2.10.2. Technology Overview

18.2.10.3. Financial Overview

18.2.10.4. Strategic Overview

18.2.11. Materion Corporation

18.2.11.1. Company Description

18.2.11.2. Technology Overview

18.2.11.3. Financial Overview

18.2.11.4. Strategic Overview

19. Primary Research: Key Insights

20. Appendix

List Of Table

Table 1: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 2: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 3: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 4: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 5: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 6: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate 2016–2025

Table 7: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 8: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 9: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 10: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 11: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 12: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 13: Global Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Region, 2016–2025

Table 14: Global Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Region, 2016–2025

Table 15: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 16: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 17: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 18: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 19: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 20: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 21: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 22: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 23: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 24: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 25: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application 2016–2025

Table 26: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application 2016–2025

Table 27: North America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Country, 2016–2025

Table 28: North America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Country, 2016–2025

Table 29: U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 30: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 31: U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 32: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 33: U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 34: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 35: U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 36: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 37: U.S. Mir and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 38: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 39: U.S. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 40: U.S. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 41: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 42: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 43: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 44: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 45: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 46: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 47: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 48: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 49: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 50: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 51: Canada Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 52: Canada Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 53: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 54: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 55: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 56: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 57: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 58: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 59: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 60: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 61: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 62: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 63: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 64: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 65: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Country and Sub-region, 2016–2025

Table 66: Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

Table 67: Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 68: Germany Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 69: Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 70: Germany Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 71: Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 72: Germany Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 73: Germany Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 74: Germany Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 75: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 76: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 77: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 78: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 79: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 80: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 81: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 82: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 83: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 84: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 85: France Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 86: France Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 87: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 88: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (Tons) Forecast, by Resin Type, 2016–2025

Table 89: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 90: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 91: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 92: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 93: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 94: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 95: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 96: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 97: U.K. Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 98: U.K. Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 99: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 100: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 101: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 102: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 103: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 104: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 105: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 106: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 107: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 108: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 109: Italy Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 110: Italy Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 111: Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 112: Spain Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 113: Spain Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 114: Spain Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 115: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 116: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 117: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 118: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (Tons) Forecast, by Technology, 2016–2025

Table 119: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 120: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (Tons) Forecast, by Substrate, 2016–2025

Table 121: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 122: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (Tons) Forecast, by VOC Type, 2016–2025

Table 123: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 124: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (Tons) Forecast, by Coating Type, 2016–2025

Table 125: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 126: Russia & CIS Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 127: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 128: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 129: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 130: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 131: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 132: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 133: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 134: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 135: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 136: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 137: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 138: Rest of Europe Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 139: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 140: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 141: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 142: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 143: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 144: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 145: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 146: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 147: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 148: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, byCoating Type, 2016–2025

Table 149: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 150: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 151: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Country and Sub-region, 2016–2025

Table 152: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

Table 153: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 154: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 155: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 156: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 157: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 158: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 159: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 160: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 161: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 162: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 163: China Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 164: China Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 165: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 166: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 167: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 168: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 169: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 170: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 171: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 172: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 173: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 174: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 175: Japan Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 176: Japan Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 177: India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 178: India Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 179: India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 180: India Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 181: India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 182: India Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 183: India Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 184: India Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 185: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 186: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 187: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 188: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 189: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 190: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 191: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 192: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 193: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 194: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 195: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 196: ASEAN Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 197: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 198: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 199: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 200: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 201: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 202: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 203: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 204: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 205: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 206: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 207: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 208: Rest of Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 209: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 210: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 211: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 212: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 213: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 214: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 215: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 216: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, byVOC Type, 2016–2025

Table 217: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 218: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 219: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 220: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 221: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Country and Sub-region, 2016–2025

Table 222: Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

Table 223: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 224: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 225: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 226: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 227: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 228: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 229: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 230: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 231: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 232: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 233: Brazil Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 234: Brazil Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 235: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 236: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 237: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 238: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 239: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 240: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 241: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 242: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 243: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 244: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 245: Mexico Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application 2016–2025

Table 246: Mexico Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application 2016–2025

Table 247: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 248: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 249: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 250: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 251: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 252: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate, 2016–2025

Table 253: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 254: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 255: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 256: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 257: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 258: Rest of Latin America Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 259: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 260: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 261: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 262: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 263: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 264: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate 2016–2025

