Analyst Viewpoint

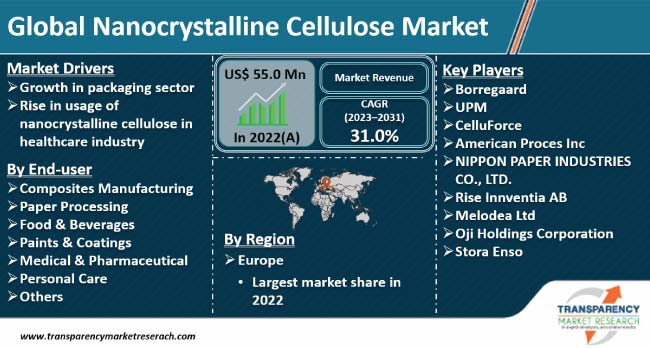

Rise in usage of nanocrystalline cellulose in various industries such as personal care, manufacturing, food & beverages, paper processing, and pharmaceuticals is driving the global nanocrystalline cellulose market size. Growth in the packaging sector, particularly food packaging, is also positively impacting market dynamics. Furthermore, nanocrystalline cellulose is employed in the healthcare sector, as it offers strong resistance to microbial contamination.

Producers of nanocrystalline cellulose are striving to adopt new and advanced techniques, such as ultrathin processing, in order to enhance their production processes. Modernization of production lines has also emerged as one of the key nanocrystalline cellulose market trends of late.

Nanocrystalline cellulose is a natural cellulose with a diameter of 10-9 meter (nanometer). It is a naturally occurring substance derived from the cellulose of wood and several plants.

The usage of nanocrystalline cellulose materials is increasing in various applications, including paper processing, composites production, and biomedical. This can be primarily ascribed to its exceptional qualities, which include high tensile strength, low density, and good thermal stability.

Large surface area of nanocrystalline cellulose is an important characteristic that allows it to interact effectively with surrounding components such as water, chemical molecules, and polymeric compounds.

Commercial nanocrystalline cellulose production methods incur high cost due to processes such as acid hydrolysis or enzymatic hydrolysis of cellulose fibrils. The final product, nanocrystalline cellulose, lacks an amorphous component in its structure.

Commercial manufacture of nanocrystalline cellulose is still in its early stage. Cost-effective production and processing procedures are required for large-scale commercial production of cellulose nanocrystals.

Nanocrystalline cellulose may also be manufactured from low-cost renewable biomass. Nanocrystalline cellulose reinforced biodegradable plastics are often employed as reinforcing ingredients in industrial biocomposites due to their low toxicity and negligible environmental risks.

Surge in applications of nanocrystalline cellulose in packaging can be largely ascribed to its benefits such as complete biodegradability. Rise in focus on manufacture of eco-friendly and sustainable nanocrystalline cellulose products in the packaging landscape is augmenting market progress. Nanocrystalline cellulose provides superior surface chemistry, biodegradability, biocompatibility, and lower toxicity.

Nanocrystalline cellulose is also employed in paper processing applications. It improves the fiber-to-fiber bond strength upon addition in paper products. Nanocrystalline cellulose can also be used as a barrier in grease-proof type papers. Thus, rise in usage of this natural cellulose in the manufacture of durable and sustainable paper-based packaging is fueling nanocrystalline cellulose market value.

As per nanocrystalline cellulose market insights, nanocrystalline cellulose (NCC) has earned considerable traction in medical and healthcare fields, owing to its unique features and potential critical uses. For instance, it is employed in medical implants, wound healing, cardiovascular disease therapy, antimicrobial or antibacterial activity limitation, drug delivery systems, and tissue engineering.

Cellulose nanowhiskers, made from NCC, can be used in wound dressings to improve their mechanical strength, flexibility, and absorbency. They can also act as scaffolds for cell development, which can help with tissue regeneration and wound healing.

Nanocrystalline cellulose can also be employed as a medicine delivery system carrier. It is used for controlled drug release due to its large surface area and capacity to encapsulate medicines. This improves therapeutic efficacy, while lowering adverse effects.

Nanocrystalline cellulose also possesses intrinsic antibacterial qualities that may be used to build antibacterial coatings for medical equipment, including catheters, implants, and surgical tools, in order to lower the risk of infection. Thus, increase in usage of nanocrystalline cellulose in the healthcare sector is augmenting the nanocrystalline cellulose market demand.

