Reports

Reports

The COVID-19 pandemic has caused distress to the global friction pads market. The shortage in raw materials due to the supply chain disruptions have led to the volatility in the friction pads market. The lockdown restrictions forced manufacturing units and production units to shut down for a brief period.

One of the recent examples of an impromptu shut down due to the pandemic was TMD Friction, a leading manufacturer of friction pads in the U.K. Nearly 15% of the staff was forced into isolation after the National Health Service (NHS) application notification of being in close contact with a COVID-19 positive individuals. These factors have had a negative impact on the growth of the friction pads market.

However, a change in the self-isolation rules is a welcoming move. The U.K. Government recently tweaked self-isolation rules to avoid partial shutdowns such as TMD friction. The changes state that fully vaccinated people do not have to isolate if they come in close contact with any COVID-19 positive individuals. These factors will help in stabilizing the growth structure of the market.

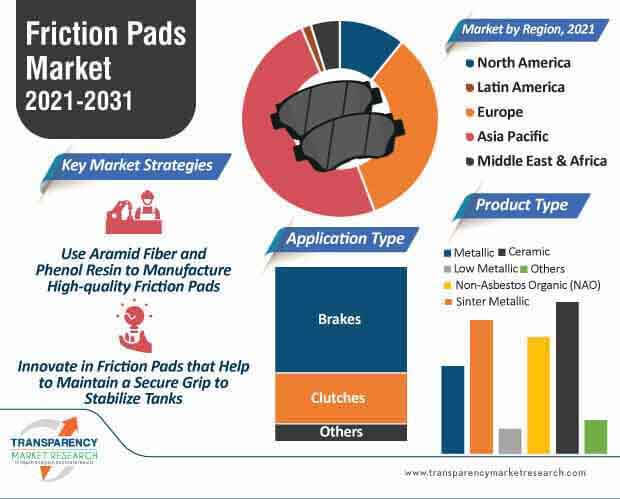

Transparency Market Research study on the friction pads market projects the global market to expand at a CAGR of 4.4% during the forecast period of 2021-2031. The friction pads market is expected to cross the valuation of US$ 7.97 Bn by 2031.

The wave of sustainability has touched almost all sectors, including the friction pads market. The use of eco-friendly materials in developing friction pads has gained considerable traction. These pads are formulated without the use of materials such as antimony trisulfide, copper, lead, and others. The demand for such pads is anticipated to drive the friction pads market.

Electric vehicles sales are increasing at a rapid rate around the world. These cars use regenerative braking mechanism. This mechanism enables to recuperate braking energy. With regenerative braking, the kinetic energy of a vehicle is converted into electrical energy. Thus, these factors are increasing the growth rate of the friction pads market. The San Francisco Municipal Transportation Agency has recently ordered 30 El Dorado hybrid buses equipped with regenerative braking. Almost all electric vehicles use this technology. Therefore, these aspects will strengthen the growth structure of the friction pads market.

Sintered friction pads are prominently used in high-energy applications. Off-road vehicles use these brakes due to their beneficial properties such as enhanced fade resistance, extended life, and superior wet-effectiveness. The rising urbanization in various countries is leading to increase in construction activities. STVs and ATVs are utilized at construction sites. In addition, recreational sports activities involving off-road vehicles have gathered considerable popularity, eventually boosting the demand for sintered friction pads.

Analysts’ Viewpoint

The friction pads market is projected to expand at a modest CAGR of 4.4% during the forecast period of 2021-2031. The emergence of eco-friendly friction pads will offer novel growth prospects for the global market. Furthermore, manufacturers in the friction pads market are focusing on strategic collaborations, which will serve as a growth-boosting factor. The booming electric vehicle industry also creates profitable growth opportunities due to the regenerative braking mechanism. Manufacturers should focus on developing technologically advanced friction pads that offer more convenience. However, the growing adoption of frictionless technologies might dent the growth trajectory of the friction pads market to a considerable extent.