Table 265: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 266: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 267: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 268: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 269: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 270: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 271: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Country and Sub-region, 2016–2025

Table 272: Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Country and Sub-region, 2016–2025

Table 273: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 274: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 275: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 276: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 277: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 278: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 279: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 280: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 281: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 282: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 283: GCC Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 284: GCC Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 285: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 286: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 287: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 288: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 289: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate , 2016–2025

Table 290: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 291: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 292: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 293: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 294: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 295: South Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 296: South Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

Table 297: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Resin Type, 2016–2025

Table 298: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Resin Type, 2016–2025

Table 299: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Technology, 2016–2025

Table 300: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Technology, 2016–2025

Table 301: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Substrate, 2016–2025

Table 302: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Substrate , 2016–2025

Table 303: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by VOC Type, 2016–2025

Table 304: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by VOC Type, 2016–2025

Table 305: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Coating Type, 2016–2025

Table 306: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Coating Type, 2016–2025

Table 307: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Volume (Tons) Forecast, by Application, 2016–2025

Table 308: Rest of Middle East & Africa Mirror and Anti-corrosive Mirror Coatings Market Value (US$ Mn) Forecast, by Application, 2016–2025

List of Figures

Figure 1: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Resin Type, 2020, 2025, and 2031

Figure 2: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Resin Type

Figure 3: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Technology, 2020, 2025, and 2031

Figure 4: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Technology

Figure 5: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate 2020, 2025, and 2031

Figure 6: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 7: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by VOC Type, 2020, 2025, and 2031

Figure 8: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by VOC Type

Figure 9: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Coating Type, 2020, 2025, and 2031

Figure 10: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Coating Type

Figure 11: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Application, 2020, 2025, and 2031

Figure 12: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Application

Figure 13: Global Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 14: Global Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Region

Figure 15: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Resin Type, 2020, 2025, and 2031

Figure 16: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Resin Type

Figure 17: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Technology, 2020, 2025, and 2031

Figure 18: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Technology

Figure 19: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate, 2020, 2025, and 2031

Figure 20: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 21: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by VOC Type, 2020, 2025, and 2031

Figure 22: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by VOC Type

Figure 23: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Coating Type, 2020, 2025, and 2031

Figure 24: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Coating Type

Figure 25: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Application, 2020, 2025, and 2031

Figure 26: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Application

Figure 27: North America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 28: North America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Country

Figure 29: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Resin Type, 2020, 2025, and 2031

Figure 30: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Resin Type

Figure 31: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Technology, 2020, 2025, and 2031

Figure 32: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Technology

Figure 33: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by VOC Type, 2020, 2025, and 2031

Figure 34: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Co Type

Figure 35: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate , 2020, 2025, and 2031

Figure 36: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 37: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate , 2020, 2025, and 2031

Figure 38: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 39: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Application, 2020, 2025, and 2031

Figure 40: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Application

Figure 41: Europe Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 42: Europe Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 43: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Resin Type, 2020, 2025, and 2031

Figure 44: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Resin Type

Figure 45: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Technology, 2020, 2025, and 2031

Figure 46: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Technology

Figure 47: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate , 2020, 2025, and 2031

Figure 48: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 49: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by VOC Type, 2020, 2025, and 2031

Figure 50: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by VOC Type

Figure 51: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Coating Type, 2020, 2025, and 2031

Figure 52: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Coating Type

Figure 53: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Application, 2020, 2025, and 2031

Figure 54: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness, by Application

Figure 55: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 56: Asia Pacific Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Country and Sub-region

Figure 57: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Resin Type, 2020, 2025, and 2031

Figure 58: Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Resin Type

Figure 59: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Technology, 2020, 2025, and 2031

Figure 60: Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness, by Technology

Figure 61: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Substrate, 2020, 2025, and 2031

Figure 62: Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Substrate

Figure 63: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by VOC Type, 2020, 2025, and 2031

Figure 64: Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by VOC Type

Figure 65: Latin America Mirror and Anti-corrosive Mirror Coatings Market Volume Share Analysis, by Coating Type, 2020, 2025, and 2031

Figure 66: Latin America Mirror and Anti-corrosive Mirror Coatings Market Attractiveness Analysis, by Coating Type