Europe dominates the global nanocrystalline cellulose market share in terms of volume. Rise in technical breakthroughs, advancements in personal care and pharmaceutical industries, and greater emphasis on biodegradable products are fueling market statistics in the region.

North America is also likely to hold key share of the global landscape, as per the nanocrystalline cellulose market forecast. This can be ascribed to the surge in demand for biodegradable products in the packaging sector in the U.S. and Canada.

Nanocrystalline cellulose industry analysis reveals that governments of several countries in Asia Pacific are increasing their investments in nanomaterial research and development activities. Of late, governments of Australia and Japan have started research and development programs to promote the manufacture of nanocrystalline cellulose on pilot and commercial sizes.

Producers of nanocrystalline cellulose are striving to achieve a competitive edge by investing in advanced and sophisticated technologies. Adoption of modern production techniques is likely to increase significantly in the nanocrystalline cellulose market in the near future. However, high production cost is hampering market expansion.

Of late, there has been a significant rise in research activities in nanocrystalline cellulose. Borregaard, UPM, CelluForce, American Process Inc, Nippon Paper Industries Co. Ltd., RISE Innventia AB, Melodea Ltd, Oji Holdings Corporation, and Stora Enso are prominent companies operating in the global landscape.

The nanocrystalline cellulose market research study summarizes these players based on parameters such as company profiles, financial overview, business strategies, business segments, and product portfolio.

| Attribute | Detail |

|---|---|

| Market Value in 2022 (Base Year) | US$ 55.0 Mn |

| Market Forecast Value in 2031 | US$ 628.2 Mn |

| Growth Rate (CAGR) | 31.0% |

| Forecast Period | 2023-2031 |

| Historical Data Available for | 2020–2022 |

| Quantitative Units | US$ Mn for Value and Kilograms for Volume |

| Market Analysis | Qualitative analysis includes drivers, restraints, opportunities, key trends, key market indicators, Porter’s Five Forces analysis, value chain analysis, and SWOT analysis. Furthermore, at the regional level, the qualitative analysis includes key trends, price trends, and key supplier analysis. |

| Competition Landscape |

|

| Format | Electronic (PDF) + Excel |

| Regions Covered |

|

| Countries Covered |

|

| Market Segmentation |

|

| Companies Profiled |

|

| Customization Scope | Available upon Request |

| Pricing | Available upon Request |

It was valued at US$ 55.0 Mn in 2022

It is likely to advance at a CAGR of 31.0% from 2023 to 2031

Growth in the packaging sector and rise in usage of nanocrystalline cellulose in the healthcare industry

The paper processing segment accounts for major share

Europe was the leading region in 2022

Borregaard, UPM, CelluForce, American Process Inc, Nippon Paper Industries Co. Ltd., RISE Innventia AB, Melodea Ltd, Oji Holdings Corporation, and Stora Enso