Increase in Automobile Production: Key Driver of Friction Pads Market

Ceramic Product Type Dominates Friction Pads Market

Friction Pads Market: Competition Landscape

1. Executive Summary

1.1. Friction Pads Market Snapshot

1.2. Current Market and Future Potential

2. Market Overview

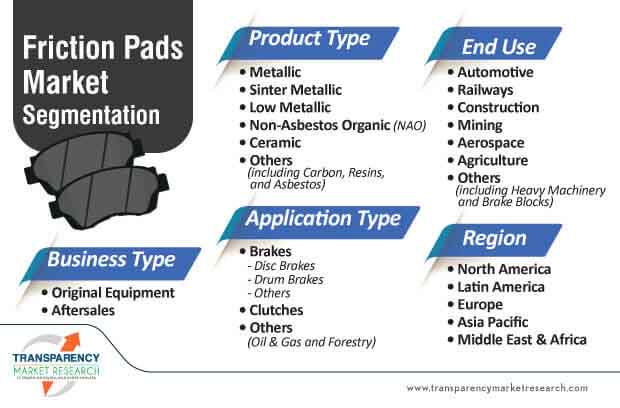

2.1. Market Segmentation

2.2. Market Indicators

2.3. Market Dynamics

2.3.1. Drivers

2.3.2. Restraints

2.3.3. Opportunities

2.4. Porter’s Five Forces Analysis

2.5. Regulatory Analysis

2.6. Value Chain Analysis

2.6.1. List of Potential Customers

2.6.2. List of Suppliers/Manufacturers

3. COVID-19 Impact Analysis

4. Production Output Analysis

5. Price Trend Analysis

6. Global Friction Pads Market Analysis and Forecast, by Product Type, 2020–2031

6.1. Introduction and Definitions

6.2. Global Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

6.2.1. Metallic Friction Pads

6.2.2. Sinter Metallic Friction Pads

6.2.3. Low Metallic Friction Pads

6.2.4. Non-Asbestos Organic (NAO)

6.2.5. Ceramic

6.2.6. Others

6.3. Global Friction Pads Market Attractiveness, by Product Type

7. Global Friction Pads Market Analysis and Forecast, by Business Type, 2020–2031

7.1. Introduction and Definitions

7.2. Global Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

7.2.1. Original Equipment

7.2.2. Aftersales

8. Global Friction Pads Market Analysis and Forecast, by Application Type, 2020–2031

8.1. Introduction and Definitions

8.2. Global Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

8.2.1. Brakes

8.2.2. Disc Brakes

8.2.2.1. Drum Brakes

8.2.2.2. Others

8.2.3. Clutches

8.2.4. Others

9. Global Friction Pads Market Analysis and Forecast, by End-use, 2020–2031

9.1. Introduction and Definitions

9.2. Global Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

9.2.1. Automotive

9.2.2. Railways

9.2.3. Construction

9.2.4. Mining

9.2.5. Aerospace

9.2.6. Agriculture

9.2.7. Others

9.3. Global Friction Pads Market Attractiveness, by End-use

10. Global Friction Pads Market Analysis and Forecast, by Region, 2020–2031

10.1. Key Findings

10.2. Global Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Region, 2020–2031

10.2.1. North America

10.2.2. Europe

10.2.3. Asia Pacific

10.2.4. Latin America

10.2.5. Middle East & Africa

10.3. Global Friction Pads Market Attractiveness, by Region

11. North America Friction Pads Market Analysis and Forecast, 2020–2031

11.1. Key Findings

11.2. North America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

11.3. North America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

11.4. North America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

11.5. North America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

11.6. North America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Country, 2020–2031

11.6.1. U.S. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

11.6.2. U.S. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

11.6.3. U.S. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

11.6.4. U.S. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

11.6.5. Canada Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

11.6.6. Canada Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

11.6.7. Canada Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

11.6.8. Canada Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

11.7. North America Friction Pads Market Attractiveness Analysis

12. Europe Friction Pads Market Analysis and Forecast, 2020–2031

12.1. Key Findings

12.2. Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.3. Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.4. Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.5. Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6. Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