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Key Facts and Figures

1.4. Trends Impacting Market

1.5. TMR’s Growth Opportunity Wheel

2. Market Overview

2.1. Market Segmentation

2.2. Key Developments

2.3. Market Definitions

2.4. Key Market Trends

2.5. Market Dynamics

2.5.1. Drivers

2.5.2. Restraints

2.5.3. Opportunities

2.6. Global Nanocrystalline Cellulose Market Analysis and Forecast, 2023-2031

2.6.1. Global Nanocrystalline Cellulose Market Volume (Kilograms)

2.6.2. Global Nanocrystalline Cellulose Market Revenue (US$ Mn)

2.7. Porter’s Five Forces Analysis

2.8. Regulatory Landscape

2.9. Value Chain Analysis

2.9.1. List of Raw Material Suppliers

2.9.2. List of Key Manufacturers

2.9.3. List of Key Suppliers

2.9.4. List of Potential Customers

2.10. Product Specification Analysis

2.11. Production Overview

2.12. Cost Structure Analysis

3. COVID-19 Impact Analysis

3.1. Impact on Supply Chain of Nanocrystalline Cellulose

3.2. Impact on Demand for Nanocrystalline Cellulose – Pre & Post Crisis

4. Production Output Analysis, 2022

4.1. North America

4.2. Europe

4.3. Asia Pacific

4.4. Latin America

4.5. Middle East & Africa

5. Impact of Current Geopolitical Scenario on Market

6. Price Trend Analysis and Forecast (US$/Ton), 2023-2031

6.1. Price Trend Analysis by End-user

6.2. Price Trend Analysis by Region

7. Global Nanocrystalline Cellulose Market Analysis and Forecast, by End-user, 2023–2031

7.1. Introduction and Definitions

7.2. Global Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

7.2.1. Composites Manufacturing

7.2.2. Paper Processing

7.2.3. Food & Beverages

7.2.4. Paints & Coatings

7.2.5. Medical & Pharmaceutical

7.2.6. Personal Care

7.2.7. Others

7.3. Global Nanocrystalline Cellulose Market Attractiveness, by End-user

8. Global Nanocrystalline Cellulose Market Analysis and Forecast, by Region, 2023–2031

8.1. Key Findings

8.2. Global Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Region, 2023–2031

8.2.1. North America

8.2.2. Europe

8.2.3. Asia Pacific

8.2.4. Latin America

8.2.5. Middle East & Africa

8.3. Global Nanocrystalline Cellulose Market Attractiveness, by Region

9. North America Nanocrystalline Cellulose Market Analysis and Forecast, 2023–2031

9.1. Key Findings

9.2. North America Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

9.3. North America Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Country, 2023–2031

9.3.1. U.S. Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

9.3.2. Canada Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

9.4. North America Nanocrystalline Cellulose Market Attractiveness Analysis

10. Europe Nanocrystalline Cellulose Market Analysis and Forecast, 2023–2031

10.1. Key Findings

10.2. Europe Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.3. Europe Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

10.3.1. Germany Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Type, 2023–2031

10.3.2. France Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.3.3. U.K. Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.3.4. Italy Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.3.5. Russia & CIS Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.3.6. Rest of Europe Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

10.4. Europe Nanocrystalline Cellulose Market Attractiveness Analysis

11. Asia Pacific Nanocrystalline Cellulose Market Analysis and Forecast, 2023–2031

11.1. Key Findings

11.2. Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user

11.3. Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

11.3.1. China Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

11.3.2. Japan Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

11.3.3. India Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

11.3.4. ASEAN Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

11.3.5. Rest of Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

11.4. Asia Pacific Nanocrystalline Cellulose Market Attractiveness Analysis

12. Latin America Nanocrystalline Cellulose Market Analysis and Forecast, 2023–2031

12.1. Key Findings

12.2. Latin America Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

12.3. Latin America Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

12.3.1. Brazil Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

12.3.2. Mexico Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

12.3.3. Rest of Latin America Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

12.4. Latin America Nanocrystalline Cellulose Market Attractiveness Analysis

13. Middle East & Africa Nanocrystalline Cellulose Market Analysis and Forecast, 2023–2031

13.1. Key Findings

13.2. Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

13.3. Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by Country and Sub-region, 2022-2031

13.3.1. GCC Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

13.3.2. South Africa Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

13.3.3. Rest of Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) and Value (US$ Mn) Forecast, by End-user, 2023–2031

13.4. Middle East & Africa Nanocrystalline Cellulose Market Attractiveness Analysis

14. Competition Landscape

14.1. Global Nanocrystalline Cellulose Market Company Share Analysis, 2022

14.2. Company Profiles (Details – Overview, Financials, Recent Developments, and Strategy)

14.2.1. Borregaard

14.2.1.1. Company Revenue

14.2.1.2. Business Overview

14.2.1.3. Product Segments

14.2.1.4. Geographic Footprint

14.2.1.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.1.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.2. UPM

14.2.2.1. Company Revenue

14.2.2.2. Business Overview

14.2.2.3. Product Segments

14.2.2.4. Geographic Footprint

14.2.2.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.2.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.3. CelluForce

14.2.3.1. Company Revenue

14.2.3.2. Business Overview

14.2.3.3. Product Segments

14.2.3.4. Geographic Footprint

14.2.3.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.3.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.4. American Process Inc

14.2.4.1. Company Revenue

14.2.4.2. Business Overview

14.2.4.3. Product Segments

14.2.4.4. Geographic Footprint

14.2.4.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.4.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.5. NIPPON PAPER INDUSTRIES CO., LTD.

14.2.5.1. Company Revenue

14.2.5.2. Business Overview

14.2.5.3. Product Segments

14.2.5.4. Geographic Footprint

14.2.5.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.5.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.6. Rise Innventia AB

14.2.6.1. Company Revenue

14.2.6.2. Business Overview

14.2.6.3. Product Segments

14.2.6.4. Geographic Footprint

14.2.6.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.6.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.7. Melodea Ltd

14.2.7.1. Company Revenue

14.2.7.2. Business Overview

14.2.7.3. Product Segments

14.2.7.4. Geographic Footprint

14.2.7.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.7.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.8. Oji Holdings Corporation

14.2.8.1. Company Revenue

14.2.8.2. Business Overview

14.2.8.3. Product Segments

14.2.8.4. Geographic Footprint

14.2.8.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.8.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

14.2.9. Stora Enso

14.2.9.1. Company Revenue

14.2.9.2. Business Overview

14.2.9.3. Product Segments

14.2.9.4. Geographic Footprint

14.2.9.5. Production Capacity/Plant Details, etc. (*As Applicable)

14.2.9.6. Strategic Partnership, Capacity Expansion, New Product Innovation, etc.

15. Primary Research: Key Insights

16. Appendix

List of Tables

Table 1: Global Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 2: Global Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 3: Global Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Region, 2023–2031

Table 4: Global Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Region, 2023–2031

Table 5: North America Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 6: North America Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 7: North America Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Country, 2023–2031

Table 8: North America Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Country, 2023–2031

Table 9: U.S. Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 10: U.S. Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 11: Canada Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 12: Canada Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 13: Europe Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 14: Europe Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 15: Europe Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Country and Sub-region, 2023–2031

Table 16: Europe Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 17: Germany Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 18: Germany Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 19: France Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 20: France Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 21: U.K. Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 22: U.K. Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 23: Italy Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 24: Italy Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 25: Spain Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 26: Spain Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 27: Russia & CIS Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 28: Russia & CIS Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 29: Rest of Europe Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 30: Rest of Europe Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 31: Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 32: Asia Pacific Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 33: Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Country and Sub-region, 2023–2031

Table 34: Asia Pacific Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 35: China Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 36: China Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user 2023–2031

Table 37: Japan Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 38: Japan Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 39: India Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 40: India Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 41: ASEAN Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 42: ASEAN Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 43: Rest of Asia Pacific Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 44: Rest of Asia Pacific Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 45: Latin America Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 46: Latin America Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 47: Latin America Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Country and Sub-region, 2023–2031

Table 48: Latin America Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 49: Brazil Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 50: Brazil Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 51: Mexico Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 52: Mexico Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 53: Rest of Latin America Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 54: Rest of Latin America Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 55: Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 56: Middle East & Africa Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 57: Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by Country and Sub-region, 2023–2031

Table 58: Middle East & Africa Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by Country and Sub-region, 2023–2031

Table 59: GCC Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 60: GCC Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 61: South Africa Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 62: South Africa Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

Table 63: Rest of Middle East & Africa Nanocrystalline Cellulose Market Volume (Kilograms) Forecast, by End-user, 2023–2031

Table 64: Rest of Middle East & Africa Nanocrystalline Cellulose Market Value (US$ Mn) Forecast, by End-user, 2023–2031

List of Figures

Figure 1: Global Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 2: Global Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 3: Global Nanocrystalline Cellulose Market Volume Share Analysis, by Region, 2022, 2027, and 2031

Figure 4: Global Nanocrystalline Cellulose Market Attractiveness, by Region

Figure 5: North America Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 6: North America Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 7: North America Nanocrystalline Cellulose Market Volume Share Analysis, by Country, 2022, 2027, and 2031

Figure 8: North America Nanocrystalline Cellulose Market Attractiveness, by Country

Figure 9: Europe Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 10: Europe Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 11: Europe Nanocrystalline Cellulose Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 12: Europe Nanocrystalline Cellulose Market Attractiveness, by Country and Sub-region

Figure 13: Asia Pacific Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 14: Asia Pacific Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 15: Asia Pacific Nanocrystalline Cellulose Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 16: Asia Pacific Nanocrystalline Cellulose Market Attractiveness, by Country and Sub-region

Figure 17: Latin America Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 18: Latin America Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 19: Latin America Nanocrystalline Cellulose Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 20: Latin America Nanocrystalline Cellulose Market Attractiveness, by Country and Sub-region

Figure 21: Middle East & Africa Nanocrystalline Cellulose Market Volume Share Analysis, by End-user, 2022, 2027, and 2031

Figure 22: Middle East & Africa Nanocrystalline Cellulose Market Attractiveness, by End-user

Figure 23: Middle East & Africa Nanocrystalline Cellulose Market Volume Share Analysis, by Country and Sub-region, 2022, 2027, and 2031

Figure 24: Middle East & Africa Nanocrystalline Cellulose Market Attractiveness, by Country and Sub-region