12.6.1. Germany Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.2. Germany Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.3. Germany Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.4. Germany Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.5. France Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.6. France Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.7. France Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.8. France Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.9. U.K. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.10. U.K. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.11. U.K. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.12. U.K. Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.13. Italy Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.14. Italy Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.15. Italy Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.16. Italy Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.17. Spain Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.18. Spain Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.19. Spain Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.20. Spain Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.21. Russia & CIS Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.22. Russia & CIS Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.23. Russia & CIS Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.24. Russia & CIS Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.6.25. Rest of Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

12.6.26. Rest of Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

12.6.27. Rest of Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

12.6.28. Rest of Europe Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

12.7. Europe Friction Pads Market Attractiveness Analysis

13. Asia Pacific Friction Pads Market Analysis and Forecast, 2020–2031

13.1. Key Findings

13.2. Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.3. Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.4. Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.5. Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.6. Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

13.6.1. China Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.6.2. China Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.6.3. China Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.6.4. China Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.6.5. Japan Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.6.6. Japan Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.6.7. Japan Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.6.8. Japan Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.6.9. India Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.6.10. India Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.6.11. India Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.6.12. India Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.6.13. ASEAN Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.6.14. ASEAN Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.6.15. ASEAN Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.6.16. ASEAN Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.6.17. Rest of Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

13.6.18. Rest of Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

13.6.19. Rest of Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

13.6.20. Rest of Asia Pacific Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

13.7. Asia Pacific Friction Pads Market Attractiveness Analysis

14. Latin America Friction Pads Market Analysis and Forecast, 2020–2031

14.1. Key Findings

14.2. Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

14.3. Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

14.4. Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

14.5. Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

14.6. Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

14.6.1. Brazil Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

14.6.2. Brazil Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

14.6.3. Brazil Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

14.6.4. Brazil Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

14.6.5. Mexico Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

14.6.6. Mexico Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

14.6.7. Mexico Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

14.6.8. Mexico Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

14.6.9. Rest of Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

14.6.10. Rest of Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

14.6.11. Rest of Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

14.6.12. Rest of Latin America Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

14.7. Latin America Friction Pads Market Attractiveness Analysis

15. Middle East & Africa Friction Pads Market Analysis and Forecast, 2020–2031

15.1. Key Findings

15.2. Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

15.3. Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

15.4. Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

15.5. Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

15.6. Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Country and Sub-region, 2020-2031

15.6.1. GCC Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

15.6.2. GCC Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

15.6.3. GCC Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

15.6.4. GCC Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

15.6.5. South Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

15.6.6. South Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

15.6.7. South Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

15.6.8. South Africa Friction Pads s Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

15.6.9. Rest of Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Product Type, 2020–2031

15.6.10. Rest of Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Business Type, 2020–2031

15.6.11. Rest of Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by Application Type, 2020–2031

15.6.12. Rest of Middle East & Africa Friction Pads Market Volume (Units) and Value (US$ Mn) Forecast, by End-use, 2020–2031

15.7. Middle East & Africa Friction Pads Market Attractiveness Analysis

16. Competition Landscape

16.1. Global Friction Pads Company Market Share Analysis, 2020

16.2. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

16.2.1. AKEBONO BRAKE INDUSTRY CO., LTD.

16.2.1.1. Company Description

16.2.1.2. Business Overview

16.2.1.3. Financial Overview

16.2.1.4. Strategic Overview

16.2.2. AISIN CORPORATION

16.2.2.1. Company Description

16.2.2.2. Business Overview

16.2.2.3. Financial Overview

16.2.2.4. Strategic Overview

16.2.3. Robert Bosch GmbH

16.2.3.1. Company Description

16.2.3.2. Business Overview

16.2.3.3. Financial Overview

16.2.3.4. Strategic Overview

16.2.4. ACDelco

16.2.4.1. Company Description

16.2.4.2. Business Overview

16.2.4.3. Financial Overview

16.2.4.4. Strategic Overview

16.2.5. ASIMCO

16.2.5.1. Company Description

16.2.5.2. Business Overview

16.2.5.3. Financial Overview

16.2.5.4. Strategic Overview

16.2.6. EBC Brakes

16.2.6.1. Company Description

16.2.6.2. Business Overview

16.2.6.3. Financial Overview

16.2.6.4. Strategic Overview

16.2.7. ZF Friedrichshafen AG

16.2.7.1. Company Description

16.2.7.2. Business Overview

16.2.7.3. Financial Overview

16.2.7.4. Strategic Overview

16.2.8. Brake Parts Inc LLC (BPI)

16.2.8.1. Company Description

16.2.8.2. Business Overview

16.2.8.3. Financial Overview

16.2.8.4. Strategic Overview

16.2.9. Brembo S.p.A.

16.2.9.1. Company Description

16.2.9.2. Business Overview

16.2.9.3. Financial Overview

16.2.9.4. Strategic Overview

16.2.10. Japan Brake Industrial Co., Ltd

16.2.10.1. Company Description

16.2.10.2. Business Overview

16.2.10.3. Financial Overview

16.2.10.4. Strategic Overview

16.2.11. ASK Automotive Pvt. Ltd

16.2.11.1. Company Description

16.2.11.2. Business Overview

16.2.11.3. Financial Overview

16.2.11.4. Strategic Overview

16.2.12. Nisshinbo Brake Inc.

16.2.12.1. Company Description

16.2.12.2. Business Overview

16.2.12.3. Financial Overview

16.2.12.4. Strategic Overview

16.2.13. MACAS Automotive

16.2.13.1. Company Description

16.2.13.2. Business Overview

16.2.13.3. Financial Overview

16.2.13.4. Strategic Overview

17. Primary Research: Key Insights

18. Appendix

List of Tables

Table 1: Global Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 2: Global Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 3: Global Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 4: Global Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 5: Global Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 6: Global Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 7: Global Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 8: Global Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 9: Global Friction Pads Market Volume (Units) Forecast, by Region, 2020–2031

Table 10: Global Friction Pads Market Value (US$ Mn) Forecast, by Region, 2020–2031

Table 11: North America Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 12: North America Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 13: North America Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 14: North America Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 15: North America Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 16: North America Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 17: North America Friction Pads Market Volume (Units) Forecast, by End-use 2020–2031

Table 18: North America Friction Pads Market Value (US$ Mn) Forecast, by End-use 2020–2031

Table 19: North America Friction Pads Market Volume (Units) Forecast, by Country, 2020–2031

Table 20: North America Friction Pads Market Value (US$ Mn) Forecast, by Country, 2020–2031

Table 21: U.S. Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 22: U.S. Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 23: U.S. Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 24: U.S. Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 25: U.S. Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 26: U.S. Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 27: U.S. Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 28: U.S. Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 29: Canada Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 30: Canada Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 31: Canada Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 32: Canada Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 33: Canada Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 34: Canada Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 35: Canada Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 36: Canada Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 37: Europe Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 38: Europe Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 39: Europe Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 40: Europe Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 41: Europe Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 42: Europe Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 43: Europe Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 44: Europe Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 45: Europe Friction Pads Market Volume (Units) Forecast, by Country and Sub-region, 2020–2031

Table 46: Europe Friction Pads Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 47: Germany Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 48: Germany Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 49: Germany Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 50: Germany Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 51: Germany Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 52: Germany Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 53: Germany Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 54: Germany Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 55: France Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 56: France Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 57: France Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 58: France Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 59: France Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 60: France Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 61: France Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 62: France Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 63: U.K. Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 64: U.K. Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 65: U.K. Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 66: U.K. Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 67: U.K. Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 68: U.K. Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 69: U.K. Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 70: U.K. Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 71: Italy Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 72: Italy Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 73: Italy Friction Pads Market Volume (Units) Forecast, by Business Type , 2020–2031

Table 74: Italy Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 75: Italy Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 76: Italy Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 77: Italy Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 78: Italy Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 79: Spain Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 80: Spain Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 81: Spain Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 82: Spain Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 83: Russia & CIS Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 84: Russia & CIS Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 85: Russia & CIS Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 86: Russia & CIS Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 87: Russia & CIS Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 88: Russia & CIS Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 89: Russia & CIS Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 90: Russia & CIS Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 91: Rest of Europe Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 92: Rest of Europe Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 93: Rest of Europe Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 94: Rest of Europe Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 95: Rest of Europe Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 96: Rest of Europe Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 97: Rest of Europe Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 98: Rest of Europe Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 99: Asia Pacific Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 100: Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 101: Asia Pacific Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 102: Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 103: Asia Pacific Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 104: Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 105: Asia Pacific Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 106: Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 107: Asia Pacific Friction Pads Market Volume (Units) Forecast, by Country and Sub-region, 2020–2031

Table 108: Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 109: China Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 110: China Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 111: China Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 112: China Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 113: China Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 114: China Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 115: China Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 116: China Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 117: Japan Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 118: Japan Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 119: Japan Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 120: Japan Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 121: Japan Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 122: Japan Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 123: Japan Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 124: Japan Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 125: India Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 126: India Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 127: India Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 128: India Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 129: India Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 130: India Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 131: India Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 132: India Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 133: ASEAN Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 134: ASEAN Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 135: ASEAN Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 136: ASEAN Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 137: ASEAN Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 138: ASEAN Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 139: ASEAN Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 140: ASEAN Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 141: Rest of Asia Pacific Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 142: Rest of Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 143: Rest of Asia Pacific Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 144: Rest of Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 145: Rest of Asia Pacific Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 146: Rest of Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 147: Rest of Asia Pacific Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 148: Rest of Asia Pacific Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 149: Latin America Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 150: Latin America Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 151: Latin America Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 152: Latin America Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 153: Latin America Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 154: Latin America Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 155: Latin America Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 156: Latin America Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 157: Latin America Friction Pads Market Volume (Units) Forecast, by Country and Sub-region, 2020–2031

Table 158: Latin America Friction Pads Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 159: Brazil Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 160: Brazil Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 161: Brazil Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 162: Brazil Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 163: Brazil Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 164: Brazil Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 165: Brazil Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 166: Brazil Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 167: Mexico Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 168: Mexico Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 169: Mexico Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 170: Mexico Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 171: Mexico Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 172: Mexico Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 173: Mexico Friction Pads Market Volume (Units) Forecast, by End-use 2020–2031

Table 174: Mexico Friction Pads Market Value (US$ Mn) Forecast, by End-use 2020–2031

Table 175: Rest of Latin America Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 176: Rest of Latin America Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 177: Rest of Latin America Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 178: Rest of Latin America Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 179: Rest of Latin America Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 180: Rest of Latin America Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 181: Rest of Latin America Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 182: Rest of Latin America Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 183: Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 184: Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 185: Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 186: Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 187: Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 188: Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 189: Middle East & Africa Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 190: Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 191: Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Country and Sub-region, 2020–2031

Table 192: Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Country and Sub-region, 2020–2031

Table 193: GCC Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 194: GCC Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 195: GCC Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 196: GCC Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 197: GCC Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 198: GCC Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 199: GCC Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 200: GCC Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 201: South Africa Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 202: South Africa Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 203: South Africa Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 204: South Africa Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 205: South Africa Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 206: South Africa Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 207: South Africa Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 208: South Africa Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

Table 209: Rest of Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Product Type, 2020–2031

Table 210: Rest of Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Product Type, 2020–2031

Table 211: Rest of Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Business Type, 2020–2031

Table 212: Rest of Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Business Type, 2020–2031

Table 213: Rest of Middle East & Africa Friction Pads Market Volume (Units) Forecast, by Application Type, 2020–2031

Table 214: Rest of Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by Application Type, 2020–2031

Table 215: Rest of Middle East & Africa Friction Pads Market Volume (Units) Forecast, by End-use, 2020–2031

Table 216: Rest of Middle East & Africa Friction Pads Market Value (US$ Mn) Forecast, by End-use, 2020–2031

List of Figures

Figure 1: Global Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 2: Global Friction Pads Market Attractiveness Analysis, by Product Type

Figure 3: Global Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 4: Global Friction Pads Market Attractiveness Analysis, by Business Type

Figure 5: Global Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 6: Global Friction Pads Market Attractiveness Analysis, by Application Type

Figure 7: Global Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 8: Global Friction Pads Market Attractiveness Analysis, by End-use

Figure 9: Global Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 10: Global Friction Pads Market Attractiveness Analysis, by Region

Figure 11: North America Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 12: North America Friction Pads Market Attractiveness Analysis, by Product Type

Figure 13: North America Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 14: North America Friction Pads Market Attractiveness Analysis, by Business Type

Figure 15: North America Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 16: North America Friction Pads Market Attractiveness Analysis, by Product Type

Figure 17: North America Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 18: North America Friction Pads Market Attractiveness Analysis, by End-use

Figure 19: North America Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 20: North America Friction Pads Market Attractiveness Analysis, by Country and Sub-region

Figure 21: Europe Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 22: Europe Friction Pads Market Attractiveness Analysis, by Product Type

Figure 23: Europe Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 24: Europe Friction Pads Market Attractiveness Analysis, by Business Type

Figure 25: Europe Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 26: Europe Friction Pads Market Attractiveness Analysis, by Application Type

Figure 27: Europe Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 28: Europe Friction Pads Market Attractiveness Analysis, by End-use

Figure 29: Europe Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 30: Europe Friction Pads Market Attractiveness Analysis, by Country and Sub-region

Figure 31: Asia Pacific Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 32: Asia Pacific Friction Pads Market Attractiveness Analysis, by Product Type

Figure 33: Asia Pacific Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 34: Asia Pacific Friction Pads Market Attractiveness Analysis, by Business Type

Figure 35: Asia Pacific Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 36: Asia Pacific Friction Pads Market Attractiveness Analysis, by Application Type

Figure 37: Asia Pacific Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 38: Asia Pacific Friction Pads Market Attractiveness, by End-use

Figure 39: Asia Pacific Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 40: Asia Pacific Friction Pads Market Attractiveness Analysis, by Country and Sub-region

Figure 41: Latin America Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 42: Latin America Friction Pads Market Attractiveness Analysis, by Product Type

Figure 43: Latin America Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 44: Latin America Friction Pads Market Attractiveness, by Business Type

Figure 45: Latin America Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 46: Latin America Friction Pads Market Attractiveness Analysis, by Application Type

Figure 47: Latin America Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 48: Latin America Friction Pads Market Attractiveness Analysis, by End-use

Figure 49: Latin America Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 50: Latin America BMI Resins Market Attractiveness Analysis, by Country and Sub-region

Figure 51: Middle East & Africa Friction Pads Market Volume Share Analysis, by Product Type, 2020, 2025, and 2031

Figure 52: Middle East & Africa Friction Pads Market Attractiveness Analysis, by Product Type

Figure 53: Middle East & Africa Friction Pads Market Volume Share Analysis, by Business Type, 2020, 2025, and 2031

Figure 54: Middle East & Africa Friction Pads Market Attractiveness Analysis, by Business Type

Figure 55: Middle East & Africa Friction Pads Market Volume Share Analysis, by Application Type, 2020, 2025, and 2031

Figure 56: Middle East & Africa Friction Pads Market Attractiveness Analysis, by Application Type

Figure 57: Middle East & Africa Friction Pads Market Volume Share Analysis, by End-use, 2020, 2025, and 2031

Figure 58: Middle East & Africa Friction Pads Market Attractiveness Analysis, by End-use

Figure 59: Middle East & Africa Friction Pads Market Volume Share Analysis, by Region, 2020, 2025, and 2031

Figure 60: Middle East & Africa Friction Pads Market Attractiveness Analysis, by Country and Sub-region